When planning a commercial or residential building project, choosing the right metal roofing system can feel overwhelming. You're facing critical decisions about durability, aesthetics, water resistance, and long-term maintenance costs. The difference between flat seam and standing seam metal roofs isn't just about appearance—it directly impacts your building's performance, lifespan, and protection against the elements. Understanding these two distinct metal roofing profiles, including innovative solutions like Flat Lock Seam Metal, will help you make an informed decision that protects your investment for decades to come.

Understanding Flat Lock Seam Metal Roofing Systems

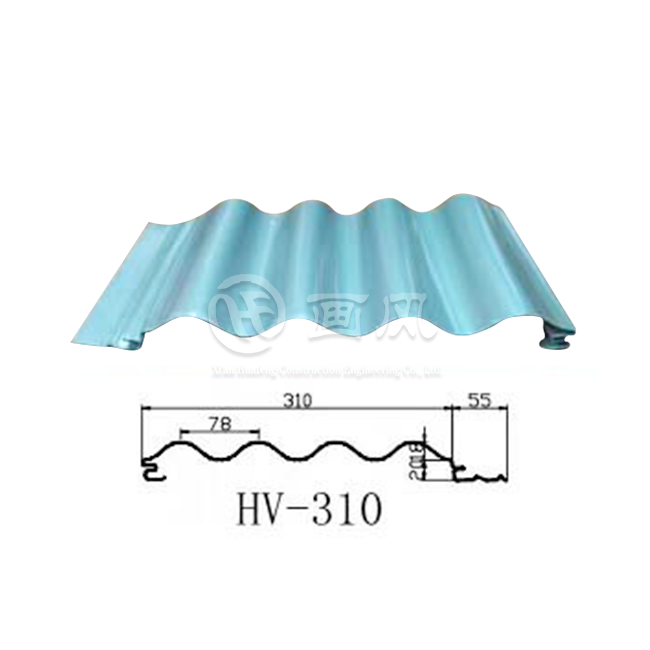

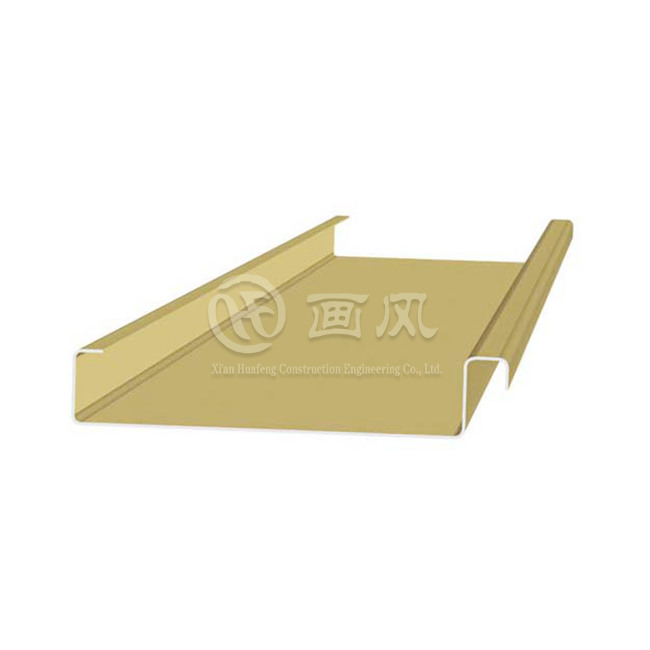

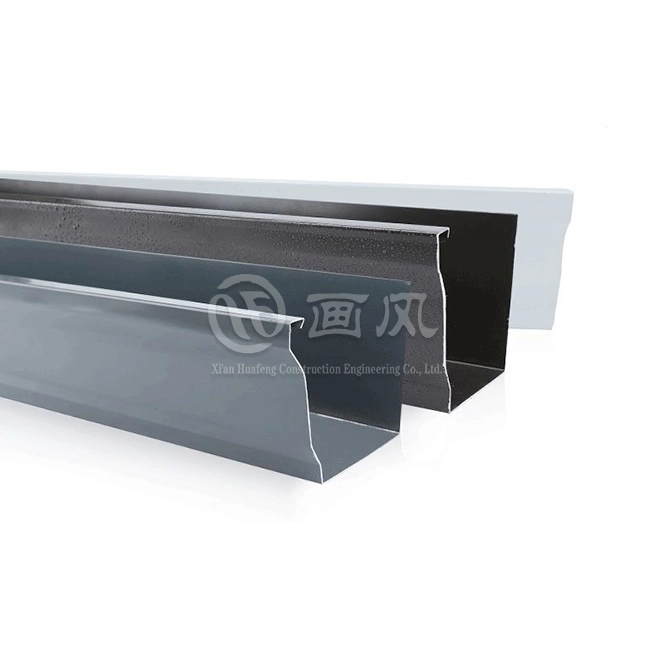

Flat seam metal roofing represents a traditional yet highly effective approach to metal roof construction. The Flat Lock Seam Metal system features rectangular panels where adjacent edges are folded over and under to create interlocking joints that lie flush with the roof surface. This installation method produces a clean, uniform appearance without the raised vertical ribs characteristic of standing seam systems. Historically used on historic buildings and architectural landmarks, flat seam roofing has evolved with modern materials and manufacturing techniques. The beauty of Flat Lock Seam Metal lies in its versatility across various geometric shapes. Unlike standing seam systems that work best on simple rectangular roof planes, flat lock panels can be configured into rectangles, rhombuses, trapezoids, and hexagons, making them ideal for complex architectural designs. The panels interlock through a specialized folding technique where each edge is bent at least three-quarters of an inch, creating a mechanical connection that resists wind uplift and provides structural integrity.

-

Installation and Water Management Characteristics

Flat Lock Seam Metal systems require careful consideration of roof slope and water management. When installed without soldered joints, these systems are designed as water-shedding applications, meaning they rely on gravity and proper drainage to move water off the roof surface quickly. Professional roofing standards recommend minimum slopes of four-in-twelve for non-soldered flat seam installations to ensure adequate water runoff and prevent ponding that could lead to premature deterioration or leakage. However, when flat seam joints are soldered together, the system transforms into a truly weatherproof assembly capable of handling lower slopes. This soldering process creates hermetic seals between panels, elevating the system's water resistance to levels suitable for demanding applications. The choice between soldered and non-soldered installations depends on your specific project requirements, budget considerations, and the building's exposure to weather conditions. Modern Flat Lock Seam Metal products manufactured by experienced companies like Xi'an Huafeng Construction Engineering incorporate advanced surface treatments including PVDF coatings and pre-passivation processes that enhance corrosion resistance and extend service life beyond thirty years.

-

Material Options and Aesthetic Flexibility

One of the most compelling advantages of Flat Lock Seam Metal systems is the extraordinary range of material choices available. Premium options include titanium-zinc alloys that develop a protective patina over time, copper that ages into distinctive blue-green tones, marine-grade stainless steel for ultimate corrosion resistance in coastal environments, and aluminum alloys offering excellent strength-to-weight ratios. Each material brings unique aesthetic qualities and performance characteristics suited to different architectural visions and environmental conditions. The thickness specifications for Flat Lock Seam Metal typically range from 0.4mm to 1.0mm depending on the base material selected and structural requirements of the application. Aluminum panels commonly utilize AA3003, AA3004, or AA5052 alloys, while stainless steel applications favor 304 or 316 grades for their superior corrosion resistance. Panel widths are customizable between 300mm and 600mm, allowing designers to create the precise visual rhythm desired for each project. Modern color-coating technologies provide virtually unlimited color options following RAL standards and custom specifications, ensuring perfect integration with overall building aesthetics.

Standing Seam Metal Roof Systems Explained

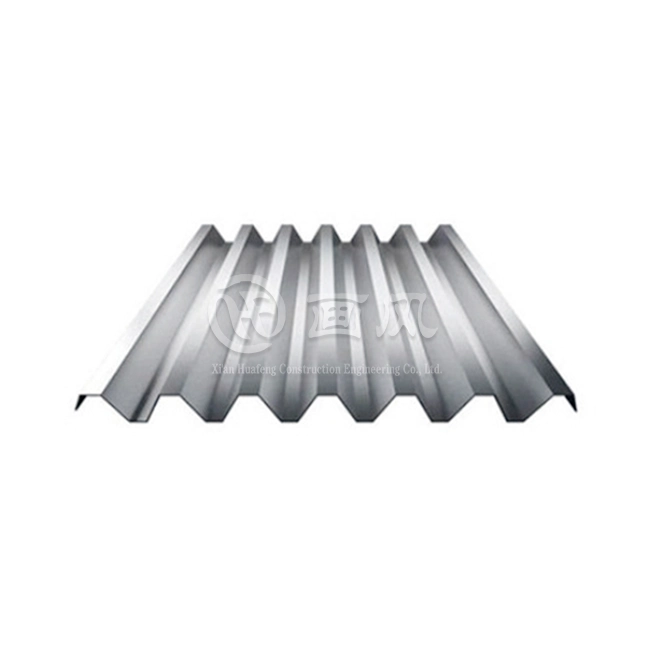

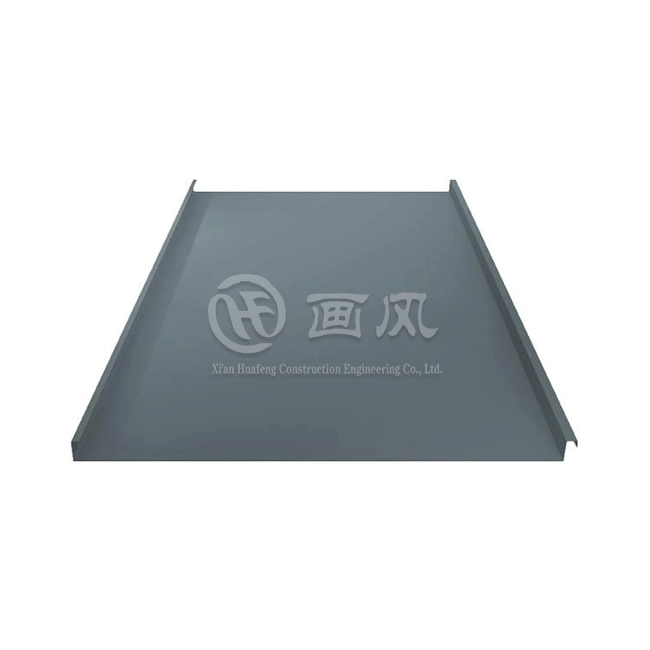

Standing seam metal roofing has become increasingly popular in contemporary architecture due to its distinctive appearance and superior performance characteristics. This concealed fastener system features wide, relatively flat metal panels separated by raised vertical ribs or seams that run continuously from ridge to eave. The defining characteristic is that all fasteners remain hidden beneath these vertical legs, eliminating potential leak points and creating clean, uninterrupted sight lines across the roof surface. The engineering behind standing seam systems focuses on accommodating thermal movement while maintaining watertight integrity. As metal panels expand and contract with temperature fluctuations, the raised seams and specialized clip systems allow controlled movement without stressing fastener connections or creating gaps that could admit moisture. This thermal accommodation is critical for long-term performance, particularly in climates experiencing significant temperature swings between seasons or even within a single day.

-

Seaming Methods and Performance Implications

Standing seam systems divide into two primary categories based on their seaming methodology. Snap-lock profiles feature pre-formed panel edges that simply snap together during installation without requiring specialized equipment. This design accelerates installation timelines and reduces labor costs, making snap-lock systems attractive for projects with tight schedules or budget constraints. However, snap-lock seams typically require minimum roof slopes of three-in-twelve to ensure adequate water shedding, limiting their application to steeper roof configurations. Mechanical seam systems represent the premium end of standing seam technology. These profiles utilize specialized seaming equipment that crimps the vertical panel edges together, creating an exceptionally tight mechanical connection. The crimping process forms a weathertight seal capable of withstanding extreme wind uplift forces and preventing water infiltration even on low-slope applications as shallow as half-in-twelve when properly installed. While mechanical seaming increases both material and labor costs compared to snap-lock alternatives, the enhanced performance justifies the investment for critical applications requiring maximum weather resistance and longevity.

-

Advantages in Modern Construction

Standing seam metal roofing delivers several compelling advantages that explain its growing market share in both commercial and residential construction. The concealed fastener design eliminates the most common failure point in traditional metal roofing—deteriorating exposed screws that create leak pathways as rubber washers degrade over time. By protecting all fasteners beneath the raised seams, standing seam systems significantly extend maintenance intervals and reduce lifecycle costs despite higher initial investment. The aesthetic appeal of standing seam roofing aligns perfectly with contemporary architectural trends favoring clean lines, minimalist details, and industrial-inspired materials. The vertical shadow lines created by raised seams add visual interest and dimensionality to roof planes while maintaining the sleek, modern appearance desired by architects and building owners. Additionally, standing seam systems accommodate accessory attachments like snow retention devices, solar panel mounting systems, and rooftop equipment without penetrating the weatherproof membrane, preserving system integrity while adding functionality.

Critical Performance Differences Between Systems

When comparing flat seam and standing seam metal roofing systems, several critical performance factors distinguish these approaches and guide appropriate selection for specific applications. Water management capabilities represent perhaps the most fundamental difference. Standing seam systems with their raised vertical ribs and concealed fasteners naturally channel water down the roof slope while preventing lateral movement that could find entry points. This design philosophy makes standing seam particularly well-suited for low-slope applications and regions experiencing heavy precipitation or snow accumulation. Flat Lock Seam Metal systems, conversely, rely on their flush surface profile and carefully engineered lapping sequences to shed water effectively. The absence of raised seams means water spreads across a broader surface area before draining, requiring steeper slopes or soldered joints to prevent infiltration. However, this characteristic also provides advantages in applications where minimal roof profile height is desired or where the architectural design calls for smooth, uninterrupted roof surfaces that blend seamlessly with building facades.

-

Structural and Thermal Considerations

The structural behavior of these two systems differs significantly under environmental loads and thermal stress. Standing seam profiles with their raised vertical ribs inherently possess greater structural depth, increasing the panels' moment of inertia and improving their ability to span longer distances between supports without intermediate purlins. This structural efficiency can reduce overall roof system costs by minimizing the required substructure while simultaneously improving wind uplift resistance—a critical consideration in hurricane-prone regions or tall buildings experiencing high wind pressures. Flat Lock Seam Metal systems distribute loads differently, relying on the mechanical interlock between adjacent panels to create a unified structural membrane. While individual panels may have less inherent stiffness than standing seam profiles, the interconnected nature of flat seam installations creates a continuous surface that effectively spreads concentrated loads across multiple panels. This load-sharing characteristic proves beneficial in applications involving foot traffic for maintenance access or when supporting rooftop equipment installations. The thermal performance of both systems depends heavily on material selection, surface coating specifications, and proper ventilation design rather than profile type, though standing seam systems facilitate easier integration of thermal breaks and continuous insulation strategies.

-

Installation Complexity and Cost Implications

Installation requirements present another significant distinction between these metal roofing approaches. Standing seam systems generally demand more specialized expertise, proprietary equipment, and careful attention to installation sequences. Portable roll-forming equipment is often deployed to fabricate panels on-site, ensuring precise lengths and minimizing transportation challenges. The seaming process itself—whether snap-lock or mechanical—requires trained installers familiar with proper clip spacing, panel alignment, and seam formation techniques to achieve manufacturer warranties and optimal performance. Flat Lock Seam Metal installation follows different protocols emphasizing precision metalworking and traditional roofing craftsmanship. Each panel must be carefully measured, cut, and folded to create the interlocking edges that form the system's mechanical connections. When soldered joints are specified, skilled craftsmen perform torch work to create permanent watertight seals between panels. This labor-intensive approach typically extends installation timelines compared to standing seam systems, though the resulting aesthetic and performance characteristics justify the additional effort for appropriate applications. Projects requiring custom panel shapes, intricate patterns, or integration with historic architectural details particularly benefit from the flexibility inherent in Flat Lock Seam Metal systems.

Selecting the Appropriate System for Your Project

Choosing between flat seam and standing seam metal roofing requires careful analysis of multiple project-specific factors that influence long-term success. Architectural design intent serves as the primary consideration—contemporary buildings with minimalist aesthetics naturally complement standing seam profiles, while traditional architecture, historic preservation projects, or designs requiring complex geometric patterns often demand the versatility of Flat Lock Seam Metal systems. The building's functional requirements also guide this decision, including factors like interior space usage, structural loading conditions, and planned service life. Climate and environmental exposure significantly impact system selection. Regions experiencing heavy snow loads benefit from standing seam systems that facilitate snow shedding and accommodate snow retention devices without roof penetrations. Coastal environments with salt spray exposure might favor Flat Lock Seam Metal fabricated from marine-grade stainless steel or specialized aluminum alloys with enhanced corrosion resistance. Areas prone to severe hail should consider material thickness, panel rigidity, and potential for cosmetic damage—standing seam profiles with broader flat areas show hail denting more readily than textured or formed flat seam configurations.

-

Budget Considerations and Lifecycle Value

Initial project budgets naturally influence roofing system selection, though savvy building owners recognize that first costs represent only one component of true lifecycle expenses. Standing seam systems typically command higher square-foot pricing due to material thickness requirements, specialized components like clips and sealants, and installation labor intensity. However, these initial costs often prove economically justified when amortized across the system's service life, which can exceed fifty years for properly specified and installed standing seam roofing with minimal maintenance requirements. Flat Lock Seam Metal systems present varied cost profiles depending on specification details. Non-soldered installations on appropriate slopes offer competitive pricing relative to standing seam alternatives while delivering distinctive aesthetics and proven performance. Premium soldered flat seam assemblies incorporating specialty metals like copper or titanium-zinc command significant investments justified by their exceptional longevity, minimal maintenance requirements, and timeless architectural appeal. When evaluating costs, consider factors beyond material and installation including maintenance frequency, energy performance contributions, potential for accommodating future building modifications, and the impact of aesthetic quality on property value.

-

Technical Support and Manufacturing Capabilities

The technical expertise and manufacturing capabilities of your metal roofing supplier significantly influence project success regardless of which system you select. Experienced manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd. bring critical advantages including engineering support for custom applications, precision manufacturing using advanced equipment, comprehensive quality control processes, and installation guidance ensuring proper system performance. Companies operating multiple production facilities with diverse equipment portfolios can accommodate various panel profiles, material options, and surface treatments within unified procurement channels, simplifying project logistics and ensuring consistency across all components. Look for suppliers demonstrating robust quality certifications including ISO9001 quality management systems, ISO14001 environmental management standards, and product-specific certifications like CE marking for international applications. Manufacturing capabilities should encompass the full spectrum of required production processes including color coating lines for pre-finished materials, roll-forming equipment for custom panel profiles, precision cutting and folding machinery for complex shapes, and comprehensive testing facilities validating material properties, coating performance, and system-level weather resistance. Suppliers maintaining extensive material inventories from premium brands ensure consistent supply chains and reduce project delays while providing traceability documentation confirming material specifications.

Conclusion

The fundamental difference between flat seam and standing seam metal roofing extends beyond mere appearance to encompass critical performance characteristics, installation requirements, and long-term value propositions. Standing seam systems excel in applications demanding maximum weather resistance, minimal maintenance, and contemporary aesthetics, while Flat Lock Seam Metal delivers unmatched versatility for complex geometries, traditional architectural styles, and projects where flush surface profiles provide distinct advantages. Your optimal choice depends on carefully weighing project-specific factors including architectural vision, environmental conditions, budget parameters, and functional requirements against each system's inherent strengths and limitations.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands ready to transform your metal roofing vision into reality through comprehensive capabilities spanning design, manufacturing, and installation services. Established in 2018 and recognized as a Shaanxi Province high-tech enterprise, Huafeng operates three advanced production facilities including a 200,000-square-meter raw material plant in Anhui and specialized processing centers in Hangzhou and Xi'an. Our manufacturing infrastructure encompasses seven color coating production lines, ten longitudinal and transverse shearing systems, fully automatic punching equipment, and more than forty specialized machines ensuring precision fabrication of standing seam panels, Flat Lock Seam Metal assemblies, aluminum-magnesium-manganese plates, titanium-zinc systems, and comprehensive roofing accessories.

As a China Flat Lock Seam Metal factory, China Flat Lock Seam Metal supplier, China Flat Lock Seam Metal manufacturer, and China Flat Lock Seam Metal wholesale provider, we deliver High Quality Flat Lock Seam Metal with competitive Flat Lock Seam Metal price and reliable Flat Lock Seam Metal for sale options. Our engineering team provides structural 3D modeling, load analysis, drainage system simulation, and material specification advisory services ensuring optimal system performance for your unique application. Quality certifications including first-level building curtain wall qualifications, third-level steel structure credentials, ISO9001, ISO14001, SGS validation, and over twenty registered patents demonstrate our commitment to excellence. Successful projects spanning major infrastructure including Xiongan Station, Xi'an International Convention Center, and Inner Mongolia Tongliao Art Museum showcase our proven capabilities. Contact us today at huafeng@hfmetalroof.com to discuss your metal roofing requirements and discover how our one-stop solutions—from raw materials through installation—deliver superior value, performance, and aesthetic excellence for your building project.

References

1. American Architectural Manufacturers Association. (2024). Metal Panel Design Guide: Flat Seam and Standing Seam Systems. AAMA Publication 501.

2. National Roofing Contractors Association. (2023). The NRCA Metal Panel and SPF Roof Systems Manual. National Roofing Contractors Association.

3. Metal Construction Association. (2022). Technical Bulletin: Comparison of Metal Roof Panel Systems Performance Characteristics. Metal Construction Association.

4. Kreh, Richard T. & Reichard, Charles W. (2021). Advanced Metal Roofing Installation Techniques: Flat Seam and Standing Seam Applications. John Wiley & Sons.