When your building faces severe weather conditions and high winds threaten roof integrity, you need Metal Standing Seam Clamps specifically engineered and tested to withstand extreme wind uplift forces. Wind-rated clamps are aluminum roof clamps for metal roofing that have undergone rigorous testing according to industry standards like ASTM E1592, UL 580, and FM 4471, ensuring they can prevent seam separation, clip disengagement, and catastrophic roof failure during wind events.

Understanding Wind-Rated Metal Standing Seam Clamps and Testing Standards

Wind-rated Metal Standing Seam Clamps represent a critical engineering solution for protecting metal roofing systems from wind damage and ensuring building code compliance. These specialized aluminum roof clamps for metal roofing undergo extensive testing to verify their performance under extreme weather conditions. The testing process involves multiple industry-recognized standards that measure how these clamps respond to static and dynamic wind pressures. The ASTM E1592 test method stands as the most reliable standard for evaluating standing seam roof uplift performance. This test subjects a five-panel-wide sample measuring ten feet by twenty-five feet to increasing pressure from underneath, simulating wind load conditions. The pressure application continues until failure occurs, identifying the ultimate uplift load capacity of the system. Unlike pass-fail tests, ASTM E1592 provides actual performance data, showing exactly how Metal Standing Seam Clamps behave under uniform static loads and revealing potential failure points such as seam separations. Additionally, UL 580 testing evaluates the uplift resistance of complete roof assemblies, rating them as Class 15, 30, 60, or 90. These classifications represent comparative ratings rather than specific wind speeds, with Class 90 involving the most rigorous testing conditions. The FM 4471 standard takes testing further by subjecting a twelve-foot by twenty-four-foot section to increased wind pressures until assembly failure, with ratings stated as 1-60, 1-90, 1-120, and higher, referring to wind pressure in pounds per square foot.

Material Specifications and Design Features That Achieve Wind Ratings

The material composition and design characteristics of Metal Standing Seam Clamps directly influence their wind-resistance capabilities. High-quality wind-rated clamps utilize aluminum alloy 6063-T5 or T6 material with a thickness of three millimeters, providing the structural integrity necessary to withstand extreme forces. The aluminum alloy selection ensures metallurgical compatibility with various roof materials including galvanized steel, Galvalume, stainless steel, titanium-zinc, and aluminum panels, preventing galvanic corrosion that could compromise long-term performance. Surface treatment plays an equally important role in maintaining wind resistance over the roofing system's lifespan. Professional-grade aluminum roof clamps for metal roofing feature anodizing treatment of at least forty micrometers thickness, combined with fluorocarbon spraying that provides superior weather resistance and UV protection. This dual-layer protection system ensures the clamps maintain their structural integrity and holding strength even after decades of exposure to harsh environmental conditions. The clamp design itself incorporates engineering features specifically intended to maximize wind uplift resistance. Point clamps, L-shaped clamps, flat clamps, and double-piece clamps each serve distinct applications depending on the seam profile and expected load directions. The round-point setscrew design creates a secure mechanical interlock with the standing seam without penetrating the roof panel, preserving the roof warranty while achieving tested holding strengths ranging from six hundred pounds to four thousand pounds ultimate load, depending on panel material, gauge thickness, and seam profile.

How Wind-Rated Clamps Increase Roof System Performance?

Installing wind-rated Metal Standing Seam Clamps at strategic locations dramatically enhances overall roof system performance by addressing the weakest links in the load chain. These clamps function as external seam reinforcement devices placed over panel seams at clip locations, particularly in edge and corner zones where wind pressures reach their highest levels. By preventing male-to-female seam separation and clip disengagement, properly engineered clamps can increase wind uplift resistance by as much as three hundred percent. The performance enhancement occurs through multiple mechanisms working simultaneously. First, the clamps distribute wind forces more evenly across the roofing system rather than concentrating stress at individual clip points. Second, they prevent the vertical seam separation that typically initiates roof failure during high-wind events. Third, they maintain panel-to-structure connectivity even when individual fasteners experience loosening due to thermal cycling or structural movement. This performance improvement translates directly into building code compliance and life safety benefits. Many existing buildings constructed under older wind load requirements now face compliance issues as design wind speeds and code requisites have been upgraded through standards like ASCE 07-16. Wind-rated aluminum roof clamps for metal roofing offer a cost-effective retrofit solution that brings structures into compliance without requiring expensive structural modifications or complete roof replacement. The installation adds pennies per square foot of roof area while potentially saving hundreds of thousands in structural reinforcement costs.

Types of Wind-Rated Metal Standing Seam Clamps for Different Applications

Different roofing profiles and project requirements demand specific clamp configurations to achieve optimal wind resistance. Understanding the distinctions between clamp types helps project specifiers select the appropriate solution for their particular standing seam system. Each clamp type has been engineered and tested for specific load directions and seam profiles, ensuring reliable performance when properly matched to the application.

Standard Two-Setscrew Clamps for Heavy-Duty Wind Protection

Standard two-setscrew Metal Standing Seam Clamps represent the industry standard for heavy-duty wind mitigation applications requiring maximum holding strength. These robust clamps utilize dual round-point setscrews manufactured from A2-70 stainless steel, providing superior gripping force against the standing seam profile. The two-point attachment distributes clamping pressure more evenly, reducing the risk of localized deformation while maximizing the mechanical interlock with the seam. Testing data demonstrates that standard clamps achieve significantly higher holding capacities in parallel-to-seam loading conditions, making them essential for applications where wind-driven panel movement represents the primary failure mode. The dual setscrew configuration also provides redundancy, ensuring that even if one fastener experiences loosening, the clamp maintains functional attachment to the seam. This redundancy proves particularly valuable in retrofit applications where maintenance access may be limited after installation. These aluminum roof clamps for metal roofing excel in edge and corner zones where building codes mandate enhanced wind resistance. Installation involves positioning the clamp over the seam at designated clip locations and tightening both setscrews using a standard screw gun with the included T30 Torx drive bit. The setscrews create a dimple in the seam material without penetrating through it, preserving the roof panel's weather-tight integrity while achieving the necessary holding force. Proper torque application ensures optimal performance while avoiding over-tightening that could damage the panel coating or base metal.

Mini Single-Setscrew Clamps for Economical Wind Reinforcement

Mini single-setscrew Metal Standing Seam Clamps offer a cost-effective solution for applications requiring moderate wind protection without the extreme holding strength of standard clamps. These streamlined clamps utilize a single round-point setscrew, reducing material costs and installation time while still providing certified wind resistance for many common applications. Testing indicates that mini clamps typically achieve approximately two-thirds the holding strength of standard clamps, making them suitable for interior roof zones experiencing lower wind pressures. The economic advantages of mini clamps become particularly significant on large-scale commercial and industrial projects where hundreds or thousands of attachment points are required. By strategically deploying standard clamps in high-stress zones and mini clamps in lower-stress areas, project engineers can optimize cost-performance ratios while maintaining full code compliance throughout the roof assembly. This graduated approach to wind protection aligns with the actual wind pressure distribution across the roof surface, avoiding over-engineering in areas where it provides no added value. Mini aluminum roof clamps for metal roofing undergo the same rigorous testing protocols as their larger counterparts, with negative load normal-to-seam testing performed to verify their pull-up resistance. While parallel-to-seam testing data remains more limited for mini clamps, conservative engineering analysis confirms they achieve more than half the strength of standard clamps in drag load conditions. For applications where certification of parallel-to-seam capacity is critical, specifications should default to standard two-setscrew designs to ensure documented performance.

Specialized Profile-Specific Wind Clamps

Certain standing seam profiles require specially designed Metal Standing Seam Clamps that account for unique geometric features or material characteristics. T-shaped seam configurations, for example, necessitate two-piece clamp designs that can be positioned over the seam cap at any desired location. These profile-specific clamps incorporate an insert piece that positions against the base of the seam, with the outer clamp rotating into place over both the seam and insert, creating a secure mechanical connection tailored to the specific seam geometry. Applied-cap architectural seam styles present particular challenges for wind resistance due to their construction method. Testing reveals that generic clamps may yield lower load-to-failure results on applied-cap seams compared with integrated seam profiles. Recognizing this performance variation, manufacturers develop specialized clamp designs optimized for applied-cap systems, incorporating features that compensate for the different load transfer mechanisms inherent in these architectural profiles. The importance of profile-specific matching cannot be overstated when specifying wind-rated aluminum roof clamps for metal roofing. Holding strength varies dramatically based on seam profile geometry, panel material composition, gauge thickness, and even manufacturer-specific forming tolerances. Test results from one seam profile cannot be reliably extrapolated to another, even when the profiles appear visually similar. Proper specification requires identifying the exact roof panel manufacturer, specific profile name, material type, and gauge thickness, then matching these parameters with clamps that have documented test results for that precise combination.

Engineering Considerations for Wind-Rated Clamp Selection

Selecting appropriate wind-rated Metal Standing Seam Clamps requires careful engineering analysis that accounts for multiple interacting factors. The selection process goes far beyond simply choosing a clamp that physically fits the seam profile. Professional engineers must evaluate actual wind loads, load directions, safety factors, and long-term durability requirements to ensure the specified clamps will perform reliably throughout the roof's service life.

Load Direction Analysis and Holding Capacity Requirements

Wind forces act on roofing systems through multiple load directions simultaneously, and Metal Standing Seam Clamps must resist each of these force vectors to prevent failure. The primary load directions include negative normal loads perpendicular to the roof slope pulling upward, parallel-to-seam forces acting along the slope direction, and lateral seismic loads in earthquake-prone regions. Each load direction produces different stress patterns in the clamp-to-seam connection, requiring separate testing and analysis. Testing protocols measure clamp holding capacity in these different load directions on identical seam profiles, revealing that performance varies significantly based on force orientation. A clamp that demonstrates four thousand pounds ultimate capacity in parallel-to-seam loading might exhibit only two thousand pounds capacity in normal pull-up loading on the same profile. This directional sensitivity means that engineers cannot simply specify a single holding strength value but must instead evaluate the clamp's performance in each relevant load direction for the specific application. Job-specific design loads must be carefully calculated based on building dimensions, roof geometry, local wind speed data, and applicable building code provisions. These design loads are then compared against allowable clamp capacities derived from certified test results using appropriate safety factors. The safety factor typically ranges from two to three, meaning the ultimate failure load must be two to three times higher than the maximum expected service load. This ensures that temporary load increases due to wind gusts or unusual weather patterns will not compromise the attachment system.

Clamp Spacing and Distribution Patterns

Determining proper spacing and distribution of wind-rated aluminum roof clamps for metal roofing requires understanding how wind pressures vary across the roof surface. Building codes recognize that wind pressures reach maximum values in corner zones, with progressively lower pressures in edge zones and interior field zones. Rational clamp layout reflects this pressure distribution by concentrating attachment points where forces are highest while reducing spacing in lower-stress areas. Corner zone requirements typically mandate the tightest clamp spacing, often requiring placement at every clip location or even between clips in extreme cases. Edge zones receive intermediate spacing that balances wind resistance against installation cost and labor. Interior field zones generally require minimal reinforcement except in very high wind regions or on roofs with unusually wide panel spans. This graduated approach optimizes material usage while ensuring adequate wind resistance throughout the roof assembly. Calculation of required clamp quantities begins with determining the total design wind pressure in each roof zone, then dividing by the allowable capacity of the selected clamp to establish the required number of attachment points per unit area. This theoretical calculation must then be adjusted to account for actual seam locations and clip spacing, resulting in a practical installation pattern that can be efficiently executed in the field. Detailed installation drawings showing exact clamp locations prevent confusion during construction and ensure the installed system matches the engineered design.

Material Compatibility and Corrosion Prevention

Long-term performance of Metal Standing Seam Clamps depends critically on metallurgical compatibility between the clamps and the roof panels they attach to. Dissimilar metals in direct contact can create galvanic cells in the presence of moisture, leading to accelerated corrosion that degrades holding strength and potentially causes premature failure. Proper material selection prevents galvanic corrosion while ensuring the clamps will last the full life of the roof system. Aluminum alloy clamps demonstrate excellent compatibility with most common roofing materials including galvanized steel, Galvalume, aluminum, and zinc-based coatings. The passive oxide layer that forms naturally on aluminum surfaces provides inherent corrosion resistance while preventing galvanic reactions with these materials. For copper roofing systems, brass clamps offer the appropriate metallurgical match, while stainless steel clamps serve as a universal option compatible with virtually all panel materials though at higher cost. Surface coatings and treatments further enhance corrosion resistance and extend service life. Anodizing treatment creates a controlled oxide layer significantly thicker than natural oxidation, providing enhanced protection against atmospheric exposure and chemical attack. Fluorocarbon spray coating adds a secondary barrier that prevents moisture infiltration and provides superior UV resistance. Together, these treatments ensure wind-rated aluminum roof clamps for metal roofing will maintain their structural integrity and appearance through decades of service, supporting thirty-year warranty programs that match typical roof system life expectancies.

Installation Best Practices for Maximum Wind Resistance Performance

Proper installation of wind-rated Metal Standing Seam Clamps is essential for achieving the tested performance levels documented in laboratory conditions. Field installation practices directly impact holding strength, with improper techniques potentially reducing wind resistance by fifty percent or more. Following manufacturer installation instructions and industry best practices ensures that the installed system will perform as engineered when subjected to actual wind events.

Pre-Installation Planning and Site Preparation

Successful clamp installation begins with thorough site preparation and planning before any clamps are positioned on the roof. Installation crews should receive detailed drawings showing exact clamp locations, quantities, and types for each roof zone. These drawings must clearly indicate corner zones, edge zones, and field zones with their respective clamp spacing requirements. Crews should also receive copies of the manufacturer's installation instructions and any project-specific requirements established by the engineer of record. Site logistics planning addresses material staging, tool availability, and crew safety considerations. Wind-rated aluminum roof clamps for metal roofing should be stored in a protected area away from construction traffic to prevent damage to the precision-machined surfaces. Installation tools including screw guns, T30 Torx drive bits, and torque-limiting drivers should be inspected and tested before beginning work. Safety equipment including fall protection systems, toe boards, and warning lines must be properly installed according to OSHA requirements before any personnel access the roof surface. Quality control procedures should be established before installation begins, specifying inspection frequency, documentation requirements, and criteria for accepting or rejecting installed clamps. Typically, a minimum percentage of installed clamps undergo torque verification testing to confirm proper installation. Photographic documentation of representative installation areas provides valuable records for building owners and can expedite future roof maintenance or modification projects. These pre-installation preparations may appear time-consuming but ultimately save time and prevent costly callbacks caused by installation deficiencies.

Proper Clamp Positioning and Torque Application

Accurate positioning of Metal Standing Seam Clamps at intended locations along the seam is critical for achieving designed wind resistance. Clamps must align with underlying clip locations to effectively prevent clip disengagement and seam separation. Misaligned clamps that fall between clip locations provide minimal wind resistance improvement and waste installation labor. Installation crews should mark clip locations before beginning clamp installation, using panel layout drawings or by carefully measuring from known reference points. The tightening sequence for multi-setscrew clamps affects final holding strength and load distribution. For two-setscrew designs, installers should partially thread both setscrews by hand before final tightening, ensuring the clamp body seats properly against the seam profile. Final tightening should proceed in an alternating pattern, gradually increasing torque on each setscrew until the specified final torque is reached. This gradual, alternating approach prevents clamp cocking and ensures even pressure distribution across the seam contact area. Torque specifications provided by clamp manufacturers reflect laboratory testing conditions and must be followed precisely to achieve rated performance. Under-torquing results in insufficient holding force and potential clamp slippage under wind loading. Over-torquing can damage panel coatings, deform base metal, or even crack the seam profile in extreme cases. Using calibrated torque-limiting drivers eliminates guesswork and ensures consistent installation quality across hundreds or thousands of clamp locations. These specialized tools automatically stop applying torque when the preset value is reached, preventing both under-tightening and over-tightening.

Post-Installation Inspection and Documentation

Comprehensive inspection following clamp installation verifies that the completed work matches the engineered design and meets quality standards. Inspection procedures should verify correct clamp type and quantity in each roof zone, proper alignment with clip locations, achievement of specified torque values, and absence of installation damage to panels or clamps. Any deficiencies discovered during inspection must be corrected before the installation is accepted as complete. Statistical sampling provides an efficient approach to quality verification on large projects. A predetermined percentage of installed aluminum roof clamps for metal roofing undergoes detailed inspection and torque verification testing. If the sample inspection reveals deficiencies exceeding acceptable thresholds, the inspection scope expands to include additional areas until quality is confirmed. This graduated inspection approach balances thoroughness against practical time and cost constraints while providing high confidence in overall installation quality. Documentation of completed installations creates valuable records for building owners and future maintenance personnel. As-built drawings should show actual clamp locations, particularly noting any deviations from original plans. Photographic documentation provides visual confirmation of proper installation techniques and can help diagnose any future issues that might develop. Installation completion certificates signed by the installing contractor and accepted by the owner or their representative formalize the transition from construction to building operation. These documents become part of the permanent building record and should be maintained throughout the roof's service life.

Conclusion

Wind-rated Metal Standing Seam Clamps represent an engineered solution for preventing wind damage and ensuring building code compliance through tested performance that can increase uplift resistance by up to three hundred percent when properly specified and installed according to manufacturer guidelines.

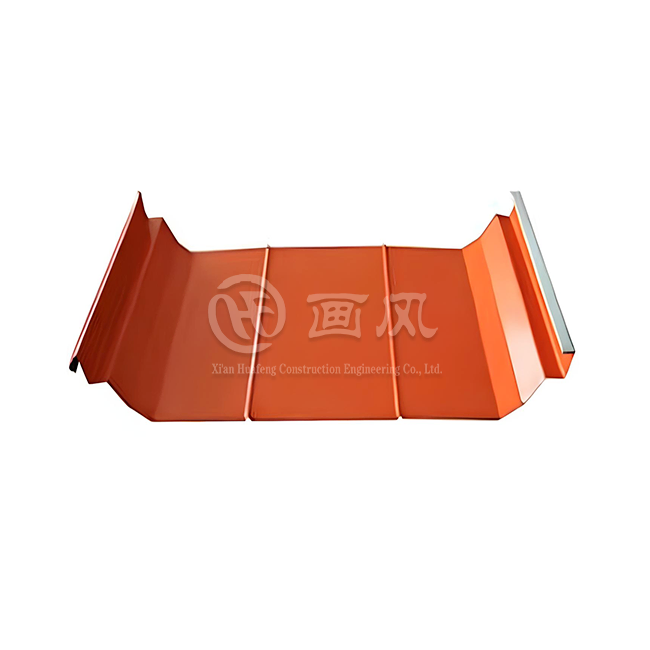

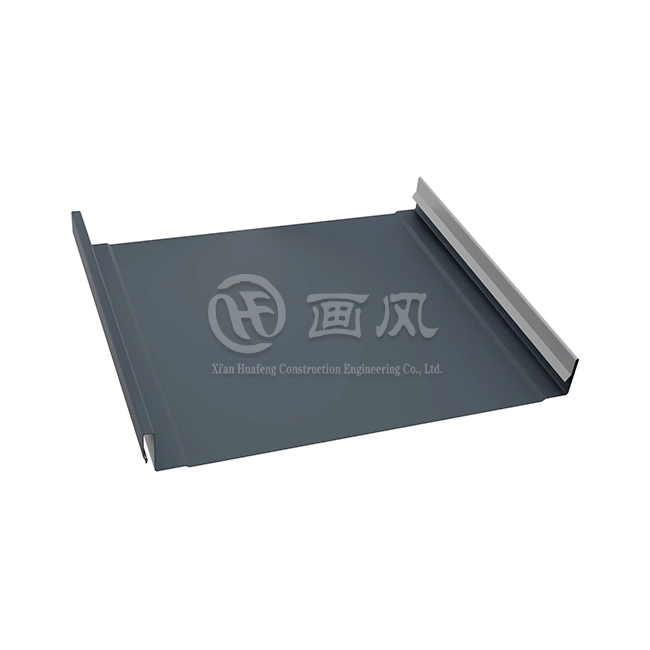

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

As a China Metal Standing Seam Clamps manufacturer and China Metal Standing Seam Clamps supplier, Xi'an Huafeng Construction Engineering Co., Ltd. offers High Quality Metal Standing Seam Clamps at competitive Metal Standing Seam Clamps price points with Metal Standing Seam Clamps for sale through our China Metal Standing Seam Clamps wholesale and China Metal Standing Seam Clamps factory direct channels. Established in Shaanxi Province in 2018, we specialize in comprehensive metal roofing solutions from design through installation, recognized as a high-tech enterprise with first-level building curtain wall qualifications and third-level steel structure qualifications.

Our manufacturing capabilities span three factories with seven production lines and more than forty specialized machines producing aluminum alloy 6063-T5/T6 clamps with three-millimeter thickness, anodizing treatment exceeding forty micrometers, and fluorocarbon spray coating. We maintain rigorous quality control aligned with ISO9001 and ISO14000:14001 standards, backed by more than twenty registered patents and comprehensive CE, ISO, and SGS certifications. Our engineering team provides customized solutions including structural modeling, load analysis, and drainage system simulation, delivering one-stop service from raw material selection through on-site installation guidance.

With successful project implementations at landmark facilities including Xiongan Station, Xi'an International Convention Center, and Inner Mongolia Tongliao Art Museum, we demonstrate proven expertise in large-scale metal roofing systems. Our supply capacity reaches ten thousand tons monthly with fifteen to twenty day delivery schedules and minimum order quantities of five hundred square meters. We offer thirty-year warranties covering our aluminum roof clamps for metal roofing, supporting your project with dedicated technical assistance throughout design, procurement, and installation phases. Contact our team at huafeng@hfmetalroof.com to discuss your wind-rated clamp requirements and receive customized solutions engineered for your specific standing seam profile and wind load conditions.

References

1. American Society of Civil Engineers. "Minimum Design Loads and Associated Criteria for Buildings and Other Structures (ASCE 7-16)." American Society of Civil Engineers, 2016.

2. ASTM International. "Standard Test Method for Structural Performance of Sheet Metal Roof and Siding Systems by Uniform Static Air Pressure Difference (ASTM E1592)." ASTM International, 2005.

3. Factory Mutual Research Corporation. "Approval Standard for Class 1 Panel Roofs (FM 4471)." FM Global, 2020.

4. Underwriters Laboratories. "Standard for Tests for Uplift Resistance of Roof Assemblies (UL 580)." Underwriters Laboratories Inc., 2006.

5. Metal Construction Association. "Technical Bulletin: Wind Design for Metal Building Systems." Metal Construction Association, 2019.