Homeowners frustrated with frequent siding maintenance, weather damage, or outdated aesthetics often struggle to find durable, attractive exterior solutions. This guide explores the five best metal siding options, including Vertical Metal Siding Sheets, that combine exceptional longevity, minimal upkeep, and modern design flexibility to transform your home's exterior while providing superior protection against harsh weather conditions.

Understanding Metal Siding Materials and Performance

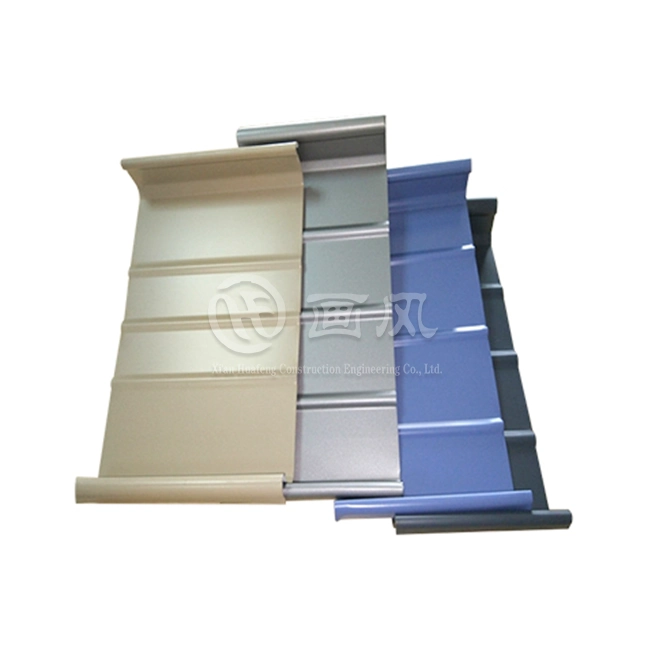

Selecting the right metal siding begins with understanding the core materials available and how they perform in different environments. The construction industry has developed sophisticated metal cladding technologies that address common homeowner concerns about durability, maintenance, and aesthetics. Vertical Metal Siding Sheets have emerged as a leading solution because they offer structural advantages alongside visual appeal. The vertical orientation naturally channels water downward, reducing moisture retention and simplifying cleaning compared to horizontal installations. Modern manufacturing processes ensure these panels meet rigorous quality standards including ISO9001 and ISO14000:14001 certifications, guaranteeing consistent performance across diverse climatic conditions. When evaluating metal siding materials, homeowners should consider galvanized steel for its corrosion resistance, aluminum-magnesium-manganese alloys for coastal environments, and specialized coatings like PVDF that provide superior fade resistance with warranties extending thirty years or more. The specifications of quality Vertical Metal Siding Sheets typically include thickness options ranging from 0.4mm to 1.2mm, with various profile configurations designed to enhance both strength and architectural character.

-

Galvanized Steel and Aluminum-Magnesium-Manganese Alloys

Galvanized steel represents the most popular choice for residential and commercial metal siding applications due to its exceptional strength-to-cost ratio. The galvanization process applies a protective zinc coating that prevents rust formation even when the surface experiences minor scratches or abrasions. For projects requiring enhanced corrosion protection, galvalume steel combines aluminum and zinc coatings to deliver superior rust resistance in humid or coastal regions. Aluminum-magnesium-manganese alloys offer distinct advantages for specific applications, particularly where weight reduction matters or salt air exposure presents challenges. These lightweight panels simplify installation while maintaining structural integrity comparable to heavier steel alternatives. The alloy composition naturally resists oxidation without requiring additional protective coatings, though manufacturers typically apply premium finishes to enhance color retention and aesthetic appeal. Professional installation ensures proper fastening techniques that accommodate thermal expansion while maintaining weathertight seals. Vertical Metal Siding Sheets manufactured from these advanced alloys combine the natural corrosion resistance of aluminum with the improved strength characteristics provided by magnesium and manganese additions, resulting in panels that excel in demanding environmental conditions while supporting customized color and pattern specifications for architectural distinctiveness.

The Five Superior Metal Siding Options

-

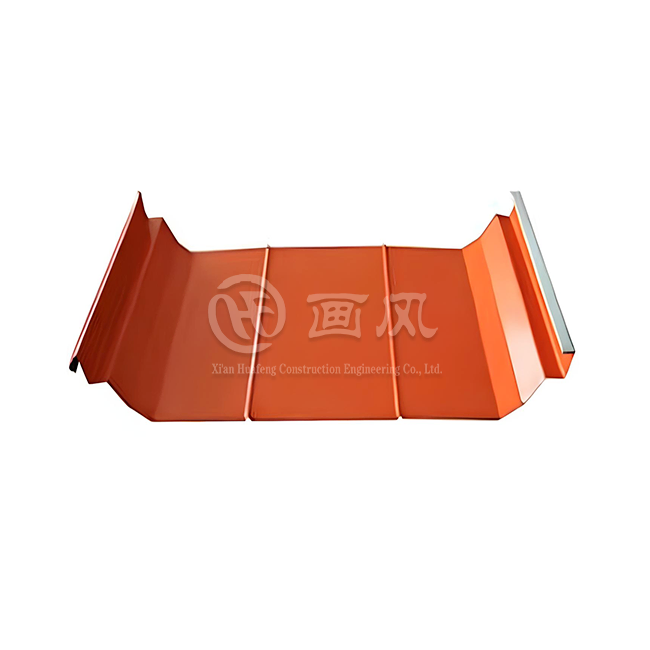

Standing Seam Vertical Metal Siding Sheets

Standing seam panels represent the pinnacle of contemporary metal siding design, featuring concealed fastener systems that create clean, uninterrupted vertical lines across building facades. These Vertical Metal Siding Sheets utilize raised seams that interlock adjacent panels while hiding all mechanical connections beneath weather-resistant caps. The concealed fastening approach eliminates potential water entry points associated with exposed screws, significantly enhancing long-term weatherproofing performance. Standing seam systems accommodate thermal movement through specialized clips that allow panels to expand and contract without stressing fasteners or creating buckling. This engineering sophistication translates into installations that maintain dimensional stability across temperature fluctuations ranging from extreme cold to intense summer heat. The vertical orientation naturally sheds water, snow, and debris more effectively than horizontal configurations, reducing maintenance requirements while minimizing moisture-related deterioration risks. Manufacturers offer standing seam Vertical Metal Siding Sheets in widths typically spanning twelve to twenty-four inches with custom length capabilities extending forty feet, enabling continuous panel coverage that eliminates horizontal seams on most residential and commercial structures. Premium coating options including polyester, high-durability polyester, and PVDF formulations provide color retention guarantees spanning decades, ensuring the architectural vision remains vibrant throughout the building's service life. Installation requires specialized tools and experienced contractors familiar with proper seaming techniques, but the investment delivers superior aesthetics and performance that justify the additional complexity compared to exposed fastener alternatives.

-

Corrugated Metal Panels with Vertical Installation

Corrugated metal siding brings industrial character and proven durability to residential applications through its distinctive wave pattern that adds both visual interest and structural rigidity. The repeating peaks and valleys of corrugated profiles create natural drainage channels that efficiently manage water runoff while the profile geometry significantly increases panel strength compared to flat sheets of equivalent thickness. When installed vertically, corrugated Vertical Metal Siding Sheets amplify these performance advantages by aligning the corrugations parallel to gravity, ensuring water flows directly downward without lateral migration across the surface. This orientation particularly benefits regions experiencing heavy rainfall or frequent washing needs, as the vertical channels prevent sediment accumulation and simplify cleaning maintenance. The exposed fastener installation method used with most corrugated panels reduces complexity and cost compared to concealed systems, making them accessible for skilled DIY enthusiasts willing to invest time learning proper installation techniques. Manufacturers produce corrugated Vertical Metal Siding Sheets in various profile depths and spacing patterns, with deeper corrugations providing enhanced strength for applications requiring additional wind load resistance or spanning capabilities between structural supports. Modern corrugated panels feature advanced coating systems that eliminate the dated "shed roof" appearance some homeowners associate with older agricultural metal buildings. Premium finishes in sophisticated color palettes enable corrugated siding to complement contemporary architectural styles while delivering the maintenance advantages and longevity expectations that drive metal siding adoption across residential markets.

-

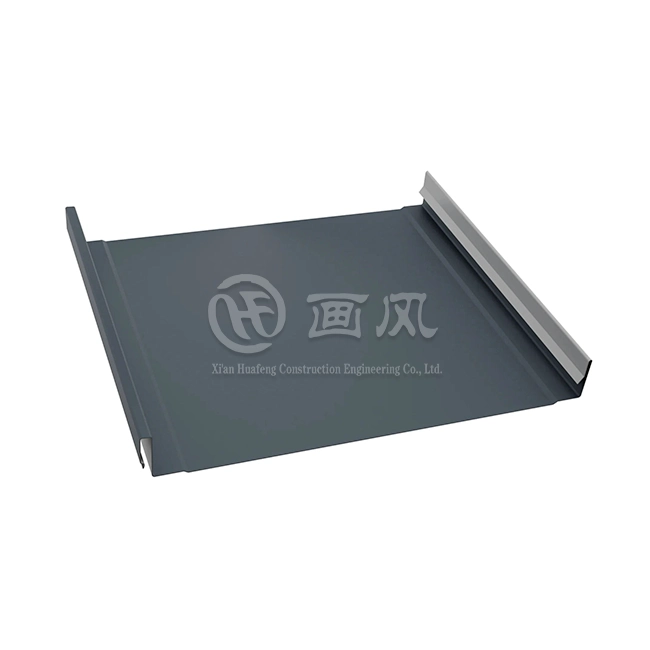

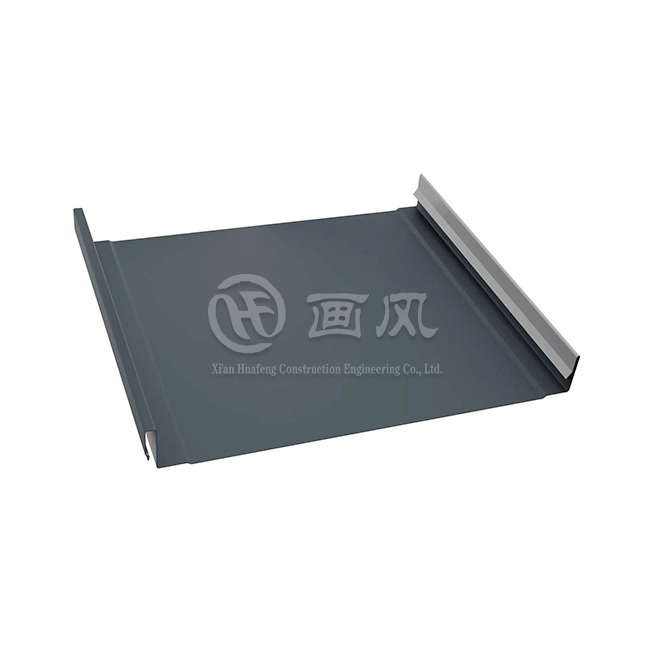

Flat Lock Panel Systems

Flat lock panels deliver smooth, sophisticated surfaces that create minimalist aesthetics particularly suited to modern and transitional architectural styles. These Vertical Metal Siding Sheets employ interlocking seam designs that create flush exterior surfaces with subtle reveal lines delineating individual panels. The flat profile provides a refined canvas for exploring color and finish variations without the visual texture introduced by ribbed or corrugated alternatives. Manufacturers offer flat lock systems in various seam widths and reveal depths, allowing designers to modulate the scale and rhythm of the siding pattern to harmonize with building proportions and architectural details. The concealed fastening approach maintains the clean visual character while delivering weatherproofing performance comparable to standing seam installations. Flat lock panels particularly excel in applications where the siding interacts with other materials such as glass curtain walls, natural stone accents, or wood elements, as the understated profile complements rather than competes with adjacent design features. Installation requires precise measurement and careful attention to panel alignment, as the flat surface makes any installation irregularities immediately visible. Quality installations demonstrate laser-straight seam lines that emphasize the geometric precision inherent in contemporary design philosophies. The smooth exterior surface simplifies maintenance by eliminating crevices where dirt accumulates and streamlines periodic cleaning with simple washing techniques. Flat lock Vertical Metal Siding Sheets accommodate customization through color selection, metallic finishes, and pattern variations that enable unique architectural expressions while maintaining the superior durability and low maintenance characteristics that define premium metal cladding systems.

-

Ribbed and Box Rib Vertical Profiles

Ribbed metal siding panels feature regular vertical grooves that create visual rhythm while enhancing structural performance through geometric strengthening. The rib pattern distributes loads more effectively than flat panels of equivalent gauge, enabling lighter weight installations that reduce structural demands on building frames while maintaining required wind load resistance and impact protection. Box rib profiles, characterized by squared rib shapes with flat areas between raised sections, provide a distinctly modern aesthetic that appeals to commercial and residential applications seeking contemporary character. The 7.2-inch spacing commonly used in box rib systems creates a balanced visual proportion that works across various building scales from compact residential additions to expansive commercial facades. Vertical Metal Siding Sheets with ribbed profiles offer practical advantages beyond aesthetics, as the raised ribs create shadow lines that add depth and dimension to building exteriors while effectively concealing minor surface irregularities that might appear obvious on completely flat installations. The rib configuration also improves panel stiffness, reducing oil-canning effects where flat metal surfaces can appear wavy under certain lighting conditions. Installation typically employs exposed fasteners placed through the flat areas between ribs, creating a straightforward mounting approach that controls costs while delivering reliable long-term attachment. The fastener locations remain visible but the ribbed pattern draws attention away from the mechanical connections, maintaining an attractive appearance. Manufacturers produce ribbed Vertical Metal Siding Sheets in various rib heights and spacing patterns, with deeper ribs providing more pronounced shadow effects and enhanced structural capabilities suitable for applications requiring extended spans between supports or additional resistance to wind pressures common in exposed locations or regions prone to severe weather events.

-

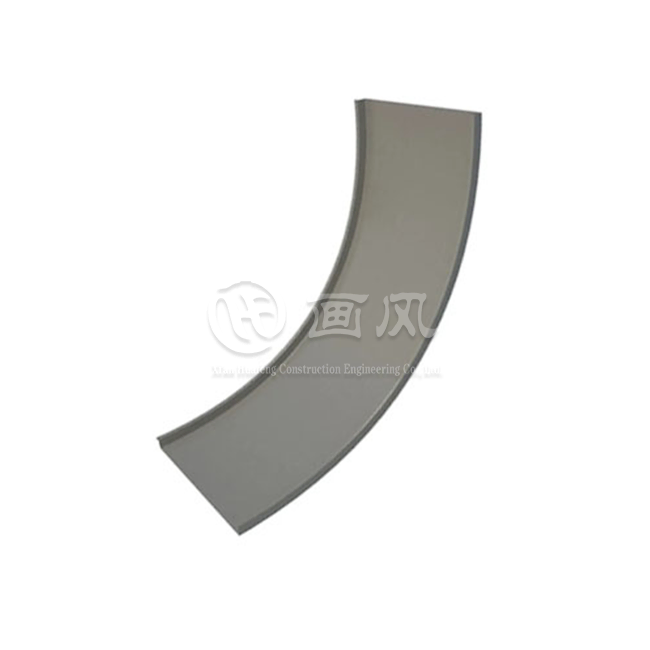

Batten-Seam Architectural Panels

Batten-seam metal siding creates traditional architectural character through raised seam caps that emphasize the vertical panel divisions while providing weather protection and visual interest. This design traces its heritage to European roof cladding traditions but translates effectively to wall applications where the prominent seam caps create strong vertical lines that visually elongate buildings and complement classical proportions. Modern batten-seam Vertical Metal Siding Sheets combine historical design language with contemporary engineering, utilizing concealed clips that secure panels while allowing thermal movement independent of the fastening system. The raised batten caps typically measure one to three inches in width, creating substantial shadow lines that provide depth and articulation to building facades. Architects appreciate batten-seam systems for their versatility in scale modulation, as varying the panel widths and batten dimensions enables fine-tuning the visual rhythm to harmonize with specific architectural contexts. Installation requires careful attention to batten alignment and consistent spacing to maintain the crisp visual order that defines quality batten-seam applications. The raised battens accommodate slight irregularities in substrate flatness that might telegraph through flatter panel systems, providing some installation tolerance while maintaining attractive appearance. Batten-seam Vertical Metal Siding Sheets work particularly well in applications mixing traditional and contemporary design elements, as the classical proportional system bridges stylistic transitions effectively. The system accommodates full building envelopes or targeted accent areas where the architectural character provides focal points within broader compositional strategies. Premium coating options ensure the distinctive visual character remains vibrant across decades of service, with manufacturers offering comprehensive warranties backed by extensive testing demonstrating performance under accelerated weathering protocols that simulate decades of real-world exposure in condensed timeframes.

Manufacturing Quality and Certification Standards

Professional metal siding manufacturers maintain rigorous quality control protocols throughout the production process, beginning with careful raw material selection and continuing through final packaging. Leading manufacturers source aluminum, steel, and specialized alloys from established suppliers who provide material certifications and comprehensive testing documentation. Incoming material inspection procedures verify specifications including thickness, composition, coating weight, and surface quality before materials enter production workflows. Modern manufacturing facilities employ automated roll-forming systems that precisely shape Vertical Metal Siding Sheets according to engineered specifications while maintaining consistent dimensional tolerances across production runs. These sophisticated machines create complex panel profiles through sequential forming stations that progressively introduce bends and folds without compromising material integrity or coating adhesion. Quality manufacturers operate multiple production lines including color coating systems, laminating equipment, and specialized punching machines that create fastener holes, ventilation perforations, or decorative patterns as project specifications require. The best manufacturers maintain certifications including ISO9001 quality management standards, ISO14000:14001 environmental management protocols, and SGS verification demonstrating compliance with international performance requirements. These certifications reflect systematic approaches to quality assurance rather than isolated testing, ensuring consistent product excellence across all production batches. Finished product inspection procedures evaluate appearance, dimensional accuracy, flatness, and coating adhesion before panels receive approval for shipment. Strategic packaging protects Vertical Metal Siding Sheets during transportation while organizing materials according to installation sequences that streamline job site logistics and minimize installation errors.

Coating Technologies and Color Durability

The long-term performance and appearance retention of metal siding depends critically on coating selection and application quality. Polyester coatings represent the entry-level finish option, providing adequate color retention and weather resistance for budget-conscious projects or applications where periodic repainting fits within maintenance expectations. High-durability polyester formulations enhance performance through advanced resin technologies that improve chalking resistance and color stability compared to standard polyester systems. PVDF coatings deliver premium performance with exceptional fade resistance, chalk resistance, and chemical resistance that maintains appearance across thirty-year service lives with minimal degradation. The fluoropolymer chemistry used in PVDF coatings creates molecular bonds that resist ultraviolet radiation damage far more effectively than conventional paint systems, ensuring rich colors remain vibrant even under intense sunlight exposure. Manufacturers apply coatings through sophisticated processes that achieve uniform coverage and optimal film thickness across the entire panel surface, including profiles with complex geometries where coating uniformity challenges lesser application methods. The coating adhesion to metal substrates receives particular attention, as poor adhesion leads to coating delamination that compromises both appearance and corrosion protection. Quality manufacturers conduct standardized adhesion testing using prescribed methods that simulate mechanical stress and thermal cycling to verify coatings maintain secure attachment throughout anticipated service conditions. Color options span comprehensive palettes including neutral tones that complement diverse architectural contexts, bold accent colors that create focal points, and metallic finishes that emphasize the material authenticity while adding subtle sophistication. Custom color matching capabilities enable Vertical Metal Siding Sheets to coordinate precisely with existing building elements or corporate identity requirements where color accuracy matters. The combination of advanced coating chemistry, precise application technology, and comprehensive quality verification ensures metal siding installations maintain their intended appearance across decades of service while requiring minimal maintenance beyond periodic washing to remove accumulated surface dirt.

Installation Methodology and Technical Support

Successful metal siding installation requires careful planning, proper tool selection, and thorough understanding of manufacturer specifications. Professional installation begins with comprehensive site evaluation to verify substrate conditions, identify potential complications, and develop detailed installation sequences that optimize efficiency while maintaining quality standards. Experienced installers prepare detailed cutting lists that minimize material waste while ensuring panel lengths match building dimensions accurately. The installation process for Vertical Metal Siding Sheets typically begins with establishing level reference lines and installing starter trim that provides proper alignment foundation for subsequent panels. Fastener selection and placement follow manufacturer specifications precisely, as proper fastening techniques dramatically influence long-term performance. Concealed fastener systems require specialized clips installed at prescribed intervals with appropriate fastener types that accommodate thermal movement without loosening over time. Exposed fastener installations utilize self-drilling screws with integrated weather seals, installed with controlled torque that achieves secure attachment without overtightening that deforms panels or crushes sealing washers. Corner treatments, window penetrations, and other transitions require careful attention to flashing details that maintain weathertight integrity while accommodating differential movement between dissimilar materials. Leading manufacturers provide comprehensive technical documentation including detailed installation manuals, CAD details for common conditions, and responsive technical support teams who assist installers encountering unusual site conditions. Many manufacturers offer on-site guidance services where experienced technicians visit project locations to review installation procedures, verify proper technique application, and address questions before issues compromise installation quality. Upon completion, thorough inspections verify proper panel alignment, secure fastening, complete flashing installation, and appropriate sealant application at critical junctions. Quality installations demonstrate attention to detail visible in clean fastener patterns, straight seam alignment, and professional finish work that reflects craftsman pride.

Conclusion

Metal siding delivers unmatched durability, minimal maintenance, and design versatility through options including standing seam, corrugated, flat lock, ribbed, and batten-seam Vertical Metal Siding Sheets. Each system offers distinct aesthetic and performance characteristics suited to specific architectural visions and project requirements while sharing common advantages of longevity, weather resistance, and environmental sustainability.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a trusted China Vertical Metal Siding Sheets manufacturer, China Vertical Metal Siding Sheets supplier, and China Vertical Metal Siding Sheets factory established in Shaanxi Province in 2018. Recognized as a high-tech enterprise with first-level building curtain wall qualifications and third-level steel structure qualifications, Huafeng operates a 200,000-square-meter raw material production facility in Anhui alongside processing plants in Hangzhou and Xi'an. Our comprehensive capabilities include seven color coating production lines, one laminating line, ten longitudinal and transverse shearing lines, and over forty specialized processing machines. We deliver High Quality Vertical Metal Siding Sheets featuring specifications ranging from 25-330/400/430/500 to 65-400/430/500 with PE, HDP, and PVDF coating options. Our one-stop solution encompasses custom metal roof engineering services with structural 3D modeling, precision manufacturing with real-time quality control, and seamless installation with on-site project management. With over twenty registered patents, ISO9001, ISO14000:14001, and SGS certifications, we provide Vertical Metal Siding Sheets for sale backed by thirty-year warranties, 1000-ton monthly supply capacity, and fifteen to twenty-day delivery times. Whether sourcing Vertical Metal Siding Sheets wholesale or requesting customized color, pattern, and design specifications, Huafeng delivers competitive Vertical Metal Siding Sheets price points without compromising quality. Contact us at huafeng@hfmetalroof.com to discuss your project requirements and discover why Fortune 500 companies trust Huafeng for architectural metal solutions.

References

1. Metal Construction Association. "Design Guide for Metal Wall Systems." Metal Construction Association Technical Committee, 2023.

2. American Iron and Steel Institute. "Steel Framing Industry Recognition: Metal Building and Roofing Systems." AISI Publications, 2024.

3. National Association of Home Builders Research Center. "Durability and Performance Testing of Residential Exterior Wall Systems." NAHB Research Center, 2023.

4. Sheet Metal and Air Conditioning Contractors National Association. "Architectural Sheet Metal Manual: 8th Edition." SMACNA Technical Publications, 2024.