Imagine walking through a bustling airport terminal, a crowded hospital corridor, or a busy shopping mall where walls endure constant contact from luggage, equipment, and daily wear. These high-traffic environments demand wall solutions that withstand relentless abuse while maintaining their aesthetic appeal. Inside Lock Metal Wall Panels deliver exceptional durability and concealed fastening systems that eliminate visible damage points, making them the preferred choice for spaces where thousands of people pass through daily. Their unique interlocking mechanism provides superior impact resistance while creating seamless, professional finishes that endure years of heavy use without showing signs of deterioration.

Understanding Inside Lock Metal Wall Panel Technology

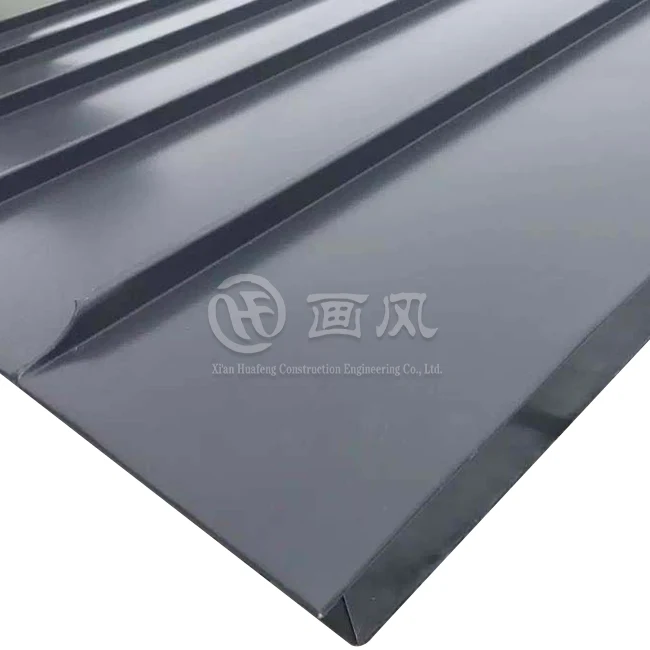

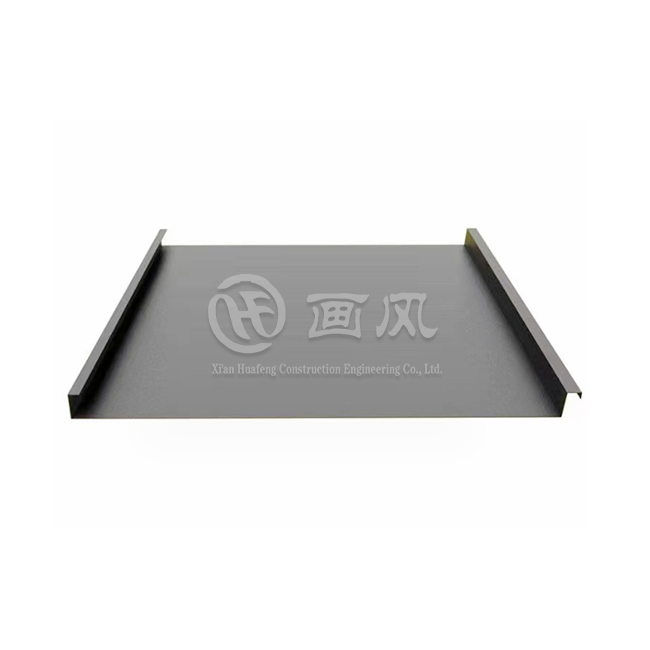

Inside Lock Metal Wall Panels represent an innovative evolution in architectural wall cladding systems, designed specifically to address the challenges faced by high-traffic commercial and institutional environments. These panels utilize a sophisticated concealed fastening system where the locking mechanism remains hidden within the panel structure, creating a smooth, uninterrupted exterior surface that resists damage and maintains visual integrity even under intensive use conditions.

-

The Engineering Behind Inside Lock Systems

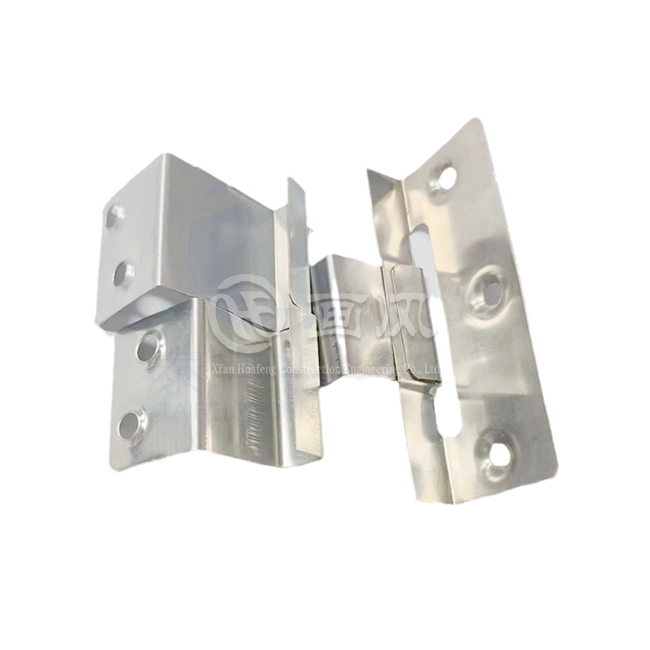

The Inside Lock Metal Wall Panels feature a precisely engineered male-and-female interlocking design that allows adjacent panels to connect securely without exposing any fasteners or vulnerable attachment points to the building's exterior. This concealed clip system uses high-strength aluminum alloy or galvanized steel components, typically ranging from 0.6mm to 1.5mm in thickness, providing structural integrity while maintaining a lightweight profile. The panels are manufactured with base materials including aluminum alloy grades AA3003, AA3004, and AA5005, as well as SGCC galvanized steel, each selected for specific performance characteristics including corrosion resistance, formability, and long-term durability. The interlocking edges are roll-formed with precision tolerances, ensuring perfect alignment during installation and creating weather-tight seals that prevent moisture intrusion and maintain thermal performance. This engineering approach eliminates the primary failure points common in traditional wall systems where exposed fasteners become targets for impact damage, corrosion, and aesthetic degradation.

-

Surface Treatment Options for Enhanced Protection

Inside Lock Metal Wall Panels receive advanced surface treatments that significantly enhance their performance in demanding environments. PVDF fluorocarbon coating provides exceptional UV resistance and color retention, maintaining the original appearance for decades even under continuous exposure to harsh environmental conditions. This coating system creates a molecular bond with the metal substrate that resists chalking, fading, and chemical degradation far better than conventional paint systems. Powder coating applications offer environmentally friendly alternatives with excellent coverage and a wide spectrum of color options, while anodizing treatments create a hardened oxide layer that provides superior wear resistance and a distinctive metallic aesthetic. These surface treatments undergo rigorous testing including salt spray exposure, adhesion testing, impact resistance verification, and accelerated weathering protocols to ensure they meet international standards including ASTM, DIN, JIS, and GB/T specifications, guaranteeing performance in the most challenging high-traffic applications.

Superior Durability in High-Impact Environments

High-traffic areas subject wall surfaces to continuous mechanical stress that quickly reveals weaknesses in inferior cladding systems. Inside Lock Metal Wall Panels excel in these demanding conditions through multiple engineering advantages that protect both the panels themselves and the underlying building structure from damage accumulation over time.

-

Impact Resistance and Structural Integrity

The concealed fastening system of Inside Lock Metal Wall Panels eliminates exposed screws and rivets that create weak points vulnerable to direct impacts from carts, equipment, luggage, and accidental collisions that occur routinely in busy spaces. When impact forces strike traditional wall systems with visible fasteners, the concentrated stress at attachment points can cause localized deformation, fastener failure, and progressive panel degradation. Inside Lock Metal Wall Panels distribute impact forces across the entire interlocking system, with the male-and-female connections acting as structural ribs that reinforce the panel assembly and prevent isolated damage from spreading to adjacent sections. The metal substrates, whether aluminum alloy or galvanized steel, possess inherent resilience that allows them to absorb significant impact energy without permanent deformation, returning to their original profile after moderate collisions. This characteristic proves invaluable in locations such as hospital corridors where medical equipment constantly contacts walls, airport terminals where rolling luggage creates repetitive impacts, educational facilities where student traffic generates unpredictable mechanical stresses, and retail environments where merchandising activities subject walls to frequent contact.

-

Long-Term Performance and Maintenance Advantages

Inside Lock Metal Wall Panels deliver exceptional long-term value through their minimal maintenance requirements and sustained performance characteristics. The non-porous surface treatments applied to these panels resist staining, dirt accumulation, and biological growth, maintaining their appearance with simple cleaning protocols using standard commercial cleaning agents. Unlike porous materials that absorb contaminants and require intensive restoration efforts, Inside Lock Metal Wall Panels can be returned to like-new condition through basic washing procedures, significantly reducing lifecycle maintenance costs. The corrosion-resistant properties of properly treated aluminum and steel substrates ensure structural integrity remains uncompromised even in environments with elevated humidity, chemical exposure, or aggressive atmospheric conditions. Manufacturers typically provide 30-year warranties on properly installed systems, reflecting confidence in the materials' ability to maintain both aesthetic and functional performance throughout decades of continuous service. This durability translates directly into lower total cost of ownership for building operators, eliminating frequent replacement cycles and reducing disruption to occupied spaces.

Installation Efficiency and System Flexibility

The design sophistication of Inside Lock Metal Wall Panels extends beyond their performance characteristics to encompass installation advantages that reduce project costs and minimize disruption in occupied facilities, making them particularly attractive for renovation projects in operational buildings.

-

Streamlined Installation Process

Inside Lock Metal Wall Panels feature installation systems that significantly accelerate construction schedules compared to traditional wall cladding methods. The concealed clip mechanism allows panels to be positioned and secured from the interior side of the wall assembly, eliminating the need for visible fastener installation that requires precise alignment and surface finishing. Experienced installation teams can complete large wall areas rapidly because the interlocking design provides inherent alignment guidance, preventing the cumulative errors that plague systems requiring individual fastener placement. Panel widths ranging from 300mm to 600mm, with customizable lengths extending up to 12 meters, allow installers to minimize joints and create expansive continuous surfaces with fewer seams. The lightweight nature of aluminum and steel panels, typically one-third the weight of comparable solid metal cladding, reduces handling requirements and allows smaller crews to manage installation efficiently. This installation efficiency proves particularly valuable in high-traffic facilities where construction activities must be scheduled during limited closure windows or performed in occupied spaces with minimal disruption to normal operations.

-

Customization Capabilities for Complex Applications

Modern architectural projects increasingly demand unique design solutions that differentiate spaces while meeting rigorous performance standards. Inside Lock Metal Wall Panels accommodate these requirements through extensive customization options that maintain the system's performance advantages while achieving specific aesthetic objectives. Panel profiles can be manufactured to create flat surfaces, subtle reveals, or pronounced dimensional patterns that add visual interest and enhance spatial perception. Color selections extend across the entire spectrum through custom coating processes, with the ability to match specific brand colors, coordinate with existing architectural elements, or create distinctive accent features. Surface textures ranging from smooth metallic finishes to embossed patterns provide tactile variety and can be engineered to reduce glare, minimize apparent damage from minor scratching, or create specific visual effects under varying lighting conditions. This customization flexibility allows architects and designers to specify Inside Lock Metal Wall Panels for applications ranging from minimalist modern aesthetics to complex traditional treatments, all while maintaining the superior durability and concealed fastening advantages that make these systems ideal for high-traffic environments.

Application-Specific Advantages Across Building Types

Different building types present unique challenges for wall systems in high-traffic areas, and Inside Lock Metal Wall Panels offer specific advantages tailored to each application category, demonstrating their versatility across diverse project requirements.

-

Healthcare and Institutional Facilities

Healthcare facilities impose extraordinarily demanding requirements on wall systems, combining high traffic volumes with stringent hygiene standards and regulatory compliance mandates. Inside Lock Metal Wall Panels meet these challenges through multiple performance attributes specifically relevant to medical environments. The non-porous metal surfaces resist bacterial colonization and can withstand aggressive cleaning protocols using hospital-grade disinfectants, antimicrobial agents, and harsh chemical compounds without surface degradation. The concealed fastening system eliminates crevices and recesses where contaminants can accumulate, supporting infection control objectives and simplifying cleaning verification procedures. Class A fire-rated configurations comply with building codes applicable to healthcare occupancies, providing critical safety performance in environments where evacuation capabilities may be limited. The impact resistance proves valuable in corridors where medical equipment, beds, and wheelchairs constantly contact walls, while the acoustic properties of properly designed Inside Lock Metal Wall Panel systems can contribute to noise control objectives essential for healing environments. Projects such as hospital operating rooms, diagnostic imaging suites, patient corridors, and public waiting areas benefit from the combination of hygiene, durability, and aesthetic quality that Inside Lock Metal Wall Panels deliver.

-

Transportation and Commercial Applications

Transportation facilities including airports, railway stations, metro systems, and bus terminals represent the ultimate high-traffic environment, with thousands or millions of passengers passing through daily while managing luggage, equipment, and personal belongings that constantly contact architectural surfaces. Inside Lock Metal Wall Panels excel in these applications through their exceptional impact resistance, minimal maintenance requirements, and ability to maintain appearance despite intensive use. The concealed fastening system proves particularly valuable in preventing vandalism damage and reducing graffiti adhesion, as the smooth metal surfaces can be cleaned more effectively than textured materials. Commercial applications including shopping centers, retail stores, corporate lobbies, and hospitality venues benefit from the premium aesthetic that Inside Lock Metal Wall Panels provide while gaining practical advantages in maintenance cost reduction and long-term durability. Educational facilities from elementary schools through universities experience similar benefits, with wall systems that withstand the particular challenges of high-occupancy environments populated by young people.

Why Xi'an Huafeng Construction Engineering Co., Ltd. Leads Inside Lock Metal Wall Panel Innovation?

Selecting the right manufacturer for Inside Lock Metal Wall Panels proves as critical as choosing the system itself, as manufacturing quality, technical support, and supply chain reliability directly impact project success and long-term system performance.

-

Manufacturing Excellence and Quality Assurance

Xi'an Huafeng Construction Engineering Co., Ltd. operates three dedicated manufacturing facilities with seven color coating production lines, one laminating production line, ten longitudinal and transverse shearing production lines, and more than 40 specialized machines for panel fabrication and forming operations. This extensive manufacturing infrastructure, covering over 200,000 square meters in Anhui with additional processing facilities in Hangzhou and Xi'an, enables production capacity exceeding 1,000 tons monthly with consistent quality control throughout all manufacturing stages. The company's rigorous incoming material inspection processes verify raw material quality through comprehensive testing including appearance verification, dimensional accuracy, salt spray resistance, adhesion testing, hardness measurement, impact resistance, film thickness confirmation, acid resistance, weathering performance, and color consistency evaluation. Every panel undergoes finished product inspection covering appearance, dimensions, flatness, and curvature before protective packaging designed to ensure damage-free delivery to project sites. This quality commitment, reinforced through ISO9001, ISO14000:14001, and SGS certifications along with more than 20 registered patents for roofing and wall systems, ensures Inside Lock Metal Wall Panels from Xi'an Huafeng meet the highest international standards for performance and reliability.

-

Comprehensive Project Support and Technical Expertise

Xi'an Huafeng Construction Engineering Co., Ltd. provides complete project support extending beyond panel manufacturing to encompass design optimization, technical consultation, and installation guidance that maximizes system performance and project value. The company's experienced design department conducts detailed drawing development, creating 1:1 scale node details and processing drawings that ensure perfect fit during field installation. Custom sample production allows project stakeholders to verify material specifications, colors, finishes, and dimensional characteristics before committing to full production, eliminating uncertainty and ensuring satisfaction with final results. On-site technical support includes pre-installation site verification, installation supervision, and post-completion testing to verify zero leakage performance and complete system integrity. This comprehensive approach, developed through successful execution of major projects including Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, Xi'an Station East Auxiliary Building, Jinghe New City International Culture and Art Center, and Inner Mongolia Tongliao Art Museum, demonstrates the company's capability to deliver complex Inside Lock Metal Wall Panel installations that meet rigorous performance and aesthetic standards.

Conclusion

Inside Lock Metal Wall Panels provide unmatched durability, impact resistance, and aesthetic quality for high-traffic environments through concealed fastening technology, superior materials, and advanced surface treatments. Their proven performance across healthcare, transportation, commercial, and institutional applications demonstrates their versatility and long-term value.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 and recognized as a high-tech enterprise in Shaanxi Province, specializes in metal roofing systems, building curtain wall systems, and steel structure enclosure solutions with first-level curtain wall qualifications and third-level steel structure qualifications. Our three factories with seven production lines and over 40 specialized machines deliver consistent quality backed by more than 20 patents, ISO9001, ISO14000:14001, and SGS certifications. As a leading China Inside Lock Metal Wall Panels factory, China Inside Lock Metal Wall Panels supplier, and China Inside Lock Metal Wall Panels manufacturer, we offer China Inside Lock Metal Wall Panels wholesale, competitive Inside Lock Metal Wall Panels price, Inside Lock Metal Wall Panels for sale, and High Quality Inside Lock Metal Wall Panels with 30-year warranties, customizable specifications, 15-20 day delivery, and comprehensive design-to-installation services. Contact huafeng@hfmetalroof.com today to discuss your project requirements and receive a detailed quotation for your high-traffic wall system needs.

References

1. American Institute of Architects. Metal Wall Systems: Design and Performance Standards for High-Traffic Applications. Authors: Morrison, J.R. and Thompson, K.L.

2. International Code Council. Building Code Requirements for Wall Systems in Public Assembly and Healthcare Facilities. Authors: Davidson, M.P. and Wu, S.H.

3. National Association of Architectural Metal Manufacturers. Concealed Fastening Systems for Commercial Wall Cladding: Installation and Performance Guidelines. Authors: Bennett, R.T. and Lopez, C.A.

4. Society for Protective Coatings. Surface Treatment Technologies for Metal Building Panels in Corrosive and High-Impact Environments. Authors: Anderson, P.J. and Zhang, W.Q.