When contractors face project failures from traditional roofing systems that leak, degrade, or require constant maintenance, they increasingly turn to standing seam pitched metal roof systems as their preferred solution. The Standing Seam Pitched Metal Roof offers unmatched durability, weather resistance, and long-term cost efficiency, making it the intelligent choice for commercial, industrial, and high-end residential applications where performance cannot be compromised.

What Makes Standing Seam Pitched Metal Roof Systems the Contractor's First Choice?

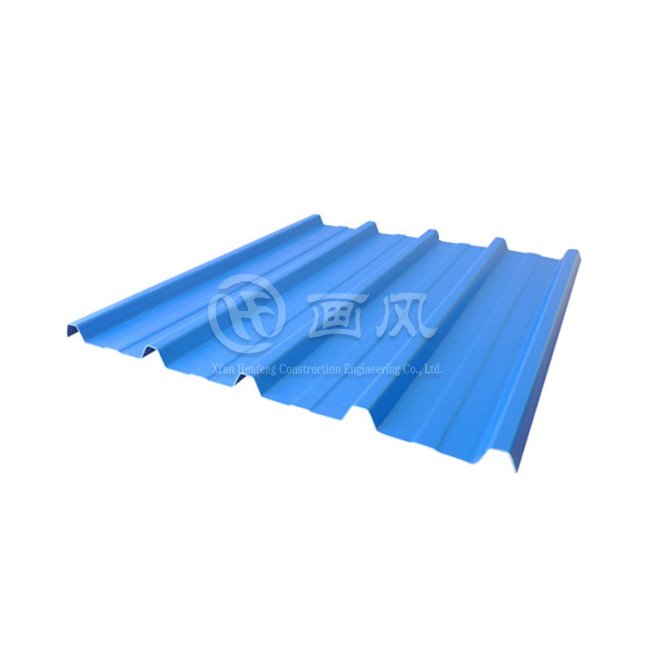

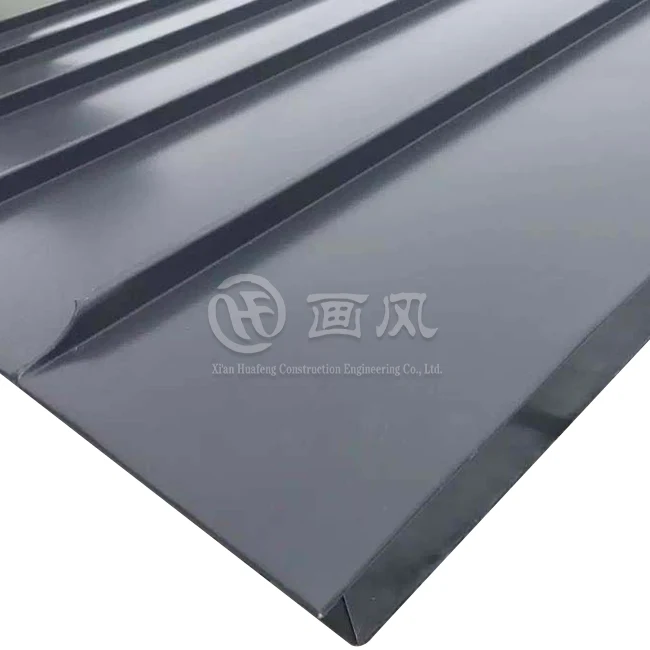

Contractors are experiencing a fundamental shift in their roofing material preferences, and standing seam pitched metal roof systems have emerged as the dominant choice for quality-conscious professionals. This transformation stems from several critical factors that directly impact project success, client satisfaction, and long-term profitability. The Standing Seam Pitched Metal Roof distinguishes itself through its innovative concealed fastener design, where panels interlock mechanically without exposing screws or nails to weather elements. This engineering approach eliminates the primary failure point of traditional roofing systems, where thousands of penetrations through the roof surface create vulnerability to water infiltration, thermal cycling stress, and premature degradation. Professional contractors recognize that a typical screw-down metal roof requires approximately 70 fasteners per square, translating to over 2,300 potential leak points on an average residential project. In contrast, standing seam systems use hidden clips that allow panels to expand and contract naturally while maintaining complete weather-tight integrity throughout decades of service. The material specifications available for standing seam pitched metal roofing provide contractors with exceptional versatility. Panel systems ranging from 25mm to 45mm rib heights, with widths from 300mm to 600mm, accommodate diverse architectural requirements and slope conditions. The availability of premium materials including aluminum-magnesium-manganese alloys, zinc-titanium compositions, copper, and stainless steel allows contractors to match performance characteristics precisely to project demands and environmental conditions. Surface treatments utilizing PVDF and PE coating technologies deliver superior color retention and corrosion resistance, with manufacturers confidently backing their products with 30-year warranties that protect both contractor reputation and client investment.

-

Enhanced Performance Through Engineering Excellence

The engineering sophistication embedded in Standing Seam Pitched Metal Roof systems represents a quantum leap beyond conventional roofing technologies. These systems undergo rigorous testing protocols established by ASTM, UL, and FM Approvals, ensuring verified performance under extreme conditions including hurricane-force winds, heavy snow loads, and intense thermal cycling. Contractors appreciate the quantifiable assurance these certifications provide when specifying materials for critical applications where failure is not an option. The hydrostatic and hydrokinetic properties of standing seam systems adapt to specific pitch requirements, with mechanically seamed profiles performing reliably on slopes as low as 0.5:12, while snap-lock configurations excel on pitches of 3:12 and above. This adaptability empowers contractors to apply standing seam technology across virtually any architectural configuration, from nearly flat commercial structures to steeply pitched residential designs. The mechanical seaming process creates a double-lock joint that can withstand static water pressure during intense rainfall events, a performance level that snap-together systems cannot match on lower slopes. Manufacturing precision directly influences installation success and long-term performance. Advanced roll-forming systems with real-time quality control produce panels with dimensional accuracy measured in fractions of millimeters, ensuring perfect alignment during installation and eliminating the fit-up problems that plague lesser systems. Contractors working with premium manufacturers benefit from raw material traceability that documents the provenance of every aluminum alloy, steel substrate, and coating formulation, providing comprehensive quality assurance from foundry to finished installation.

The Economic Advantages Driving Contractor Adoption

-

Lifecycle Cost Analysis Reveals Superior Value

Forward-thinking contractors have moved beyond initial material cost comparisons to embrace comprehensive lifecycle cost analysis, and this analytical approach consistently favors Standing Seam Pitched Metal Roof systems. While the upfront investment exceeds alternatives like asphalt shingles or exposed fastener metal panels, the total cost of ownership calculation over a 30 to 50-year service life demonstrates substantial economic advantages. The maintenance burden of traditional roofing systems creates ongoing expense that erodes profit margins and damages contractor-client relationships. Exposed fastener systems require periodic inspection and replacement of degrading washers and screws, with each service visit incurring labor costs and creating liability exposure. Standing seam systems eliminate this recurring expense through their concealed fastener design, where clips remain protected beneath panels and never require replacement. The PVDF paint systems applied to premium standing seam products maintain color integrity and corrosion resistance for three decades without significant fading or degradation, eliminating the repainting costs associated with lesser coating technologies. Energy performance represents another dimension of economic value that sophisticated contractors leverage when presenting proposals to environmentally conscious clients. The natural reflective and emissive properties of metal roofing, enhanced by cool-metal coating technologies, reduce cooling loads by up to 25 percent in hot climates. This performance advantage translates directly to reduced HVAC system sizing requirements during construction and lower utility expenses throughout the building's operational life, creating quantifiable value that justifies premium material investment.

-

Risk Mitigation Through Proven Reliability

Contractor businesses thrive on reputation, and standing seam pitched metal roof systems provide the reliability foundation that builds lasting professional credibility. The comprehensive warranties offered by established manufacturers, including weathertight guarantees that protect against water infiltration failures, transfer financial risk away from contractors and onto well-capitalized manufacturing entities with proven track records. The reduced maintenance requirements and extended service life of Standing Seam Pitched Metal Roof systems minimize callback risks that consume contractor resources and damage profitability. When installations are executed properly using quality materials and experienced installation crews, these systems perform flawlessly for decades without generating the complaint calls and emergency repairs that plague contractors working with inferior roofing technologies. This reliability advantage allows forward-thinking contractors to build sustainable business models based on new construction and planned renovation work rather than constantly firefighting maintenance emergencies on previously completed projects.

Installation Efficiency and Technical Superiority

-

Streamlined Construction Processes

Modern standing seam pitched metal roof installation has evolved into a highly efficient process when executed by properly trained crews equipped with appropriate tools. On-site roll-forming equipment allows contractors to produce custom-length panels that eliminate end laps and reduce material waste, while portable seaming machines ensure consistent joint quality regardless of weather conditions or operator experience level. The clip attachment system used in Standing Seam Pitched Metal Roof installations provides significant advantages during the construction phase. Clips fasten directly to the roof deck or structural purlins, creating secure attachment points that do not penetrate the metal panels themselves. This approach dramatically reduces installation time compared to screw-down systems that require precise placement of thousands of individual fasteners, with each attachment point requiring pilot hole drilling, fastener installation, and washer inspection to ensure proper compression without overtightening. Panel alignment and joint formation represent critical quality control points where standing seam systems demonstrate clear superiority. The male and female panel legs are precisely formed during the roll-forming process, ensuring perfect fit-up when panels are positioned for seaming. Mechanical seaming machines crimp the panel legs together with controlled force that creates uniform joint strength along the entire seam length, eliminating the human variability that compromises hand-formed joints. Snap-lock systems provide even faster installation on appropriate pitch conditions, with panels simply snapping together over pre-positioned clips without requiring additional tooling or specialized techniques.

-

Quality Control and Installation Standards

Professional contractors understand that material quality means nothing without proper installation execution, and standing seam systems demand higher skill levels than simpler roofing technologies. This reality creates a competitive advantage for contractors who invest in training, proper equipment, and experienced installation crews capable of delivering the craftsmanship these premium systems require. The limited availability of qualified standing seam contractors actually benefits those professionals who develop these capabilities, creating market differentiation that supports premium pricing and selective project acceptance. Clients seeking superior roofing performance quickly learn that not all contractors possess the expertise to install standing seam systems properly, driving qualified contractors toward them and away from less sophisticated competitors who cannot deliver comparable quality.Installation protocols for standing seam pitched metal roofing extend beyond simple panel placement to encompass comprehensive waterproofing strategies at critical transition points. Proper flashing design and installation at roof-to-wall intersections, penetrations, valleys, and eave conditions requires detailed understanding of water management principles and meticulous execution that cannot be compromised. Contractors who master these technical details produce installations that perform flawlessly throughout their design life, while those who cut corners create failure risks that damage their professional reputation.

Aesthetic Versatility and Architectural Integration

-

Modern Design Language Meets Functional Performance

The clean, contemporary appearance of Standing Seam Pitched Metal Roof systems resonates with architects, developers, and building owners seeking distinctive aesthetics that set their projects apart from conventional construction. The strong vertical lines created by raised panel seams create visual rhythm and shadow patterns that enhance architectural character, particularly on complex roof geometries where panel runs emphasize building forms and structural elements. Color selection flexibility empowers designers to achieve precise aesthetic visions while maintaining the technical performance that contractors demand. The availability of diverse RAL and Pantone color formulations, applied using durable PVDF coating systems, ensures that specified colors remain vibrant and true throughout decades of exposure to ultraviolet radiation and weather elements. Custom color matching services offered by premium manufacturers allow contractors to satisfy even the most demanding design requirements while delivering products backed by comprehensive warranties. The material palette available for standing seam applications spans from utilitarian galvalume steel to exotic copper and zinc-titanium alloys, each offering distinct aesthetic character and performance attributes. Contractors working on high-visibility projects appreciate the design flexibility this material diversity provides, allowing them to propose solutions that balance aesthetic objectives, performance requirements, and budget parameters while maintaining their commitment to quality and longevity.

-

Versatile Application Across Building Types

The adaptability of Standing Seam Pitched Metal Roof systems extends across virtually every building category, from massive industrial facilities to intimate residential structures. Large-scale commercial applications benefit from the system's ability to cover expansive areas without horizontal joints, reducing leak potential while accelerating construction schedules through efficient panel installation. The self-supporting structural capabilities of heavier-gauge systems allow direct attachment to purlins without solid decking, reducing material costs and structural dead loads on commercial projects. Residential applications showcase standing seam technology's aesthetic sophistication, with sleek panel profiles enhancing curb appeal and property values. Contractors increasingly specify standing seam for accent applications on mixed-material roofs, where metal panels highlight architectural features like front porches, dormers, and bay window covers while providing superior weather protection at vulnerable transition points. These accent applications introduce homeowners to standing seam performance benefits at accessible price points, building market awareness and future demand for complete roof systems. Institutional and public buildings represent another growth sector for standing seam pitched metal roofing, where life-cycle cost considerations, sustainability requirements, and aesthetic aspirations align perfectly with the system's strengths. Contractors serving this market segment leverage the comprehensive testing documentation, fire-resistance ratings, and environmental certifications that standing seam systems provide to satisfy stringent procurement requirements while delivering installations that perform flawlessly throughout extended service lives.

Sustainability and Environmental Responsibility

The construction industry faces increasing pressure to reduce environmental impacts, and Standing Seam Pitched Metal Roof systems provide contractors with credible sustainability advantages that resonate with environmentally conscious clients. Metal roofing materials contain significant recycled content, with steel panels typically incorporating 25 to 95 percent post-consumer recycled material depending on grade and supplier. At the end of their service life, metal roofing panels retain full recyclability, returning to the material stream without degradation or downcycling into lower-value applications. Energy efficiency represents another critical sustainability dimension where standing seam systems excel. The reflective properties of metal surfaces, enhanced by specialized cool-metal coating formulations, dramatically reduce solar heat gain compared to asphalt shingles and other conventional materials. This thermal performance reduces cooling energy consumption, shrinks carbon footprints, and contributes to LEED certification point accumulation on projects pursuing green building recognition. Contractors who understand and articulate these benefits position themselves as sustainability partners rather than mere material suppliers. The exceptional durability and extended service life of standing seam pitched metal roofing deliver profound sustainability advantages by eliminating the resource consumption and waste generation associated with premature roof replacement. When a properly installed standing seam system serves a building for 50 years or more, it avoids the two or three replacement cycles required for short-lived alternatives, preventing thousands of pounds of waste material from reaching landfills while eliminating the manufacturing energy and transportation emissions embodied in replacement materials.

Conclusion

Standing seam pitched metal roof systems have earned their position as the preferred choice among quality-focused contractors through demonstrated superiority in performance, durability, aesthetic versatility, and life-cycle economics, making them the intelligent solution for projects where excellence cannot be compromised and long-term value matters.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a China Standing Seam Pitched Metal Roof manufacturer and China Standing Seam Pitched Metal Roof supplier of exceptional capability, offering comprehensive solutions from engineering design through final installation. Established in 2018 and recognized as a high-tech enterprise in Shaanxi Province, Huafeng operates three production facilities with seven color coating lines and more than 40 advanced processing machines, delivering 1,000 tons monthly production capacity backed by ISO 9001, ISO 14001, and SGS certifications.

Our Standing Seam Pitched Metal Roof for sale encompasses aluminum-magnesium-manganese alloys, zinc-titanium compositions, copper, and stainless steel in thicknesses from 0.4mm to 1.2mm, with panel specifications including 25-330/400/430, 32-410, and 45-300/400/500 configurations. As a China Standing Seam Pitched Metal Roof wholesale provider, we offer High Quality Standing Seam Pitched Metal Roof systems with PVDF/PE surface treatments in diverse RAL and Pantone colors, all manufactured to ASTM, DIN, JIS, BS, and GB/T standards with competitive Standing Seam Pitched Metal Roof price positioning.

Our one-stop solution encompasses structural 3D modeling, drainage system simulation, material specification advisory, precision roll-forming manufacturing with real-time quality control, comprehensive raw material traceability, on-site project management, and safety compliance documentation. With successful installations at Xiongan Station, Xi'an International Convention and Exhibition Center, and Inner Mongolia Tongliao Art Museum, Huafeng delivers proven excellence backed by 30-year warranties and 15-20 day delivery schedules. Contact our technical team at huafeng@hfmetalroof.com to discuss your standing seam pitched metal roof requirements and discover why discerning contractors worldwide trust Huafeng for their most demanding projects.

References

1. Metal Roofing Alliance. "Standing Seam Metal Roofing Systems: Design and Installation Guidelines." Technical Publication Series, National Roofing Contractors Association.

2. Sheffield Metals International. "Comprehensive Guide to Standing Seam Metal Roof Systems." Industry Technical Manual, Construction Specifications Institute Format.

3. McElroy Metal Manufacturing. "Roof Slope and Panel Selection: Engineering Considerations for Standing Seam Applications." Technical Bulletin Series, Metal Construction Association.

4. ASTM International Standards Organization. "Standard Test Methods for Metal Roof Panel Systems." Performance Testing Protocols, Construction Materials Division.

(1)_1763110678300.webp)