Are you facing mounting pressure to meet green building standards while keeping construction costs under control? Traditional building materials like wood and vinyl create environmental burdens through resource depletion and landfill waste, leaving architects and developers struggling to balance sustainability goals with project budgets. Sustainable Corrugated Sheet Metal Wall Panels offer a proven solution with exceptional recyclable benefits that address both environmental responsibility and long-term cost efficiency, making them the intelligent choice for modern construction projects seeking LEED certification and reduced carbon footprints.

Understanding Recyclable Metal Building Materials and Environmental Impact

The construction industry accounts for nearly forty percent of global carbon emissions, driving an urgent need for sustainable building materials. Corrugated Sheet Metal Wall Panels represent a transformative approach to green construction, offering environmental advantages that extend far beyond initial installation. These panels are manufactured primarily from steel and aluminum, materials that maintain their structural properties through unlimited recycling cycles without quality degradation. Unlike wood products that end up in landfills or plastic materials that persist in the environment for centuries, metal cladding systems create a closed-loop material economy that conserves natural resources and minimizes environmental impact. The recyclable nature of Corrugated Sheet Metal Wall Panels begins at the manufacturing stage, where up to ninety percent of content comes from post-consumer recycled materials. Your previous steel automobile, household appliances, or even soup cans may become part of your next building envelope. This high recycled content dramatically reduces the energy consumption associated with virgin material extraction and processing. Manufacturing metal panels from recycled sources requires significantly less energy and water compared to producing new materials from raw ore, while simultaneously generating fewer greenhouse gas emissions. The energy savings achieved through metal recycling translate directly into lower carbon footprints for construction projects, helping developers meet increasingly stringent environmental regulations and achieve green building certifications.

Complete Life Cycle Sustainability of Metal Wall Cladding Systems

When evaluating the true sustainability of Corrugated Sheet Metal Wall Panels, examining the complete life cycle reveals compelling environmental advantages. These panels deliver exceptional service lives exceeding fifty years under normal conditions, far surpassing alternative materials like vinyl siding that typically require replacement within fifteen to twenty years, or wood products that deteriorate even faster in harsh climates. This extended durability means reduced material consumption over the building's lifetime, as frequent replacements create repeated cycles of manufacturing, transportation, installation, and disposal that multiply environmental impacts. The longevity of metal cladding systems directly supports sustainable design principles by minimizing resource consumption across decades of service. Buildings constructed with Corrugated Sheet Metal Wall Panels avoid the environmental costs associated with multiple replacement cycles, including the energy required for manufacturing new materials, the fuel consumed during transportation, and the landfill space occupied by discarded products. Furthermore, metal panels maintain their structural integrity and aesthetic appeal throughout their service life with minimal maintenance requirements, eliminating the need for chemical cleaners, paints, and preservatives that introduce additional environmental concerns. This low-maintenance characteristic reduces both the ongoing costs for building owners and the ecological footprint associated with routine upkeep.

At the end of their useful life on a building, Corrugated Sheet Metal Wall Panels can be completely recovered and recycled into new metal products without any loss of material properties. Steel and aluminum are infinitely recyclable, meaning the same atoms can be reformed into new panels, structural components, or other metal products countless times. This circular economy approach contrasts sharply with linear material flows where resources are extracted, used once, and discarded. The scrap value of metal panels provides economic incentive for recovery, ensuring high recycling rates that approach one hundred percent for steel building products. Building owners benefit financially from this residual value while contributing to resource conservation efforts.

High Recycled Content Manufacturing and Energy Efficiency

Modern production facilities for Corrugated Sheet Metal Wall Panels incorporate advanced technologies that maximize recycled content while maintaining strict quality standards. Xi'an Huafeng Construction Engineering Co., Ltd. operates manufacturing facilities with seven color coating production lines and more than forty specialized machines that process recycled metal materials alongside carefully selected virgin materials to achieve optimal performance characteristics. The company's material selection includes premium brands like BAOSTEEL, GUANZHOU, and XINYU for steel products, with specifications ranging from 0.3mm to 1.2mm thickness and widths of 600mm to 1200mm customizable to project requirements. The manufacturing process for high-quality Corrugated Sheet Metal Wall Panels combines recycled materials with precision engineering to deliver products that meet international standards including ASTM, DIN, JIS, BS, and GB/T certifications. Raw material suppliers must provide comprehensive material certification and third-party testing reports to ensure consistent quality. Incoming material inspection procedures include multiple verification steps covering appearance, dimensions, salt spray resistance, adhesion, hardness, impact resistance, film thickness, acid resistance, weather resistance, and color consistency. These rigorous quality control measures guarantee that panels manufactured with high recycled content perform identically to those made from virgin materials, eliminating any compromise between sustainability and performance.

Thermal Performance and Operational Energy Savings

Beyond the embodied energy savings achieved through recycled content, Corrugated Sheet Metal Wall Panels contribute to building energy efficiency through superior thermal performance characteristics. When properly installed with appropriate insulation systems, these panels create highly effective building envelopes that minimize heat transfer and reduce heating and cooling demands. The reflective properties of metal surfaces naturally deflect solar radiation, helping maintain cooler interior temperatures during hot weather and reducing air conditioning loads. Advanced coating technologies including PVDF and HDP finishes enhance this reflective performance, creating cool wall systems that can significantly lower operational energy consumption. The corrugated profile itself contributes to thermal efficiency by creating an air cavity behind the panels when installed with proper ventilation spacing. This ventilated cavity allows air circulation that dissipates heat buildup during summer months while providing an additional thermal buffer during winter conditions. The combination of reflective surfaces, quality insulation, and ventilated installation creates a high-performance wall system that supports both environmental sustainability and occupant comfort. Federal and state governments increasingly recognize these energy-saving benefits through tax incentives and expedited permitting for energy-efficient construction, making sustainable Corrugated Sheet Metal Wall Panels an economically attractive choice beyond their environmental advantages.

Contribution to Green Building Certifications and Standards

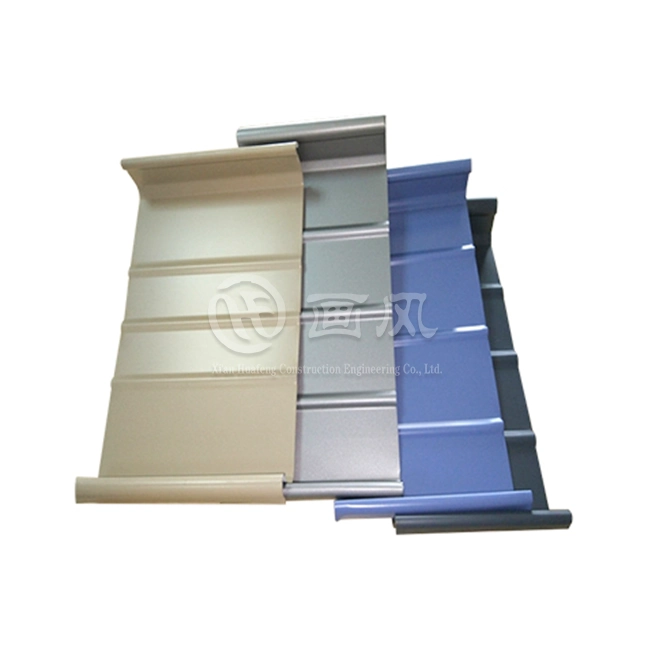

Architects and developers pursuing LEED certification or other green building standards find that Corrugated Sheet Metal Wall Panels contribute valuable points across multiple categories. The high recycled content qualifies for Materials and Resources credits, while the long service life supports credits related to durability and waste reduction. Energy performance benefits contribute to Energy and Atmosphere credits when properly documented through building energy modeling. Additionally, the recyclability of metal panels at end-of-life supports circular economy principles increasingly emphasized in updated green building rating systems. The versatility of Corrugated Sheet Metal Wall Panels allows integration into diverse architectural styles from industrial warehouses to contemporary commercial buildings and residential projects. Available in numerous colors, finishes, and corrugation profiles, these panels meet aesthetic requirements while delivering sustainability benefits. Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive customization services including color, pattern, and design modifications to match specific project visions, ensuring that environmental responsibility does not require aesthetic compromise. The company's portfolio includes landmark projects such as the Xi'an International Convention and Exhibition Center Metal Roof Project, demonstrating expertise in large-scale sustainable construction applications.

Reduced Construction Waste and Installation Efficiency

The lightweight nature of Corrugated Sheet Metal Wall Panels generates significant sustainability advantages during construction phases. These panels weigh substantially less than alternative materials like brick, concrete, or stone cladding, reducing structural load requirements and allowing for lighter foundation systems that consume fewer materials and require less excavation. The reduced weight also simplifies transportation logistics, allowing more material to be transported per truck load and reducing fuel consumption and emissions associated with construction deliveries. On-site handling becomes easier and safer, reducing labor requirements and accelerating installation schedules. Precision manufacturing ensures that panels arrive at construction sites cut to exact specifications, minimizing on-site cutting and virtually eliminating material waste. Xi'an Huafeng Construction Engineering Co., Ltd. employs detailed design coordination processes that include project drawing deepening, factory processing of samples, and sequential numbering of components according to project specifications. This systematic approach ensures that each panel fits precisely in its designated location, preventing the measurement errors and cutting mistakes that generate waste with field-fabricated materials. Installation proceeds efficiently following detailed technical drawings, with on-site guidance from experienced technicians who verify proper installation methods and conduct zero-leakage testing upon completion.

Long-Term Economic Benefits of Sustainable Metal Cladding

While initial material costs for Corrugated Sheet Metal Wall Panels may exceed some alternative products, comprehensive life-cycle cost analysis reveals superior economic value. The extended service life of metal panels eliminates replacement costs that multiply over building lifetimes with shorter-lived materials. Minimal maintenance requirements reduce ongoing operational expenses, as metal panels resist rot, insect damage, warping, and degradation that plague wood products. The panels maintain their appearance without periodic painting or refinishing, saving both labor costs and the expense of maintenance materials over decades of service. Energy savings achieved through superior thermal performance compound over time, reducing utility costs throughout the building's operational life. The combination of durability, low maintenance, and energy efficiency creates total cost of ownership advantages that far outweigh any initial cost premium. Furthermore, buildings incorporating sustainable materials and energy-efficient systems command premium values in real estate markets and attract environmentally conscious tenants willing to pay higher rents for green-certified spaces. These market advantages enhance return on investment while supporting broader environmental objectives.

Supporting Circular Economy Construction Practices

The recyclability of Corrugated Sheet Metal Wall Panels positions these products as key components in emerging circular economy approaches to construction. Traditional linear construction models extract virgin resources, manufacture building products, use them once, and discard them as waste at end-of-life. Circular economy models instead view materials as valuable resources to be kept in productive use through multiple life cycles. Metal building products exemplify circular principles through their ability to be recovered, recycled, and remanufactured into new products without material degradation. Xi'an Huafeng Construction Engineering Co., Ltd. supports circular economy objectives through comprehensive quality management systems that ensure long product life, detailed documentation that facilitates future recovery, and material specifications that optimize recyclability. The company's thirty-year warranty demonstrates confidence in product durability while providing building owners assurance of long-term performance. At project completion, panels can be readily disassembled using reversible fastening systems, sorted by material type, and returned to recycling streams where they become feedstock for new metal products. This closed-loop approach conserves natural resources, reduces landfill burdens, and supports sustainable construction practices that minimize environmental impact across the entire building sector.

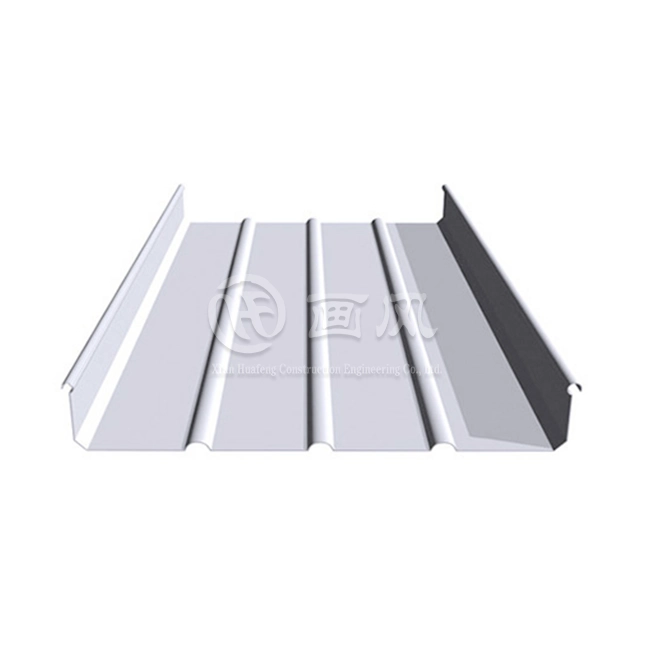

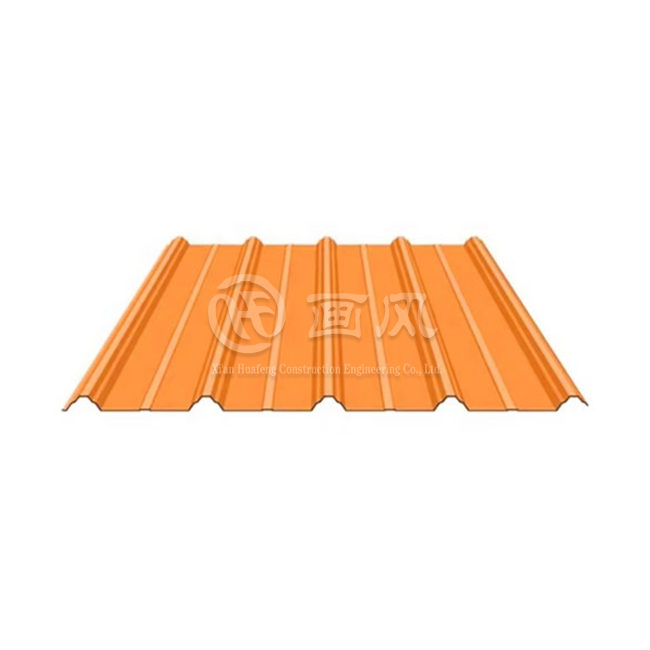

Material Specifications and Performance Standards

High-quality Corrugated Sheet Metal Wall Panels manufactured by Xi'an Huafeng Construction Engineering Co., Ltd. are available in multiple material options including galvanized steel, Galvalume, aluminum, and stainless steel, each offering specific performance characteristics suited to different applications and environmental conditions. Galvanized steel panels provide excellent corrosion resistance through zinc coating protection, making them ideal for most climate conditions and delivering cost-effective performance. Galvalume combines aluminum and zinc coatings for enhanced corrosion protection particularly valuable in coastal environments or industrial areas with aggressive atmospheric conditions. Aluminum panels offer superior corrosion resistance with exceptionally light weight, while stainless steel delivers maximum durability for the most demanding applications. Panel thickness ranges from 0.3mm to 1.2mm with width options from 600mm to 1200mm and customizable lengths typically between two and twelve meters. These dimensional options allow precise matching to project requirements while minimizing material waste. Standard corrugation profiles include wave heights from fifteen to thirty millimeters, with box rib and tile profile options available to meet specific aesthetic and performance needs. Surface finish options encompass pre-painted systems using PVDF or polyester coatings that deliver decades of color retention and weather resistance, along with bare metal finishes for applications where patina development is desired.

Quality Assurance and Testing Protocols

Ensuring consistent quality and performance requires comprehensive testing and quality control throughout the manufacturing process. Xi'an Huafeng Construction Engineering Co., Ltd. implements multiple inspection stages including incoming material verification, in-process quality checks, and finished product testing before shipment. Material certification from suppliers must document composition, mechanical properties, and coating characteristics, while third-party testing reports verify compliance with specified standards. Incoming materials undergo visual inspection, dimensional verification, and performance testing for critical characteristics including salt spray resistance, coating adhesion, and weather resistance. Production processes are monitored continuously using statistical process control methods that identify variations before they result in non-conforming products. Finished panels receive thorough inspection covering appearance quality, dimensional accuracy, flatness, and profile consistency. Products must meet rigorous standards established by international organizations including ISO9001 quality management certification and ISO14001 environmental management certification. SGS testing verification and more than twenty registered patents for roofing system innovations demonstrate the company's commitment to quality and continuous improvement in sustainable building products.

Installation Best Practices for Maximum Performance

Proper installation proves critical to achieving the full sustainability benefits and performance potential of Corrugated Sheet Metal Wall Panels. Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive installation support including detailed technical drawings, on-site guidance from experienced technicians, and thorough briefings on installation methods and safety protocols. Installation begins with verification of substrate conditions to ensure adequate structural support and proper drainage provisions. Panel layout follows systematic sequencing based on detailed shop drawings that show exact placement of each numbered component. Fastening methods depend on specific panel profiles and substrate conditions but typically employ self-drilling screws with weather-resistant washers installed through panel valleys to avoid water infiltration. Fastener selection must consider thermal expansion characteristics of metal panels, allowing appropriate movement while maintaining weather-tight connections. Lap joints between adjacent panels require precise alignment and proper sealant application to ensure water-tightness. Corner conditions and penetration details demand special attention with custom-fabricated flashings that integrate seamlessly with the overall panel system. Installation proceeds systematically from bottom to top or following other sequences specified in project documents to maintain proper water shedding.

Quality Verification and Maintenance Requirements

Upon completion of installation, comprehensive testing verifies system performance and identifies any deficiencies requiring correction. Water testing simulates rainfall conditions to confirm zero leakage through panel joints, fastener penetrations, and interface details with adjacent building components. Visual inspection confirms proper alignment, consistent reveal dimensions, and aesthetic quality meeting project specifications. Any identified issues receive immediate attention with corrective measures implemented before final acceptance. Long-term performance of Corrugated Sheet Metal Wall Panels requires minimal maintenance compared to alternative cladding materials. Periodic visual inspection identifies any damage from impact or unusual weather events requiring repair. Panel surfaces benefit from occasional washing to remove accumulated dirt and maintain appearance, though this maintenance proves far less intensive than painting or refinishing required by other materials. Fastener inspection verifies continued secure attachment and allows tightening if necessary. Sealant joints at penetrations and transitions may require renewal after years of service depending on specific sealant products used. These modest maintenance requirements preserve the sustainability advantages of metal panels by avoiding chemical treatments, preventing premature material failure, and extending already long service lives even further.

Conclusion

Sustainable Corrugated Sheet Metal Wall Panels deliver unmatched recyclable benefits combining environmental responsibility with economic value through high recycled content, complete recyclability, exceptional durability, and superior energy performance that make them the optimal choice for green construction projects.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 and recognized as a Shaanxi Province high-tech enterprise in 2020, specializes in metal roofing and wall systems with comprehensive capabilities spanning design, production, and construction. Our three manufacturing facilities covering 200,000 square meters in Anhui plus processing plants in Hangzhou and Xi'an house seven color coating production lines, one laminating line, ten shearing production lines, and more than forty specialized machines. We hold first-level qualification for building curtain walls and third-level qualification for building steel structures, ensuring professional expertise for your projects.

As a leading China Corrugated Sheet Metal Wall Panels factory, China Corrugated Sheet Metal Wall Panels supplier, and China Corrugated Sheet Metal Wall Panels manufacturer, we offer China Corrugated Sheet Metal Wall Panels wholesale pricing with Corrugated Sheet Metal Wall Panels for sale at competitive Corrugated Sheet Metal Wall Panels prices without compromising our High Quality Corrugated Sheet Metal Wall Panels standards. Our collaboration with Fortune 500 companies, thirty-year product warranty, more than twenty registered patents, and certifications including ISO9001, ISO14001, and SGS demonstrate our commitment to excellence. We provide one-stop procurement from raw materials to accessories, customization services for color, pattern, and design, fast delivery within fifteen to twenty days, and flexible MOQ starting at 500 square meters. Contact us at huafeng@hfmetalroof.com to discuss how our sustainable Corrugated Sheet Metal Wall Panels can elevate your next green building project while meeting your budget and schedule requirements.

References

1. Metal Construction Association. "Recycled Content of Metal Roofing and Siding Panels." Metal roofing education series on sustainable building materials and environmental benefits of metal construction products.

2. Carlton, Ken. "Why Corrugated Metal Is a Sustainable Choice for Roofing and Siding." Corrugated Metals technical publication examining durability, recyclability, and energy efficiency of metal building envelope systems.

3. Carlton, Ken. "Sustainable Building Practices: The Role of Corrugated Metal Siding in Green Architecture." Corrugated Metals technical paper on LEED certification contributions and circular economy applications.

4. PAC-CLAD Technical Documentation. "Sustainability: Metal Wall Panel and Roof Systems." Comprehensive analysis of metal cladding longevity, carbon footprint reduction, and LEED certification pathways.

5. Das, S. and Ali, M. "Multiscale Evaluation of Recycled Plastic Corrugated Panels for Sustainable Construction." MDPI Buildings journal research on waste polymer valorization and sustainable roofing materials performance testing.