Metal Standing Seam Roofing Systems

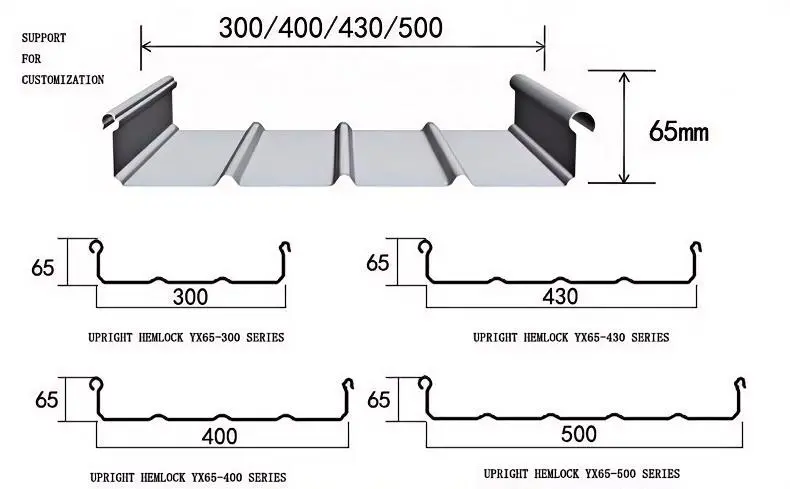

Specifications: 65-300/400/430/500

Finishes:PE, HDP,PVDF COATING

Supply Ability:1000 Ton/month

Service life:30-year warranty

MOQ:500㎡

Delivery time: 15-20 days

Provide customized services: color, pattern, design customization

Standard:ISO9001, ISO14000:14001,SGS guidelines

Metal Standing Seam Roofing Systems: Durable, Versatile, and High-Performance

Xi'an Huafeng Construction Engineering Co., Ltd. is a leading manufacturer and supplier of Metal Standing Seam Roofing systems. Roofing solutions of the highest quality for large-scale projects are guaranteed by our proficiency in design, production, and installation. We provide first-rate products that are up to par with the best in the business because of our state-of-the-art production facilities and dedication to innovation.

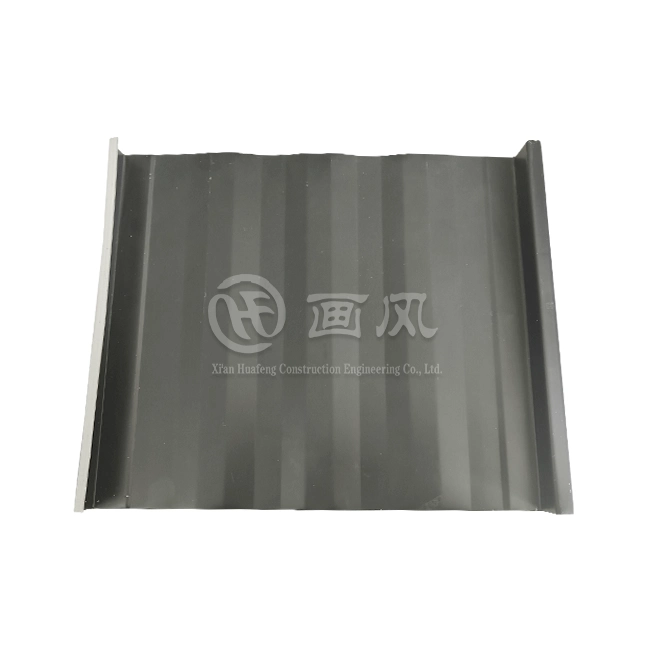

Product Introduction

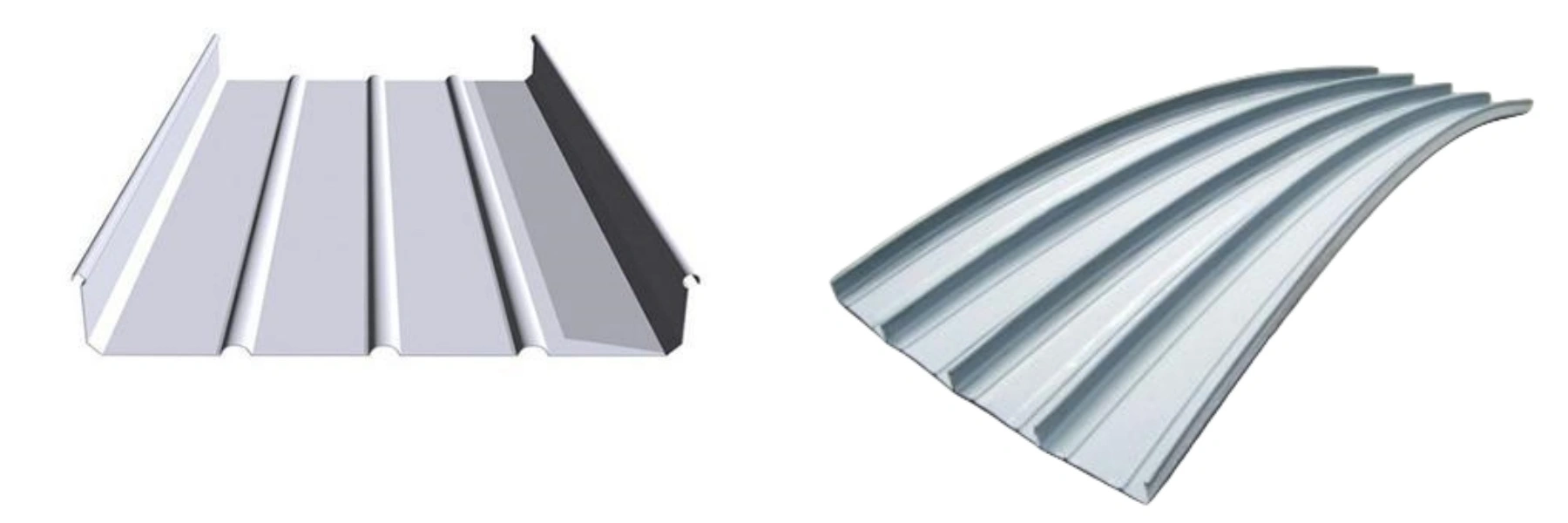

The standing seam metal roof system is a high-performance metal roof solution, widely used in large public buildings, airports, stadiums, industrial plants and other projects with high requirements for waterproofing, wind resistance and durability. Its core advantage lies in the high-rib design, which provides stronger structural rigidity and drainage capacity, while using hidden mechanical locking technology to ensure long-term waterproof sealing.

Specifications

一、Technical Specifications

1、Material Specifications

| Type | Thickness | Coating/treatment | Features |

| Aluminum | 0.9–1.2 mm | 3003/3004 series, H44 hardened state, fluorocarbon spray | Lightweight, salt spray resistant, suitable for coastal areas |

| Galvalume | 0.6–1.0 mm | AZ150 coating (150g/m² aluminum zinc) + PVDF coating | Strong corrosion resistance, cost-effective, suitable for most climates |

| Stainless steel | 0.5-0.8mm | 304 stainless steel, fluorocarbon coating | High corrosion resistance, suitable for coastal areas, industrial areas or high humidity environments |

| Zinc | 0.7–1.0 mm | Titanium zinc plate | Self-repairing properties, lifespan of 80 years+, environmentally friendly materials |

| Copper | 0.8–1.0 mm | TU1 oxygen-free copper | Ultra-long life (100 years+), beautiful appearance |

2、Panel Dimensions

| Parameters | Standard Range | Remarks |

| Panel Width | 300–600 mm (effective coverage width) | Adjust according to rib height and edge locking method |

| Seam Height | 65 mm (2.55") | Ultra-high rib design to enhance structural strength and drainage performance |

| Panel length | Customized (up to 13m long, no transverse seams) | Fewer seams, less risk of water leakage |

| Thickness tolerance | ±0.02 mm | Complies with ASTM A924/A755 standards |

3、Surface Treatment

| Type | Coating/Process | Performance Characteristics |

| PVDF coating | 25–30μm thickness, containing 70% fluororesin | UV and chemical corrosion resistance, color retention 20 years + |

| PE coating | 20–25μm polyester coating | Economical, suitable for general climate |

| Natural oxidation | Copper/Zinc uncoated, naturally formed protective film | Lifespan 50–100 years, maintenance-free |

二、Structural Performance

1、Mechanical properties

| Test items | Standard value | Test Method |

| Wind pressure resistance | ≥4.5 kPa (resistant to 16-level typhoon) | ASTM E1592/GB 50223 |

| Snow load capacity | ≥1.5 kN/m² (applicable in snowy areas) | EN 1991-1-3 |

| Impact resistance | 1kg steel ball free falls from a height of 3m without breaking | ASTM D3746 |

| Heat deformation temperature | Aluminum: 150°C / Steel: 260°C | Linear expansion coefficient needs to be calculated for expansion joints |

2、Waterproof and Airtight

- Watertightness: Passed 1000Pa negative pressure test (no leakage), in compliance with GB/T 7106-2008

- Airtightness: ≤0.1 m³/(m²·h)

- Locked edge: Double-Lock Seam, mechanical bite

3、Fire Prevention and Environmental Protection

- Fire rating: A1 non-combustible material (GB 8624-2012)

- Environmental protection: 100% recyclable, reflectivity ≥ 0.65 (cool roof standard)

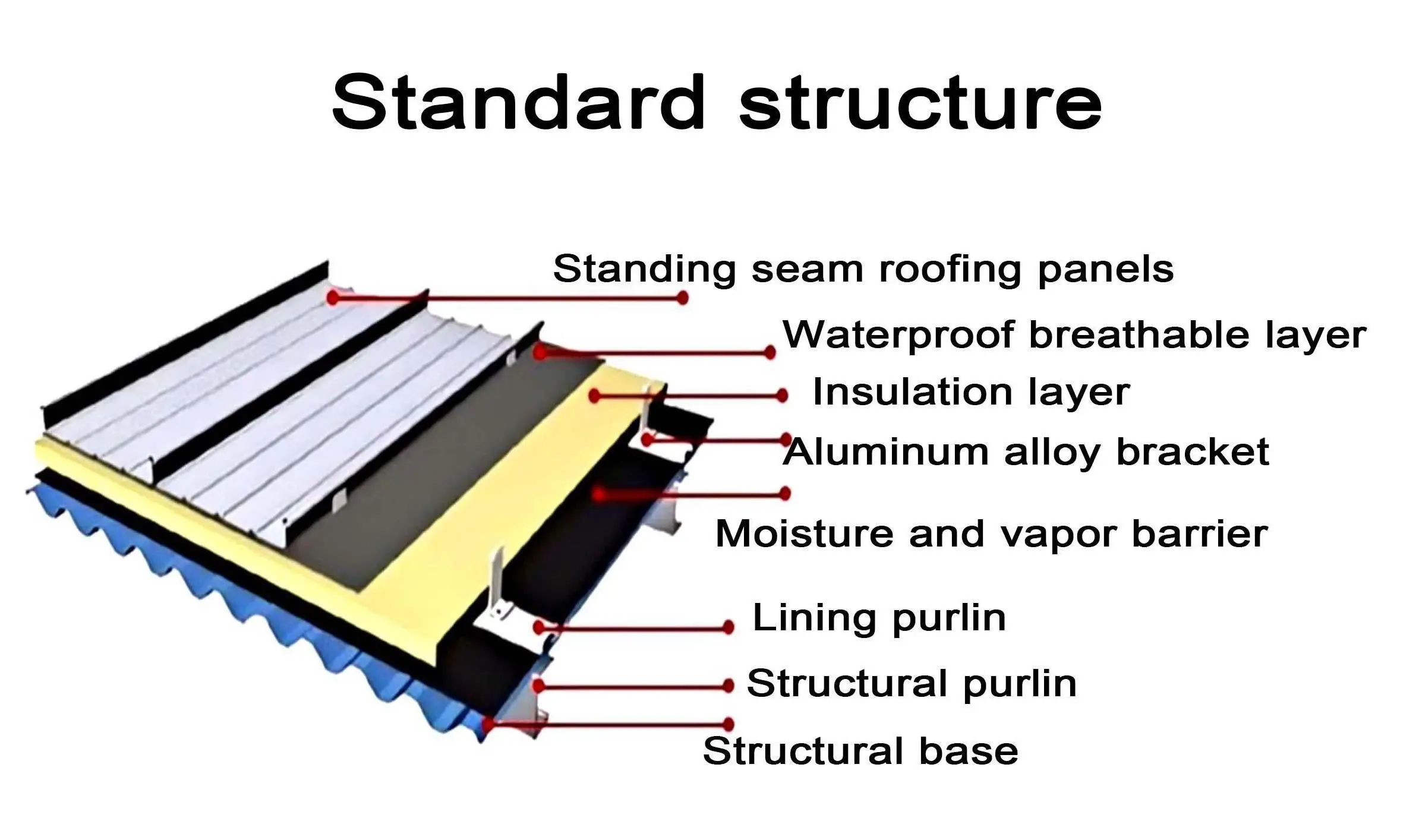

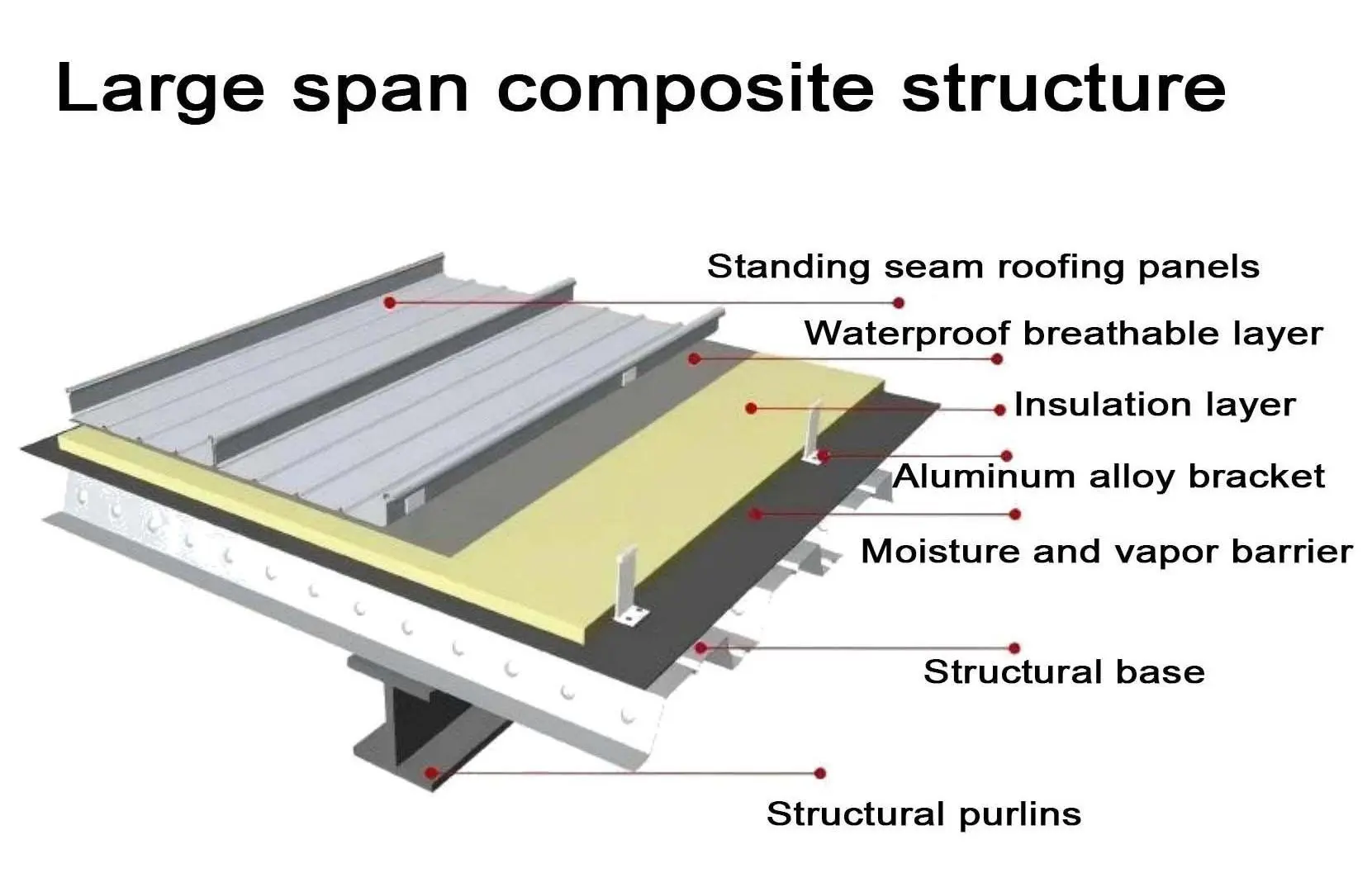

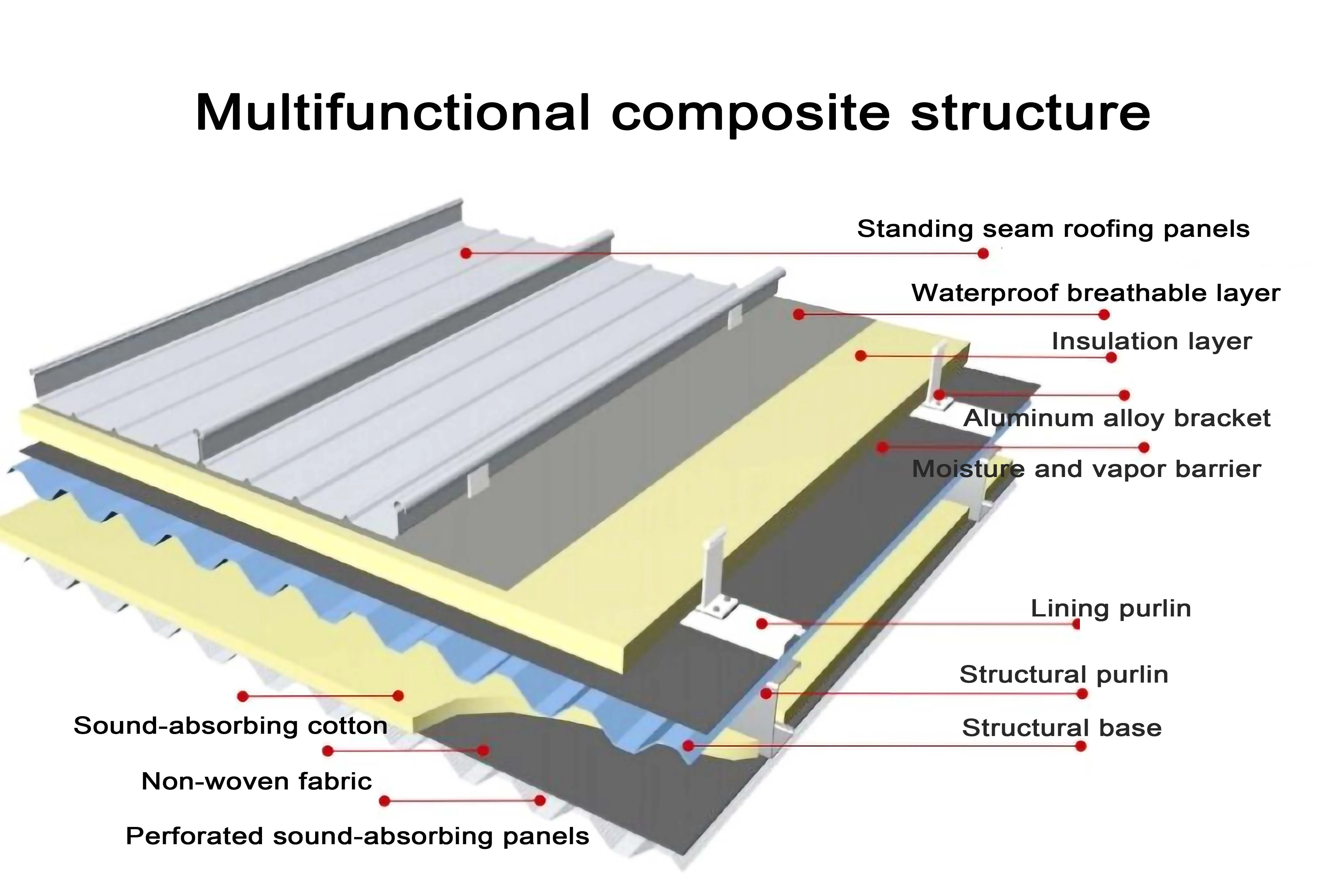

三、standing seam roof system structure

1、Standing seam roof panel: The thickness is usually 0.9mm-1.2 mm.

2、Waterproof and breathable membrane: It is a high-density polyethylene non-woven fabric that blocks the invasion of wind and rain on the building structure. While strengthening the air tightness and water tightness of the building, it can also provide rare breathability, so that the water inside the enclosure structure can be quickly discharged, effectively avoiding the formation of mold and condensation water.

3、Insulation and sound insulation layer: Rock wool is usually used, and its thickness needs to be determined according to calculation. It mainly plays the role of heat preservation and noise reduction, such as the noise after heavy rain and hail hit the surface layer.

4、Vapor barrier: Generally, polyester film or high-density spunbond polyethylene film is used, and glass wool (with moisture-proof veneer) can also be selected. The vapor barrier can limit the water vapor inside the building from entering the roof, thereby minimizing the occurrence of condensation.

5、Sound-absorbing cotton: Glass wool is usually used, and its bulk density and thickness need to be determined according to calculation.

6、Dustproof layer: Generally, non-woven fabric is used, which is mainly used for dust and dust isolation, and is laid on the upper surface of the roof base plate.

7、Structural base plate: generally perforated galvanized or galvanized corrugated steel plate is used, the thickness is designed according to the purlin distance, and the perforation rate is calculated according to the project. It supports sound-absorbing cotton and thermal insulation cotton, and also plays a decorative role.

8、Roof purlin: generally uses lining purlin and steel purlin, which play the role of structural support and slope adjustment

四、Scope of Application

- Large-span buildings: airports, high-speed rail stations, exhibition centers

- Stadiums: open roofs, high drainage performance required

- Industrial plants: projects with high requirements for corrosion resistance and wind resistance

- Photovoltaic integration: 65mm high ribs compatible with photovoltaic fixtures

Why Choose Us?

- Extensive engineering design and construction experience

- State-of-the-art production facilities with 7 raw material lines

- Over 20 patent certificates and international certifications

- Customization capabilities to meet specific project requirements

- Collaboration with Fortune 500 companies

- One-stop procurement from raw materials to accessories

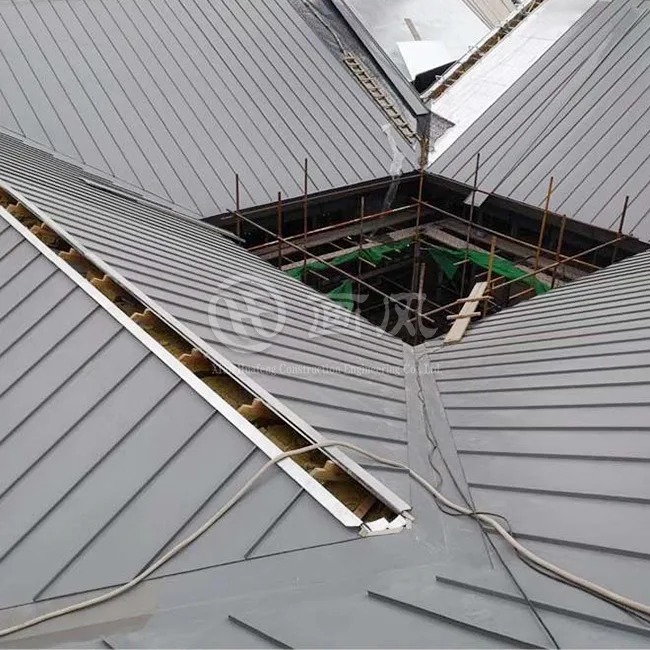

Project Cases

Our Metal Standing Seam Roofing systems have been successfully implemented in numerous high-profile projects worldwide.

Factory Strength

Our advanced manufacturing facilities ensure consistent quality and timely delivery of the products.

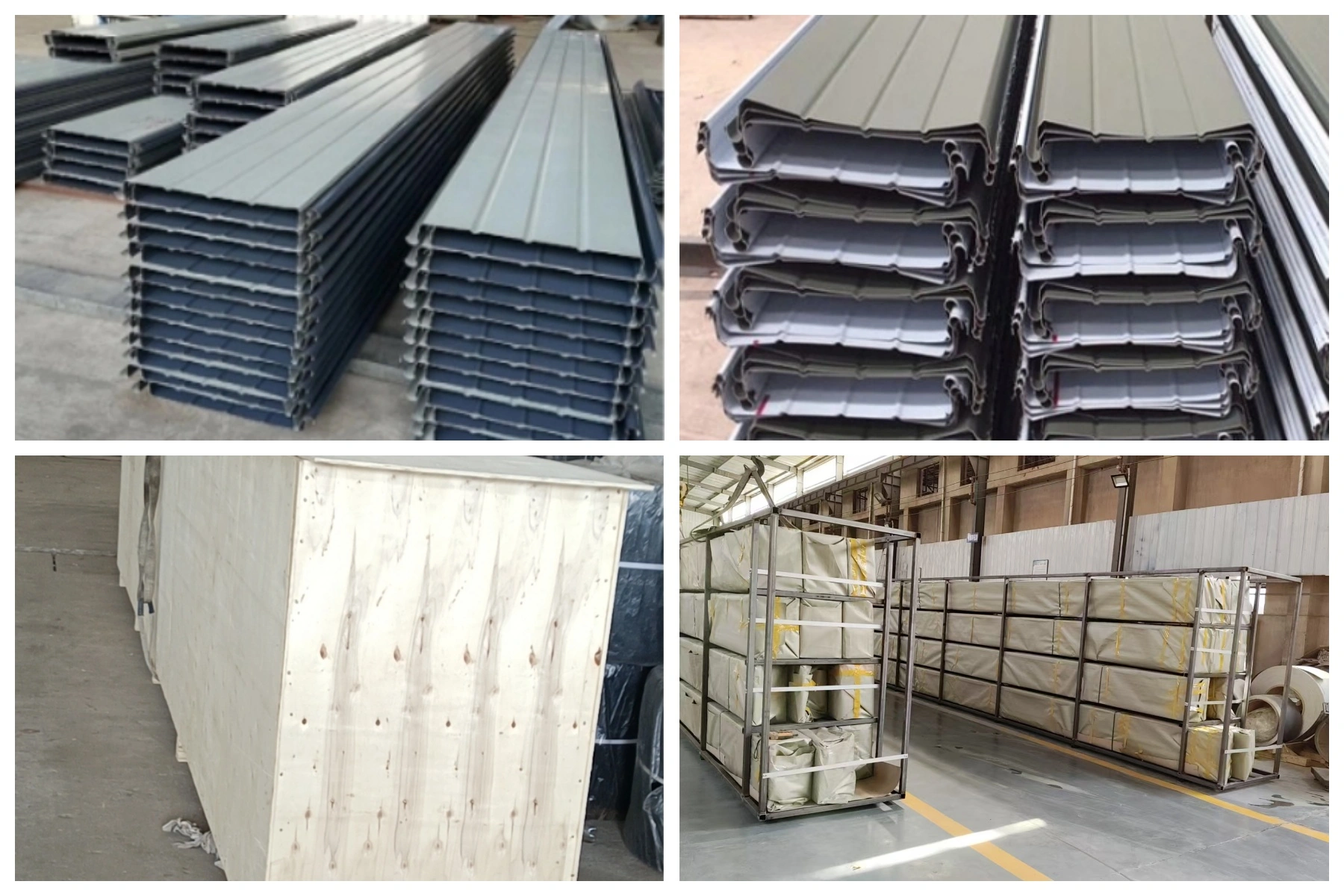

Packaging

We offer secure packaging and efficient transportation solutions to ensure safe delivery of our products.

Qualification Certification

Our products meet international standards, backed by ISO, CE, and SGS certifications.

FAQ

Q: What is the lifespan of your products?

A: Depending on the material, our systems can last 30-100+ years with proper maintenance.

Q: Can your roofing systems withstand extreme weather conditions?

A: Yes, our systems are designed to resist high winds, heavy snow loads, and intense UV exposure.

Q: Are your products environmentally friendly?

A: Absolutely. Our products are 100% recyclable and meet cool roof standards for energy efficiency.

Q: Do you offer installation services?

A: We provide comprehensive support, including installation guidance and on-site technical assistance.

Q: What is the minimum order quantity for your roofing systems?

A: Our standard MOQ is 500㎡, but we can discuss custom orders based on project requirements.

Contact Us

For more information about our Metal Standing Seam Roofing systems, please contact us at huafeng@hfmetalroof.com.