Seam Metal Roof Systems

Specifications: 65-300/400/430/500

Finishes:PE, HDP,PVDF COATING

Supply Ability:1000Ton/month

Service life:30-year warranty

MOQ:500㎡

Delivery time: 15-20 days

Provide customized services: color, pattern, design customization

Standard:ISO9001, ISO14000:14001,SGS guidelines

Seam Metal Roof Systems: Durable, Versatile, and Efficient Roofing Solutions

Xi'an Huafeng Construction Engineering Co., Ltd. is a leading manufacturer and supplier of high-quality seam metal roof systems. With over 5 a long time of encounter, we offer inventive material arrangements that combine solidness, aesthetics, and vitality effectiveness. Our items are planned to meet the requesting needs of commercial, mechanical, and organization ventures, giving long-lasting security and esteem for your speculation.

Product Introduction

The roof system is a crucial component of any building, with strict design requirements. It must provide safety, durability, weather resistance, thermal insulation, sound insulation, aesthetic appeal, and easy maintenance. Our products excel in all these aspects, offering a comprehensive solution for modern construction needs.

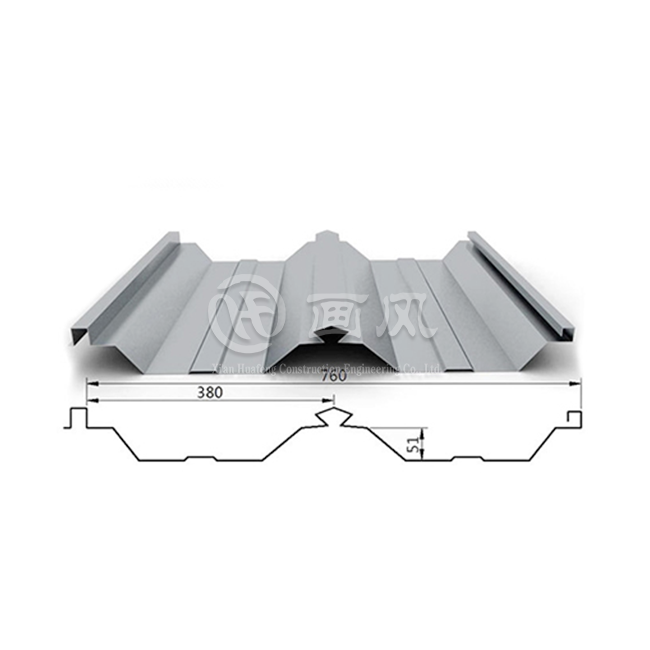

Specifications

| Feature | Details |

|---|---|

| Material | AA3003, 3004 aluminum magnesium manganese alloy |

| Panel Width | 300–600 mm (effective coverage width) |

| Seam Height | 65 mm |

| Panel Length | Customized (up to 13m long, no transverse seams) |

| Surface Treatment | PVDF coating: 25–30μm thickness, 70% fluororesin |

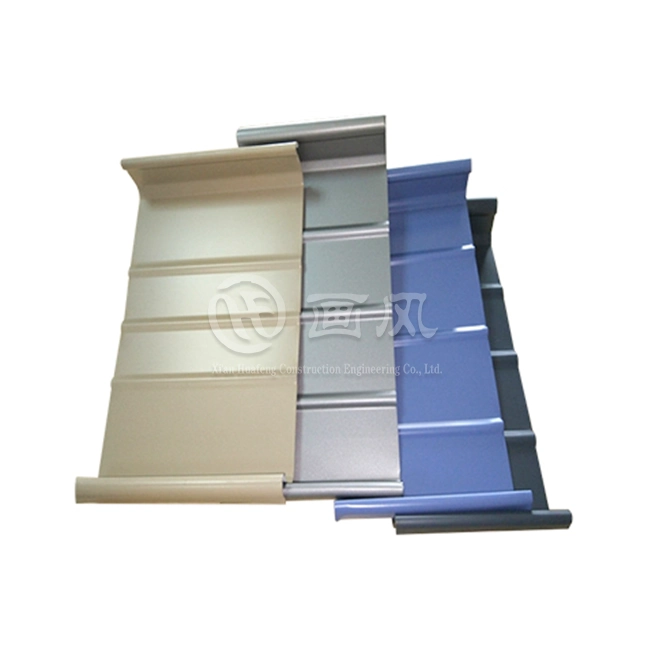

| Shape Options | Straight, positive/inverted arc, fan-shaped plates |

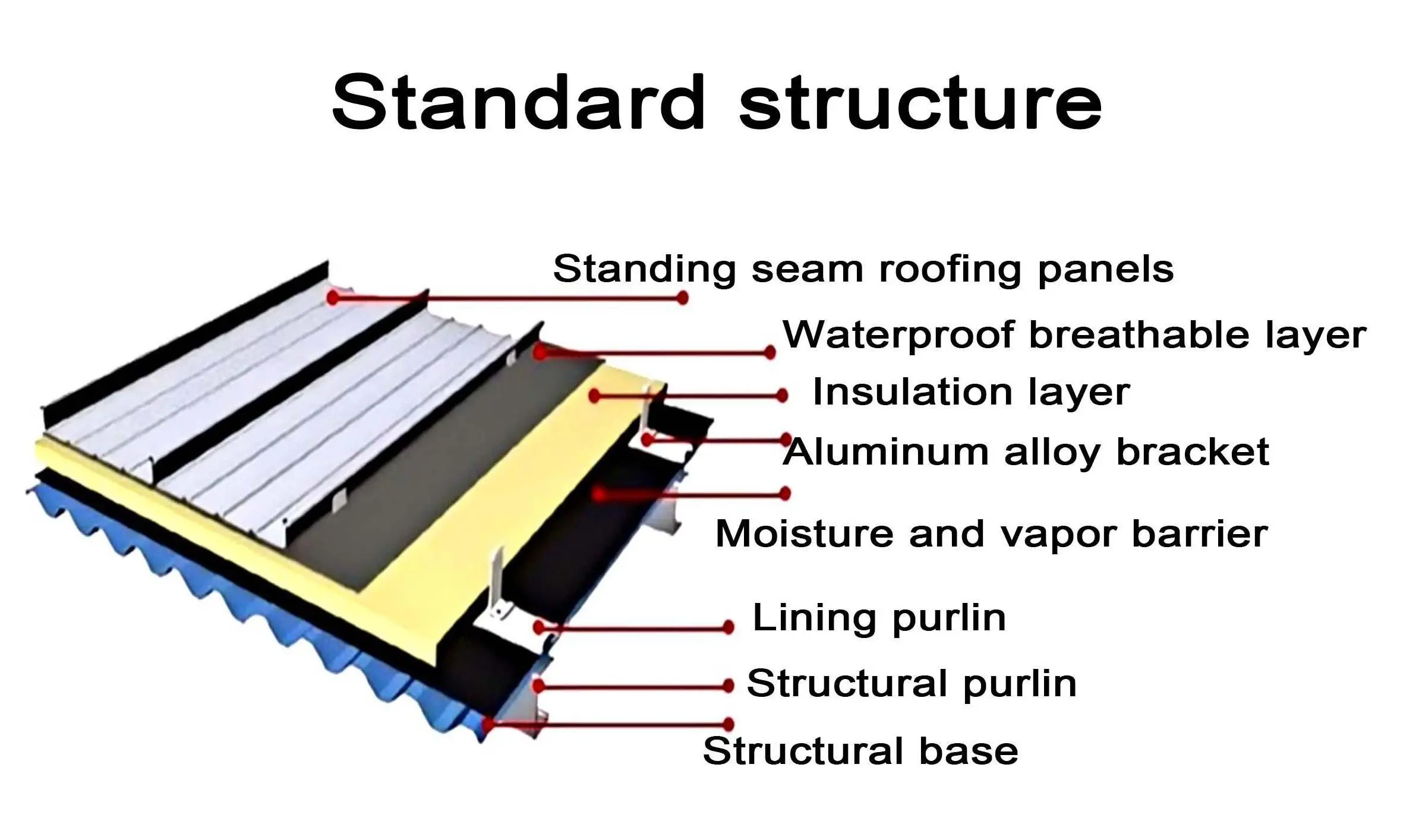

System Structure

- Standing seam roof panel: The thickness is usually 0.9mm-1.2 mm.

- Waterproof and breathable membrane: It is a high-density polyethylene non-woven fabric that blocks the invasion of wind and rain on the building structure. While strengthening the air tightness and water tightness of the building, it can also provide rare breathability, so that the water inside the enclosure structure can be quickly discharged, effectively avoiding the formation of mold and condensation water.

- Insulation and sound insulation layer: Rock wool is usually used, and its thickness needs to be determined according to calculation. It mainly plays the role of heat preservation and noise reduction, such as the noise after heavy rain and hail hit the surface layer.

- Vapor barrier: Generally, polyester film or high-density spunbond polyethylene film is used, and glass wool (with moisture-proof veneer) can also be selected. The vapor barrier can limit the water vapor inside the building from entering the roof, thereby minimizing the occurrence of condensation.

- Sound-absorbing cotton: Glass wool is usually used, and its bulk density and thickness need to be determined according to calculation.

- Dustproof layer: Generally, non-woven fabric is used, which is mainly used for dust and dust isolation, and is laid on the upper surface of the roof base plate.

- Structural base plate: generally perforated galvanized or galvanized corrugated steel plate is used, the thickness is designed according to the purlin distance, and the perforation rate is calculated according to the project. It supports sound-absorbing cotton and thermal insulation cotton, and also plays a decorative role.

- Roof purlin: generally uses lining purlin and steel purlin, which play the role of structural support and slope adjustment

Features and Advantages

1、Anti-corrosion base material, strong durability

(1)Adopting grade AA3004 aluminum-magnesium-manganese alloy, it has strong anti-corrosion performance;

(2)Surface damage caused by transportation or construction does not affect its anti-corrosion performance;

(3)Certification by the British National Standards Bureau: The service life of this product in ordinary environment is not less than 40 years.

2、Reliable waterproof performance

(1)The fixing method adopts concealed buckle plus mechanical locking method, without any screws passing through the roof to avoid water leakage;

(2)The panel cross-sectional area is used to maximize drainage, with high drainage efficiency.

(3)The horizontal overlapped edges are hinged by a special hinge machine, which has good sealing and anti-capillary action measures.

(4)The sliding fixing seat is used to avoid panel damage due to temperature deformation.

(5)The use of mobile profiling equipment breaks through the restrictions on the length of the board under transportation conditions and reduces the longitudinal overlap of the board.

(6)Aluminum alloy roof panels and flashing boards are allowed to be welded, which perfectly handles the waterproofing problem of roof openings.

3、Good adaptability to shape

(1)The aluminum-magnesium-manganese alloy material used has both considerable strength and good flexibility, and is particularly suitable for roofs with complex shapes such as three-dimensional curved surfaces;

(2)The unique production technology of fan plates, curved plates and fan curved plates can perfectly realize various design shapes while ensuring waterproof capabilities.

4、Beautiful materials and easy to use

(1)The original color panel has a very strong metallic luster;

(2)PE or PVDF coating can be applied externally to meet the color requirements of design and use;

(3)Generally, no washing and maintenance are required during use.

5、On-site press production method

High flexibility, easy to adjust production parameters according to the construction site conditions, conducive to shortening the production cycle and ensuring product quality

Why Choose Us?

- Industry-leading expertise in seam metal roof systems

- Customizable solutions for diverse project requirements

- Comprehensive quality control and certifications

- Dedicated technical support and after-sales service

- Commitment to innovation and sustainability

Project Cases

We've successfully implemented our products in numerous high-profile projects across various industries.

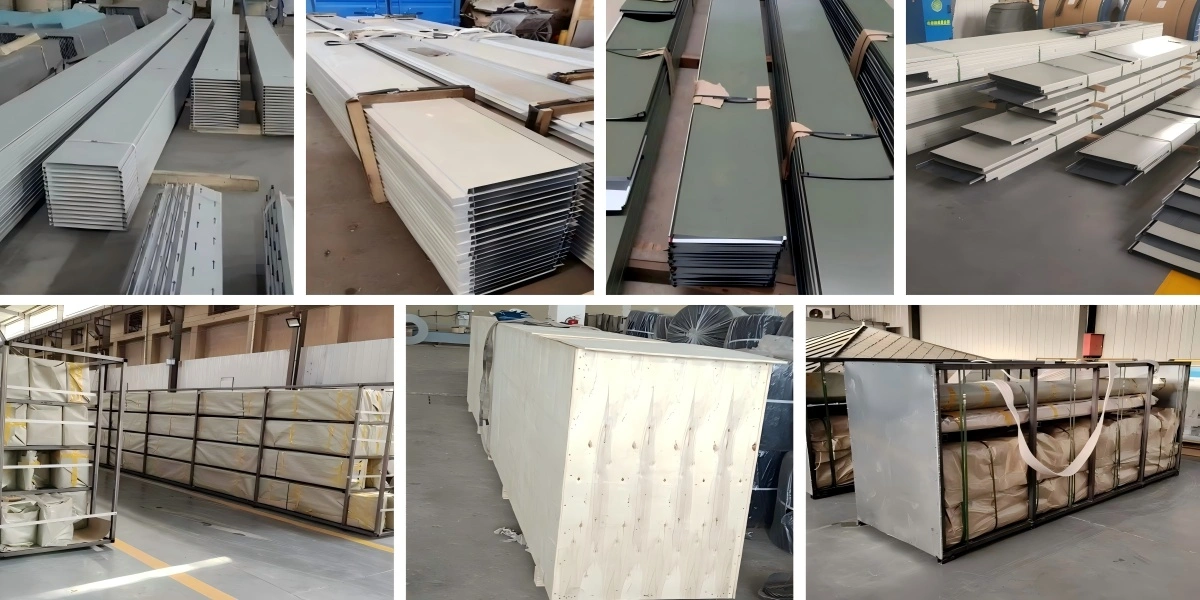

Factory Strength

Our state-of-the-art manufacturing facility ensures consistent quality and timely delivery of all orders.

Packaging

We offer secure packaging and reliable logistics solutions to ensure your products arrive safely and on time.

Qualification Certification

Our products meet international standards, including ISO9001, ISO14000:14001, and SGS guidelines.

FAQ

Q: What is the lifespan of your products?

A: Our systems come with a 30-year warranty and can last 40+ years in ordinary environments.

Q: Can you customize the color and design of the roof panels?

A: Yes, we offer customization options for color, pattern, and design to meet your specific needs.

Q: What is the minimum order quantity (MOQ)?

A: Our MOQ is 500㎡ for products.

Q: How long does it take to deliver an order?

A: Typical delivery time is 15-20 days, depending on order specifics and quantity.

Q: Are your products suitable for areas with extreme weather?

A: Yes, our systems are designed to withstand various weather conditions, including high winds and heavy rainfall.

Contact Us

For more information about our seam metal roof systems or to discuss your project requirements, please contact us at huafeng@hfmetalroof.com.