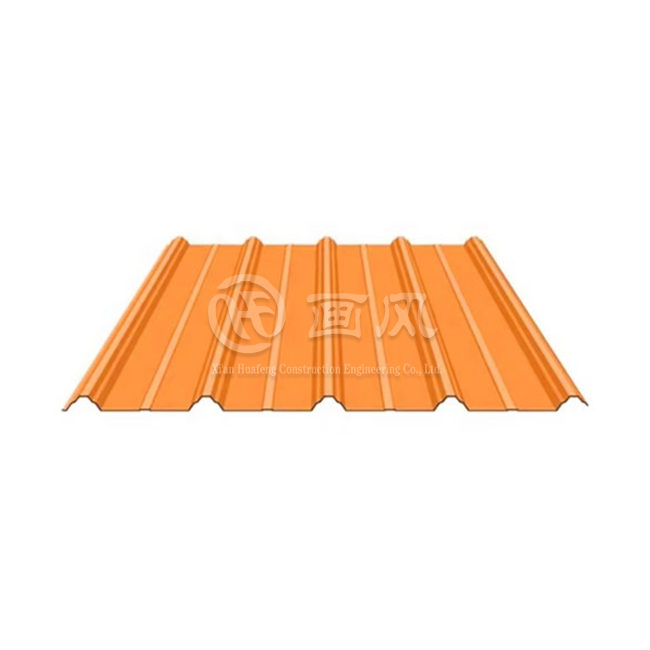

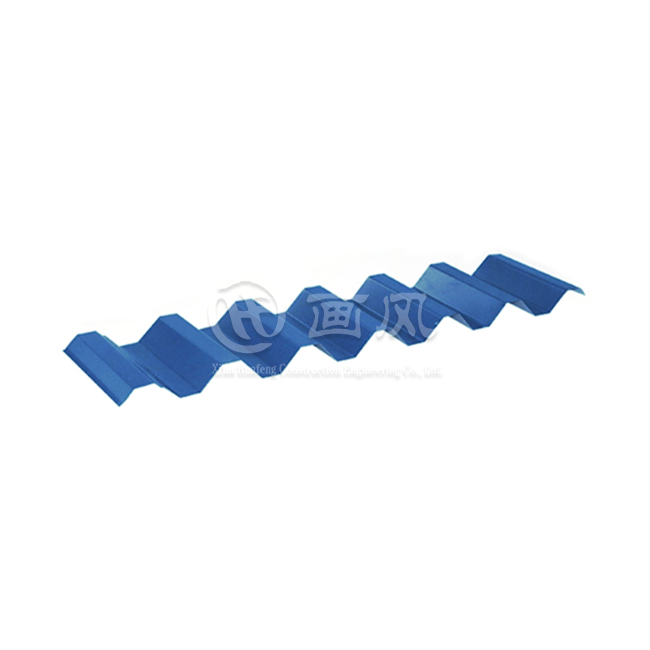

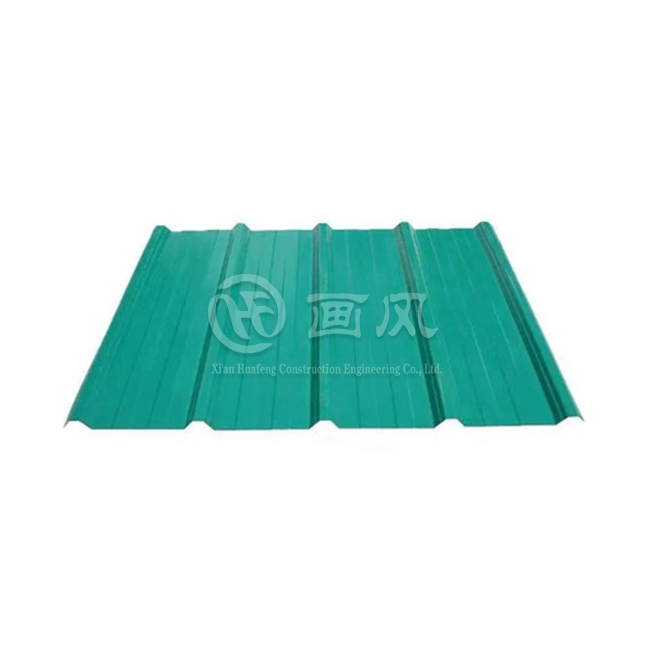

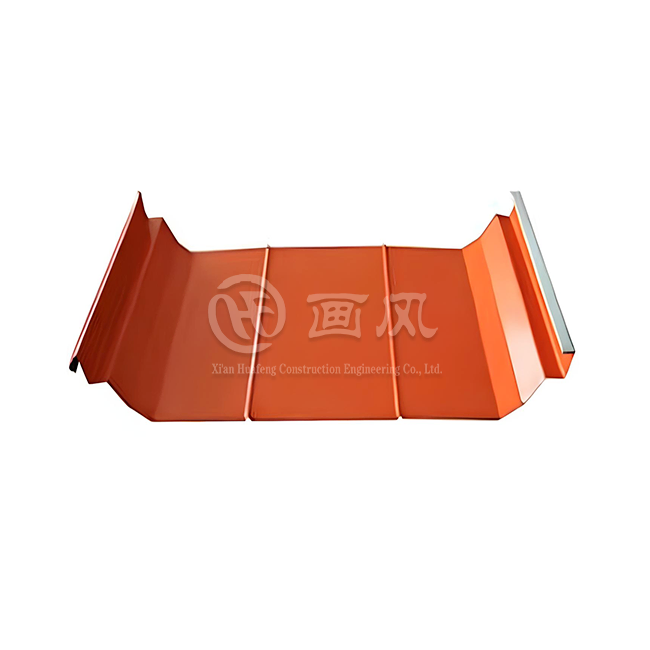

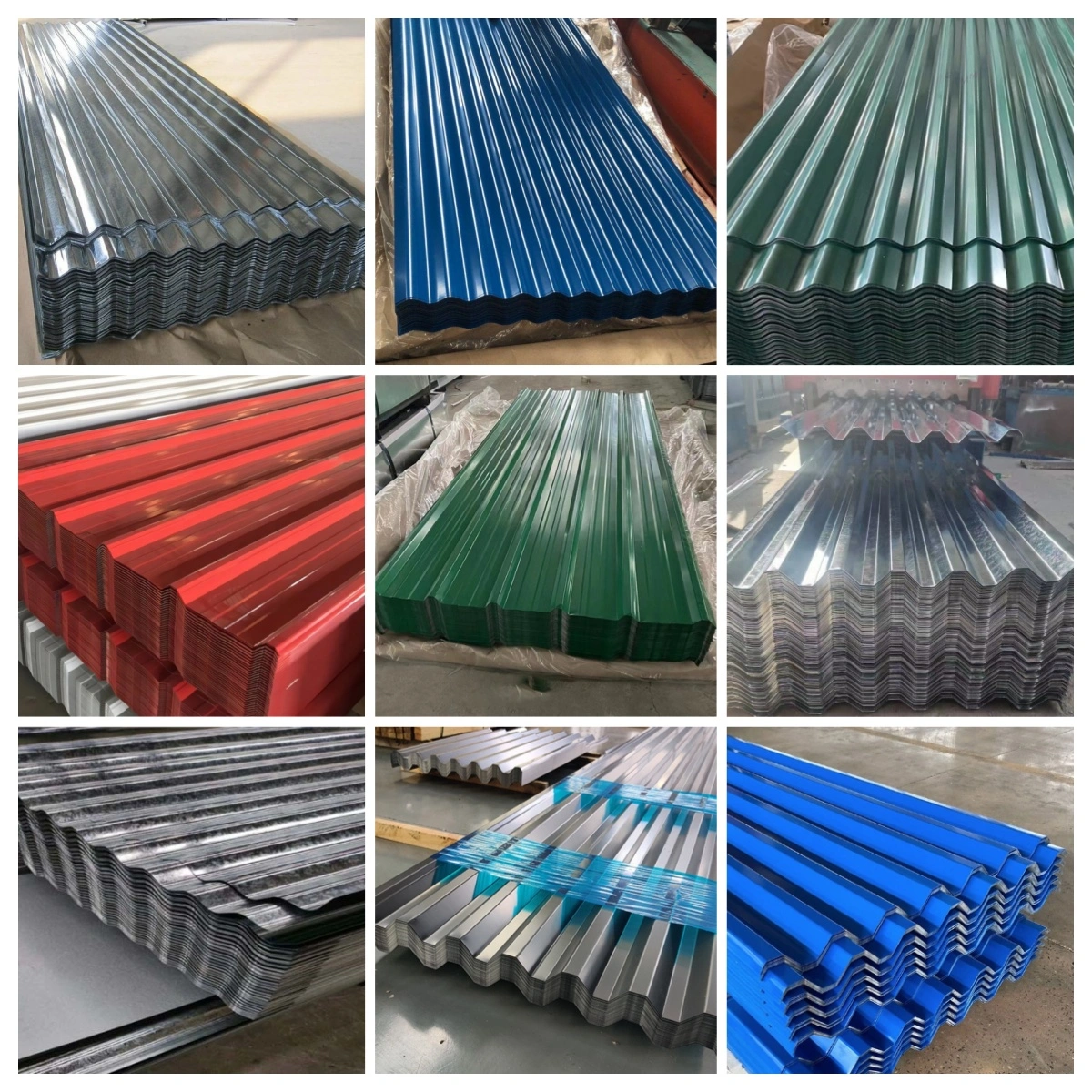

Corrugated Roofing Metal Panels

Width: 750-1500 mm,or customized as required

Thickness: 0.4-1.2mm, or customized as required

Finishes: PE, HDP, PVDF COATING

3 factories&7 production lines&more than 40 machines

Supply Ability:1000 Ton/month

Service life:30-year warranty

MOQ:500㎡

Standard:ASTM,DIN,JIS,BS,GB/T

Delivery time: 15-20 days

Provide customized services: color, pattern, design customization

Corrugated Roofing Metal Panels: Durable, Versatile, and Cost-Effective

Xi'an Huafeng Construction Engineering Co., Ltd. is a leading manufacturer and supplier of high-quality corrugated roofing metal panels. With our state-of-the-art generation offices and broad industry encounter, we offer predominant material arrangements that combine quality, toughness, and aesthetics. Our items are planned to meet the assorted needs of development ventures, from mechanical stockrooms to private buildings.

Product Introduction

Corrugated metal sheets are versatile building materials featuring a wavy surface structure. Produced through roll forming, these panels offer exceptional strength and lightweight properties, making them ideal for various construction applications.

Main features

- High strength: The corrugated structure increases the rigidity and bending resistance of the plate, enabling it to withstand greater loads.

- Lightweight: Compared with flat plates, the corrugated design reduces weight while ensuring strength.

- Weather resistance: Usually galvanized, sprayed or anodized, corrosion-resistant and UV-resistant.

- Good drainage: The corrugated groove design facilitates drainage and is suitable for roofs or outdoor coverings.

- Easy installation: It can be quickly installed by bolts, welding or snap-on methods.

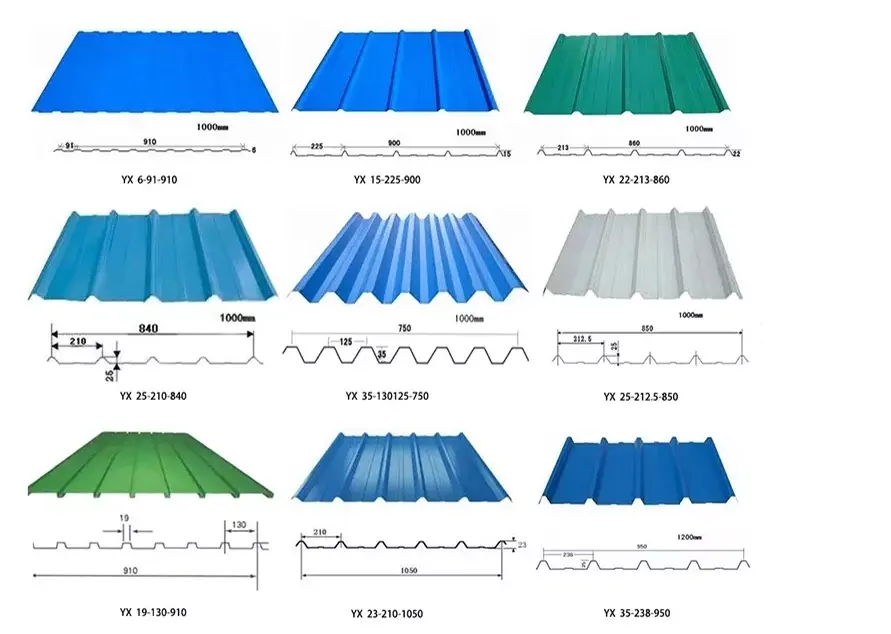

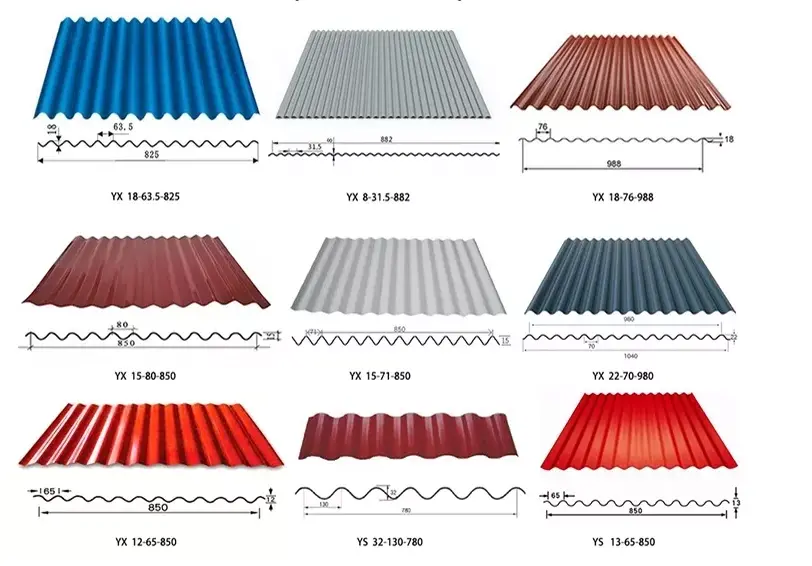

Material specifications

| Parameters | Common specifications |

|---|---|

| Base Material | Galvanized steel (SGCC, DX51D), aluminum (AA3003, AA3004,AA5052), stainless steel (304, 316), copper |

| Thickness | Steel: 0.4-1.0mm, Aluminum: 0.5-1.0mm |

| Surface Treatment | Hot-dip galvanizing, color coating (PVDF, PE), anodizing, spraying |

| Length | Customizable, typically 1-13m |

| Width | 600-1200mm (varies by corrugation type) |

| Weight | ~4kg/m² (0.5mm thick galvanized steel) |

Performance parameters

| Indicator | Typical value |

|---|---|

| Tensile Strength | Steel: 280-550MPa, Aluminum: 150-300MPa |

| Fire Resistance | Class A (non-combustible) |

| Temperature Range | -50°C to +120°C (color-coated) |

| Service Life | Galvanized: 15-30 years, Aluminum: 30+ years |

Why Choose Us?

- Customization: Tailored solutions to meet your specific project requirements

- Quality Assurance: ISO, CE, and SGS certified products

- Competitive Pricing: Direct manufacturer with bulk order discounts

- Technical Support: Expert advice and CAD assistance available

- Fast Delivery: 15-20 day lead time with efficient logistics

Project Cases

We've successfully supplied corrugated roofing metal panels for numerous high-profile projects worldwide.

Factory Strength

Our 3 factories, 7 production lines, and 40+ machines ensure consistent quality and timely delivery.

Packaging

We use industry-standard packaging to protect your products during transit.

Qualification Certification

Our products meet international standards, backed by ISO, CE, and SGS certifications.

FAQ

Q: What is the minimum order quantity (MOQ)?

A: Our MOQ is 500m² for products.

Q: Can you provide custom colors and designs?

A: Yes, we offer customization services for colors, patterns, and designs.

Q: What is the warranty on your products?

A: We provide a 30-year warranty on our products.

Q: How long does it take to fulfill an order?

A: Typical delivery time is 15-20 days, depending on order size and specifications.

Q: Do you offer installation services?

A: While we don't provide direct installation, we can recommend certified installers in your area.

Contact Us

Ready to start your project with our premium corrugated roofing metal panels? Contact us at huafeng@hfmetalroof.com for a quote or consultation.