Imagine standing outside your commercial building after a severe storm, watching neighboring properties suffer from roof leaks and wind damage while your facility remains completely protected. This scenario plays out repeatedly for property owners who invest in Metal Standing Seam Roofing Systems. These advanced roofing solutions represent a critical decision point for building managers, architects, and property developers who face mounting pressure to balance upfront costs against long-term performance, energy efficiency, and maintenance requirements. Understanding both the advantages and limitations of standing seam technology empowers you to make informed decisions that protect your investment for decades to come.

Understanding Metal Standing Seam Roofing Systems Technology

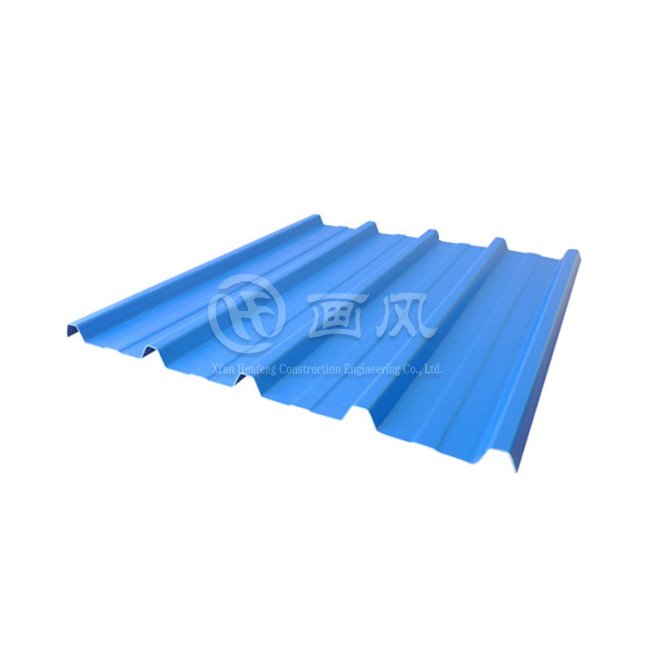

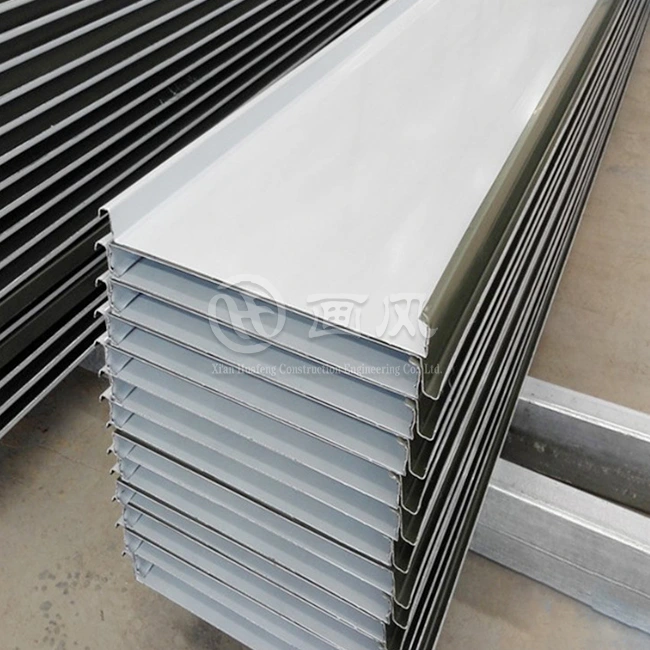

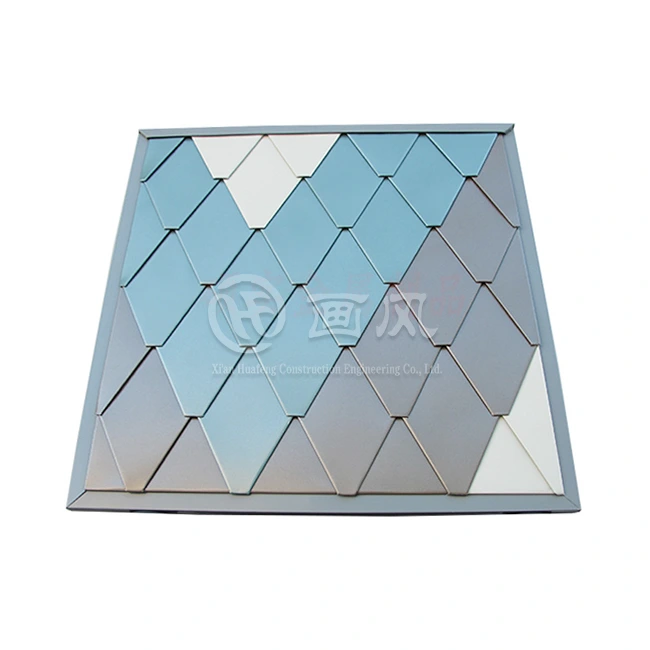

Metal Standing Seam Roofing Systems represent a sophisticated approach to building protection that distinguishes itself through innovative engineering and superior performance characteristics. Unlike traditional exposed fastener systems, these roofing solutions feature vertical metal panels with raised seams that mechanically interlock, creating a continuous weathertight barrier across the entire roof surface. The defining characteristic lies in the concealed fastener system, where clips or fastener flanges attach panels to the underlying roof deck without penetrating the exposed metal surface, eliminating thousands of potential leak points that plague conventional roofing systems. The architectural beauty of Metal Standing Seam Roofing Systems extends beyond mere aesthetics to encompass structural intelligence. High-rib designs, typically ranging from 65mm to higher profiles, provide enhanced structural rigidity while simultaneously improving drainage performance during heavy precipitation events. This elevation creates natural channels that direct water away from the building envelope efficiently, preventing ponding and reducing stress on the roof structure. The mechanical locking technology employed in these systems ensures long-term waterproof sealing even as building materials naturally expand and contract through seasonal temperature fluctuations, maintaining integrity where other roofing types might fail.

-

Material Options and Performance Specifications

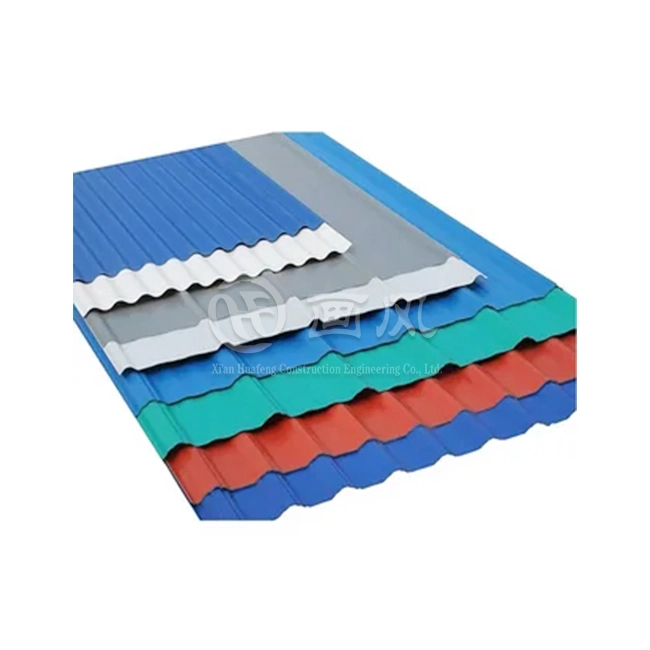

Modern Metal Standing Seam Roofing Systems offer diverse material selections tailored to specific environmental conditions and performance requirements. Aluminum panels ranging from 0.9 to 1.2mm thickness provide lightweight corrosion resistance ideal for coastal installations where salt spray threatens conventional materials. The 3003 and 3004 series aluminum alloys in H44 hardened state deliver exceptional durability when combined with fluorocarbon spray finishes that resist weathering and maintain color vibrancy for decades. Galvalume steel options featuring AZ150 coating with PVDF surface treatments offer remarkable cost-effectiveness while providing strong corrosion resistance suitable for most climate zones, making them the preferred choice for budget-conscious projects requiring reliable performance. Premium material selections expand possibilities for projects demanding maximum longevity and distinctive aesthetics. Stainless steel panels in 304 grade with fluorocarbon coatings excel in harsh coastal environments, industrial areas, and high-humidity locations where lesser materials deteriorate rapidly. Titanium-zinc plates demonstrate self-repairing properties through natural oxidation processes, achieving lifespans exceeding 80 years while maintaining environmental sustainability credentials. Copper roofing systems utilizing TU1 oxygen-free copper deliver ultra-long service lives potentially surpassing 100 years, developing characteristic patinas that enhance visual appeal while providing natural protection against corrosion. These material choices within Metal Standing Seam Roofing Systems allow architects and building owners to optimize performance against budget constraints and aesthetic preferences.

Advantages of Metal Standing Seam Roofing Systems

-

Superior Weather Protection and Durability

The concealed fastener design inherent to Metal Standing Seam Roofing Systems provides unmatched weather protection compared to alternative roofing technologies. Hidden fasteners remain completely protected from ultraviolet radiation, wind-driven rain, thermal cycling, and other environmental factors that systematically degrade exposed hardware over time. This protection translates directly into extended service life and reduced maintenance requirements, as fasteners maintain their holding power and weather seal integrity throughout decades of exposure. The mechanical seaming process creates interlocking joints that resist water penetration even under extreme negative pressure conditions, with properly installed systems passing 1000Pa negative pressure tests without leakage, meeting stringent international waterproofing standards. Wind resistance capabilities of Metal Standing Seam Roofing Systems far exceed requirements for most geographic locations, including areas prone to hurricane-force winds. Engineered systems demonstrate wind pressure resistance exceeding 4.5 kPa, equivalent to withstanding category 5 hurricane conditions, when tested according to ASTM E1592 and GB 50223 standards. The structural design distributes loads efficiently across the roof assembly, while the mechanical locking seams maintain panel connections even under extreme uplift forces. Snow load capacity ratings of 1.5 kN/m² or greater make these systems appropriate for regions experiencing heavy winter precipitation, preventing structural failure and ice dam formation that compromise lesser roofing technologies. Impact resistance testing confirms that properly specified Metal Standing Seam Roofing Systems withstand 1kg steel balls dropped from 3-meter heights without panel penetration or coating damage, protecting buildings from hail damage that destroys conventional roofing materials.

-

Energy Efficiency and Environmental Benefits

Metal Standing Seam Roofing Systems deliver measurable energy savings through superior reflective properties and thermal performance characteristics. The natural reflectivity of metal surfaces, enhanced by specialized coatings, redirects solar radiation away from building interiors, reducing cooling loads during warm weather. PVDF coatings with 70% fluororesin content achieve reflectivity ratings of 0.65 or higher, meeting cool roof standards that qualify for energy efficiency incentives in many jurisdictions. This reflective performance translates into reduced HVAC operating costs, with property owners reporting cooling cost reductions of 20-40% compared to traditional dark-colored roofing materials. The thermal properties remain consistent throughout the roof's service life, unlike reflective coatings on other materials that degrade and lose effectiveness within years of installation. Environmental sustainability represents another compelling advantage of Metal Standing Seam Roofing Systems, addressing growing concerns about construction industry waste and resource consumption. These roofing systems achieve 100% recyclability at end-of-life, with aluminum, steel, and copper materials retaining significant scrap value that offsets demolition costs. Many Metal Standing Seam Roofing Systems incorporate substantial recycled content in their manufacturing, reducing demand for virgin materials and lowering embodied carbon footprints. The exceptional longevity of these systems, with service lives extending 30-50 years for steel and aluminum, 80+ years for zinc, and potentially exceeding 100 years for copper, drastically reduces the frequency of roof replacements compared to conventional materials requiring renewal every 15-20 years. This longevity translates into reduced landfill waste, fewer manufacturing cycles, and lower lifetime environmental impact per square meter of roof coverage.

-

Structural Performance and Customization Flexibility

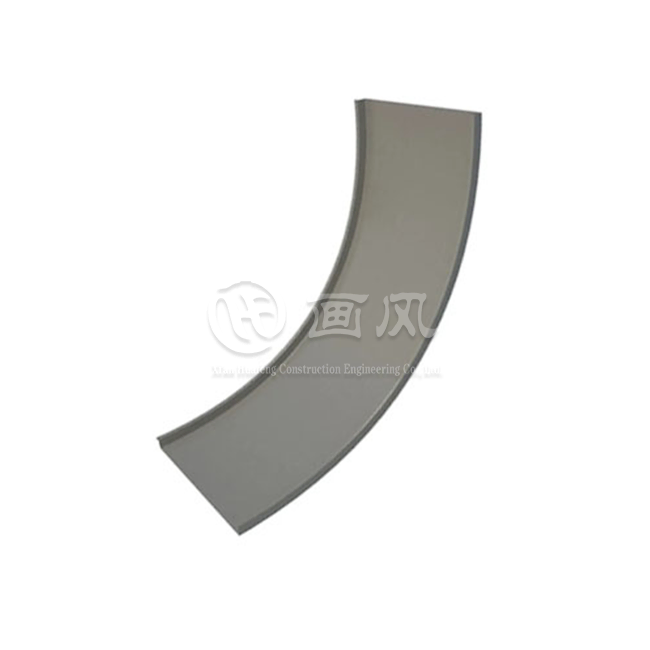

The engineering advantages of Metal Standing Seam Roofing Systems enable architectural possibilities unattainable with traditional roofing technologies. Panel lengths extending up to 13 meters without transverse seams eliminate weak points where panel-to-panel connections create opportunities for water infiltration and structural discontinuity. This continuous panel design simplifies installation on large-span structures like airports, exhibition centers, and industrial facilities while reducing material waste and labor requirements. The high-rib profiles provide exceptional structural rigidity, allowing wider spacing between roof purlins and potentially reducing structural support requirements compared to lower-profile roofing systems. This structural efficiency can yield cost savings in building framework even as roofing material costs increase, partially offsetting the premium pricing of Metal Standing Seam Roofing Systems. Customization capabilities allow Metal Standing Seam Roofing Systems to meet diverse aesthetic and functional requirements across project types. Panel widths ranging from 300-600mm accommodate various architectural scales and design preferences, while seam heights of 65mm or more create distinctive shadow lines that enhance visual interest. Color selections span virtually unlimited options through custom color-coating processes, with PE, HDP, and PVDF finishes providing different performance levels and price points. Surface treatments include glossy, matte, and textured options that complement building designs ranging from contemporary to traditional. The ability to integrate photovoltaic systems directly into the roofing assembly expands functionality beyond weather protection, enabling buildings to generate renewable energy without compromising roof integrity. These customization options ensure Metal Standing Seam Roofing Systems adapt to project-specific requirements rather than forcing design compromises.

Disadvantages and Considerations for Metal Standing Seam Roofing Systems

-

Initial Investment and Cost Implications

The most significant barrier preventing widespread adoption of Metal Standing Seam Roofing Systems remains the substantial initial investment required compared to alternative roofing technologies. Material costs for Metal Standing Seam Roofing Systems typically run two to three times higher than architectural asphalt shingles, with price premiums reflecting superior materials, precision manufacturing processes, and performance-engineered components. A project requiring exposed fastener corrugated metal roofing at approximately $8 per square foot might demand $15-20 per square foot for equivalent coverage using standing seam technology. These cost differentials become particularly pronounced on large commercial projects where total roof areas measure tens of thousands of square meters, potentially adding hundreds of thousands of dollars to construction budgets. Project decision-makers must carefully evaluate whether the performance advantages and extended service life justify the increased capital expenditure within their specific financial constraints. Installation complexity contributes additional cost premiums beyond material expenses for Metal Standing Seam Roofing Systems projects. The specialized skills required for proper installation command premium labor rates, as contractors must understand thermal movement accommodation, proper clip spacing, mechanical seaming techniques, and flashing integration details that differ substantially from conventional roofing practices. Installation time extends significantly compared to simpler roofing systems, with the precision alignment and mechanical seaming processes requiring careful attention that cannot be rushed without compromising performance. Geographic availability of qualified installers varies considerably, with some regions lacking contractors experienced in Metal Standing Seam Roofing Systems installation, potentially requiring importation of specialized labor at additional expense. These labor-related costs can increase total project expenditures by 40-60% compared to simpler roofing systems, requiring careful budgeting and financial planning during project development phases.

-

Installation Complexity and Contractor Requirements

The technical sophistication of Metal Standing Seam Roofing Systems demands installation expertise substantially exceeding requirements for conventional roofing materials. Proper installation begins with meticulous roof deck preparation, ensuring adequate ventilation, appropriate slope, and structural capacity to support the roofing system under design loads. Panel installation requires precise alignment to maintain consistent seam spacing and appearance across large roof areas, with misalignment creating visual irregularities and potential performance compromises. Clip or fastener flange installation must follow engineered spacing requirements that accommodate thermal expansion while maintaining adequate attachment strength, with improper spacing leading to fastener withdrawal, panel buckling, or inadequate wind resistance. Mechanical seaming operations demand specialized equipment and operator skill to create consistent, weathertight seams without damaging panel coatings or deforming metal substrates. The limited availability of qualified contractors creates practical challenges for property owners seeking Metal Standing Seam Roofing Systems installation. Many roofing contractors focus exclusively on asphalt shingle or built-up roofing technologies, lacking the specialized training, equipment, and experience necessary for standing seam projects. Geographic regions distant from major metropolitan areas may offer no local contractors capable of proper installation, necessitating contractor travel expenses and coordination challenges that complicate project execution. The specialized nature of this work means repairs also require experienced professionals, with panel replacement necessitating seam separation and precise reinstallation procedures that general contractors cannot perform adequately. Property owners must invest significant time identifying and vetting qualified contractors, verifying their experience with similar projects, and confirming their access to necessary specialized equipment before committing to Metal Standing Seam Roofing Systems installation.

-

Acoustic Considerations and Noise Transmission

The acoustic properties of Metal Standing Seam Roofing Systems present considerations that some building occupants find objectionable, particularly in residential applications or noise-sensitive commercial environments. Rain events create distinctive sound patterns as water droplets strike metal surfaces, producing volume levels substantially higher than experienced with asphalt shingles or tile roofing systems. Heavy downpours and hail storms generate particularly pronounced noise levels that can interfere with conversation, sleep, or concentration in spaces directly below the roof assembly. While some property occupants find these sounds pleasant and even soothing, others experience them as disruptive intrusions that diminish indoor environmental quality. The acoustic transmission varies based on roof assembly details, with solid roof decking, insulation layers, and ceiling systems moderating but not eliminating sound transmission. Mitigation strategies can reduce but rarely eliminate acoustic transmission through Metal Standing Seam Roofing Systems. Installing rigid insulation boards between roof decking and metal panels adds mass and dampening that absorbs sound energy before it enters the building structure. Increased attic insulation provides additional sound buffering, though effectiveness depends on insulation type, thickness, and installation quality. Some installations incorporate acoustic barriers or specialized underlayment products designed to interrupt sound transmission pathways. However, even with these interventions, the acoustic signature of metal roofing remains detectable during precipitation events, requiring building occupants to accept this characteristic as inherent to the roofing system. Projects involving noise-sensitive occupancies like recording studios, theaters, or healthcare facilities must carefully evaluate whether acoustic mitigation measures can achieve acceptable interior sound levels before selecting Metal Standing Seam Roofing Systems.

-

Aesthetic Integration and Oil Canning Concerns

Visual appearance considerations influence Metal Standing Seam Roofing Systems acceptance in contexts where architectural character and neighborhood compatibility matter significantly. The contemporary linear aesthetic of standing seam profiles complements modern architectural styles effectively but may appear incongruous on traditional buildings designed around different roofing materials and forms. Some homeowners associations and historic preservation districts restrict or prohibit metal roofing based on appearance concerns, requiring property owners to navigate approval processes or select alternative materials despite preferring standing seam performance characteristics. The visible panel lines and seam shadows create strong directional elements that can either enhance or conflict with building proportions depending on design execution. Color selection becomes critical to architectural success, with inappropriate choices creating visual discord regardless of roofing system performance quality. Oil canning represents a persistent aesthetic challenge affecting Metal Standing Seam Roofing Systems despite representing no structural or performance deficiency. This phenomenon manifests as visible waviness or distortion in the flat panel areas between raised seams, resulting from stress-induced deformation during manufacturing, transportation, installation, or thermal cycling. While oil canning does not compromise waterproofing or structural integrity, the visual effect often troubles property owners and architects who expect perfectly flat panel surfaces. Multiple factors contribute to oil canning including improper panel storage, over-tensioning during seaming operations, inadequate thermal expansion accommodation, and inherent material stress from coil processing. Manufacturing improvements and installation best practices minimize but cannot completely eliminate oil canning tendency, particularly in wider panel profiles and lighter gauge materials. Property owners considering Metal Standing Seam Roofing Systems must understand that some degree of panel waviness represents normal characteristics rather than defective installation, tempering aesthetic expectations accordingly.

Conclusion

Metal Standing Seam Roofing Systems deliver exceptional performance through superior weather protection, extended service life, and environmental sustainability, yet demand significant initial investment and specialized installation expertise. The decision ultimately balances upfront costs against decades of reliable protection and reduced maintenance.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

As a leading China Metal Standing Seam Roofing Systems manufacturer, China Metal Standing Seam Roofing Systems supplier, and China Metal Standing Seam Roofing Systems factory, Xi'an Huafeng Construction Engineering Co., Ltd. brings unmatched expertise to your roofing projects. Established in 2018 and recognized as a Shaanxi Province high-tech enterprise in 2020, we hold first-level building curtain wall qualifications and third-level steel structure qualifications. Our 200,000-square-meter raw material production facility in Anhui, combined with processing plants in Hangzhou and Xi'an, operates 7 color coating lines and over 40 specialized equipment units. We provide China Metal Standing Seam Roofing Systems wholesale solutions featuring high quality Metal Standing Seam Roofing Systems with competitive Metal Standing Seam Roofing Systems price structures, offering Metal Standing Seam Roofing Systems for sale with complete customization capabilities in color, pattern, and design. Our comprehensive services span structural 3D modeling, material procurement from premium brands including Alucosuper aluminum and Baosteel products, precision manufacturing with ISO9001 and ISO14000:14001 certification, and seamless installation with zero-leakage guarantee. With over 20 registered patents and successful implementations at landmark projects including Xiongan Station and Xi'an International Convention Center, we deliver one-stop solutions from raw materials to accessories. Contact our team at huafeng@hfmetalroof.com to discuss your project requirements and discover why Fortune 500 companies trust Huafeng for their critical roofing investments.

References

1. Metal Roofing Alliance, "Standing Seam Metal Roof Systems: Design and Performance Guide," Technical Publication Series

2. National Roofing Contractors Association, "Metal Panel Roof Systems Design Manual," Professional Standards Committee

3. American Society for Testing and Materials, "Standard Specifications for Metallic-Coated Steel Roofing Products," ASTM International Standards

4. Cool Roof Rating Council, "Energy Performance of Metal Roofing Systems," Research and Testing Division