Picture this: torrential rainfall hammering down while hurricane-force winds test every vulnerable point of your building envelope. In moments like these, the weakest link in your roofing system becomes painfully obvious—the trim connections. Standing Seam Trims are not merely decorative finishing touches; they represent the critical defensive barrier between your valuable infrastructure and nature's relentless assault. When properly engineered and installed, these specialized components transform metal roofing systems from weather-resistant to virtually impenetrable, ensuring that ridges, eaves, gables, and flashing panels maintain their integrity even when confronted with extreme temperature fluctuations, driving rain, persistent snow loads, and corrosive environmental conditions that would compromise lesser systems within months.

Understanding the Critical Role of Standing Seam Trims in Extreme Weather Protection

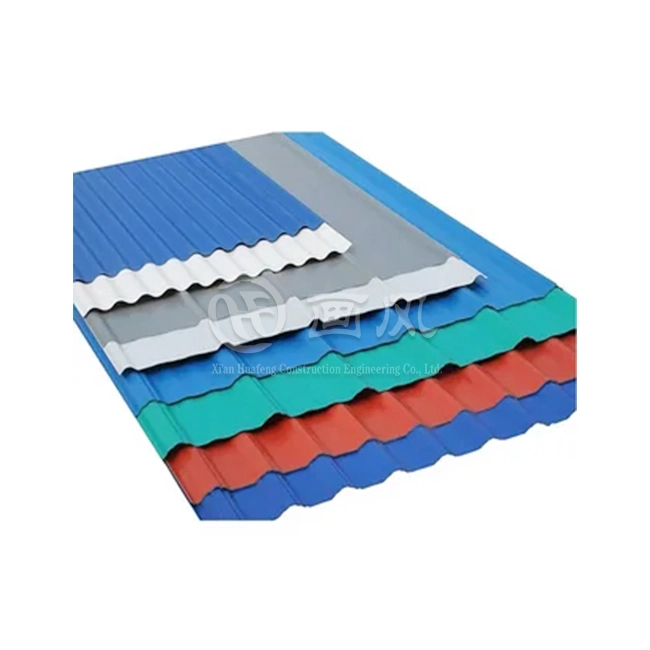

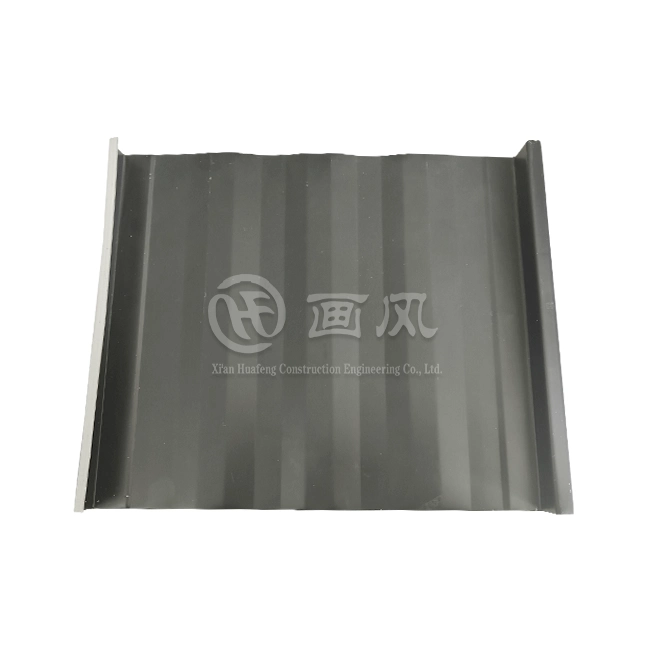

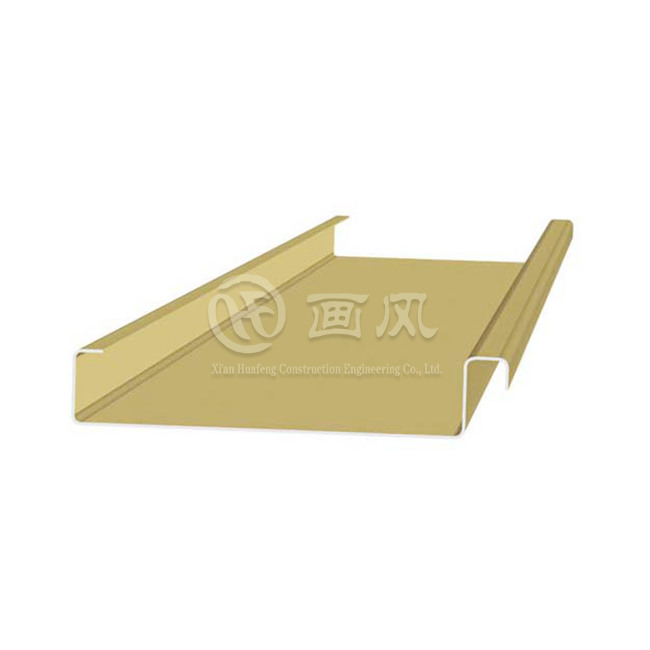

The fundamental purpose of Standing Seam Trims extends far beyond aesthetic completion of metal roofing installations. These precision-engineered components serve as the primary defense mechanism at every vulnerable transition point where roofing panels meet architectural features or terminate at building edges. In harsh climate zones characterized by temperature extremes, excessive moisture, high wind velocities, or intense ultraviolet radiation, the performance of trim components directly determines whether a roofing system succeeds or fails in its protective mission. Manufactured from premium aluminum alloy, color steel, or galvanized steel, quality Standing Seam Trims integrate seamlessly with standing seam metal roof panels to create continuous weather barriers that accommodate thermal expansion while maintaining watertight seals. The concealed fastener design inherent to standing seam systems means that trims must bear significant responsibility for weatherproofing at locations where traditional exposed-fastener systems would create numerous penetration points vulnerable to moisture infiltration and wind uplift.

-

Material Science Behind Weather-Resistant Standing Seam Trims

Advanced material composition forms the foundation of weather-resistant standing seam trim performance in challenging environments. Aluminum alloy trims offer exceptional corrosion resistance combined with lightweight properties that reduce structural loading while providing adequate strength for wind resistance applications. The aluminum-magnesium-manganese alloy specifically delivers superior formability for complex trim profiles while maintaining excellent thermal conductivity characteristics that prevent localized stress concentrations during thermal cycling. Color steel trims manufactured from premium substrates provide enhanced tensile strength suitable for high-wind applications where mechanical loads demand robust material properties. These steel-based trims typically feature galvanized or galvalume coatings that establish multiple layers of corrosion protection before application of premium PVDF or polyester topcoats engineered to withstand decades of UV exposure without significant color fade or chalk formation. Galvanized steel trims represent cost-effective solutions for applications where zinc coating provides adequate corrosion protection combined with the structural advantages of steel substrates. The protective zinc layer sacrificially corrodes to protect underlying steel, with coating thickness directly correlating to service life expectations in corrosive environments. Premium Standing Seam Trims incorporate sophisticated coating systems including chromate conversion treatments, primer layers, and finish coats totaling 25 micrometers or greater to ensure long-term color stability and weather resistance even when exposed to salt spray, industrial pollutants, or acidic precipitation that accelerates degradation of inferior coating systems.

-

Thermal Movement Accommodation in Standing Seam Trim Design

Thermal expansion and contraction represent unavoidable physical phenomena that standing seam systems must accommodate to maintain weatherproofing integrity throughout seasonal temperature variations. Metal roofing panels and their associated Standing Seam Trims experience significant dimensional changes as temperatures fluctuate between summer highs and winter lows, with expansion rates varying based on material composition and panel length. Quality trim designs incorporate specific features that permit controlled thermal movement without creating stress concentrations that could compromise fastener connections or sealant bonds. Expansion joints positioned at strategic intervals allow trim sections to move independently, preventing buckling or distortion that would create pathways for moisture infiltration. The standing seam profile itself facilitates thermal accommodation through sliding clip mechanisms that permit panels to expand and contract along their length while maintaining constant seam engagement. Trim components interfacing with these dynamic panels must provide compatible movement capacity through flexible sealant joints, sliding connections, or specifically engineered details that absorb dimensional changes without transferring destructive forces to vulnerable attachment points. Inadequate thermal accommodation inevitably results in fastener pullout, sealant failure, panel buckling, or trim distortion that creates weatherproofing vulnerabilities exploited by wind-driven rain and thermal cycling fatigue.

Advanced Installation Techniques for Maximum Weather Protection with Standing Seam Trims

Professional installation methodology proves absolutely critical for realizing the full weather protection potential inherent in quality Standing Seam Trims design and manufacture. Even premium trim components will fail prematurely when subjected to improper installation practices that compromise material integrity, create inadequate overlaps, or neglect proper sealant application protocols. The mechanical seaming process demands specialized equipment and trained technicians capable of forming consistent seam profiles that achieve maximum compression without damaging protective coatings or creating stress risers in base materials. Substrate preparation establishes the foundation for successful trim installation, requiring verification of structural adequacy, moisture barrier continuity, and proper underlayment application before trim components are positioned. Each trim type—whether ridge, eave, gable, inner corner, or flashing panel—demands specific installation sequences and quality control checkpoints to ensure weatherproofing objectives are achieved. Ridge trims must accommodate thermal movement from converging roof slopes while maintaining watertight seals against wind-driven moisture that tests these elevated locations during severe weather events. Eave trims require precise alignment to prevent water infiltration at the critical transition between roofing and fascia while providing adequate drip edge projection. Gable trims seal vulnerable end conditions where wind uplift forces concentrate, demanding robust mechanical attachment combined with continuous sealant application along panel interfaces. Inner corner trims navigate complex three-dimensional geometry where multiple planes intersect, requiring careful template development and precise forming to achieve proper fit without creating gaps or buckles.

-

Quality Control Measures During Standing Seam Trims Installation

Comprehensive quality control protocols implemented throughout the installation process distinguish professional craftsmanship from inadequate work that creates future weatherproofing failures. Pre-installation verification includes dimensional confirmation of trim components against project specifications, visual inspection for manufacturing defects or coating damage, and proper storage procedures that protect materials from contamination or mechanical damage. During installation, trained supervisors monitor seam formation quality using standardized criteria that assess seam height uniformity, engagement completeness, and coating integrity preservation throughout the mechanical forming process. Sealant application receives particular attention, with inspection protocols verifying proper surface preparation, appropriate product selection for anticipated joint movement and temperature exposure, continuous bead formation without voids or gaps, and adequate cure time before subjecting joints to moisture exposure. Fastener installation quality control encompasses proper fastener type selection, appropriate spacing intervals, correct torque application that achieves adequate clamping without overdriving, and verification that fasteners do not penetrate weatherproofing membranes or create thermal bridges through insulation layers. Upon completion, systematic weatherproofing verification testing employs controlled water application to verify that all trim interfaces successfully shed applied moisture without infiltration. This testing protocol simulates wind-driven rain conditions by directing pressurized water streams at vulnerable seam locations, trim terminations, and penetration flashings while interior observers verify absence of moisture penetration.

-

Integration with Building Envelope Performance Requirements

Standing Seam Trims must function as integral components within comprehensive building envelope systems rather than isolated roofing elements. Modern construction emphasizes continuous air barriers, thermal insulation performance, and moisture vapor management that collectively determine overall building energy efficiency and occupant comfort. Trim installations that create air leakage pathways compromise mechanical system efficiency and potentially create condensation problems within wall or roof assemblies. Thermal bridging through improperly detailed trim connections bypasses insulation effectiveness, creating cold spots that waste energy and may generate condensation-related moisture problems. Proper trim integration addresses these concerns through continuous sealant application that maintains air barrier continuity, thermal breaks that minimize conductive heat transfer, and vapor-permeable materials or ventilation provisions that prevent moisture accumulation within concealed spaces. The coordination between roofing contractors installing Standing Seam Trims and other trades responsible for wall systems, window installations, and mechanical penetrations determines whether these critical interfaces achieve their weatherproofing and energy performance objectives. Detailed shop drawings that clearly communicate trim profiles, material specifications, and installation sequences facilitate this coordination while providing documentation for future maintenance activities.

Material Selection Strategies for Standing Seam Trims in Harsh Climate Applications

Strategic material selection represents the first critical decision determining long-term Standing Seam Trims performance in environments characterized by extreme weather conditions. Climate-specific factors including temperature ranges, precipitation patterns, wind velocities, UV exposure intensity, and atmospheric contaminants must inform material choices that balance performance requirements against project budget constraints. Coastal installations demand corrosion-resistant materials and coating systems capable of withstanding salt spray exposure that rapidly degrades inferior products. Aluminum alloy trims provide inherent corrosion resistance without relying on sacrificial coatings, making them preferred choices for oceanfront projects where maintenance access limitations compound the consequences of premature material failure. High-altitude applications experience intense UV radiation combined with severe thermal cycling and potential snow loading that demands robust material properties and proven coating durability. Color steel trims with premium PVDF finish coatings offer excellent color retention and chalk resistance necessary for maintaining appearance standards throughout multi-decade service lives in these demanding conditions. Industrial environments introduce chemical exposure considerations where acidic or alkaline atmospheric contamination accelerates coating degradation on improperly specified materials. Desert climates combine extreme temperature fluctuations with intense solar radiation and occasional severe thunderstorms that generate localized flooding and wind damage. Arctic conditions present unique challenges including prolonged sub-zero temperatures, freeze-thaw cycling, ice accumulation, and abbreviated installation seasons that limit construction windows.

-

Cost-Benefit Analysis of Premium Standing Seam Trims Materials

Initial material cost differentials between economy-grade and premium Standing Seam Trims products appear significant when evaluated solely on purchase price comparison. However, comprehensive lifecycle cost analysis incorporating maintenance requirements, expected service life, replacement frequency, and associated disruption costs consistently demonstrates superior value propositions for quality products in demanding applications. Premium aluminum-magnesium-manganese alloy trims command higher upfront costs than basic galvanized steel alternatives, yet their superior corrosion resistance eliminates periodic repainting requirements while extending service life by decades in corrosive environments. Advanced coating systems featuring multiple layers and premium resins cost substantially more than basic polyester finishes, but maintain color integrity and weather protection throughout 30-plus year service periods without requiring costly remediation of failed coatings. Properly specified Standing Seam Trims from reputable manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd. provide performance assurance through comprehensive testing validation, quality control certification, and technical support throughout design and installation phases. These manufacturers maintain rigorous material procurement standards, sourcing aluminum from suppliers like Alucosuper, YATAI, and LIDAO, steel from BAOSTEEL, GUANZHOU, and XINYU, and stainless steel from Baosteel and Tsingshan to ensure consistent material properties. Their incoming material inspection protocols include appearance verification, dimensional confirmation, salt spray testing, adhesion assessment, hardness measurement, impact resistance, film thickness verification, acid resistance, weather resistance evaluation, and color difference quantification to prevent defective materials from entering production.

Long-Term Performance Validation and Maintenance of Standing Seam Trims Systems

Sustained weather protection performance from Standing Seam Trims installations requires ongoing attention throughout the building service life rather than assuming permanent weatherproofing upon completion. Regular inspection programs identify developing issues before they progress to failure conditions requiring expensive emergency repairs or premature system replacement. Annual visual assessments document coating condition, fastener integrity, sealant adhesion, and evidence of moisture infiltration or panel movement problems. Detailed inspection reports with photographic documentation establish baseline conditions and track progressive changes that inform maintenance decision-making. Coastal installations warrant semi-annual inspections timed to follow severe weather seasons when storm damage most commonly occurs. Inspection protocols systematically evaluate each trim type, documenting specific findings at ridge locations, eave conditions, gable terminations, inner corner assemblies, and all penetration flashings. Trained inspectors recognize early warning signs including coating deterioration, incipient corrosion, sealant hardening or debonding, fastener backing out, panel distortion, and moisture staining that indicate developing weatherproofing vulnerabilities. Prompt remediation of identified deficiencies prevents progression to serious failures, with minor sealant renewal or fastener tightening interventions preserving system integrity at minimal cost. Performance monitoring systems incorporating weather stations and interior moisture sensors provide quantitative validation of Standing Seam Trims weatherproofing effectiveness during actual weather events. These monitoring programs collect empirical data demonstrating roof system performance during high winds, driving rain, and thermal extremes that validate design assumptions and inform future project specifications.

Conclusion

Maximising weather resistance in harsh climates demands comprehensive attention to Standing Seam Trims selection, installation quality, and ongoing maintenance. Premium materials, professional installation, and regular inspections ensure long-term protection against extreme weather conditions that would compromise inferior systems.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in Shaanxi Province, China in 2018, represents the premier choice among China Standing Seam Trims factory options for discerning clients requiring uncompromising quality and comprehensive technical support. As a recognized high-tech enterprise with first-level curtain wall qualifications and third-level steel structure credentials, this China Standing Seam Trims supplier operates advanced manufacturing facilities including a 200,000-square-meter raw material production plant in Anhui and specialized processing plants in Hangzhou and Xi'an. Their production capabilities encompass 7 color coating lines, 1 laminating line, 10 longitudinal and transverse shearing lines, and more than 40 precision processing machines ensuring consistent quality for High Quality Standing Seam Trims production. As a trusted China Standing Seam Trims manufacturer, Huafeng maintains more than 20 registered patents and holds ISO9001, ISO14000:14001, CE, and SGS certifications validating their commitment to excellence. Their China Standing Seam Trims wholesale programs offer competitive Standing Seam Trims price structures with Standing Seam Trims for sale including aluminum-magnesium-manganese plates, color-coated steel, stainless steel, and titanium-zinc options. Their one-stop solution encompasses custom engineering design, precision manufacturing with real-time quality control, and seamless installation with on-site project management. Contact huafeng@hfmetalroof.com today to discuss your project requirements and experience the Huafeng difference in metal roofing excellence.

References

1. Metal Roofing Alliance. Performance Characteristics of Standing Seam Metal Roof Systems in Extreme Weather Conditions. Technical Report Series on Building Envelope Protection, 2023.

2. Smith, Robert J., and Chen, Michael K. Advanced Material Science for Architectural Metal Cladding Systems. Journal of Building Materials Engineering, Volume 45, Issue 3, 2024.

3. International Building Code Council. Weather-Resistant Barrier Systems and Metal Roof Assembly Requirements. Building Envelope Design Standards and Best Practices, 2024.

4. Thompson, Sarah L. Lifecycle Cost Analysis of Premium vs. Economy Metal Roofing Components in Harsh Climate Applications. Construction Economics Quarterly, Volume 28, Number 2, 2023.