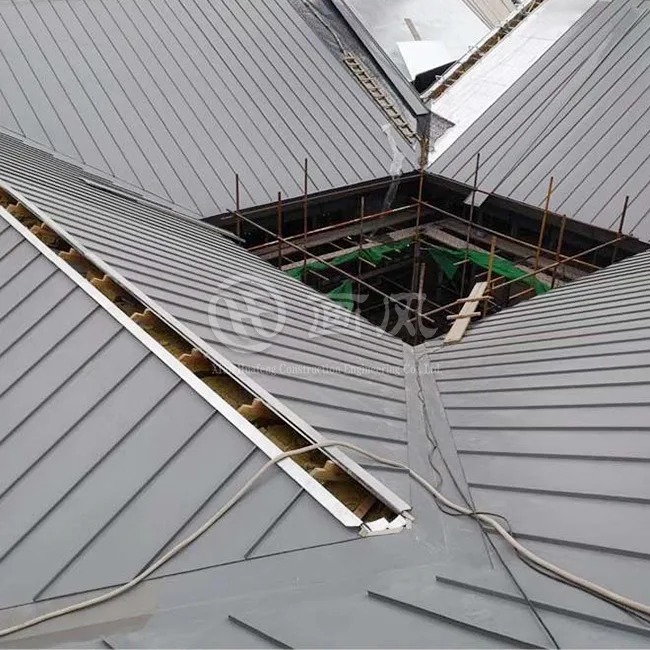

When large-scale construction projects face water infiltration issues, structural integrity concerns, and aesthetic inconsistencies at critical roof junctions, the selection and implementation of Standing Seam Trims becomes a make-or-break decision. These precision-engineered components serve as the critical interface between metal roofing panels and building transitions, directly impacting long-term performance, maintenance costs, and visual coherence across thousands of square meters. This comprehensive guide reveals how Standing Seam Trims transform conceptual architectural drawings into weathertight, durable building envelopes for convention centers, transportation hubs, cultural facilities, and industrial complexes.

Understanding Standing Seam Trims in Modern Construction

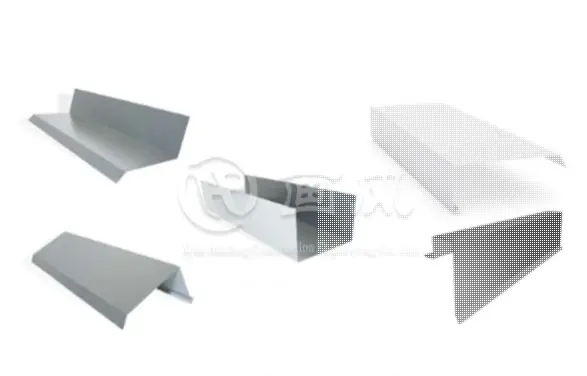

Standing Seam Trims represent far more than decorative finishing elements in contemporary metal roofing systems. These specialized components function as engineered transitions that protect vulnerable areas where roofing panels terminate, change direction, or meet vertical surfaces. In large-scale building projects such as convention centers, railway stations, and cultural institutions, Standing Seam Trims must accommodate significant structural movements, manage complex drainage patterns, and maintain visual consistency across expansive roof surfaces that can exceed tens of thousands of square meters. The technical sophistication required for these applications distinguishes premium trim systems from standard agricultural or residential alternatives.

-

The Critical Role of Trims in Building Envelope Performance

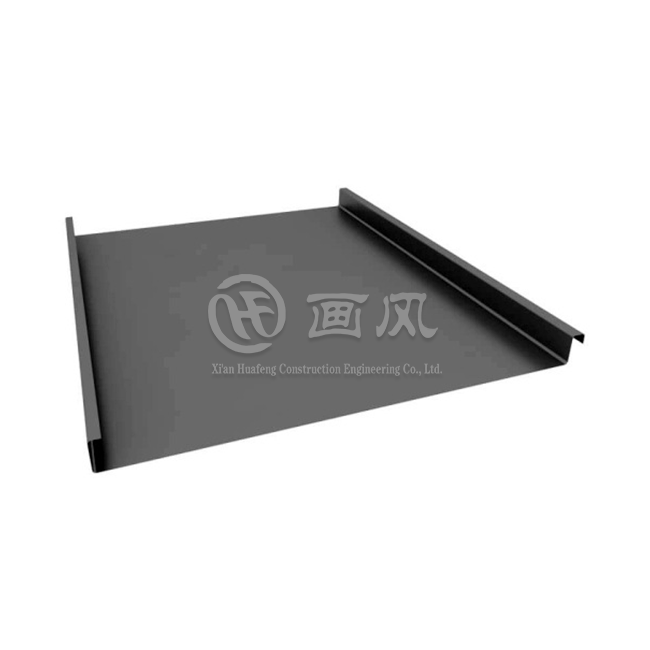

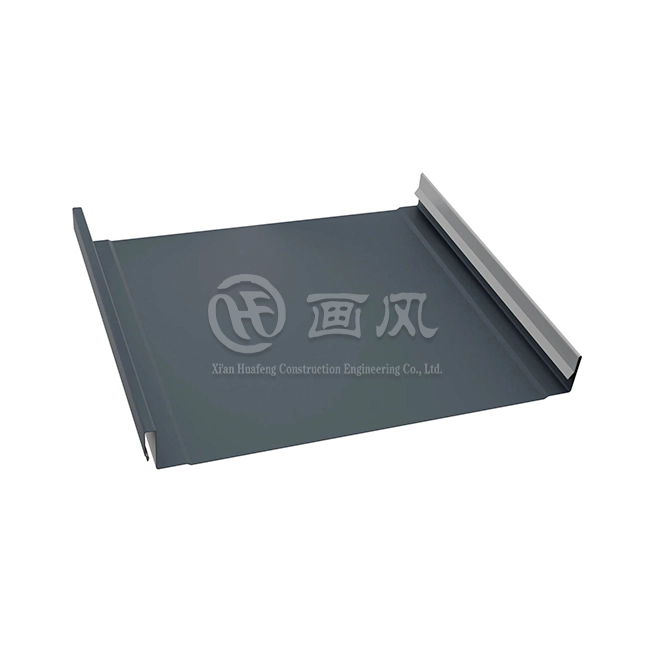

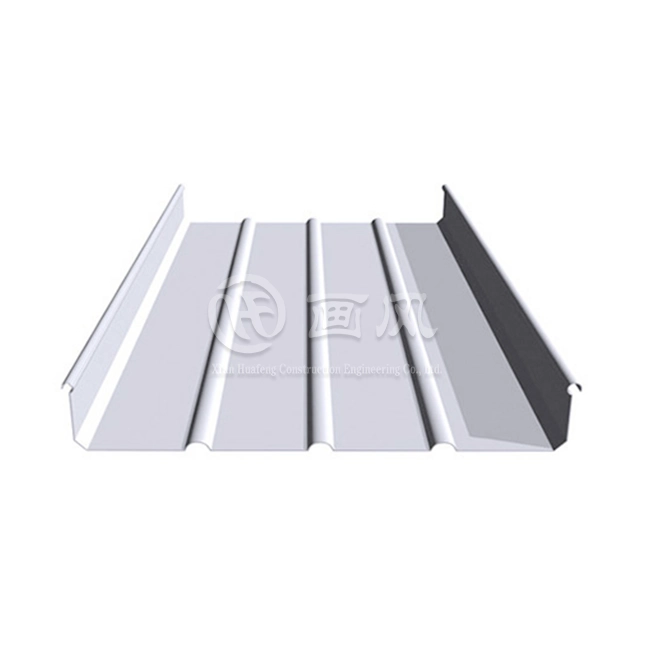

The building envelope represents the physical separator between controlled interior environments and exterior climate conditions. Within this critical system, Standing Seam Trims serve multiple simultaneous functions that directly influence overall building performance. These components create weathertight seals at ridges, eaves, gables, valleys, and penetrations where standard roofing panels cannot provide adequate protection. Premium trim systems utilize concealed fastening methods that eliminate thermal bridging and potential leak paths while accommodating the thermal expansion and contraction characteristics inherent in large metal roof installations. Material compatibility becomes paramount, as dissimilar metals in contact can create galvanic corrosion that compromises system integrity within years rather than decades. Manufacturing precision directly impacts field installation efficiency and long-term performance. High-quality Standing Seam Trims feature consistent dimensional tolerances, pre-formed profiles that match specific panel geometries, and material specifications that align with base roofing components. Advanced production facilities employ roll-forming technology capable of creating custom profiles for project-specific requirements while maintaining the structural characteristics necessary for spanning between structural supports. Color consistency across trim components and roofing panels requires sophisticated coating application processes that ensure uniform appearance under varying lighting conditions and viewing angles typical of large-scale architectural projects.

-

Material Selection and Performance Characteristics

Material selection for Standing Seam Trims in large-scale buildings demands careful analysis of multiple performance criteria beyond simple cost considerations. Aluminum alloy options offer exceptional corrosion resistance and favorable strength-to-weight ratios, making them ideal for coastal environments or locations with aggressive atmospheric conditions. The 3003, 3004, and 5052 aluminum alloy designations provide progressively increasing strength characteristics while maintaining excellent formability for complex trim geometries. Color-coated steel alternatives deliver superior structural performance at competitive price points, particularly when projects specify galvanized or galvalume substrates with advanced polymer coating systems rated for decades of weathering resistance. Titanium-zinc and copper materials represent premium alternatives for projects emphasizing longevity, distinctive aesthetics, or compatibility with heritage architectural contexts. These materials develop natural patinas that evolve over time, creating living finishes that many architects specify for their unique visual characteristics. However, successful implementation requires comprehensive understanding of material behavior, appropriate detailing to accommodate thermal movement, and strict separation from incompatible metals throughout the assembly. Stainless steel variants in 304 and 316 grades provide exceptional durability in extreme environments but demand specialized fabrication capabilities and installation techniques to achieve optimal performance.

Design Integration from Concept Through Documentation

Successful Standing Seam Trim implementation begins during conceptual design phases, long before manufacturing or installation activities commence. Early collaboration between architects, structural engineers, and roofing specialists ensures that trim details complement overall building geometry while addressing specific performance requirements. Three-dimensional modeling technologies enable design teams to visualize complex intersections, identify potential water management challenges, and optimize trim configurations before committing to fabrication. Load analysis calculations determine appropriate clip spacing, fastener specifications, and structural support requirements based on project-specific wind exposure, snow accumulation, and seismic conditions.

-

Technical Drawing Development and Coordination

The transition from conceptual designs to buildable details requires meticulous drawing development that captures every aspect of Standing Seam Trim installation. Initial architectural drawings provide overall roof geometry, material specifications, and aesthetic intentions, but lack the precision necessary for manufacturing and field installation. Drawing deepening processes involve analyzing floor plans, elevations, and preliminary node diagrams to identify all locations requiring specialized trim components. This analysis generates comprehensive lists of required trim types, quantities, and specifications organized by roof section and installation sequence. Communication between design teams and manufacturing specialists ensures that specified trim profiles can be produced efficiently while meeting performance requirements. Design departments conduct one-to-one scale drawing development for critical nodes throughout projects, detailing exact dimensions, material transitions, and fastening methods. Multiple review cycles with clients and general contractors refine these details until all parties confirm that drawings accurately represent project requirements and can be executed within budget and schedule constraints. Signed and approved drawings become the controlling documents for subsequent manufacturing and quality assurance activities. Processing drawings represent the final evolution of design documentation, translating architectural intent into shop-floor instructions that production teams can execute without ambiguity. These detailed drawings break down complex assemblies into individual components, specify material grades and thicknesses, indicate forming sequences, and establish quality control checkpoints. Sequential numbering systems track every trim piece from fabrication through packaging and installation, preventing errors that could delay construction or compromise system performance. This documentation-intensive approach distinguishes professional Standing Seam Trim suppliers from commodity manufacturers focused primarily on standard profiles and minimal customization.

Precision Manufacturing and Quality Assurance

Manufacturing excellence separates premium Standing Seam Trims from standard alternatives, directly influencing installation efficiency and long-term performance. State-of-the-art production facilities integrate multiple specialized production lines capable of processing various base materials through coating, forming, and finishing operations. Color coating lines apply precisely controlled layers of protective and decorative finishes that bond permanently to metal substrates, creating surfaces resistant to fading, chalking, and environmental degradation. Laminating capabilities enable the application of noise-reducing membranes or additional protective layers that enhance system performance beyond basic weatherproofing.

-

Material Procurement and Incoming Inspection

Quality Standing Seam Trims begin with premium raw materials sourced from established suppliers with documented quality management systems. Purchasing departments maintain approved supplier lists specifying acceptable brands for each material category, ensuring consistency across multiple projects and production runs. For aluminum components, approved brands include Alucosuper, YATAI, and LIDAO providing certified 3003, 3004, and 5052 alloys meeting international specifications. Steel products from BAOSTEEL, GUANZHOU, and XINYU encompass cold rolled, galvanized, galvalume, and color-coated variants suitable for diverse project requirements. Stainless steel from Baosteel and Tsingshan in 316 and 304 grades addresses applications demanding maximum corrosion resistance. Incoming material inspection protocols verify that delivered materials match purchase specifications before entering production workflows. Third-party material testing reports from suppliers provide initial documentation, but responsible manufacturers conduct independent verification testing on representative samples. Inspection procedures encompass product appearance evaluation, dimensional verification, and comprehensive performance testing including salt spray exposure, coating adhesion assessment, hardness measurement, impact resistance, film thickness verification, acid resistance evaluation, weathering simulation, and color consistency analysis. Materials failing any inspection criteria are rejected and returned to suppliers, preventing defective components from compromising finished products.

-

Production Processing and Quality Control

Modern production facilities employ sophisticated equipment capable of transforming raw materials into precisely dimensioned Standing Seam Trims matching project-specific requirements. Longitudinal and transverse shearing lines cut materials to exact dimensions with minimal waste generation. Fully automatic punching systems create fastening holes, drainage perforations, and assembly features with positioning accuracy measured in millimeters. Press brakes and roll-forming equipment bend materials into complex three-dimensional profiles that interlock seamlessly with roofing panels and adjacent trim components. Advanced equipment can produce trim lengths exceeding ten meters when projects require continuous runs between structural supports. Real-time quality control throughout production processes identifies and corrects deviations before defective components progress to subsequent operations. Finished product inspection evaluates appearance characteristics, dimensional accuracy, flatness across unsupported spans, and curvature conformance for pre-bent components. Statistical process control methods track production metrics, identifying trends that might indicate equipment wear or process drift requiring corrective maintenance. Only components passing all inspection criteria advance to packaging and shipping operations, ensuring that construction sites receive products ready for immediate installation without field modifications or corrections.

Installation Expertise and On-Site Execution

Even premium Standing Seam Trims cannot deliver intended performance without proper installation by experienced technicians using appropriate methods and tools. On-site construction management begins with detailed planning sessions that consider site-specific constraints, product delivery logistics, and installation sequencing coordinated with other trades. Storage area layout protects materials from damage while facilitating efficient distribution to work areas as installation progresses. Product identification systems using sectioned floor plans and component number lists enable crews to locate required pieces quickly, minimizing handling and reducing installation time.

-

Pre-Installation Preparation and Technical Coordination

Installation technicians must visit construction sites in advance of material deliveries to assess working conditions and verify that supporting substrates meet specifications. Site inspections confirm that structural decking provides adequate fastening surfaces, insulation layers are properly installed, and underlayment membranes create continuous barriers against moisture infiltration. Tool inventories verify that crews possess specialized equipment including seaming machines, edge-locking tools, fastening systems, and measuring instruments necessary for precision installation. Auxiliary material procurement ensures availability of clips, fasteners, sealants, and backing materials compatible with specified trim components. Technical briefing meetings review installation sequences, critical quality checkpoints, and safety protocols before field work commences. Installation drawings are confirmed current and distributed to all crew members requiring access during construction activities. Complex trim intersections receive particular attention, with experienced supervisors demonstrating proper assembly methods and quality standards. Safety discussions address fall protection requirements, material handling procedures, and weather-related work restrictions that might impact installation schedules. These preparatory activities establish clear expectations and empower installation teams to execute work efficiently while maintaining quality standards.

-

Field Installation and Performance Testing

Systematic installation procedures ensure that Standing Seam Trims are positioned accurately and fastened securely according to engineering specifications. Fixed cleats are spaced at prescribed intervals and attached to structural substrates using fasteners rated for anticipated loads. Trim components are positioned to maintain consistent reveals, proper drainage slopes, and alignment with adjacent panels and building elements. Concealed fastening systems are engaged according to manufacturer specifications, ensuring that thermal movement provisions function correctly throughout seasonal temperature cycles. Sealant applications at critical junctions follow strict surface preparation protocols and utilize compatible materials that maintain elasticity under weathering exposure. Upon installation completion, comprehensive testing verifies that roofing systems achieve zero-leakage performance standards. Water testing procedures simulate rainfall conditions at vulnerable areas including ridge caps, valley flashings, eave terminations, and penetration flashings. Observed leaks are documented, corrected, and retested until complete system integrity is confirmed. Final inspections document that all Standing Seam Trims meet dimensional tolerances, color matching requirements, and aesthetic standards specified in contract documents. Customer walkthroughs provide opportunities to review completed installations, address any concerns, and establish maintenance protocols that preserve system performance throughout building lifecycles.

Conclusion

Standing Seam Trims represent essential components linking conceptual architectural visions with durable, weathertight large-scale building realities. Success demands integrated expertise spanning design optimization, precision manufacturing, and skilled installation execution. Projects achieving optimal outcomes engage experienced suppliers early in design processes, maintain rigorous quality standards throughout manufacturing operations, and deploy trained installation teams capable of translating technical specifications into field performance. When properly specified, manufactured, and installed, Standing Seam Trims protect substantial infrastructure investments while delivering the aesthetic coherence that distinguishes exceptional architecture from merely adequate construction.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as your comprehensive partner for large-scale metal roofing projects requiring exceptional Standing Seam Trims and complete system solutions. Established in 2018 and recognized as a Shaanxi Province high-tech enterprise in 2020, Huafeng combines first-level building curtain wall qualifications and third-level steel structure credentials with extensive manufacturing capabilities. Our 200,000-square-meter Anhui raw material production facility and dedicated processing plants in Hangzhou and Xi'an operate seven color coating lines, one laminating line, ten shearing production lines, and over forty specialized forming equipment ensuring precision output. More than twenty registered roofing system patents and ISO9001, ISO14000:14001, SGS certifications demonstrate our commitment to innovation and quality excellence.

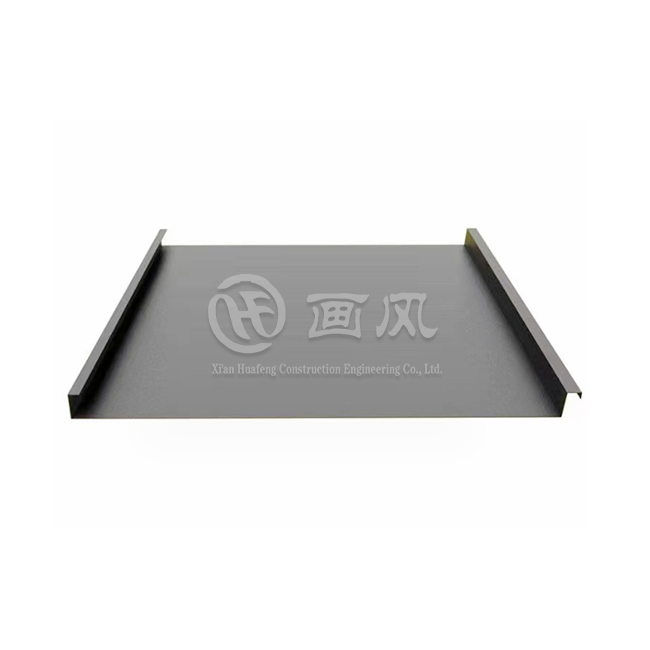

As a leading China Standing Seam Trims factory, China Standing Seam Trims supplier, and China Standing Seam Trims manufacturer, we deliver China Standing Seam Trims wholesale solutions with competitive Standing Seam Trims prices without compromising High Quality Standing Seam Trims standards. Our Standing Seam Trims for sale encompass aluminum alloy, color steel, and galvanized steel variants suitable for ridges, eaves, gables, inner corners, and flashing panel applications. From structural 3D modeling and drainage simulation through precision roll-forming and seamless on-site installation, our one-stop approach eliminates coordination challenges while accelerating project schedules. Notable installations including Xiongan Station, Xi'an International Convention Center, and Inner Mongolia Tongliao Art Museum demonstrate our capability delivering world-class results for demanding applications. Contact our engineering team at huafeng@hfmetalroof.com to discuss your project requirements and discover how Huafeng's integrated expertise transforms architectural concepts into enduring building envelope excellence. Save this resource for immediate access whenever Standing Seam Trims questions arise during your planning and execution phases.

References

1. Metal Construction Association. "Performance Standards for Metal Roof Panel Systems." Technical Guidelines for Standing Seam Applications. Metal Construction Association Industry Standards Committee.

2. Thompson, J. R., and Harrison, M. K. "Architectural Metal Roofing: Design Principles and Installation Practices for Large-Scale Building Applications." Journal of Building Envelope Design, Vol. 42, Issue 3.

3. National Roofing Contractors Association. "Metal Roofing Systems: Design Manual for Commercial and Institutional Buildings." NRCA Technical Services Department.

4. Williams, D. S. "Thermal Performance and Weathertightness in Standing Seam Metal Roofing Systems: A Comprehensive Analysis of Trim Component Integration." International Journal of Construction Engineering and Management, Vol. 18, No. 2.