- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Own Factory Equipment

Multiple Quality Certifications

Customized Solutions

One-Stop Service

One-Stop Solution

Xi'an Huafeng Construction Engineering Co., Ltd. specializes in metal roofing systems, wall systems and building envelope solutions, providing one-stop services from design, production to construction. Its products include aluminum-magnesium-manganese plates, color-coated steel plates, stainless steel plates, titanium-zinc plates, etc., which are widely used in industrial, commercial and public buildings.

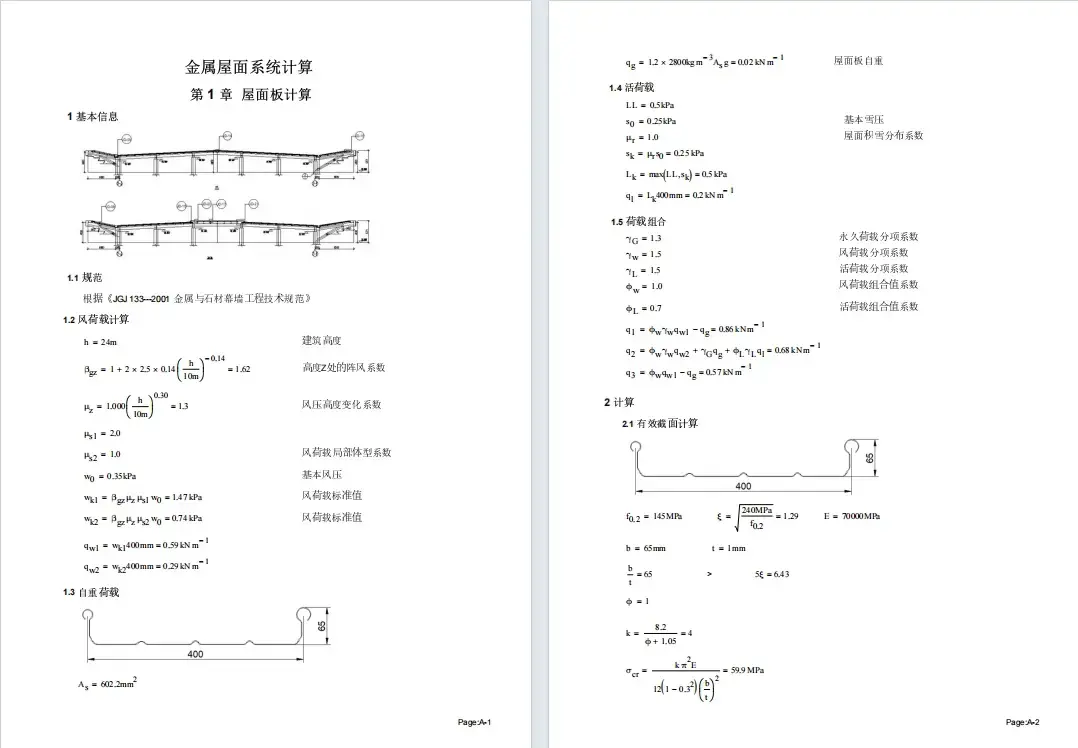

一、Custom Metal Roof Engineering Services & Design

» Structural 3D Modeling & Load Analysis

» Drainage System Simulation

» Material Specification Advisory

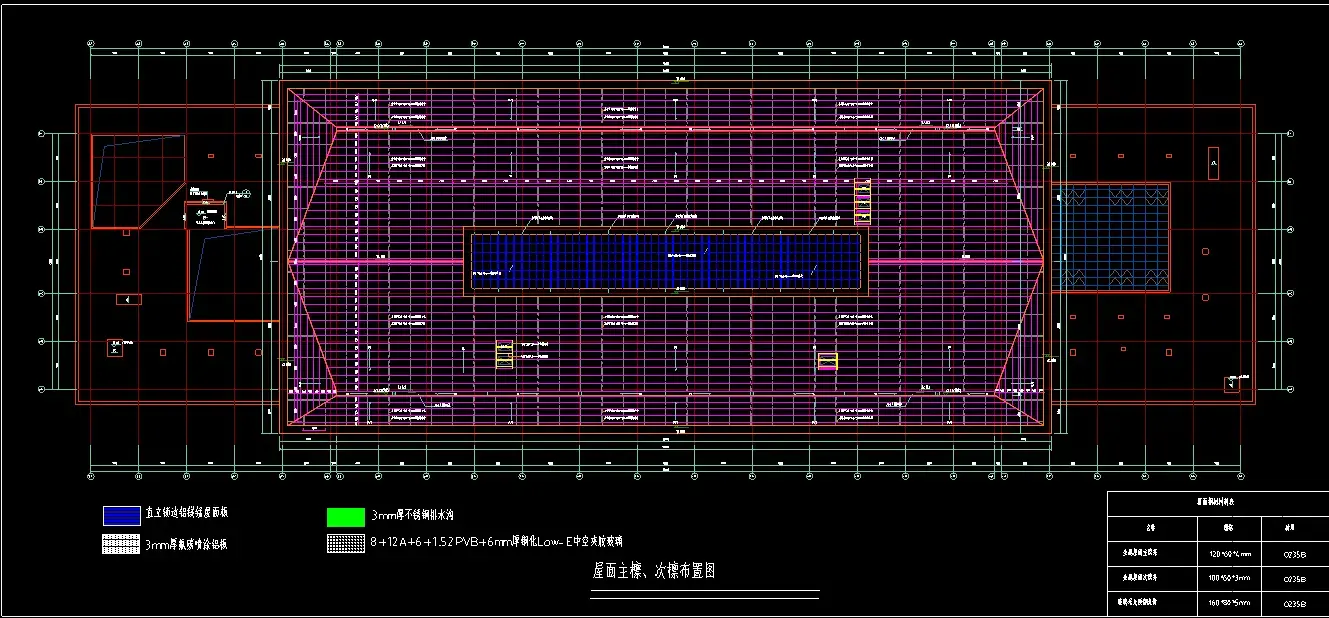

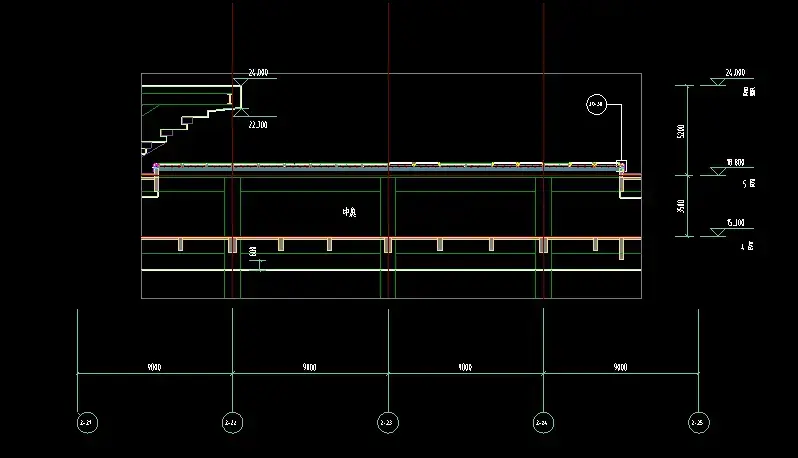

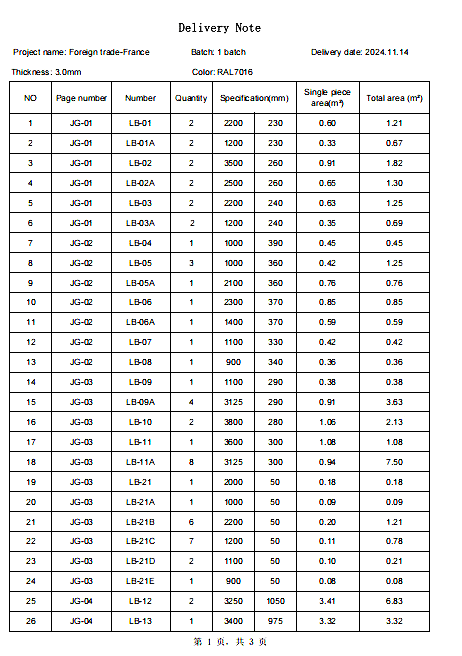

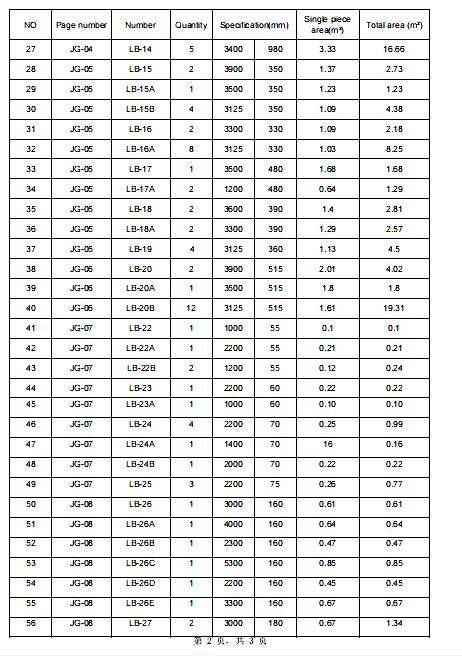

01. Project drawing deepening

1. Analyze and list feasible alternatives based on the floor plan, elevation and node diagram of all architectural engineering drawings of the project.

2. Communicate with the customer and determine the roof panel type for the corresponding project roof structure.

3. Our design department conducts 1:1 drawing deepening of nodes in different parts of the project based on the determined model.

4. After multiple communications and confirmations, the two parties sign and confirm the deepening drawings.

02. Factory processing samples

1. Samples are produced based on the confirmed parameters such as board type, material, thickness, surface treatment method and color.

2. After the customer confirms the size, material, color and other parameters of the sample, the sample is sealed.This is used as a standard for later product processing, production and acceptance.

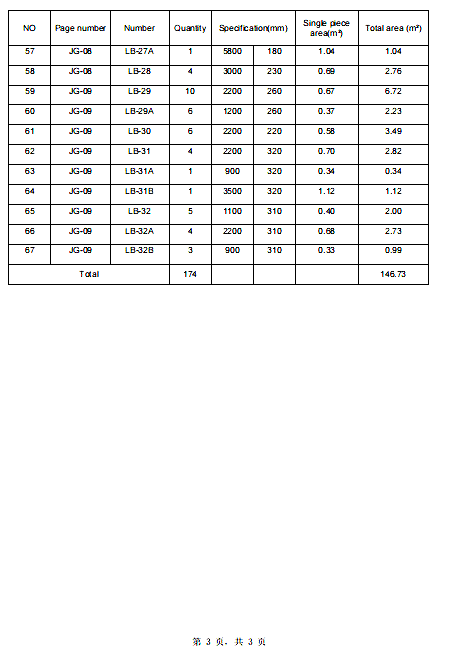

03. Processing drawing deepening

1. The design department breaks down the detailed drawings into detailed processing drawings, which are then produced by the production department.

2. Each unit is numbered sequentially according to the specifications and quantity of the project. This ensures that processing by the production department, inspection and packaging by the quality assurance department, and on-site installation are carried out according to the numbers to avoid confusion.

二、Precision Manufacturing

» Roll-Forming Systems

» Real-Time Quality Control

» Raw Material Traceability

01. Material procurement

1. The Purchasing Department completes material inventory and purchases based on the processing list and drawings submitted by the Technical Department.

2. Based on the supplier registration list and the test reports provided by the supplier, our company conducts multiple inspections to confirm the brand before use.

HUAFENG material selection brand library

|

Product Name |

Brand |

Trademark |

|

Aluminum |

Alucosuper、YATAI、LIDAO |

3003、3004、5052 |

|

Steel |

BAOSTEEL、GUANZHOU、 XINYU |

Cold rolled sheet, galvanized sheet, galvalume sheet, color coated sheet |

|

Stainless steel |

Baosteel, Tsingshan |

316、304 |

|

Titanium zinc plate |

NedZink |

|

|

Copper |

Chinalco |

T2/TP2 |

02. Incoming material inspection

1. Incoming material inspection refers to the quality verification and verification of incoming raw materials (such as copper, aluminum, steel, etc.) or components. This involves sampling and testing the quality of raw materials delivered by the supplier, ultimately determining whether the batch should be accepted or rejected. Raw material manufacturers are required to provide material certification and third-party material testing reports.

2. Inspection methods include full inspection (for small quantities and high unit prices) and random inspection (for large quantities or frequent materials) to prevent defective materials from entering the warehouse.

3. Carry out more than a dozen inspection steps including product appearance inspection, size inspection, salt spray, adhesion, hardness, impact, film thickness, acid resistance, weather resistance, color difference, etc.

![]()

03. Production and processing

04.Finished product inspection

1、Carry out product appearance inspection, size inspection, flatness, curvature and other steps

05.Finished product packaging

1、To facilitate on-site disassembly and installation, the product packaging is divided into sections according to the roof plan. The product identification card on the outer packaging contains a section plan and a list of product numbers.

三. Seamless Installation

» On-Site Project Management

» Safety Compliance Documentation

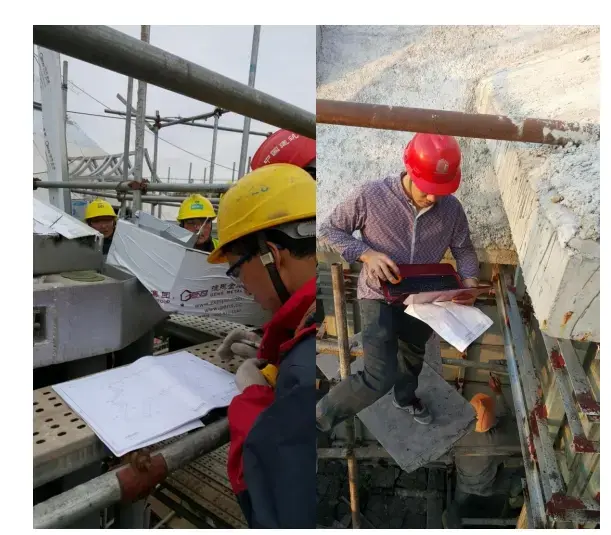

01.On-site Construction or Guidance

1. Based on the actual construction site conditions, consult with the customer to confirm the specific construction site layout. This primarily includes the product and related accessories, storage space, and on-site processing area.

2. Product Arrival and Warehousing: Verify data and arrange products in the correct locations based on the packaging identification card, the sectioned floor plan, and the product number list included with the box.

3. On-site Guidance: Installation technicians must visit the construction site one day in advance to inspect the work area and verify that their tools (such as pliers, edge-locking machines, and hammers) and auxiliary materials (rivets, structural adhesive, screws, and other accessories) are complete.

4. Confirm and print the drawings; hold a technical briefing meeting to thoroughly review work details and safety precautions.

5. On-site Installation

6. Upon installation completion, conduct on-site testing to ensure zero leakage.

02.Acceptance and Maintenance

1. Invite the customer to review the installation interface. After confirmation, they will sign and complete the acceptance procedures.

2. Confirm the signature.

3. Provide guidance to the customer or arrange for personnel to perform regular maintenance.