Snap Lock Standing Seam Roof

Brand:HF

Finishes: PVDF/PE

3 factories&7 production lines&more than 40 machines

Thickness:0.5-1.2mm

Height:45mm

Material Aluminum alloy, steel,stainless steel,copper, titanium zinc

Supply Ability:1000 Ton/month

Service life:30-year warranty

MOQ:500㎡/1T

Color: RAL and other customized colors

Standard:ASTM,DIN,JIS,BS,GB/T

Delivery time: 15-20 days

Snap Lock Standing Seam Roof: Innovative Roofing Solution

Xi'an Huafeng Construction Engineering Co., Ltd. is a leading manufacturer and supplier of high-quality snap lock standing seam roof systems. Our inventive material arrangements combine toughness, productivity, and stylish offer. With over 20 protected advances and state-of-the-art generation offices, we convey prevalent items custom fitted to your extend needs.

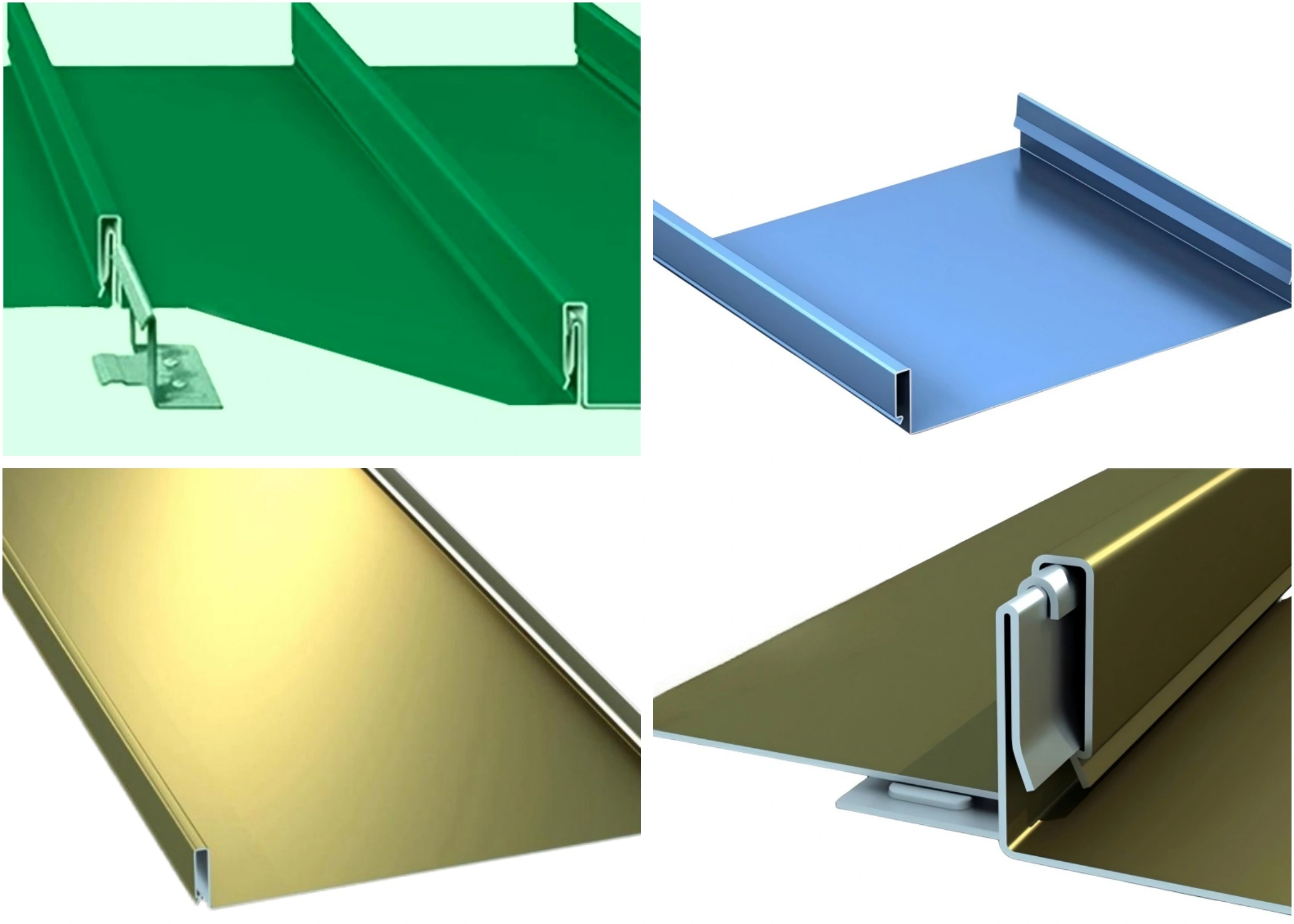

Product Introduction

The product is a high-performance metal roofing system that uses snap-on standing seam biting technology. Its unique 1.75-inch high standing seam design provides excellent waterproof, wind resistance and durability. Hidden fixing clips and panels make the system easy to put up quickly. It can be used in business, industrial, and high-end residential buildings.

Typical Product Specifications

| Item | Parameters/Description |

|---|---|

| Standard height | 45mm |

| Effective width of panel | Usually 300mm-600mm |

| Material thickness | Steel substrate: 0.5mm-1.0mm (galvanized or galvanized), Aluminum: 0.7mm-1.2mm |

| Single board length | Customized production (up to 13m for a single board, reducing lateral overlap) |

| Edge type | Single or double-sided Snap-Lock (clip-on mechanical bite) |

| Applicable slope | Minimum 1:12 (about 4.8°) (needs to be matched with waterproof cushion) |

Material Performance

1、 Substrate Type and Coating

| Material | Features | Applicable scenarios |

|---|---|---|

| Galvalume steel | Substrate: 55% aluminum, 43.4% zinc, 1.6% silicon | Most climates (especially dry inland areas) |

| Corrosion resistance ≈ 2-6 times that of ordinary galvanized steel | ||

| Lifespan up to 30~50 years | ||

| Aluminum alloy | Lightweight (density 2.7g/cm³), resistant to salt spray corrosion | Coastal and high humidity areas |

| 100% recyclable | ||

| Lifespan over 50 years | ||

| Stainless steel | Extremely high corrosion resistance (such as 304/316L) | Chemical industry area, extreme environment |

| High cost |

2、Surface coating

- PVDF coating: best weather resistance (color retention for more than 20 years), UV resistance.

- PE coating: economical, suitable for non-harsh environments.

- No coating (natural oxidation): such as copper plate, titanium zinc plate, forming a protective oxide layer.

Structural Performance

| Load type | Performance parameters | Influencing factors |

|---|---|---|

| Wind pressure | Can withstand wind speeds of ≥60m/s (216km/h) (EN 15601 standard) | Clip strength, panel thickness, tightness of bite |

| When the spacing between the fixing clips is ≤1.5m, the wind resistance is ≥3.0kN/m² | ||

| Snow load/live load | 0.7mm aluminum plate @600mm purlin spacing: ≥1.5kN/m²; | Substrate yield strength, purlin support density |

| 1.0mm galvanized steel: ≥2.0kN/m² | ||

| Seismic resistance | Flexible connection of metal panels, allowable displacement ±15mm (to adapt to structural deformation) | Sliding clip design |

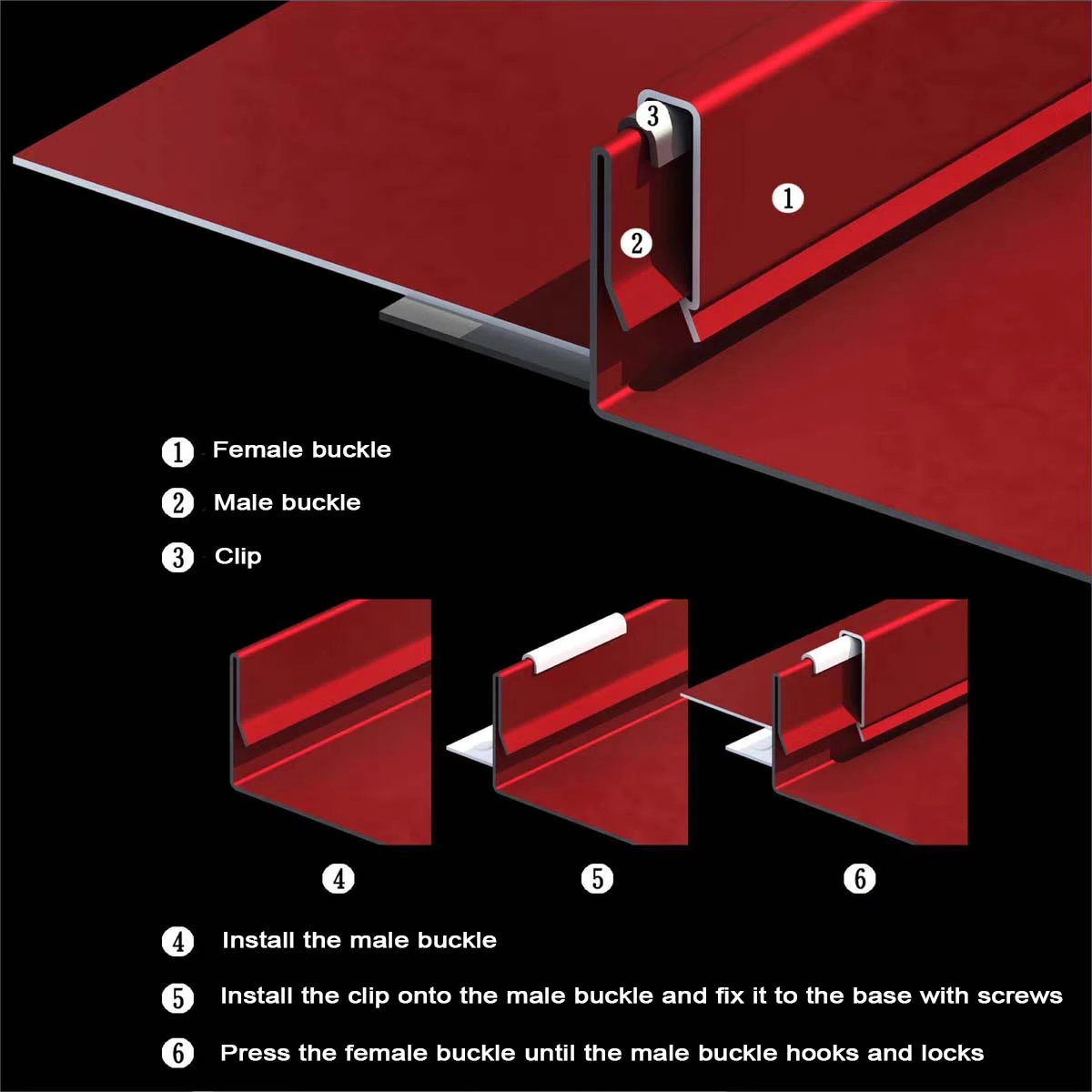

Installation Advantages

- Fast construction: Snap-Lock design is 30%~50% more efficient than mechanical edge locking (no on-site rolling required).

- Low skill requirements: Ordinary workers can operate it after 1 day of training, without the need for a professional edge locking machine.

- No risk of perforation: The fixing clip is hidden under the bite edge to avoid water leakage.

Why Choose Us?

- Industry-leading expertise with 5+ years of engineering and manufacturing experience

- Customizable solutions to meet your specific project requirements

- ISO 9001 certified quality management system ensuring consistent product excellence

- Competitive pricing and flexible MOQ options for projects of all sizes

- Comprehensive technical support and installation guidance

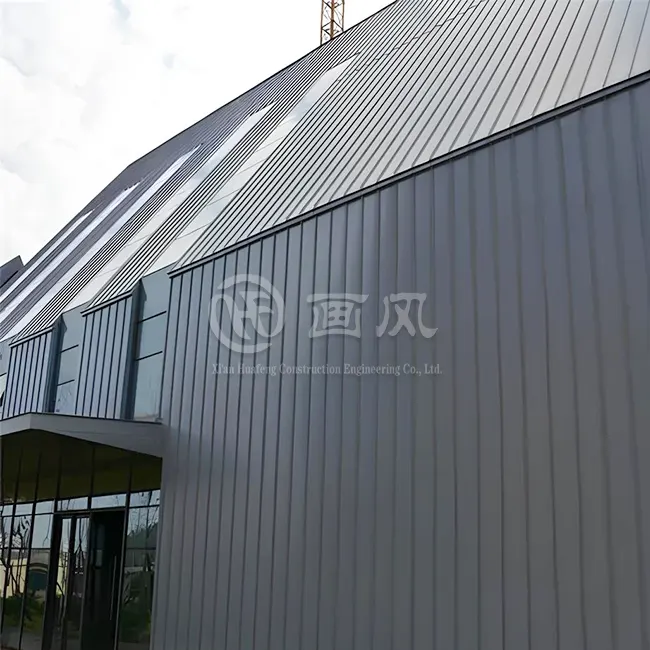

Project Cases

Our snap lock standing seam roof systems have been successfully implemented in numerous high-profile commercial and industrial projects worldwide.

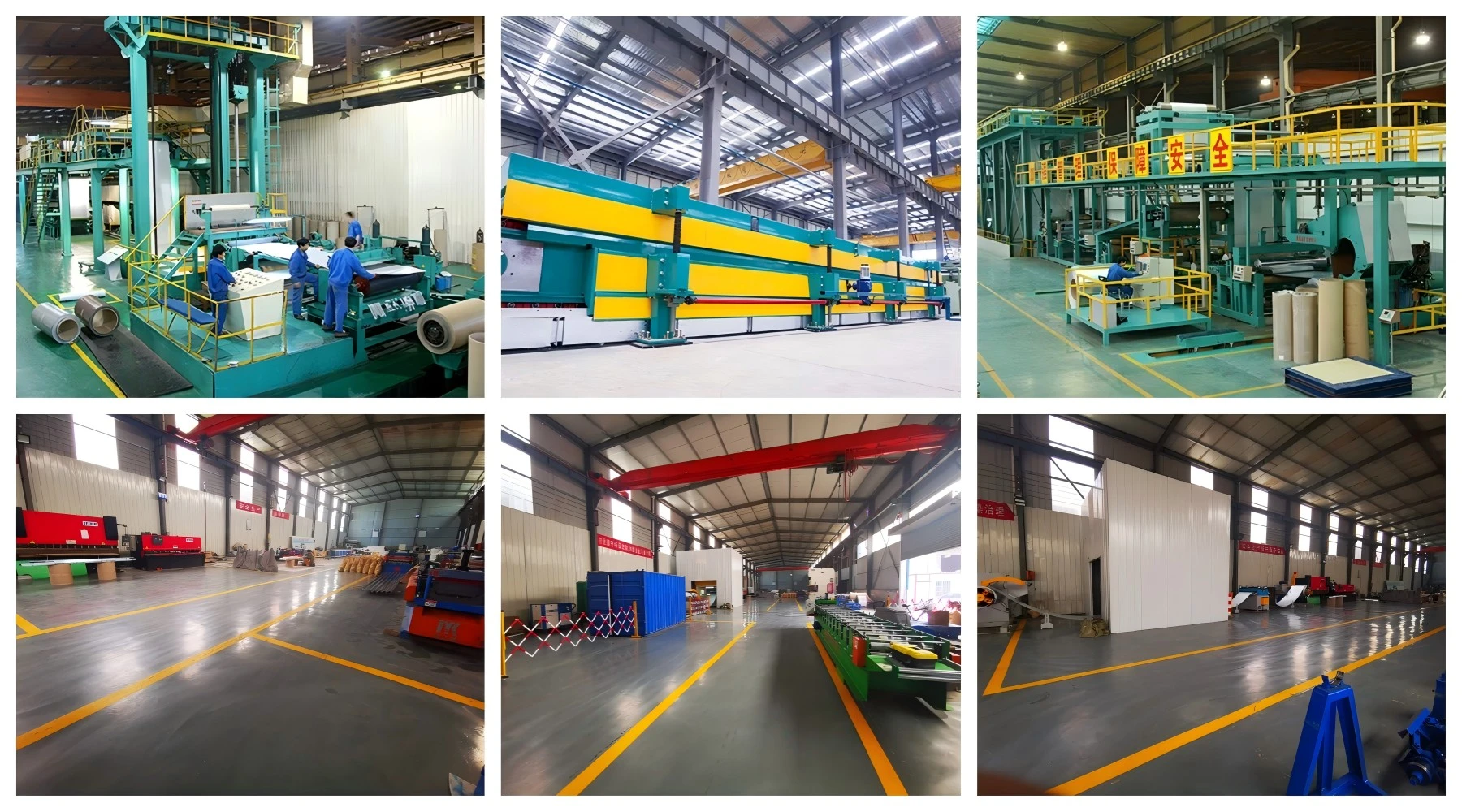

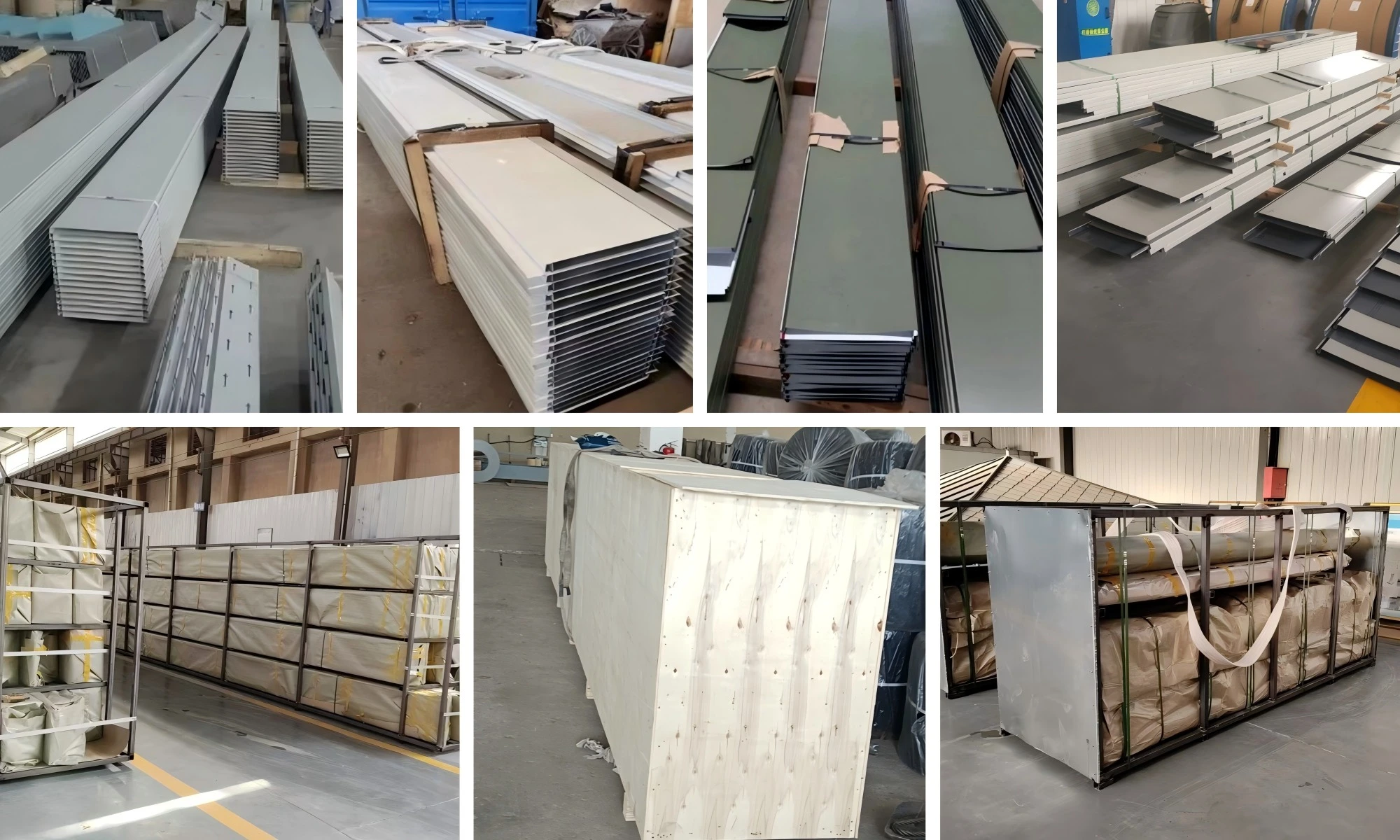

Factory Strength

With 3 state-of-the-art factories, 7 production lines, and over 40 advanced machines, we ensure superior quality and timely delivery.

Packaging

We offer secure packaging and efficient logistics solutions to ensure your product arrives safely and on time.

Qualification Certification

Our products meet international standards and are certified by CE, ISO, and SGS, guaranteeing quality and compliance.

FAQ

Q: What is the minimum order quantity for the product?

A: Our MOQ is 500㎡ or 1 ton, allowing flexibility for various project sizes.

Q: How long is the warranty on your product?

A: Our goods come with a 30-year warranty, so you can be sure you'll be happy with them for a long time.

Q: Can you customize the color of the roofing panels?

A: Yes, we offer RAL color options and can accommodate custom color requests.

Q: What is the typical delivery time for an order?

A: Our standard delivery time is 15-20 days, depending on order size and specifications.

Q: Is your product suitable for areas with high wind loads?

A: Absolutely. Our system can withstand wind speeds of up to 60m/s (216km/h), making it ideal for areas prone to strong winds.

Contact Us

For more information about our snap lock standing seam roof products or to request a quote, please contact us at huafeng@hfmetalroof.com.