Imagine standing in front of a building that's suffered from rust, corrosion, and weather damage after just a few years of installation. The maintenance costs are mounting, and the aesthetic appeal has completely deteriorated. This is the nightmare scenario that drives construction managers to seek better roofing solutions. Pre Painted Corrugated Sheets offer the answer to these challenges by combining factory-applied protective coatings with structural strength, delivering decades of maintenance-free performance while maintaining visual appeal. These engineered metal panels represent a significant advancement in building envelope technology, providing exceptional durability, weather resistance, and cost-effectiveness for industrial, commercial, and residential construction projects worldwide.

Understanding Pre Painted Corrugated Sheets Technology

Pre Painted Corrugated Sheets are advanced metal building materials manufactured through a sophisticated process where galvanized or galvalume steel substrates receive high-performance protective coatings before being roll-formed into their characteristic wavy profiles. The manufacturing sequence begins with premium-grade steel coils that undergo surface preparation, followed by the application of multiple coating layers including primer, color coat, and topcoat, with each layer being precisely baked to create a durable, chemically bonded finish. This pre-coating approach fundamentally differs from post-fabrication painting because the coating is applied under controlled factory conditions, ensuring uniform coverage, optimal adhesion, and superior longevity compared to field-applied paints. The corrugation process that follows creates the distinctive wave pattern featuring alternating ridges and grooves, which dramatically enhances the structural rigidity and load-bearing capacity of the metal sheet without adding significant weight. These sheets typically utilize substrates including cold-rolled steel, hot-dip galvanized steel, galvalume steel, or aluminum alloy, with each material offering specific advantages in terms of corrosion resistance, weight, and cost considerations for different application environments.

Manufacturing Process and Quality Control

The production of Pre Painted Corrugated Sheets involves rigorous quality control at every stage to ensure consistent performance characteristics. Raw material selection begins with verification of substrate properties through material certifications and third-party testing reports that confirm chemical composition, mechanical properties, and surface quality meet international standards such as ASTM, DIN, JIS, BS, and GB/T specifications. The coating application process employs continuous coil coating lines where steel coils pass through cleaning stations, chemical treatment zones, and multiple coating applicators, with each coating layer being cured in precision-controlled ovens at specific temperatures to achieve optimal cross-linking and adhesion. Advanced coating technologies including Polyester, High-Durability Polyester, and Polyvinylidene Fluoride provide varying levels of weather resistance, with PVDF coatings offering the highest performance with coating thicknesses of 25 micrometers or greater for exceptional UV resistance and color retention over 20-30 years of exposure. After coating, the material undergoes roll-forming through precision dies that create the corrugated profile while maintaining the integrity of the protective coating system, with careful control of forming speeds and angles to prevent coating damage or delamination during the shaping process.

Technical Specifications and Performance Characteristics

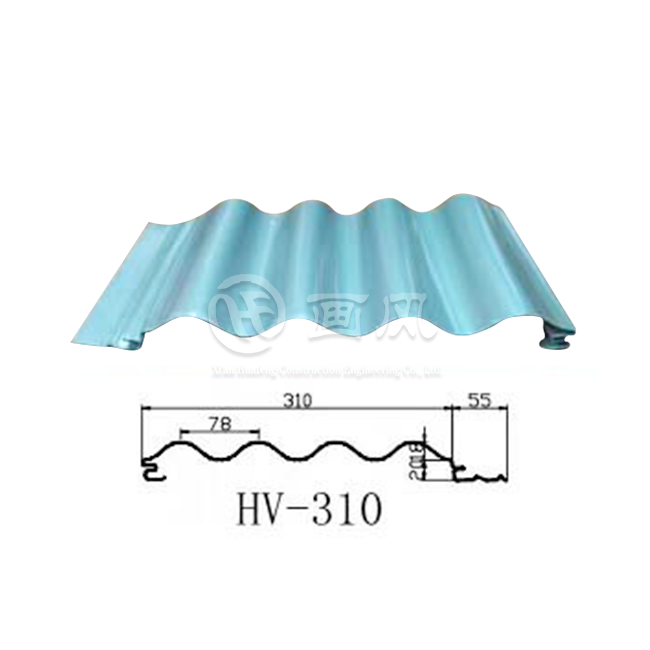

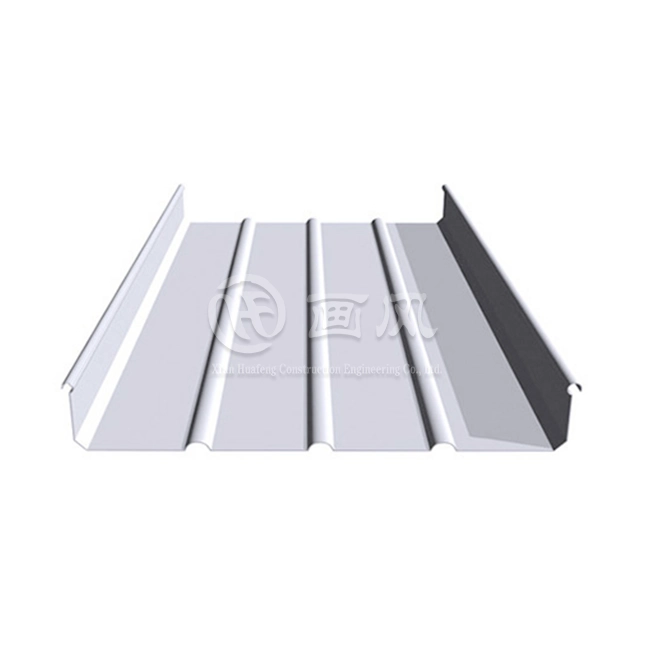

Pre painted corrugated roofing sheet products are available in comprehensive specification ranges to accommodate diverse project requirements and structural demands. Width dimensions typically range from 720mm to 1500mm, with custom widths available to optimize coverage and minimize waste for specific roof geometries and spanning requirements. Thickness options span from 0.4mm to 1.2mm, with heavier gauges selected for applications demanding greater load-bearing capacity, wind resistance, or spanning distances between structural supports. The corrugation profiles themselves vary in depth and pitch, with common configurations including trapezoidal waves, sinusoidal curves, and custom profiles designed to provide specific structural characteristics, water drainage patterns, and aesthetic appearances. Performance testing demonstrates that these sheets achieve tensile strengths ranging from 280 to 550 MPa depending on substrate selection, yield strengths exceeding 220 MPa, and thermal expansion coefficients of approximately 11.5×10⁻⁶ per degree Celsius that match steel's natural expansion characteristics. Wind pressure resistance testing confirms these panels can withstand category 12 typhoon conditions generating pressures up to 1.5 kPa when properly installed with appropriate purlin spacing and fastening systems.

Key Benefits of Pre Painted Corrugated Sheets

The advantages of Pre Painted Corrugated Sheets extend across multiple performance dimensions that directly impact project economics, construction schedules, and long-term building performance. Factory-applied coatings eliminate the need for on-site painting operations, reducing labor costs, weather-related construction delays, and the quality inconsistencies associated with field application under varying environmental conditions. The coating systems provide exceptional corrosion resistance by creating a complete barrier between the steel substrate and environmental elements including moisture, oxygen, salt spray, industrial pollutants, and UV radiation that would otherwise degrade unprotected metal surfaces. Weather resistance testing including salt spray exposure, humidity cycling, and accelerated weathering demonstrates that properly coated sheets maintain their protective properties and aesthetic appearance for 20-30 years in normal exposure conditions, with premium PVDF coatings extending this performance to 30+ years even in aggressive coastal or industrial environments. The corrugated profile contributes structural efficiency by distributing loads through the alternating ridges and valleys, allowing these relatively thin metal sheets to span considerable distances between supports while resisting deflection under wind, snow, and maintenance loads.

Economic and Installation Advantages

Pre Painted Corrugated Sheets deliver compelling economic benefits throughout the project lifecycle from initial procurement through decades of service life. Material costs remain competitive compared to alternative roofing systems, with the combination of durability and low maintenance requirements producing favorable life-cycle cost analysis results that account for total ownership expenses rather than just initial investment. The lightweight nature of these panels, typically 4-7 kilograms per square meter depending on thickness and substrate, reduces structural support requirements and foundation loads compared to heavier roofing materials like concrete tiles or clay, potentially generating significant savings in the overall building structure design and construction costs. Installation efficiency represents another major advantage, as the large-format sheets provide rapid coverage of extensive roof areas with minimal joints and seams, reducing labor hours and allowing construction schedules to progress quickly even on large commercial or industrial buildings. The pre-finished surface eliminates painting operations and associated drying times, enabling immediate progression to subsequent construction activities and accelerating overall project completion timelines.

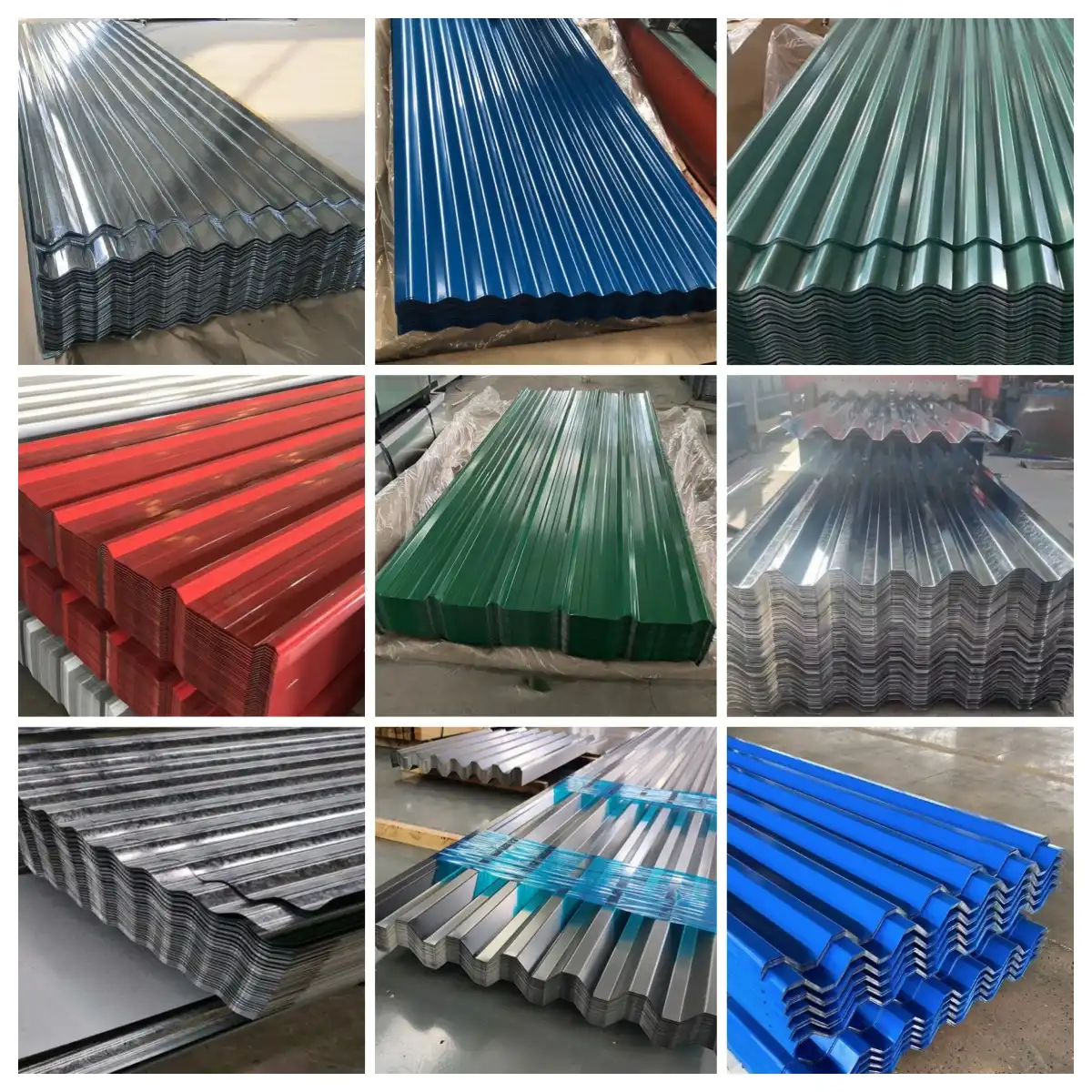

Aesthetic Flexibility and Design Options

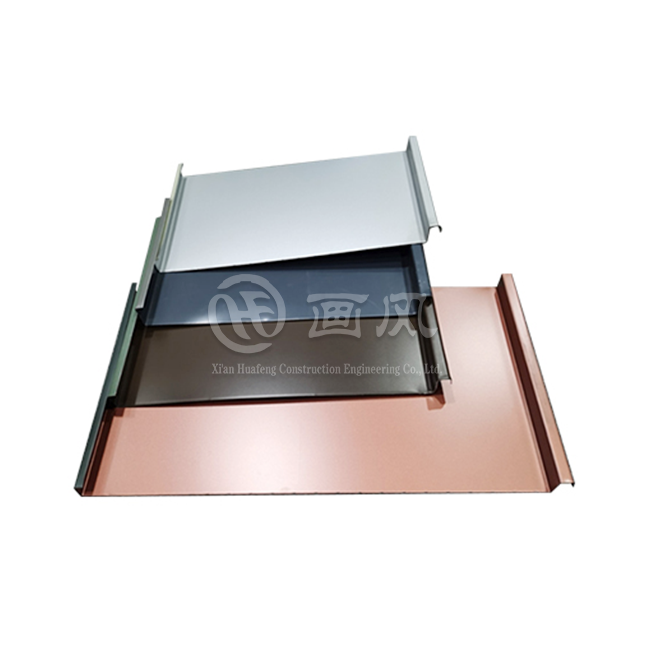

Modern Pre Painted Corrugated Sheets offer extensive aesthetic customization capabilities that support diverse architectural visions and branding requirements. Color selection typically includes standard options in blue, white, gray, and earth tones, with expanded RAL color system selections and custom color matching services enabling precise coordination with corporate identity programs, architectural design schemes, or neighborhood aesthetic requirements. Surface finishes range from high-gloss formulations that provide brilliant color saturation and light reflection to matte and textured finishes that offer sophisticated, subdued appearances with reduced glare characteristics. Advanced coating technologies can incorporate special effects including metallic pigments, granite-like textures, wood grain patterns, and even printed designs that simulate traditional building materials while retaining all the performance advantages of metal construction. The corrugation profile itself contributes to visual character, with different wave amplitudes and frequencies creating varied shadow lines and texture patterns that add dimensional interest to large roof and wall surfaces.

Applications of Pre Painted Corrugated Sheets

The versatility of Pre Painted Corrugated Sheets makes them suitable for an extraordinarily broad range of building applications across multiple market sectors. Industrial facilities including manufacturing plants, warehouses, distribution centers, and logistics facilities represent primary application areas where the combination of large-span capability, rapid installation, and durability aligns perfectly with operational requirements for cost-effective, low-maintenance building envelopes. Agricultural buildings such as barns, equipment storage structures, livestock facilities, and grain storage buildings benefit from the weather protection, natural lighting options through translucent panel integration, and resistance to the corrosive environments common in agricultural operations. Commercial construction applications encompass retail centers, office buildings, recreational facilities, and mixed-use developments where Pre painted corrugated roofing sheet systems provide both functional weather protection and architectural expression through color and profile selection.

Specialized Applications and Innovative Uses

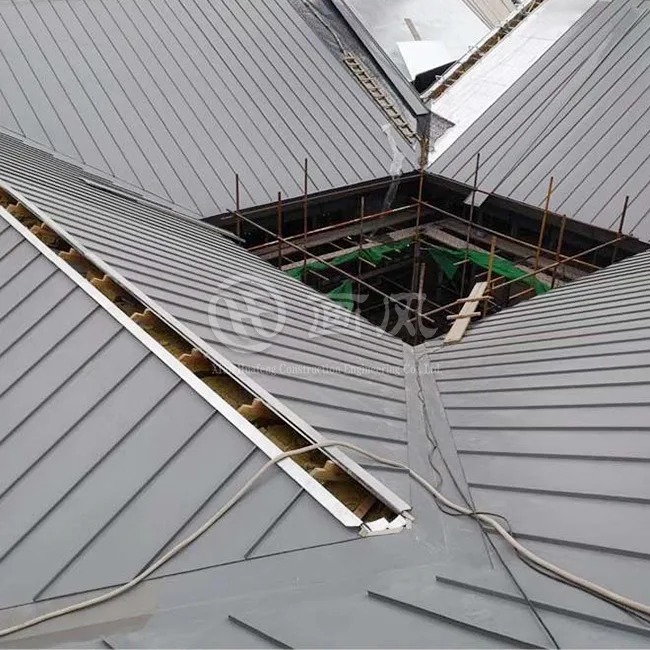

Beyond conventional roofing applications, Pre Painted Corrugated Sheets serve numerous specialized building envelope functions. Wall cladding systems utilize these panels to create durable, attractive facades for industrial buildings, noise barriers along highways and railways, and architectural accent walls that add visual interest to contemporary building designs. Canopy and awning structures including carports, loading dock covers, outdoor pavilions, and transit station shelters leverage the material's spanning capability and weather resistance to create protected outdoor spaces with minimal structural support requirements. Temporary and modular construction applications take advantage of the panels' ease of installation and removal for disaster relief shelters, construction site facilities, seasonal structures, and relocatable buildings where speed of deployment and reconfiguration flexibility are paramount considerations. Residential applications are expanding as architects and homeowners recognize the aesthetic potential of corrugated metal alongside its practical benefits, with applications including main roof systems, porch covers, garage roofs, and accent walls that introduce industrial-modern design elements.

Geographic and Climate Considerations

The performance characteristics of Pre Painted Corrugated Sheets make them particularly well-suited to challenging environmental conditions. Coastal regions with salt-laden atmosphere and high humidity benefit from the corrosion resistance provided by galvalume substrates and premium coating systems that prevent the rust and degradation that rapidly compromise unprotected steel in these aggressive environments. High-wind zones including typhoon and hurricane-prone areas rely on the structural strength of corrugated profiles and proper fastening systems to maintain building envelope integrity during extreme weather events, with documented performance in category 12 wind conditions providing confidence for critical facility applications. Snow load regions utilize thicker gauge sheets and closer support spacing to handle the substantial distributed loads from accumulated snow, while the smooth coated surface facilitates snow shedding to reduce loading duration. High-temperature environments benefit from light-colored or specially formulated heat-reflective coatings that reduce solar heat gain and lower cooling energy requirements for conditioned spaces beneath the roof assembly.

Selecting the Right Pre Painted Corrugated Sheets

Successful specification of Pre Painted Corrugated Sheets requires careful consideration of multiple technical and performance factors to ensure optimal results. Substrate material selection forms the foundation of the specification process, with galvanized steel offering proven corrosion protection at economical cost points, galvalume steel providing enhanced corrosion resistance particularly in rural and industrial environments, aluminum alloy delivering maximum corrosion resistance with reduced weight for applications where structural load considerations are critical, and stainless steel representing the premium choice for the most demanding corrosive environments or applications requiring extended service life. Coating system selection must align with expected service life requirements, environmental exposure conditions, and budget constraints, with Polyester coatings providing good performance for 10-15 years in normal conditions, High-Durability Polyester extending performance to 15-20 years with improved chalk and fade resistance, and PVDF coatings delivering 25-30+ year performance with exceptional color retention and chemical resistance for premium applications.

Technical Evaluation Criteria

Thickness determination involves balancing structural requirements, spanning capabilities, and economic considerations to identify the optimal gauge for specific applications. Minimum thickness requirements are established by local building codes based on design loads including dead load, live load, wind pressure, and snow accumulation, with typical industrial applications utilizing 0.5-0.8mm thicknesses while more demanding applications or longer spans may require 0.8-1.2mm gauges. Profile selection influences both structural performance and aesthetic character, with deeper corrugations providing greater rigidity and spanning capability while creating more pronounced shadow lines and visual texture. Fire resistance ratings are verified through testing to relevant standards including GB 8624, with B1 ratings achievable through standard coatings and A-level ratings possible with specialized flame-retardant coating formulations for applications with stringent fire safety requirements. Sound insulation performance ranges from 25 decibels for single-layer installations to 40+ decibels when combined with insulation materials, an important consideration for applications near residential areas, transportation corridors, or noise-sensitive operations.

Quality Assurance and Supplier Evaluation

Partnering with a qualified China Pre Painted Corrugated Sheets manufacturer ensures access to quality products backed by comprehensive technical support and service capabilities. Certification verification should include confirmation of ISO 9001 quality management systems, ISO 14001 environmental management standards, and product-specific certifications such as CE marking for European markets and SGS testing documentation that validates product performance claims. Factory capability assessment examines production capacity including the number of coating lines, forming machines, and monthly output potential to ensure the China Pre Painted Corrugated Sheets supplier can meet project volume and schedule requirements without compromising quality through rushed production. Technical support services distinguish leading manufacturers from commodity suppliers, with capabilities including structural engineering assistance, drainage system design, thermal performance modeling, and material specification advisory services that help optimize system selection for specific project requirements. Customization flexibility enables tailored solutions including non-standard widths, custom color matching, special coating formulations, and modified profile geometries that address unique architectural or performance requirements.

Installation Best Practices and Long-Term Performance

Proper installation techniques are critical to realizing the full performance potential of Pre Painted Corrugated Sheets systems. Substrate preparation begins with verification that the supporting structure provides adequate strength, proper spacing, and appropriate slope to ensure water drainage and prevent ponding that could lead to premature coating degradation or structural problems. Fastening system selection must account for thermal expansion and contraction of the metal panels, utilizing appropriate fastener types, spacing, and installation techniques that secure the panels while accommodating movement without causing distortion or coating damage. Sealant and flashing details at panel terminations, penetrations, and transitions require careful execution using compatible materials and proven detailing sequences to prevent water infiltration that could compromise building integrity and lead to interior damage or structural corrosion.

Maintenance and Service Life Optimization

While Pre Painted Corrugated Sheets require minimal maintenance compared to many roofing systems, implementing a basic maintenance program optimizes long-term performance and extends service life. Periodic inspection protocols should include visual assessment of the coating condition, fastener tightness, and sealant integrity, with particular attention to areas subject to increased wear such as roof valleys, ridges, and equipment mounting locations. Cleaning procedures using mild detergents and low-pressure water washing remove accumulated dirt, organic growth, and atmospheric deposits that can retain moisture and potentially accelerate coating degradation in localized areas. Touch-up coating application addresses minor scratches or damaged areas before they can propagate, using compatible coating materials and proper surface preparation techniques to restore protective coverage and prevent the initiation of corrosion processes. Documentation systems track maintenance activities, inspection findings, and any repairs performed, creating a historical record that supports warranty claims and provides valuable data for facility management planning and budget forecasting.

Conclusion

Pre Painted Corrugated Sheets represent an optimal convergence of durability, economy, and versatility for modern construction applications. The factory-applied coating systems deliver decades of weather protection with minimal maintenance requirements, while the corrugated structural profile provides exceptional strength-to-weight ratios that enable efficient spanning and reduced support requirements. From industrial warehouses to commercial complexes and specialized structures, these engineered panels offer proven performance backed by rigorous quality control and comprehensive technical support from qualified manufacturers.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a leading China Pre Painted Corrugated Sheets factory, combining advanced manufacturing capabilities with comprehensive engineering expertise to deliver superior roofing and wall cladding solutions. As a recognized High Quality Pre Painted Corrugated Sheets manufacturer, our company operates three strategically located production facilities including a 200,000 square meter raw material plant in Anhui and plate processing facilities in Hangzhou and Xi'an, equipped with 7 color coating production lines and more than 40 specialized machines that ensure consistent quality and reliable supply capacity of 1000 tons per month. Our expertise as a trusted China Pre Painted Corrugated Sheets supplier extends beyond manufacturing to include complete design optimization services, structural 3D modeling, drainage system simulation, and material specification advisory that help clients achieve optimal system performance and value. Recognized as a high-tech enterprise in Shaanxi Province with first-level building curtain wall qualifications and third-level steel structure qualifications, we maintain rigorous quality standards confirmed through ISO9001, ISO14000:14001, and SGS certifications alongside more than 20 registered patents for roofing systems that demonstrate our commitment to innovation and technical excellence. Our customization capabilities address unique project requirements through tailored solutions in width from 720-1500mm, thickness from 0.4-1.2mm, PE/HDP/PVDF coating options, and complete RAL color matching services with competitive Pre Painted Corrugated Sheets price structures and 15-20 day delivery timelines. With a proven track record on major projects including Xiongan Station Commercial Complex, Xi'an International Convention and Exhibition Center, and numerous public buildings across China, we deliver one-stop solutions from initial design through final installation and ongoing maintenance support. When you need reliable Pre Painted Corrugated Sheets for sale backed by engineering excellence and manufacturing quality, contact our team at huafeng@hfmetalroof.com for technical consultation, competitive Pre Painted Corrugated Sheets wholesale pricing, and customized solutions tailored to your specific project requirements. Save this resource for future reference and reach out today to discover how our integrated capabilities can optimize your building envelope performance while meeting schedule and budget objectives.

References

1. American Galvanizers Association. "Galvanization Process and Corrosion Protection Standards." Technical Publication Series on Hot-Dip Galvanizing.

2. International Organization for Standardization. "ISO 9001:2015 Quality Management Systems - Requirements." Geneva: ISO Central Secretariat.

3. National Roofing Contractors Association. "Metal Roofing Systems: Design and Installation Best Practices." NRCA Technical Manual.

4. Steel Construction Institute. "Structural Performance of Corrugated Metal Profiles Under Wind and Snow Loading." Technical Report Series.

5. Zhang, L., Wang, M., & Chen, H. "Durability and Weather Resistance of Pre-Painted Steel Sheets in Building Applications." Journal of Materials in Civil Engineering, American Society of Civil Engineers.

(1)_1763110678300.webp)