Picture this: You've invested in a premium metal roofing system, expecting decades of worry-free protection, only to discover unexpected water stains spreading across your ceiling after the first major storm. Or perhaps you've noticed unsightly waves forming across your roof panels, compromising both aesthetics and performance. These scenarios represent just a fraction of the challenges that can emerge with metal roofing installations. Understanding these Metal Standing Seam Roofing Systems problems before they escalate isn't just about protecting your investment—it's about ensuring your building remains secure, efficient, and visually appealing for years to come. This comprehensive guide examines seven critical issues that commonly affect metal roofs and provides expert solutions to help you navigate these challenges with confidence.

Understanding Critical Metal Roofing Challenges and Prevention Strategies

-

Oil Canning: The Aesthetic and Structural Concern in Metal Standing Seam Roofing Systems

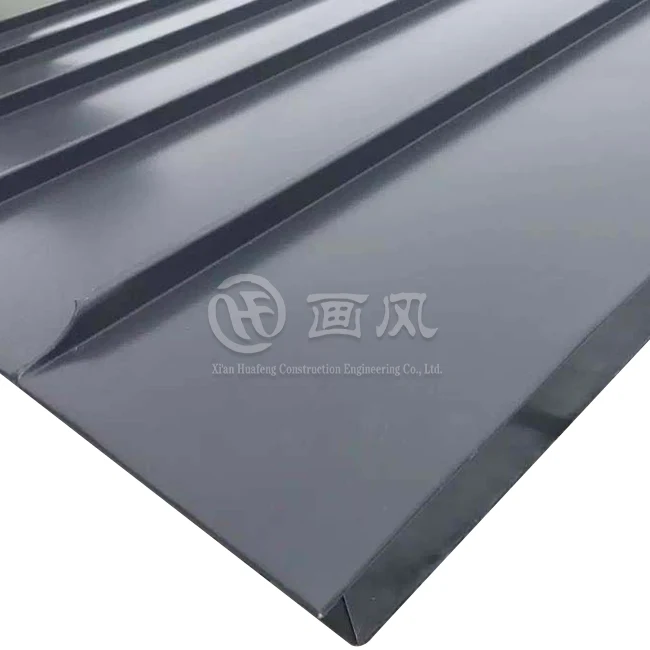

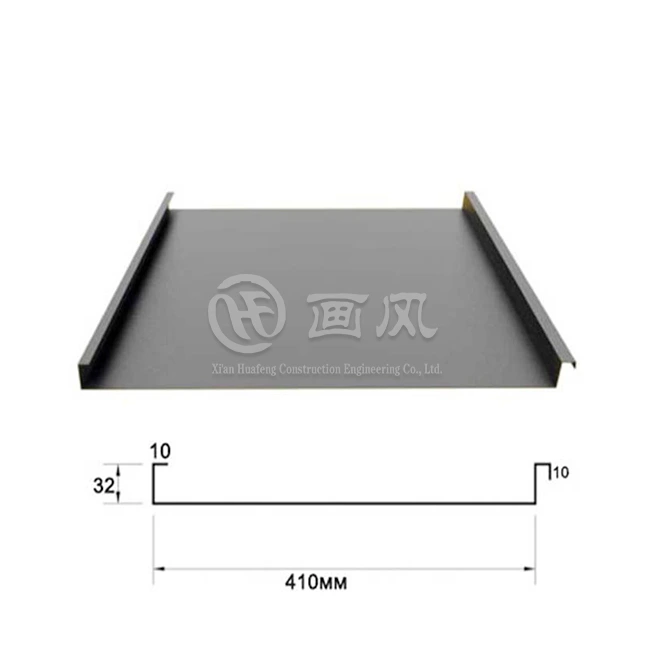

Oil canning represents one of the most frequently encountered yet misunderstood phenomena in Metal Standing Seam Roofing Systems installations. This condition manifests as visible waviness or stress wrinkling across the flat expanses of metal panels, creating an undulating appearance that can significantly detract from your roof's aesthetic appeal. The underlying mechanism involves elastic buckling, where metal panels become over-stressed and lose their ability to maintain a completely flat profile. This can occur across any metal type, whether you're working with aluminum, steel, zinc, or copper panels. The root causes of oil canning are multifaceted and often interconnected. Excessive pressure during the metal coiling manufacturing process can introduce residual stresses that later manifest as waviness. Inadequate accommodation for thermal expansion and contraction creates internal tensions that force panels to buckle. Poor handling and storage practices by contractors during transportation and installation can introduce mechanical stresses that compromise panel flatness. Additionally, the rollforming process itself, particularly when panels are subjected to frequent stress during coil slitting and forming operations, can contribute to this condition. Prevention strategies for oil canning require attention to detail throughout the entire supply and installation chain. Specifying thicker gauge materials provides greater structural rigidity and resistance to buckling forces. For Metal Standing Seam Roofing Systems projects, selecting materials in the range of 0.9mm to 1.2mm thickness significantly reduces susceptibility to oil canning. Opting for rib roller profiles or panels with higher seam heights, such as the 65mm ultra-high rib design, enhances structural strength and minimizes the visible impact of any waviness that does occur. Working exclusively with experienced installers who understand proper handling techniques and installation procedures is non-negotiable. These professionals recognize the importance of allowing adequate expansion joints and using appropriate fastening methods that don't introduce additional stresses into the panel system.

-

Leak Development: Protecting Your Investment Through Proper Sealing

Water infiltration represents perhaps the most serious threat to any roofing system, and Metal Standing Seam Roofing Systems are no exception despite their inherent water-resistant design. Leaks can develop through multiple pathways, each requiring specific diagnostic and remediation approaches. The consequences of unaddressed leaks extend far beyond simple water staining, potentially compromising structural integrity, fostering mold growth, damaging interior finishes and contents, and dramatically increasing long-term repair costs. Common leak sources in Metal Standing Seam Roofing Systems include improperly sealed seams where adjacent panels connect, flashing details around penetrations and roof edges that haven't been properly integrated, fastener penetrations where inadequate sealing allows water infiltration, and panel damage or deterioration that creates openings in the weather barrier. Additionally, extreme weather events, particularly freeze-thaw cycles in colder climates, can compromise sealing materials and create pathways for water entry. Addressing leak issues requires a systematic diagnostic approach. Professional inspection should include careful examination of all seam connections, verification that the double-lock seam mechanical bite maintains integrity, assessment of flashing installations at all transition points, and evaluation of fastener conditions. High-quality sealants specifically formulated for metal roofing applications provide crucial secondary protection at vulnerable locations. For standing seam systems with concealed fasteners, the mechanical seaming process itself forms the primary waterproof barrier, significantly reducing leak potential compared to exposed fastener systems. Regular maintenance inspections, conducted at least semi-annually, enable early detection of potential issues before they develop into active leaks.

-

Surface Damage: Scratching and Scuffing Compromising Protection

The protective coating systems applied to Metal Standing Seam Roofing Systems panels serve multiple critical functions, including corrosion resistance, UV protection, aesthetic appearance, and thermal performance. When these coatings become compromised through scratching or scuffing, the underlying metal becomes vulnerable to accelerated deterioration. Surface damage typically occurs during several phases of a project's lifecycle: improper handling during transportation when panels rub against each other or storage surfaces, installation activities where workers must traverse the roof surface, post-installation maintenance when equipment or personnel access the roof, and environmental impacts from falling branches or other debris. The severity of surface damage determines the appropriate remediation approach. Minor scratches that affect only the topcoat layer without penetrating to the metal substrate can often be addressed using color-matched touch-up paint or repair pens specifically formulated for the coating system in use. For Metal Standing Seam Roofing Systems with PVDF coatings containing 70% fluororesin, manufacturers typically provide compatible repair products that restore both protection and appearance. However, deeper gouges that penetrate through the coating system to expose bare metal require immediate panel replacement. Exposed metal, particularly in galvanized or galvalume substrates, will begin oxidizing rapidly when the protective zinc layer is breached.

Prevention strategies focus on minimizing opportunities for surface damage throughout the project lifecycle. Proper packaging using protective interleaf materials prevents panel-to-panel contact during transportation. Establishing designated walkways and access routes limits foot traffic on finished roofing surfaces. Using walk pads or temporary protective coverings during construction phases shields vulnerable areas. Specifying more durable coating systems, such as the PVDF coatings with 25-30μm thickness used in premium Metal Standing Seam Roofing Systems, provides enhanced resistance to wear and impact. Additionally, educating all project personnel about proper handling procedures creates a culture of care that minimizes damage incidents.

Advanced Technical Considerations for Metal Roofing System Longevity

-

Corrosion Mechanisms and Prevention in Metal Standing Seam Roofing Systems

Corrosion represents a complex electrochemical process that can compromise the structural integrity and longevity of Metal Standing Seam Roofing Systems if not properly addressed. While modern metal roofing materials incorporate sophisticated corrosion-resistant features, understanding the various corrosion mechanisms enables proactive prevention strategies. The primary corrosion types affecting metal roofing include uniform surface corrosion where the entire exposed surface oxidizes gradually, galvanic corrosion resulting from contact between dissimilar metals, crevice corrosion occurring in confined spaces with limited oxygen access, and stress corrosion developing at points of mechanical tension. Environmental factors significantly influence corrosion rates and patterns. Coastal installations face accelerated saltwater corrosion as airborne salt particles settle on roof surfaces and create aggressive electrochemical conditions. Industrial environments with elevated pollution levels expose roofing to acidic compounds and corrosive chemicals. High humidity regions maintain persistent moisture presence that facilitates oxidation reactions. Even cut edges where panels have been trimmed during fabrication or installation represent vulnerable points where protective coatings have been breached, exposing raw metal to environmental attack.

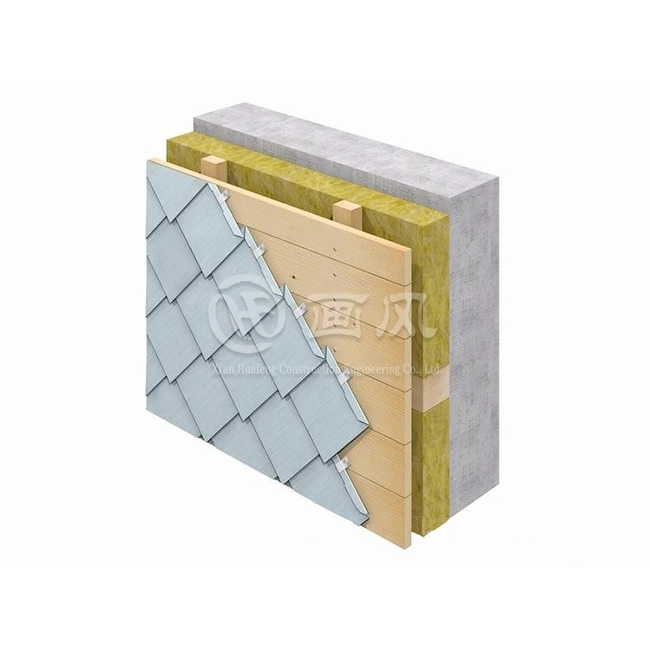

Comprehensive corrosion prevention strategies incorporate multiple protective layers and careful material selection. For Metal Standing Seam Roofing Systems in challenging environments, material specification becomes critical. Aluminum alloys in the 3003 or 3004 series with H44 hardened state provide excellent salt spray resistance for coastal applications. Galvalume with AZ150 coating delivering 150g/m² of aluminum-zinc protection plus PVDF topcoats offers strong corrosion resistance for most climate zones. Stainless steel grades like 304 provide superior performance in industrial areas or high-humidity environments. For ultimate longevity, titanium-zinc plates with self-repairing properties can achieve lifespans exceeding 80 years. Proper underside protection proves equally important. Waterproof and breathable membranes installed beneath roofing panels prevent moisture accumulation while allowing vapor transmission, effectively eliminating the conditions that foster underside corrosion. These high-density polyethylene non-woven fabrics block wind and rain invasion while strengthening both air tightness and water tightness. The breathability component enables water vapor inside the enclosure structure to be quickly discharged, effectively avoiding mold formation and condensation accumulation that would otherwise promote corrosion.

-

Dissimilar Metals: Managing Galvanic Reactions

The interaction between different metals in roofing assemblies introduces complex electrochemical considerations that can lead to accelerated corrosion if not properly managed. This phenomenon, known as galvanic corrosion or bimetallic corrosion, occurs when two dissimilar metals come into contact in the presence of an electrolyte such as water. The resulting electrical current causes electrons to flow from the more active metal (anode) toward the less active metal (cathode), accelerating corrosion of the anodic material far beyond its normal rate. Common problematic metal combinations in Metal Standing Seam Roofing Systems include aluminum panels with steel fasteners, copper flashing with galvanized steel panels, stainless steel components with carbon steel supports, and various metal combinations in drainage systems. The severity of galvanic corrosion depends on several factors: the relative position of metals in the galvanic series, the size relationship between anode and cathode materials, the conductivity and presence of electrolytes, and environmental conditions including humidity and temperature.

Effective management of dissimilar metal interactions requires careful planning and implementation of isolation strategies. The ideal approach involves specifying compatible metals throughout the roofing system, ensuring all components fall within close proximity in the galvanic series. When dissimilar metals must be used, physical barriers such as neoprene washers, isolation tape, or protective coatings prevent direct metal-to-metal contact. For Metal Standing Seam Roofing Systems projects, Xi'an Huafeng Construction Engineering Co., Ltd. maintains extensive experience in material compatibility assessment, leveraging their technical expertise to recommend appropriate combinations that avoid galvanic corrosion risks. Professional installation teams understand the importance of maintaining proper separation between incompatible materials. This includes using compatible fasteners that match the roofing panel material, installing isolation pads at support points, applying protective coatings to cut edges and connections, and ensuring drainage systems don't allow water to flow from more noble metals onto less noble metals in the assembly. These precautions, combined with regular inspection protocols, ensure long-term system integrity.

-

Chalking and Fading: Maintaining Aesthetic and Thermal Performance

The paint systems applied to Metal Standing Seam Roofing Systems serve multiple critical functions beyond simple aesthetic appeal. These sophisticated coating systems provide UV radiation protection, chemical resistance, thermal reflectivity, and corrosion barrier properties. Over time, exposure to environmental factors causes coating degradation through two primary mechanisms: chalking and fading. Chalking manifests as a white, powdery residue that develops on the coating surface as resin binders break down under UV exposure. Fading involves gradual color change as pigments degrade, typically shifting toward lighter or altered hues. The rate and severity of coating degradation depend on multiple interrelated factors. Geographic location and solar intensity directly correlate with UV exposure levels, with equatorial regions and high-altitude installations experiencing more aggressive conditions. Coating quality and formulation significantly impact longevity, with premium systems incorporating advanced resins and stabilizers that resist degradation. Panel orientation and slope affect both UV exposure and water runoff patterns, influencing coating stress levels. Environmental pollutants and chemical exposure can accelerate breakdown through reactive mechanisms.

High-performance coating systems represent the primary defense against chalking and fading in Metal Standing Seam Roofing Systems. PVDF (polyvinylidene fluoride) coatings containing 70% fluororesin provide exceptional UV and chemical resistance, typically maintaining color integrity for 20+ years. These coatings, applied at thicknesses of 25-30μm, significantly outperform conventional polyester systems. For projects prioritizing long-term aesthetic consistency and thermal performance, PVDF represents the gold standard. The superior color retention directly translates to maintained Solar Reflectance Index (SRI) values, ensuring continued energy efficiency throughout the roof's service life. Quality manufacturers back their premium coating systems with comprehensive warranties that specify acceptable chalking and fading limits over defined timeframes. These warranties provide crucial assurance that coating performance will meet expectations. When evaluating Metal Standing Seam Roofing Systems options, reviewing warranty terms for specific performance metrics enables informed decision-making. Additionally, regular maintenance including periodic cleaning with approved methods removes accumulated contaminants that can accelerate coating degradation, further extending system aesthetics and performance.

Installation Excellence and Long-Term System Integrity

-

Installation Errors: The Foundation of Long-Term Performance in Metal Standing Seam Roofing Systems

Even the highest quality Metal Standing Seam Roofing Systems components cannot overcome poor installation practices. Installation errors represent a critical category of roofing problems because they typically manifest as multiple, interconnected issues that compound over time. The complexity of proper metal roofing installation demands specialized knowledge, appropriate tooling, and meticulous attention to detail throughout every phase of the process. Common installation errors include panel misalignment creating uneven seam lines and compromising water shedding, inadequate or improperly installed fasteners leading to panel movement and potential detachment, flashing deficiencies at penetrations and transitions allowing water infiltration, insufficient accommodation for thermal expansion causing panel buckling or fastener failure, and improper seam formation compromising the waterproof barrier. The consequences of installation errors extend far beyond immediate visible defects. Improperly aligned panels may appear acceptable initially but develop progressive issues as thermal cycling and weather exposure stress the system. Inadequate fastener installation creates vulnerability to wind uplift forces that can progressively worsen over time. Flashing deficiencies often remain hidden until significant water damage has occurred. These compounding effects underscore the critical importance of installation quality from project inception.

Xi'an Huafeng Construction Engineering Co., Ltd. addresses installation quality through comprehensive service protocols that span the entire project lifecycle. Their approach begins with detailed project drawing deepening, where technical teams analyze architectural engineering drawings to develop feasible alternatives. Communication with customers determines optimal roof panel types for specific project roof structures. Design departments conduct 1:1 drawing deepening of nodes in different project areas based on selected models. Multiple communication rounds and confirmations culminate in signed, approved deepening drawings that serve as installation roadmaps. The company's installation methodology incorporates rigorous quality control measures. On-site technicians visit construction sites one day in advance to inspect work areas and verify tool completeness, including specialized equipment like pliers, edge-locking machines, and hammers. Auxiliary materials including rivets, structural adhesive, screws, and accessories undergo verification. Technical briefing meetings thoroughly review work details and safety precautions before installation commences. Upon completion, on-site testing ensures zero leakage, providing verification of installation integrity. This systematic approach, backed by extensive engineering design and construction experience, ensures Metal Standing Seam Roofing Systems achieve their full performance potential.

-

Thermal Movement: Designing for Expansion and Contraction

Metal roofing materials exhibit significant thermal expansion and contraction in response to temperature fluctuations, a characteristic that must be accommodated through proper system design and installation. The coefficient of thermal expansion varies by material type, with aluminum showing approximately 23 × 10⁻⁶ per °C, steel approximately 12 × 10⁻⁶ per °C, and copper approximately 17 × 10⁻⁶ per °C. For Metal Standing Seam Roofing Systems with panel lengths extending up to 13 meters, even modest temperature swings can produce several centimeters of length change. Failure to properly accommodate thermal movement manifests through multiple problematic symptoms. Fasteners can become loose or completely dislodged as panels move relative to the support structure. Panel warping occurs when expansion forces encounter excessive resistance. Seam integrity may be compromised if the mechanical lock cannot accommodate movement. In severe cases, accumulated stresses can cause panel buckling or structural damage to supporting elements.

Proper system design incorporates multiple strategies to manage thermal movement effectively. Standing seam systems with concealed clip attachments inherently allow panel movement independent of fastener locations, representing a fundamental advantage of this design approach. The clips themselves permit longitudinal movement while maintaining secure attachment. Expansion joints positioned at strategic intervals provide defined locations for movement accommodation. Material selection considering expansion coefficients relative to panel lengths and expected temperature ranges ensures movement remains within manageable parameters. For large-span applications common with Metal Standing Seam Roofing Systems, such as airports, high-speed rail stations, and exhibition centers, thermal movement considerations become particularly critical. Panel lengths, roof slopes, color selections affecting solar absorption, and local climate conditions all influence thermal performance. Xi'an Huafeng Construction Engineering Co., Ltd.'s engineering teams perform detailed calculations considering these factors, ensuring system designs accommodate expected movement throughout the service life. Their structural 3D modeling and load analysis capabilities enable comprehensive assessment of thermal effects alongside other performance requirements.

Conclusion

Metal Standing Seam Roofing Systems offer exceptional durability when properly specified, installed, and maintained. Understanding potential problems enables proactive prevention and rapid remediation, ensuring your investment delivers decades of reliable performance, aesthetic appeal, and weather protection for your critical building assets.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 and recognized as a high-tech enterprise in Shaanxi Province, brings comprehensive expertise to Metal Standing Seam Roofing Systems projects. With first-level qualifications for building curtain walls and third-level qualifications for building steel structures, the company delivers complete solutions from design through construction. Their 200,000 square meter raw material production plant in Anhui and processing plants in Hangzhou and Xi'an house 7 color coating production lines, 1 laminating production line, 10 longitudinal and transverse shearing production lines, and over 40 specialized equipment units.

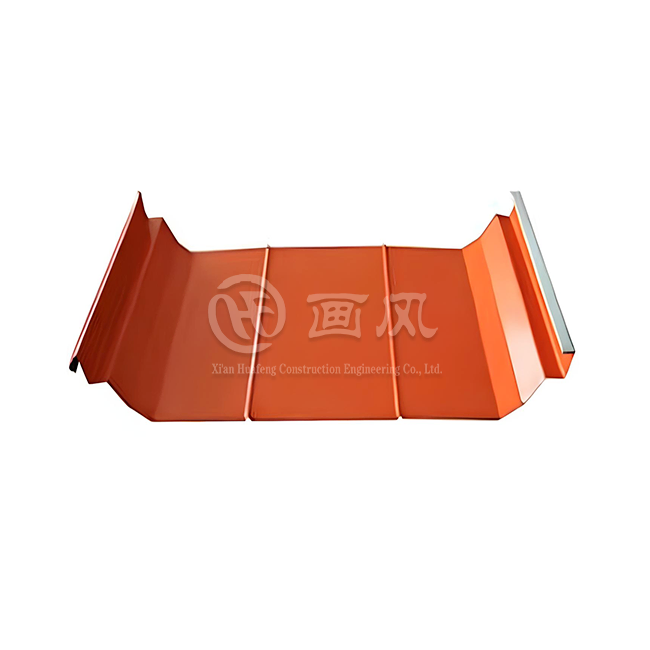

As a China Metal Standing Seam Roofing Systems factory, China Metal Standing Seam Roofing Systems supplier, China Metal Standing Seam Roofing Systems manufacturer offering China Metal Standing Seam Roofing Systems wholesale, the company provides Metal Standing Seam Roofing Systems for sale at competitive Metal Standing Seam Roofing Systems price points while maintaining High Quality Metal Standing Seam Roofing Systems standards. Their product range includes specifications from 65-300/400/430/500 with PE, HDP, and PVDF coating finishes, backed by 30-year warranties and ISO9001, ISO14000:14001, SGS certifications. With 1000 ton monthly supply capacity, 500㎡ minimum order quantities, and 15-20 day delivery times, Xi'an Huafeng offers customized services for color, pattern, and design requirements.

The company's one-stop solution encompasses structural 3D modeling and load analysis, drainage system simulation, material specification advisory, precision manufacturing with roll-forming systems and real-time quality control, and seamless installation with on-site project management. Their portfolio includes prestigious projects such as Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, and Inner Mongolia Tongliao Art Museum. With over 20 registered patents and collaboration experience with Fortune 500 companies, Xi'an Huafeng delivers engineering excellence. Contact them at huafeng@hfmetalroof.com to discuss your project requirements and receive expert guidance for your Metal Standing Seam Roofing Systems application.

References

1. Metal Roofing Problems and Solutions: A Technical Guide - Sheffield Metals International, Inc., Technical Documentation Department

2. Corrosion Prevention in Architectural Metal Systems - Anderson, James R. and Martinez, Sofia, Journal of Building Envelope Research

3. Standing Seam Metal Roof Installation Standards - Metal Construction Association Technical Committee, Industry Best Practices Manual

4. Thermal Performance and Movement in Metal Building Envelopes - Chen, Wei and Thompson, Robert K., International Journal of Architectural Engineering