- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Own Factory Equipment

Multiple Quality Certifications

Customized Solutions

One-Stop Service

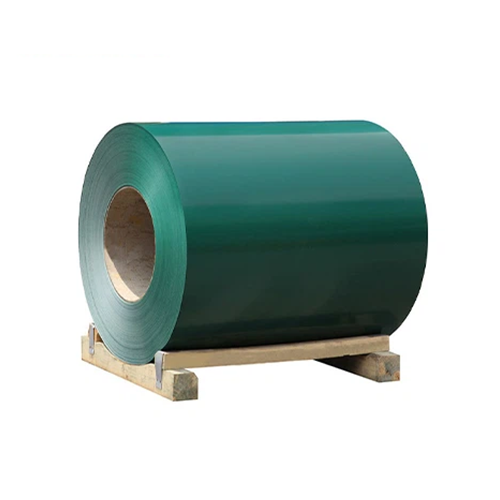

Galvanized Steel Coil

Color-coated galvanized steel coil (color-coated sheet/color steel sheet) is a metal material with a galvanized and painted surface. It has both corrosion resistance, decorativeness and durability. It is widely used in construction, home appliances, transportation and other fields.

Product characteristics

1. Corrosion resistance

- The substrate is galvanized steel (hot-dip galvanized or electro-galvanized), which provides bottom rust protection; the surface coating (polyester, silicon-modified polyester, PVDF, etc.) further isolates the corrosive medium.

2. Decorativeness

- It can be customized with a variety of colors (such as RAL color cards), gloss (high gloss, matte) and texture (wood grain, stone grain), which is beautiful.

3. Processing performance

- Easy to cut, bend, and stamp, suitable for cold processing (such as rolling and bending).

4. Weather resistance

- Special coatings (such as PVDF) are resistant to ultraviolet rays and will not fade or powder after long-term outdoor use.

5. Lightweight

- It is lighter than traditional building materials (such as concrete) and is easy to transport and install.

6. Environmental protection

- Some products can be recycled, and the coating can be treated with chrome-free environmental protection

Common specifications

| Substrate type | Hot-dip galvanizing (GI), hot-dip galvanized (GL), electrogalvanized (EG). |

| Thickness range | Substrate thickness: 0.21.5mm (common 0.30.8mm); the total thickness increases slightly after coating. |

| Width range | 600~1500mm (customizable striping or ultra-wide). |

| Coating structure | Double layer (primer + topcoat) or three layers (primer + topcoat + backcoat), the coating thickness is usually 5~25μm. |

| Roll weight | Single roll weight 3~15 tons, inner diameter 508mm or 610mm. |

Main uses

1. Construction field

- Roof/wall: factory, warehouse, gymnasium, etc.

- Sandwich panels: polyurethane/PVC interlayers for thermal insulation buildings.

- Decorative components: awnings, ceilings, billboards.

2. Home appliance industry

- Refrigerators, air conditioner housings, washing machine panels (high gloss or antibacterial coating required).

3. Transportation

- Carriage linings, ship partitions, container housings.

4. Furniture and office supplies

- File cabinets, display racks, partitions.

5. Others

- Solar panel back panels, ventilation ducts, agricultural greenhouse trellises.

Comparison of coating types

|

Coating material |

Features |

Applicable scenarios |

|

*Polyester (PE) |

Low cost, rich colors, general weather resistance |

Indoor, temporary buildings |

|

Silicon modified polyester (SMP) |

Weather resistance is better than PE, UV resistance |

Moderate outdoor environment requirements |

|

PVDF |

Super strong weather resistance (more than 20 years), high price |

High-end buildings, seaside facilities |

|

PVC plastisol |

Thick coating, wear and corrosion resistance |

Industrial plants, home appliance parts |

Precautions

Selection suggestions:

-PVDF coating is preferred for outdoor environments, and high zinc layer substrates are required for corrosive environments (such as chemical plants).

Processing protection:

-Avoid scratches on the coating, and the incision needs to be rust-proof after cutting.

Storage requirements:

-Dry and ventilated to avoid water accumulation between layers causing white rust.