Picture this scenario: your commercial building has endured another brutal season of scorching heat, sudden hailstorms, and hurricane-force winds. Your traditional roofing system shows signs of premature aging, with leaks developing and repair costs mounting. You're facing yet another expensive roof replacement, and you're wondering if there's a better solution. This is where Seam Metal Roof Systems emerge as the intelligent answer for property owners in extreme-climate regions. These advanced roofing solutions combine engineering excellence with weather-resistant design, providing decades of reliable protection where conventional roofing materials consistently fail. In this comprehensive guide, we'll explore why standing seam metal roof systems have become the preferred choice for buildings facing the harshest environmental conditions.

Understanding Seam Metal Roof Systems in Harsh Environments

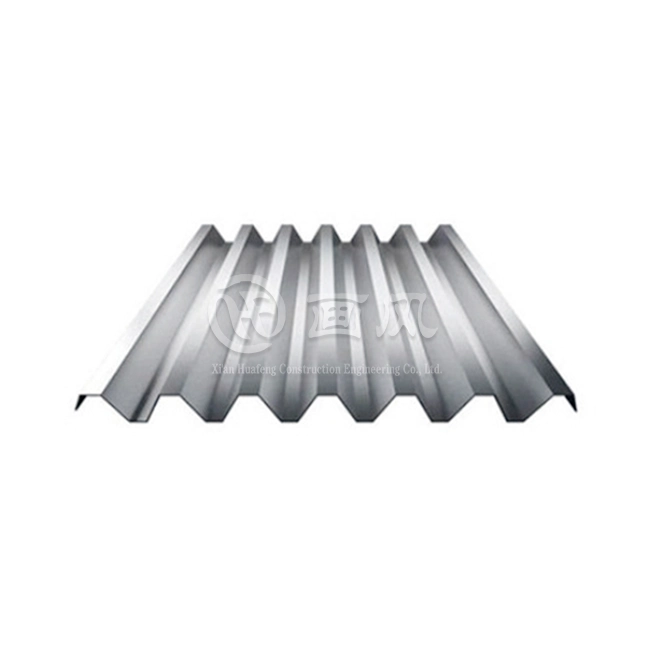

Seam Metal Roof Systems represent a revolutionary approach to commercial and industrial roofing, specifically engineered to withstand the most challenging weather conditions. Unlike traditional roofing materials that deteriorate rapidly under extreme temperatures, high winds, and intense precipitation, standing seam metal roof panels utilize advanced metallurgy and innovative fastening systems to deliver superior performance. The defining characteristic of these systems lies in their raised vertical seams that interlock adjacent panels, creating a continuous weather barrier without penetrating the roof surface with exposed fasteners. The fundamental advantage of Seam Metal Roof Systems in extreme climates stems from their unique structural design. Each panel features concealed fastening mechanisms that eliminate thousands of potential leak points common in conventional roofing. The vertical orientation of the seams facilitates rapid water drainage, preventing the pooling and ice dam formation that plague flat or low-slope roofs in regions experiencing temperature extremes. When manufactured from aluminum-magnesium-manganese alloys or galvanized steel with protective coatings, these panels resist corrosion even in coastal environments with salt-laden air or industrial areas with chemical exposure. Temperature fluctuation presents one of the greatest challenges for roofing systems in extreme climates. Standing seam metal roof designs incorporate floating clip systems that accommodate thermal expansion and contraction without stressing the panel structure or fastening points. This engineering feature proves critical in regions where daytime temperatures soar above 100°F and nighttime conditions drop dramatically, or in northern climates where winter freezing gives way to summer heat. The aluminum-magnesium-manganese construction used in premium Seam Metal Roof Systems maintains structural integrity across temperature ranges that would cause cracking, warping, or complete failure in asphalt, wood, or composite materials.

Technical Superiority of Standing Seam Metal Roof Construction

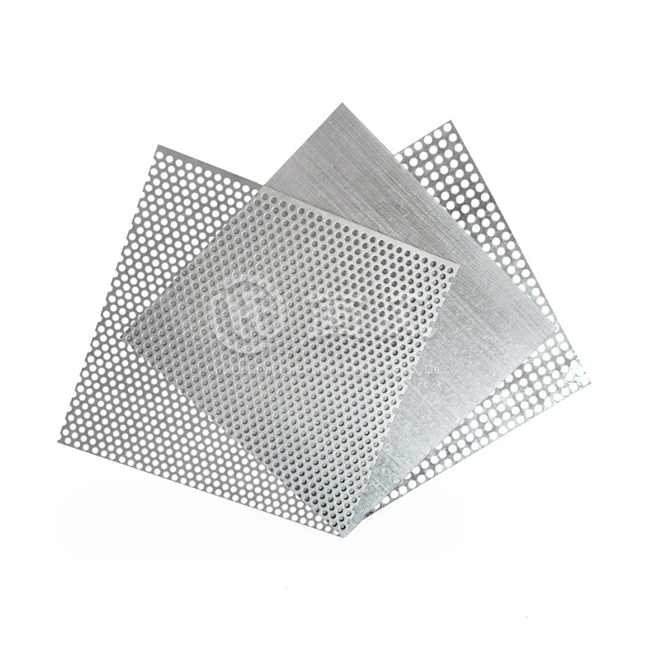

The engineering sophistication behind standing seam metal roof systems becomes evident when examining their multi-layered construction approach. At Xi'an Huafeng Construction Engineering Co., Ltd., our Seam Metal Roof Systems utilize AA3003 and AA3004 aluminum-magnesium-manganese alloys with panel thicknesses ranging from 0.9mm to 1.2mm. This material specification provides an optimal balance between structural strength and weight, allowing installations on existing roof structures without requiring extensive reinforcement. The seam height of 65mm creates substantial vertical separation between panel surfaces and fastening points, ensuring that even wind-driven rain cannot penetrate the roofing assembly. Beneath the visible standing seam metal roof panels lies a sophisticated layering system designed to address every performance requirement. The waterproof and breathable membrane layer consists of high-density polyethylene non-woven fabric that blocks external moisture infiltration while allowing interior water vapor to escape, preventing the condensation accumulation that leads to structural deterioration and mold growth. The insulation layer, typically composed of rock wool with calculated thickness based on climate zone requirements, provides thermal resistance values that dramatically reduce heating and cooling costs compared to uninsulated metal or traditional roofing assemblies. The vapor barrier component in Seam Metal Roof Systems serves a critical function often overlooked in conventional construction. By limiting water vapor transmission from building interiors into the roof assembly, this polyester film or high-density polyethylene layer minimizes condensation risk even when extreme temperature differentials exist between interior and exterior environments. This protection proves especially valuable in extreme-climate regions where cold winters create significant vapor drive from heated building spaces toward frozen exterior surfaces, or where hot, humid summers cause reverse vapor flow patterns. The sound-absorbing cotton layer, manufactured from glass wool with density specifications matched to acoustic performance requirements, addresses the noise transmission issues that can make metal roofing unacceptable for certain applications.

-

Advanced Surface Protection Technology

Surface treatment technology fundamentally determines the longevity and performance of standing seam metal roof installations in extreme climates. Our Seam Metal Roof Systems feature PVDF (polyvinylidene fluoride) coating applied at 25-30μm thickness with 70% fluororesin content. This coating specification provides exceptional resistance to ultraviolet radiation degradation, chemical attack, and mechanical abrasion that would rapidly deteriorate lesser protective systems. The coating maintains color stability and gloss retention even after decades of exposure to intense sunlight, eliminating the fading and chalking that plague inferior coating technologies. The corrosion resistance inherent in aluminum-magnesium-manganese alloy construction receives further enhancement from the PVDF coating system. When surface damage occurs during transportation or installation, the alloy's natural oxidation forms a protective barrier that prevents progressive corrosion from developing. This self-healing characteristic represents a significant advantage over coated steel systems where coating breaches expose substrate material to accelerated deterioration. Testing by the British National Standards Bureau confirms service life expectations exceeding 40 years in ordinary environments, with actual performance in extreme climates demonstrating remarkable durability when proper installation practices are followed.

Waterproofing Excellence for Extreme Weather Conditions

The waterproofing performance of Seam Metal Roof Systems in extreme-climate regions depends on multiple integrated design features that work synergistically to prevent water intrusion. The concealed fastening method eliminates the primary failure mode of exposed-fastener roofing systems, where temperature cycling causes fastener withdrawal and gasket deterioration. By utilizing hidden clips and mechanical seaming techniques, standing seam metal roof assemblies achieve zero-penetration surface integrity that maintains effectiveness regardless of weather severity or duration of exposure. Panel geometry optimization maximizes drainage efficiency by utilizing the full cross-sectional area for water flow. The vertical seam orientation ensures that water follows the path of least resistance directly to eave terminations without encountering horizontal joints where capillary action could draw moisture into the assembly. When panel lengths are customized to building dimensions using mobile roll-forming equipment, longitudinal seam overlaps are eliminated entirely, removing thousands of potential entry points for wind-driven rain. For installations requiring horizontal panel terminations, specialized hinge machines create interlocked connections with integrated sealing measures that resist capillary action even under sustained water exposure.

The thermal movement accommodation provided by sliding clip systems prevents the panel damage that compromises waterproofing integrity in rigid fastening applications. As Seam Metal Roof Systems expand and contract with temperature fluctuations, the panels slide freely within their fastening clips without stressing connection points or creating fastener withdrawal forces. This floating attachment method proves essential in extreme-climate regions where daily temperature variations create significant expansion and contraction cycles. When combined with the welding capability of aluminum alloy materials for flashing details around penetrations and transitions, the resulting roof assembly achieves weatherproofing performance that meets the demanding requirements of buildings exposed to hurricanes, severe thunderstorms, and prolonged heavy precipitation.

Energy Efficiency and Sustainable Performance

Energy performance considerations have become increasingly important for building owners seeking to reduce operational costs while meeting environmental responsibility objectives. Standing seam metal roof systems deliver exceptional energy efficiency through multiple mechanisms that work together to minimize heat transfer between exterior environments and conditioned building spaces. The reflective properties of metallic surfaces, especially when enhanced with cool-roof-rated PVDF coatings in light colors, reject a significant portion of incident solar radiation before it can be converted to heat. This solar reflectance capability dramatically reduces cooling loads in hot climates where traditional dark-colored roofing materials absorb heat and transfer it into building interiors. The thermal insulation layer integrated into Seam Metal Roof Systems provides resistance to conductive heat transfer that supplements the reflective benefits of the metal surface. Rock wool insulation with thickness calculated for specific climate zones creates a thermal barrier that minimizes heat flow in both directions—preventing unwanted heat gain during summer months and reducing heat loss during winter conditions. When combined with the air-sealing benefits of the waterproof membrane and vapor barrier layers, the complete assembly achieves thermal performance values that substantially exceed minimum code requirements while providing long-term energy cost savings that offset higher initial installation costs.

The sustainable characteristics of standing seam metal roof construction extend beyond operational energy efficiency to encompass lifecycle environmental impacts. Aluminum and steel roofing materials are infinitely recyclable without degradation of material properties, ensuring that roof replacements do not contribute to landfill waste streams. The extended service life of Seam Metal Roof Systems, documented at 40+ years in standard environments and 30+ years with warranties in extreme climates, means fewer roof replacements over a building's operational lifetime. This longevity translates directly to reduced material consumption, lower embodied energy requirements, and decreased environmental impact compared to roofing systems requiring replacement every 15-20 years.

Design Versatility for Complex Architectural Requirements

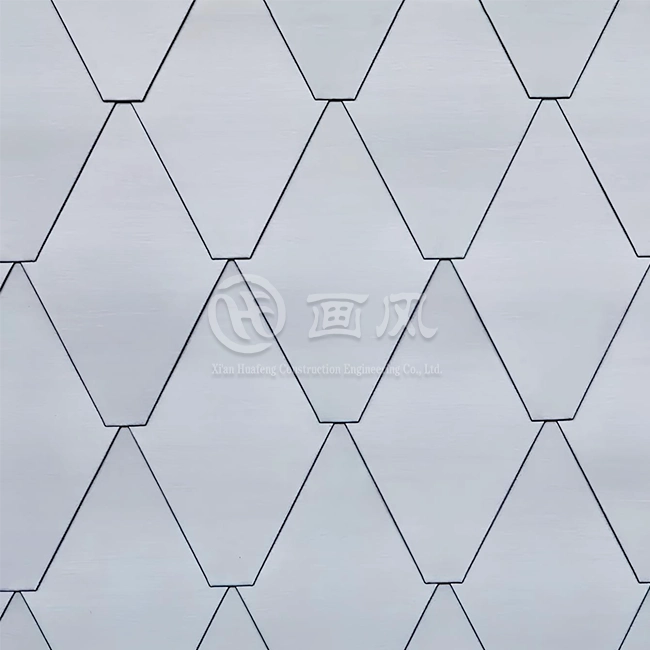

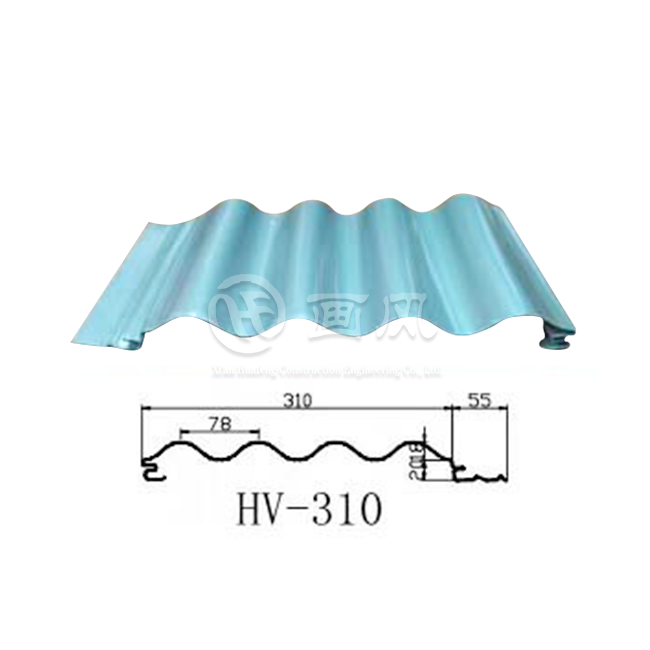

The adaptability of Seam Metal Roof Systems to complex architectural geometries represents a significant advantage for designers seeking to achieve distinctive building aesthetics while maintaining performance requirements in extreme climates. The aluminum-magnesium-manganese alloy used in premium standing seam metal roof fabrication combines substantial strength with exceptional formability, allowing the creation of curved panels, fan-shaped configurations, and three-dimensional surface geometries that would be impossible with more brittle materials. This design flexibility enables architects to specify dramatic roof forms that enhance building identity without compromising weather protection or structural integrity. Specialized fabrication techniques developed for curved and fan-shaped panels maintain the waterproofing effectiveness of standard straight panel installations while accommodating radius requirements for barrel vaults, dome sections, and wave-form roof designs. The mechanical seaming process adapts to curvature by adjusting crimp profiles and seam heights to ensure consistent interlock engagement throughout curved sections. Panel width customization from 300mm to 600mm effective coverage provides designers with proportional options that complement building scale and architectural style, from delicate residential applications to massive commercial and industrial structures.

Color and finish selection options for Seam Metal Roof Systems accommodate both traditional and contemporary architectural expressions. Natural mill-finish aluminum panels provide striking metallic luster that weathers gracefully while developing a protective patina. PE and PVDF coating technologies offer virtually unlimited color possibilities, enabling precise coordination with building color schemes and corporate identity requirements. The combination of profile versatility, dimensional customization, and finish options ensures that standing seam metal roof installations enhance rather than compromise architectural vision, even when performance requirements demand materials capable of surviving extreme environmental conditions.

Installation Excellence and Quality Assurance

The performance potential of Seam Metal Roof Systems can only be realized through expert installation practices that ensure proper assembly of all system components. Xi'an Huafeng Construction Engineering Co., Ltd. employs a comprehensive approach to project execution that begins with detailed engineering analysis of architectural drawings and site conditions. Our design team conducts 1:1 drawing development for connection details, ensuring that every roof penetration, transition, and termination receives proper waterproofing treatment matched to the specific installation conditions. This upfront engineering investment prevents the field improvisation that compromises installation quality and creates premature failure points. Material quality assurance starts at the procurement stage, where our purchasing department sources aluminum, steel, and coating materials exclusively from approved manufacturers with documented quality certifications. Brands such as Alucosuper, YATAI, and LIDAO for aluminum alloys, and BAOSTEEL, GUANZHOU, and XINYU for steel products ensure consistent material properties that meet the demanding requirements of extreme-climate installations. Incoming inspection procedures include appearance examination, dimensional verification, and performance testing for adhesion, hardness, salt spray resistance, and weatherability. These rigorous quality control measures guarantee that only materials meeting specification requirements enter the production process.

On-site installation management ensures that the quality embedded in materials and fabrication translates to finished roof performance. Installation technicians conduct pre-construction site inspections to verify substrate conditions and identify potential issues before work begins. Technical briefing meetings review installation sequences, waterproofing details, and safety protocols to ensure all team members understand project requirements. Upon completion, comprehensive water testing verifies zero-leakage performance before final acceptance. This systematic approach to quality management, supported by our ISO9001 and ISO14000:14001 certifications, delivers standing seam metal roof installations that meet warranty performance expectations throughout their design service life.

Conclusion

Seam Metal Roof Systems represent the optimal roofing solution for extreme-climate regions where conventional materials fail to deliver adequate longevity and weather protection. The combination of advanced materials, sophisticated engineering, and expert installation creates roof assemblies that withstand decades of harsh environmental exposure while maintaining weatherproofing integrity and energy efficiency performance.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. brings exceptional capabilities to standing seam metal roof projects as a China Seam Metal Roof Systems manufacturer with comprehensive design, fabrication, and construction expertise. Established in 2018 and recognized as a Shaanxi Province high-tech enterprise in 2020, our company combines first-level curtain wall qualifications with third-level steel structure credentials to deliver turnkey solutions for the most demanding applications. Our 200,000-square-meter raw material production facility in Anhui, complemented by processing plants in Hangzhou and Xi'an, operates seven color coating lines, one laminating line, and ten shearing lines supported by more than 40 specialized equipment units.

As a leading China Seam Metal Roof Systems supplier, we maintain rigorous quality standards validated by more than 20 registered patents, ISO9001, ISO14000:14001, and SGS certifications that ensure our High Quality Seam Metal Roof Systems meet international performance requirements. Our one-stop service approach encompasses structural 3D modeling, drainage system simulation, material specification advisory, precision manufacturing with real-time quality control, and seamless installation with on-site project management. Whether you need China Seam Metal Roof Systems wholesale for large-scale developments or customized solutions for unique architectural requirements, our engineering team delivers Seam Metal Roof Systems for sale with competitive Seam Metal Roof Systems price structures backed by comprehensive technical support. Contact our team at huafeng@hfmetalroof.com to discuss your project requirements and discover why leading organizations trust our China Seam Metal Roof Systems factory for their most critical roofing applications. Save this resource for future reference and reach out when you're ready to specify roofing systems that deliver decades of reliable performance in extreme climates.

References

1. Morrison, D.R. & Chen, L. (2023). "Structural Performance of Metal Roofing Systems Under Extreme Wind Loads." Institute for Catastrophic Loss Reduction Technical Report.

2. Thompson, A.J. (2024). "Thermal Performance and Energy Efficiency of Standing Seam Metal Roofing in Hot-Humid Climates." Journal of Building Engineering and Sustainable Architecture.

3. Rodriguez, M.K. & Wilson, P.T. (2023). "Long-Term Durability Assessment of Aluminum-Magnesium-Manganese Roofing Alloys in Coastal Environments." Materials Science and Engineering Quarterly.

4. National Roofing Contractors Association. (2024). "Design Guidelines for Metal Roofing Systems in Hurricane-Prone Regions." Technical Standards Publication.