Are you struggling to choose the right building material that balances durability, cost-effectiveness, and performance for your specific project needs? Whether you're constructing a livestock shelter that must withstand harsh weather conditions or developing a modern commercial facility requiring aesthetic appeal alongside functionality, corrugated side panels offer versatile solutions. Understanding the distinct requirements between agricultural and commercial applications is crucial to making informed decisions that ensure long-term structural integrity, operational efficiency, and return on investment. This comprehensive guide explores how corrugated side panels serve different purposes across agricultural and commercial sectors, helping you select the optimal solution for your unique building requirements.

Understanding Corrugated Side Panels and Their Core Applications

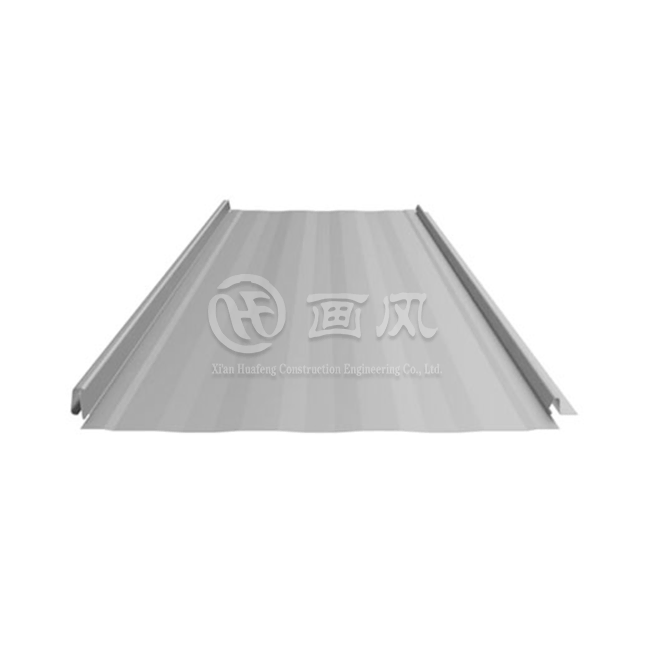

Corrugated side panels represent one of the most enduring and versatile building materials in modern construction, characterized by their distinctive wavy or ribbed profile that provides exceptional structural strength while maintaining lightweight properties. These panels are manufactured from various materials including galvanized steel, aluminum, and specialized coatings, with the corrugated design significantly enhancing load-bearing capacity compared to flat sheets of equivalent thickness. The corrugation pattern creates a structural geometry that distributes stress evenly across the panel surface, making corrugated side panels ideal for both vertical wall applications and roof installations where wind resistance and weather protection are paramount considerations. The manufacturing process for high-quality corrugated side panels involves precision roll-forming techniques that shape flat metal coils into consistent corrugated profiles. Xi'an Huafeng Construction Engineering Co., Ltd. utilizes advanced production equipment including seven color coating production lines and more than forty specialized machines to produce corrugated side panels with exceptional dimensional accuracy. Standard panel widths range from 600mm to 1200mm with customization options available to accommodate specific project requirements, while thickness variations from 0.3mm to 1.2mm allow designers to optimize the balance between structural performance and material economy. Premium finishes such as HDP and PVDF coatings provide superior weather resistance and color retention, extending the functional lifespan of corrugated side panels to thirty years or more under normal environmental conditions.

Material Selection and Performance Characteristics

The choice of base material for corrugated side panels fundamentally influences their suitability for agricultural versus commercial applications. Galvanized steel panels offer excellent strength-to-weight ratios and corrosion resistance through zinc coating protection, making them particularly appropriate for agricultural buildings where exposure to moisture, chemical fertilizers, and animal waste creates aggressive environmental conditions. Aluminum corrugated side panels provide superior corrosion resistance in coastal or highly humid environments while offering reduced weight that simplifies installation and reduces structural support requirements. The corrugation depth, typically ranging from 10mm to 50mm with common specifications between 15mm and 25mm, directly affects panel stiffness and spanning capability, with deeper corrugations enabling longer unsupported spans that reduce the number of structural supports required. Surface treatments and protective coatings significantly extend the service life of corrugated side panels while enhancing their aesthetic qualities. Pre-painted panels with polyester or PVDF coatings offer extensive color options that satisfy commercial architectural requirements while providing UV resistance and preventing chalking or fading. For agricultural applications where initial cost considerations may outweigh aesthetic factors, galvanized or galvalume finishes without paint coatings deliver reliable performance at reduced material costs. Advanced coating systems incorporating multiple layers of primers, base coats, and topcoats create barrier protection against environmental degradation, with premium PVDF coatings demonstrating exceptional resistance to acid rain, salt spray, and industrial pollutants that can compromise panel integrity in challenging exposure conditions.

Agricultural Applications of Corrugated Side Panels

Agricultural buildings present unique challenges that make corrugated side panels an ideal construction material for barns, livestock shelters, grain storage facilities, and equipment sheds. The agricultural environment subjects building materials to harsh conditions including temperature extremes, high humidity levels, exposure to corrosive substances from animal waste and agricultural chemicals, and potential mechanical impact from equipment and livestock. Corrugated side panels address these challenges through inherent material properties that combine durability, weather resistance, and ease of maintenance. The open-framed construction typical of agricultural buildings allows corrugated panels to span between widely-spaced supports, reducing structural costs while providing adequate ventilation that helps control interior humidity and prevents condensation accumulation that could damage stored crops or equipment. Cost-effectiveness represents a primary consideration in agricultural construction where building square footage requirements often exceed those of commercial facilities while budget constraints remain stringent. Corrugated side panels manufactured from galvanized steel or galvalume-coated materials offer optimal value by delivering thirty-year service life expectations at competitive material costs. The lightweight nature of these panels simplifies installation processes, allowing farm owners to complete construction projects using basic equipment and minimal specialized labor. Standard panel widths of 600mm to 1200mm accommodate typical agricultural building dimensions efficiently, minimizing material waste during installation. The exposed fastener installation method commonly employed with corrugated side panels further reduces labor costs compared to concealed fastener systems while providing reliable weather-tightness when properly installed with appropriate sealants and closure strips.

Specific Agricultural Building Requirements

Livestock housing facilities require building materials that withstand aggressive chemical environments created by animal waste while providing adequate ventilation to maintain healthy interior air quality. Corrugated side panels excel in these applications through their inherent resistance to corrosion when protected by hot-dip galvanizing or aluminum-zinc alloy coatings. The corrugated profile facilitates installation of ventilation openings and louvers that can be precisely positioned to optimize air circulation patterns based on prevailing wind directions and seasonal climate variations. Panel lengths customizable up to twelve meters enable construction of continuous sidewalls without intermediate horizontal joints that could compromise weather-tightness or create maintenance challenges. The smooth panel surfaces resist accumulation of dust, cobwebs, and organic debris, allowing periodic cleaning with pressure washing equipment to maintain hygienic conditions essential for animal health. Grain storage structures and agricultural processing facilities demand building enclosures that protect valuable commodities from moisture infiltration while controlling interior temperature fluctuations. Corrugated side panels with appropriate thickness specifications (typically 0.5mm to 0.7mm for agricultural applications) provide structural integrity adequate to resist wind loading and snow accumulation while maintaining cost-effectiveness for large building envelopes. The thermal expansion characteristics of metal panels must be accommodated through proper installation techniques including appropriate fastener spacing and allowance for panel movement at connections. Insulation systems can be readily integrated with corrugated panels using blanket insulation products installed between the metal cladding and interior vapor barriers, creating energy-efficient building enclosures that minimize heating and cooling costs in climate-controlled agricultural facilities.

Commercial Building Applications and Design Considerations

Commercial construction projects utilizing corrugated side panels range from industrial warehouses and manufacturing facilities to retail developments and architectural statement pieces where the distinctive corrugated aesthetic contributes to contemporary design themes. Unlike agricultural applications where functional performance and economy predominate, commercial projects frequently prioritize architectural appearance, brand identity expression, and compliance with building codes that may impose stricter requirements for fire resistance, structural performance, and energy efficiency. Corrugated side panels serve commercial applications effectively when specified with appropriate material grades, protective coatings, and installation details that satisfy both performance requirements and aesthetic objectives. The availability of extensive color selections through powder coating and coil coating processes enables architects to integrate corrugated metal cladding into sophisticated facade compositions that complement other building materials including glass, concrete, and composite panels. Building code compliance represents a critical consideration in commercial construction, with corrugated side panels required to meet specific performance criteria for fire resistance, wind load capacity, and thermal performance. Non-combustible corrugated panels manufactured from steel or aluminum can achieve Class A fire ratings when properly detailed with non-combustible insulation and substrate materials, making them suitable for commercial occupancies with stringent fire safety requirements. Structural engineering calculations must verify that specified panel thickness, corrugation depth, and fastener spacing provide adequate strength to resist design wind pressures based on building height, geographic location, and exposure category. Third-party testing and certification through recognized standards including ASTM, DIN, and international building codes provides documented evidence of product performance that facilitates plan approval and inspection acceptance during commercial construction projects.

Aesthetic Integration and Architectural Detailing

The architectural expression achievable with corrugated side panels has evolved significantly from purely utilitarian applications to encompass sophisticated design treatments that celebrate the material's inherent qualities. Horizontal panel orientation creates distinctive shadow lines and visual rhythm across building facades, while vertical installation emphasizes building height and creates dramatic proportions. Mixed orientations combining horizontal and vertical panel sections enable architects to articulate building masses and create visual interest through texture variation. Color selection profoundly influences the architectural character, with natural metallic finishes including galvanized, galvalume, and weathering steel providing industrial aesthetics, while painted finishes in custom colors enable precise coordination with corporate branding requirements or contextual design themes responding to surrounding built environments. Detailing quality at panel terminations, corners, and transitions between materials significantly affects the perceived quality of commercial installations utilizing corrugated side panels. Precision-fabricated trim components including corner channels, base trims, and top caps create clean terminations that conceal panel edges and fasteners, elevating the installation from utilitarian to refined architectural expression. Integration with other facade materials requires careful coordination to establish appropriate reveal dimensions, flashing details, and thermal movement accommodation. Window and door openings necessitate robust framing systems and weather-resistant sealant applications to maintain building envelope integrity. Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive design services including 3D modeling and detailed shop drawings that ensure accurate fabrication and seamless installation of corrugated side panels in complex commercial applications.

Performance Comparison: Agricultural vs Commercial Specifications

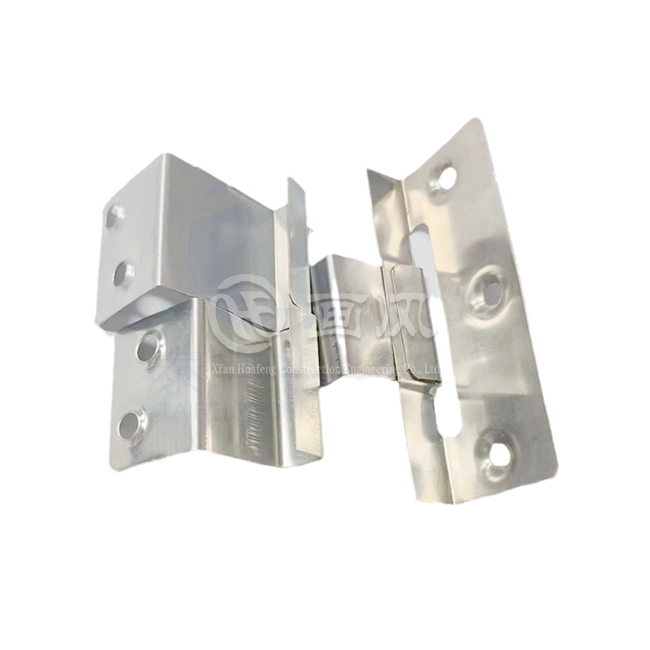

Direct comparison between agricultural and commercial applications of corrugated side panels reveals distinct differences in material specifications, installation methodologies, and performance expectations that reflect the divergent priorities of these building sectors. Agricultural projects typically specify corrugated panels in the 0.3mm to 0.7mm thickness range utilizing galvanized or galvalume base materials without paint finishes, prioritizing corrosion resistance and structural adequacy while minimizing material costs. Commercial applications frequently require heavier gauge panels ranging from 0.5mm to 1.2mm thickness with premium paint systems including polyester or PVDF coatings that provide extended color retention and resistance to environmental weathering. The cost differential between agricultural and commercial grade corrugated side panels can range from thirty to sixty percent, reflecting differences in base material thickness, coating sophistication, and color availability. Installation practices also diverge between agricultural and commercial applications, with agricultural projects commonly utilizing exposed fastener systems where self-drilling screws penetrate directly through panel high points into structural supports. This installation method offers simplicity and economy while providing reliable weather performance when executed with appropriate sealant washers and proper fastener torque control. Commercial installations increasingly employ standing seam concealed fastener systems or architectural clip attachments that eliminate visible fasteners from the finished facade, creating refined appearances consistent with contemporary commercial architectural standards. These sophisticated attachment systems require more precise panel fabrication, specialized installation training, and higher material costs, but deliver superior thermal movement accommodation and eliminate potential fastener weathering concerns that could compromise long-term appearance quality.

Long-Term Performance and Maintenance Requirements

Service life expectations for corrugated side panels vary significantly based on material specifications, environmental exposure conditions, and maintenance practices. Agricultural installations utilizing galvanized steel panels in moderate climate conditions can reasonably expect twenty-five to thirty-year service lives before requiring replacement, with periodic maintenance limited to fastener inspections and spot repairs of damaged coating areas. Commercial installations with premium PVDF coatings and heavier gauge substrates often carry manufacturer warranties extending to forty years, with expected service lives potentially reaching fifty years or more when properly maintained. The superior corrosion resistance of aluminum corrugated panels makes them particularly suitable for coastal commercial applications where salt spray exposure would rapidly degrade steel panels even with protective coatings. Maintenance protocols differ substantially between agricultural and commercial applications, reflecting different tolerance levels for aesthetic degradation and functional performance. Agricultural buildings typically receive minimal cosmetic maintenance with interventions limited to addressing structural deficiencies, significant corrosion penetration, or panel damage affecting weather-tightness. Commercial properties maintain rigorous maintenance schedules including periodic facade cleaning, coating inspections, and proactive repairs to preserve architectural appearance and protect property values. Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive maintenance guidance and can arrange periodic inspection services to identify potential issues before they compromise panel performance. The company's thirty-year warranty on corrugated side panels demonstrates confidence in product durability while providing owners with financial protection against premature material failures.

Selecting the Right Corrugated Side Panels for Your Project

The decision-making process for selecting appropriate corrugated side panels should systematically evaluate project-specific requirements including functional performance needs, budget constraints, aesthetic objectives, and long-term ownership costs. Agricultural projects prioritize fundamental performance characteristics including corrosion resistance, structural adequacy, and installation economy, making galvanized steel panels with 0.5mm to 0.7mm thickness and exposed fastener installation the typical specification. Commercial projects must balance performance requirements with architectural design intent, potentially justifying premium materials including aluminum substrates, PVDF coatings, and concealed fastener systems that deliver superior appearance quality and extended service life. The total cost analysis should consider not only initial material and installation expenses but also long-term maintenance costs, energy performance implications of different insulation strategies, and potential impacts on building resale values. Technical specifications for corrugated side panels must address numerous parameters including base material composition, coating system details, panel profile dimensions, fastener type and spacing, and installation sequencing requirements. Working with experienced manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd. provides access to technical expertise that ensures specifications align with project requirements and comply with applicable building codes. The company's design services including structural analysis, thermal performance modeling, and drainage system calculations help optimize panel selection decisions. Material procurement from established suppliers utilizing certified materials conforming to ASTM, DIN, JIS, BS, and GB/T standards ensures consistent quality and reliable performance. Third-party testing documentation and material certifications provide verification that supplied products meet specified requirements, protecting project stakeholders from substandard material substitutions that could compromise building performance.

Customization Options and Value Engineering

Xi'an Huafeng Construction Engineering Co., Ltd. offers extensive customization capabilities that enable corrugated side panels to be precisely tailored to project-specific requirements. Panel width customization accommodates unique architectural modules or structural bay dimensions that differ from standard product offerings, minimizing field cutting and associated labor costs. Thickness selection can be optimized based on engineering calculations that consider design wind pressures, panel spanning conditions, and deflection limits, potentially identifying opportunities to reduce material costs without compromising structural performance. Color customization through the company's extensive powder coating capabilities enables perfect coordination with architectural color schemes or corporate branding requirements, with color matching services available to replicate specific color standards. Pattern customization including perforation patterns for acoustic absorption or decorative effects expands the architectural possibilities for corrugated panels beyond simple functional cladding applications. Value engineering reviews conducted during project development phases can identify opportunities to optimize corrugated panel specifications without compromising essential performance requirements. Standardizing panel lengths to maximize material yield from standard coil sizes reduces waste and associated costs. Simplifying color schemes to minimize coating changeovers during production reduces manufacturing costs that translate to lower material pricing. Coordinating structural framing designs to accommodate standard panel widths eliminates custom width requirements that increase fabrication costs. Xi'an Huafeng Construction Engineering Co., Ltd.'s technical team collaborates with project designers to explore these value engineering opportunities, leveraging their extensive manufacturing experience and supply capacity of 1000 tons per month to deliver cost-effective solutions without sacrificing quality or performance standards.

Conclusion

Corrugated side panels serve both agricultural and commercial construction effectively through versatile performance characteristics, though specification differences reflect distinct priorities. Agricultural applications emphasize economy and durability while commercial projects balance performance with aesthetic sophistication. Careful material selection, proper installation, and appropriate maintenance ensure corrugated panels deliver reliable long-term service across diverse building applications, making them enduring construction solutions.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a leading China Corrugated Side Panels manufacturer, China Corrugated Side Panels supplier, and China Corrugated Side Panels factory, offering High Quality Corrugated Side Panels with competitive Corrugated Side Panels price structures for China Corrugated Side Panels wholesale and Corrugated Side Panels for sale globally. Established in 2018 and recognized as a Shaanxi Province high-tech enterprise in 2020, the company operates three manufacturing facilities with seven production lines and over forty specialized machines producing metal roofing systems, building curtain wall systems, and steel structure enclosure systems. Their 200,000-square-meter raw material plant in Anhui and processing facilities in Hangzhou and Xi'an support 1000-ton monthly production capacity with fifteen to twenty-day delivery timeframes.

The company provides one-stop solutions from initial design through final installation, including structural 3D modeling, load analysis, drainage system simulation, precision manufacturing with real-time quality control, and comprehensive on-site project management. With more than twenty registered patents, ISO9001, ISO14000:14001, and SGS certifications, plus successful project completions at major facilities including Xiongan Station, Xi'an International Convention and Exhibition Center, and Inner Mongolia Tongliao Art Museum, Xi'an Huafeng demonstrates proven expertise across industrial, commercial, and public building applications. Their commitment to green sustainable development and integration of architecture, technology, and aesthetics positions them as ideal partners for demanding corrugated panel projects. Contact their team at huafeng@hfmetalroof.com to discuss your specific requirements and receive customized solutions backed by their thirty-year warranty and comprehensive technical support.

References

1. Agricultural Building Systems and Their Applications in Modern Farm Construction - Smith, Robert J. and Henderson, Michael K. - American Society of Agricultural and Biological Engineers Technical Review

2. Metal Panel Systems for Commercial Building Envelopes: Performance and Specification Guidelines - Thompson, David L. - National Roofing Contractors Association

3. Corrosion Resistance of Metallic Coatings in Agricultural Environments - Chen, Wei and Martinez, Carlos R. - International Journal of Corrosion Science and Engineering

4. Architectural Applications of Corrugated Metal Cladding in Contemporary Commercial Design - Wilson, Sarah M. - Journal of Architectural Engineering and Design

5. Structural Performance and Wind Load Resistance of Corrugated Metal Panels - Anderson, Erik P. and Kumar, Rajesh - Structural Engineering Institute Technical Standards