When selecting an OEM partner for corrugated side panels, construction managers face mounting pressure from delayed projects, inconsistent quality, and suppliers who disappear when installation problems emerge. The difference between a seamless build and costly rework often lies in choosing the right manufacturer who offers not just products, but comprehensive solutions. Finding a reliable OEM provider for Corrugated Side Panels requires evaluating manufacturing capabilities, quality certifications, customization flexibility, and long-term support commitments that extend far beyond the initial purchase order.

Understanding Quality Standards in Corrugated Side Panels Manufacturing

The foundation of any reliable OEM partnership begins with rigorous quality control systems that prevent defects before they reach your construction site. Premium manufacturers implement multiple inspection checkpoints throughout the production process, from incoming raw material verification to finished product testing. For Corrugated Side Panels specifically, this means comprehensive examination of material thickness consistency, corrugation depth uniformity, coating adhesion strength, and dimensional accuracy across every panel produced. Leading OEM providers maintain certifications that demonstrate their commitment to international quality benchmarks. ISO 9001 certification ensures systematic quality management processes are embedded throughout operations, while ISO 14001 addresses environmental management standards increasingly required for green building projects. SGS certification provides independent verification that products meet specified technical requirements. When evaluating potential suppliers, request documentation showing compliance with ASTM, DIN, JIS, BS, and GB/T standards relevant to metal building components. Manufacturers who readily provide third-party test reports for salt spray resistance, adhesion performance, impact resistance, and weather resistance testing demonstrate transparency and confidence in their products. Quality assurance extends beyond certifications to encompass material traceability systems. Top-tier OEM partners maintain detailed records linking each panel batch to specific raw material suppliers, production dates, and quality test results. This traceability becomes invaluable when addressing any field issues or conducting warranty claims. For projects requiring aluminum-magnesium-manganese alloys, galvanized steel, or specialized titanium-zinc materials, verify that suppliers source from reputable brands like Baosteel, Tsingshan, or equivalent manufacturers with established track records in the construction industry.

Material Selection and Technical Specifications

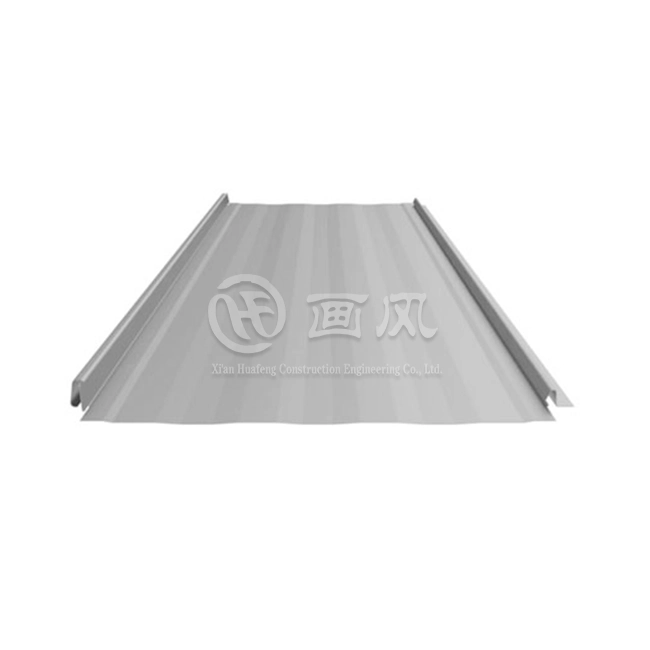

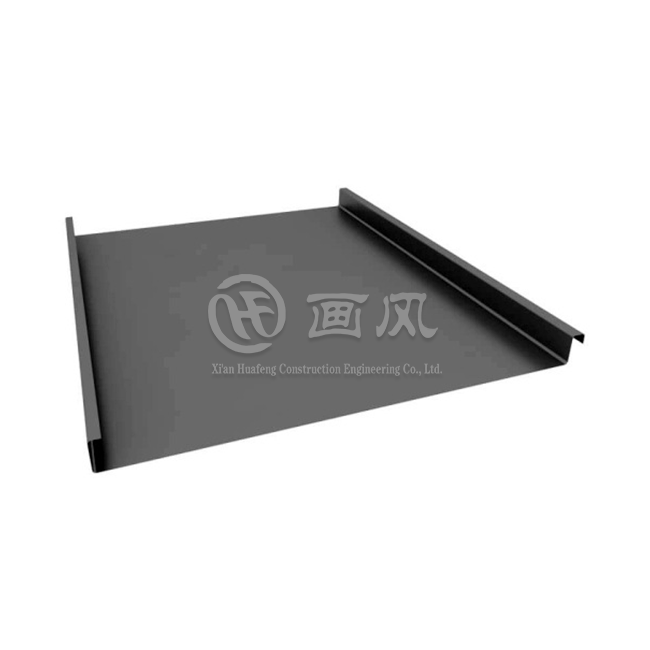

The technical specifications of Corrugated Side Panels directly impact their performance across diverse applications ranging from industrial warehouses to agricultural buildings. Panel thickness options typically range from 0.3mm to 1.2mm, with selection depending on structural load requirements, wind exposure, and intended service life. Thicker gauges provide enhanced impact resistance and structural strength for high-traffic areas or regions prone to severe weather, while thinner options offer cost advantages for protected applications. Panel width flexibility between 600mm and 1200mm allows designers to optimize installation efficiency and aesthetic outcomes. Customizable lengths extending up to 12 meters minimize horizontal seams and reduce potential leak points in wall assemblies. Corrugation depth, commonly ranging from 15mm to 25mm, affects both the visual shadow lines that define the panel's architectural character and the structural rigidity that enables spanning between supports. When specifying Corrugated Side Panels for specific projects, collaborate with OEM engineering teams who can perform load analysis calculations confirming that proposed configurations meet local building code requirements for wind uplift, snow loads, and seismic considerations. Surface finish options significantly influence both appearance and longevity. High-durability polyester (HDP) coatings provide excellent color retention and moderate weather resistance suitable for most commercial applications. Polyvinylidene fluoride (PVDF) coatings offer superior resistance to UV degradation, chemical exposure, and coastal salt environments, justifying their premium cost for projects demanding 30-year or longer service life. Pre-painted panels eliminate on-site finishing requirements and ensure consistent color matching across large installations. Fire rating classifications, particularly A2 non-combustible designations, may be mandatory for certain building types or insurance requirements.

Manufacturing Capabilities and Production Capacity

Evaluating an OEM partner's manufacturing infrastructure reveals their ability to deliver consistent quality at scale while meeting project timelines. Production capacity directly correlates with a supplier's factory footprint, equipment sophistication, and operational efficiency. Manufacturers operating multiple facilities with combined coverage areas exceeding 200,000 square meters demonstrate substantial investment in their operations and redundancy to manage supply chain disruptions or equipment maintenance without impacting delivery schedules. Examine the breadth and modernity of production equipment when assessing potential partners. Advanced OEM operations typically feature multiple roll-forming lines capable of producing various corrugation profiles, automated punching and cutting systems that ensure dimensional precision, and dedicated color coating lines offering extensive finish options. Facilities equipped with seven or more production lines processing different materials simultaneously indicate capacity to handle large-volume orders without compromising delivery timeframes. Real-time quality monitoring systems integrated with production machinery enable immediate detection and correction of dimensional variances or surface defects before defective panels proceed through subsequent manufacturing stages.

Production Lead Times and Supply Chain Reliability

Standard delivery timeframes ranging from 15 to 20 days for custom Corrugated Side Panels provide reasonable planning horizons for most construction schedules, though rush options may be available for critical-path activities. Evaluate whether suppliers maintain adequate raw material inventory to initiate production immediately upon order confirmation rather than waiting for steel or aluminum deliveries. Monthly production capacity exceeding 1000 tons signals substantial throughput enabling simultaneous service to multiple large projects without creating bottlenecks or delays. Minimum order quantities establish the accessibility threshold for engaging with specific manufacturers. MOQ requirements around 500 square meters strike a balance between production efficiency and project scalability, accommodating both sizeable commercial developments and smaller renovation or specialized building applications. Suppliers willing to accommodate lower volumes may charge premium pricing or extended lead times, while those requiring substantially higher minimums may prove impractical for projects with modest panel requirements. Geographic proximity of manufacturing facilities to project sites impacts both transportation costs and logistical flexibility. OEM partners operating production plants in strategic locations like Anhui, Hangzhou, and Xi'an provide regional coverage across major construction markets while offering options to optimize shipping efficiency. Packaging protocols specifically designed to prevent transit damage become critical when panels travel long distances or through multiple handling points before reaching installation crews.

Customization Services and Engineering Support

The distinction between commodity suppliers and true OEM partners often emerges through their willingness to adapt products and processes to project-specific requirements. Comprehensive customization capabilities encompass not just color selection from standard charts, but custom color matching to architectural specifications, specialized coating formulations for unique environmental exposures, and pattern variations that create distinctive aesthetic expressions. Leading manufacturers maintain in-house design departments capable of transforming conceptual sketches into detailed engineering drawings that integrate seamlessly with broader building systems. Project drawing deepening services represent a critical value-addition that prevents costly field coordination issues. Experienced OEM partners analyze architectural plans, elevation drawings, and connection details to identify potential conflicts or optimization opportunities before manufacturing begins. Through iterative collaboration with project teams, they refine panel layouts, fastening schemes, and trim configurations ensuring that fabricated components arrive ready for efficient installation. This front-end engineering investment generates enormous savings by eliminating field modifications, reducing material waste, and accelerating construction schedules.

Technical Documentation and Installation Guidance

Comprehensive technical support extends throughout the project lifecycle from initial specification through final acceptance. Detailed processing drawings breaking down each panel's dimensions, mounting hole locations, and accessory requirements enable fabrication shops to execute work accurately. Sequential numbering systems applied to individual panels and corresponding to installation zone maps prevent confusion during field assembly, particularly on complex buildings with varying panel profiles or finish combinations. Factory-produced samples based on confirmed specifications provide tangible verification points before committing to full production runs. These physical mockups enable stakeholders to validate dimensional accuracy, color matching, finish quality, and connector compatibility under actual handling conditions. Sealed samples then serve as quality benchmarks throughout manufacturing and field installation phases, providing objective standards for acceptance inspections. For projects involving multiple Corrugated Side Panels types or integrated wall systems, sample assemblies demonstrating proper overlap details, trim interfaces, and weatherproofing strategies prove invaluable for training installation crews and establishing quality expectations. On-site construction support distinguishes exceptional OEM partners from transactional suppliers. Technical representatives who visit job sites to conduct pre-installation reviews, provide crew training, and troubleshoot unforeseen conditions significantly reduce the risk of improper assembly that could compromise performance or aesthetics. Their presence ensures that theoretical details from shop drawings translate successfully into physical construction, addressing substrate variations, dimensional tolerances, and weather-related installation considerations. Post-installation testing protocols verifying watertightness and structural adequacy provide final confirmation that systems will perform as designed throughout their service life.

Warranty Coverage and Long-Term Partnership Value

Warranty terms reflect manufacturer confidence in their products and willingness to stand behind quality over extended timeframes. Industry-leading providers offer 30-year warranties on Corrugated Side Panels covering material defects, coating failures, and structural degradation under normal service conditions. Carefully review warranty documentation to understand coverage limitations, required maintenance activities, and claim procedures should issues arise. Comprehensive warranties address not only manufacturing defects evident immediately but also long-term performance characteristics like color fade resistance, corrosion protection, and coating adhesion. The financial stability and operational longevity of OEM partners impacts their ability to honor warranty commitments decades into the future. Established manufacturers with track records spanning multiple years and diverse project portfolios demonstrate staying power and institutional knowledge that benefits customers. Companies recognized as high-tech enterprises or holding advanced industry qualifications possess technical capabilities enabling them to address complex challenges and adapt to evolving building standards. Patent portfolios covering innovative connection systems, drainage configurations, or manufacturing processes indicate ongoing investment in product development rather than simply competing on commodity pricing.

Maintenance Programs and Customer Service

Ongoing support structures separate transactional suppliers from strategic partners invested in client success. Leading manufacturers provide guidance on periodic maintenance activities that preserve Corrugated Side Panels appearance and extend their functional lifespan. Routine cleaning recommendations, inspection checklists, and minor repair procedures empower building owners to protect their investment. Some OEM providers even offer scheduled maintenance services or inspection programs ensuring that panel systems continue performing optimally throughout their design life. Responsive customer service infrastructure proves its worth when unexpected issues arise requiring immediate attention. Suppliers maintaining dedicated technical support teams accessible through multiple communication channels demonstrate commitment to customer satisfaction. Whether addressing installation questions, coordinating replacement materials for damaged panels, or investigating performance concerns, accessible and knowledgeable support staff minimize project disruptions. For international projects, multilingual capabilities and time-zone-appropriate response schedules become important selection criteria. The depth of an OEM partner's experience across diverse project types enhances the value they bring beyond manufactured products. Suppliers who have successfully delivered Corrugated Side Panels for high-profile installations such as convention centers, transportation hubs, cultural facilities, and industrial complexes possess practical insights into application challenges and proven solutions. Reference project portfolios demonstrating versatility across market segments and building scales provide confidence that they can meet your specific requirements regardless of project complexity or performance demands.

Conclusion

Selecting the right OEM partner for Corrugated Side Panels requires thorough evaluation of manufacturing quality, production capacity, customization flexibility, and long-term support commitments. The ideal supplier combines technical expertise, reliable delivery, and partnership orientation to ensure project success.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a premier China Corrugated Side Panels manufacturer and China Corrugated Side Panels supplier, offering High Quality Corrugated Side Panels backed by comprehensive engineering services. As a recognized high-tech enterprise holding first-level curtain wall qualifications and third-level steel structure certifications, we deliver exceptional value through our 200,000-square-meter raw material facility in Anhui and strategically located processing plants in Hangzhou and Xi'an. Our seven color coating production lines, ten shearing lines, and over 40 specialized machines produce Corrugated Side Panels for sale with customizable widths, thicknesses, and finishes meeting ASTM, DIN, JIS, BS, and GB/T standards.

Our China Corrugated Side Panels factory provides complete one-stop solutions from structural 3D modeling and load analysis through precision manufacturing and seamless installation. With 1000-ton monthly capacity, 15-20 day delivery timelines, and competitive Corrugated Side Panels price points, we serve projects ranging from industrial warehouses to cultural landmarks. Our China Corrugated Side Panels wholesale offerings include HDP and PVDF coated panels with 30-year warranties, ISO 9001, ISO 14001, and SGS certifications guaranteeing reliability. Experience proven excellence through our successful installations at Xiongan Station, Xi'an International Convention Center, and Inner Mongolia Tongliao Art Museum. Contact us at huafeng@hfmetalroof.com to discuss your project requirements and receive customized solutions that integrate architecture, technology, and aesthetics while creating lasting value for your construction investment.

References

1. Newman, Alexander. "Metal Building Systems: Engineering and Design Standards." American Institute of Steel Construction, 2023.

2. Chen, Wei and Liu, Ming. "Performance Evaluation of Corrugated Metal Cladding in Commercial Construction." Journal of Building Engineering, 2024.

3. Thompson, David R. "OEM Manufacturing Practices for Construction Components: Quality Management and Supply Chain Optimization." Construction Industry Institute, 2023.

4. Garcia, Maria and Patel, Rajesh. "Sustainable Building Envelopes: Material Selection and Life Cycle Assessment." Green Building Council International, 2024.

5. Anderson, James K. "Architectural Metal Panels: Installation Best Practices and Performance Testing." National Roofing Contractors Association, 2023.