Are you tired of replacing your roof every decade due to leaks, weather damage, or material degradation? Imagine investing in a roofing system that not only withstands extreme weather conditions but also enhances your building's aesthetic appeal for over fifty years. Snap Lock Standing Seam Roof technology represents a revolutionary approach to modern metal roofing, combining innovative installation methods with exceptional durability. This comprehensive guide explores everything you need to know about snap lock metal roofing systems, from their unique design features to their long-term performance benefits, helping you make an informed decision for your next roofing project.

Understanding Snap Lock Standing Seam Roof Systems

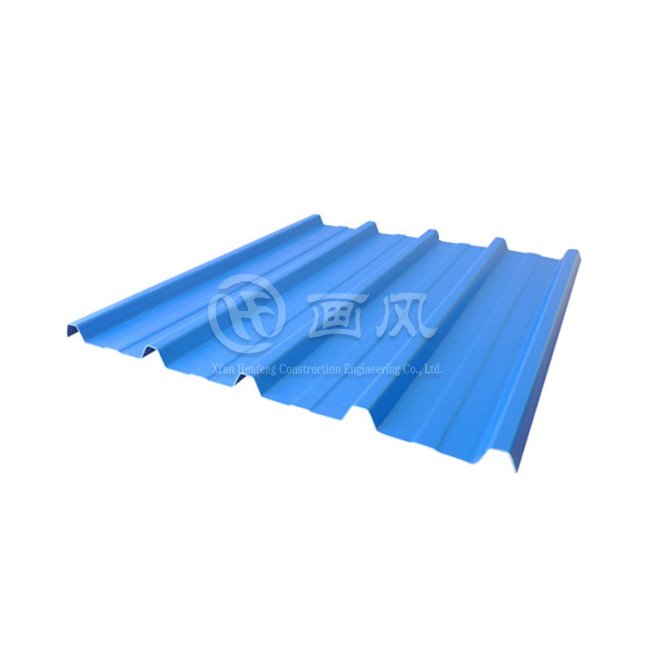

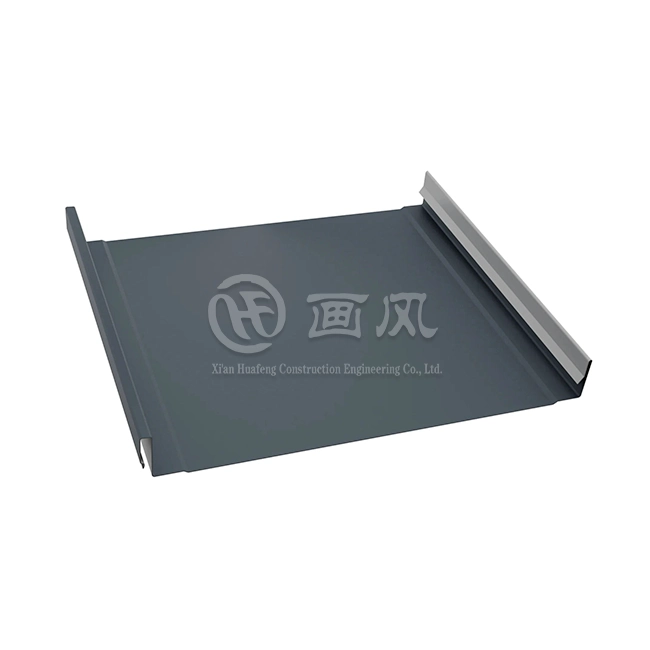

Snap Lock Standing Seam Roof is a specialized type of concealed fastener metal roofing system that has transformed the commercial and residential roofing industry. Unlike traditional roofing methods that expose fasteners to weather elements, this innovative system utilizes an interlocking mechanism where panels snap together through male and female legs. The design eliminates the need for mechanical seaming equipment during installation, making it one of the most efficient and weather-resistant roofing solutions available today. The system features vertical panel ribs that run continuously from the ridge to the eave, creating distinctive standing seams typically measuring between one to two inches in height. These elevated seams not only provide superior water drainage but also create clean, modern lines that enhance any building's architectural appearance. The fundamental principle behind Snap Lock Standing Seam Roof technology lies in its concealed clip attachment system. Hidden fasteners secure the panels to the roof deck beneath the interlocking seams, protecting them from direct exposure to rain, snow, ultraviolet radiation, and thermal expansion stress. This engineering approach significantly extends the roof's service life while minimizing maintenance requirements. The panels are manufactured with precise tolerances, ensuring consistent quality and fit across the entire roof surface. When properly installed on slopes of three inches per foot or greater, these systems provide exceptional weather resistance and can withstand wind speeds exceeding 130 miles per hour.

-

Key Components of Snap Lock Metal Roofing Systems

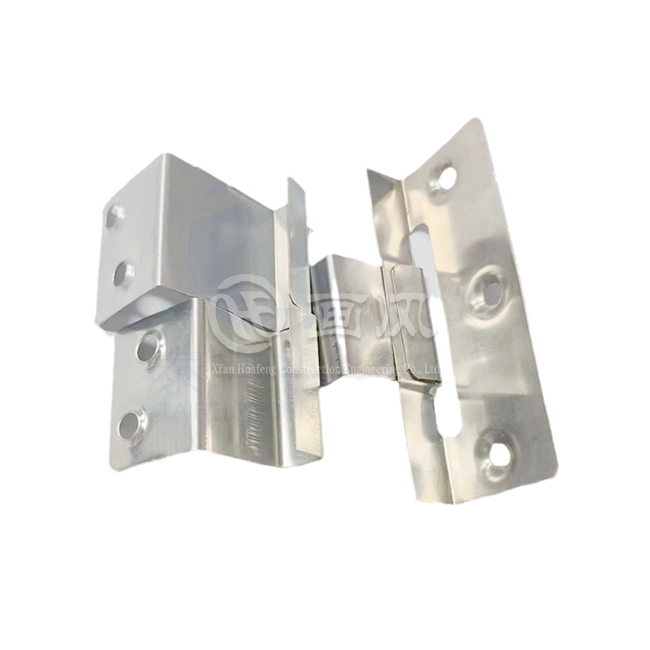

The complete Snap Lock Standing Seam Roof assembly consists of several critical components working in harmony. The metal panels themselves form the visible surface and primary weather barrier, typically manufactured from aluminum alloy, galvanized steel, galvalume steel, stainless steel, copper, or titanium zinc materials. Each panel features a flat central section with raised edges designed to interlock with adjacent panels. The hidden clips, constructed from corrosion-resistant materials matching or exceeding the panel's durability specifications, attach directly to the structural deck using appropriate fasteners. These clips incorporate a spring-loaded design that allows controlled thermal movement while maintaining secure panel attachment. Underlayment materials provide a secondary moisture barrier beneath the metal panels, typically consisting of synthetic materials or high-temperature ice and water shield products in vulnerable areas. Proper underlayment installation is crucial for achieving weathertight performance, particularly on lower slope applications. Trim components including ridge caps, eave drips, rake edges, and transition flashings complete the system by sealing panel terminations and directing water flow. Each trim piece must be carefully designed and installed to maintain the system's aesthetic consistency while providing reliable weather protection. The interaction between these components creates a complete roofing assembly capable of protecting structures for decades with minimal intervention.

Material Selection and Performance Characteristics

Choosing the appropriate substrate material for your Snap Lock Standing Seam Roof significantly impacts both initial investment and long-term performance. Galvalume steel, comprising fifty-five percent aluminum, forty-three point four percent zinc, and one point six percent silicon, offers corrosion resistance approximately two to six times superior to ordinary galvanized steel. This material excels in most climate conditions, particularly in dry inland regions, with documented service lives ranging from thirty to fifty years when properly maintained. The aluminum-zinc coating forms a protective barrier that self-heals minor scratches through galvanic action, significantly extending panel life even in moderately corrosive environments. Available in thicknesses from point five to one point two millimeters, galvalume steel provides excellent strength-to-weight ratios for most commercial and residential applications. Aluminum alloy panels present distinct advantages for coastal and high-humidity installations where salt spray corrosion poses significant challenges. With a density of just two point seven grams per cubic centimeter, aluminum panels weigh considerably less than steel alternatives, potentially reducing structural requirements and installation complexity. The material's inherent corrosion resistance stems from the natural oxide layer that forms on exposed surfaces, protecting the underlying metal indefinitely. Aluminum is one hundred percent recyclable without quality degradation, making it an environmentally sustainable choice for green building projects. These panels typically utilize three zero zero three, three zero zero four, or five zero five two alloy designations, each offering specific performance characteristics suitable for different applications. Service life frequently exceeds fifty years in properly maintained installations, though initial material costs typically run higher than steel alternatives.

-

Surface Coating Technologies

Surface treatments dramatically influence Snap Lock Standing Seam Roof longevity and aesthetic retention. Polyvinylidene fluoride, commonly referenced as PVDF coating, represents the premium finish option for metal roofing applications. This advanced resin system provides exceptional weathering resistance, maintaining color stability and gloss retention for over twenty years in harsh environments. PVDF coatings resist chalking, fading, and chemical attack from industrial pollutants, making them ideal for high-visibility applications where appearance matters. The coating's molecular structure creates a tight bond with the metal substrate while remaining flexible enough to accommodate thermal expansion without cracking or delaminating. Testing demonstrates that properly applied PVDF finishes can maintain seventy percent or greater gloss retention after twenty years of weathering exposure. Polyester, referenced as PE coating, offers a more economical alternative suitable for applications in non-harsh environments or where budget constraints limit premium finish selection. While PE coatings provide adequate protection and acceptable color retention for ten to fifteen years, they demonstrate inferior weathering resistance compared to PVDF formulations. Some specialty applications utilize uncoated natural metals such as copper, titanium zinc, or weathering steel that develop protective patina layers through controlled oxidation. These materials appeal to architects seeking distinctive appearances that evolve over time, though they require different design considerations regarding runoff staining and compatibility with adjacent materials. The patina formation process typically stabilizes within two to seven years depending on climate conditions and material composition.

Structural Performance and Load Resistance

Engineering analysis of Snap Lock Standing Seam Roof systems considers multiple load scenarios that panels must withstand throughout their service life. Wind uplift represents perhaps the most critical design consideration, as negative pressure on roof surfaces during storm events can generate forces exceeding three kiloNewtons per square meter. Properly engineered systems with clip spacing maintained at one point five meters or less can resist wind velocities reaching sixty meters per second, equivalent to two hundred sixteen kilometers per hour, meeting European Standard fifteen six zero one requirements. The clip strength, panel thickness, and seam engagement tightness collectively determine wind resistance capacity. Independent testing laboratories subject representative assemblies to simulated wind conditions, measuring deflection and failure modes to establish reliable performance ratings. Snow accumulation and concentrated live loads from maintenance activities or equipment placement impose different stress patterns on Snap Lock Standing Seam Roof panels. A point seven millimeter thick aluminum panel installed on purlins spaced six hundred millimeters apart typically supports at least one point five kiloNewtons per square meter, while one point zero millimeter galvanized steel panels on identical framing resist two kiloNewtons per square meter or greater. These capacities depend heavily on the substrate material's yield strength and the support density provided by the underlying structure. Panels spanning longer distances between supports require increased thickness or alternative profiles with enhanced stiffness characteristics. Engineers must account for potential snow drift patterns, concentrated loads at valley intersections, and combined loading scenarios when specifying appropriate panel gauges and support arrangements.

-

Seismic and Thermal Movement Accommodation

Snap Lock Standing Seam Roof systems excel at accommodating structural movements induced by seismic events and thermal cycling. The flexible clip connection between panels and structure permits lateral displacement of plus or minus fifteen millimeters, allowing the roof assembly to respond to building movement without inducing panel damage or fastener withdrawal. This characteristic proves particularly valuable in seismically active regions where rigid connections might fail during ground motion events. The sliding clip design functions like a mechanical fuse, protecting both the roof system and underlying structure by allowing controlled relative movement rather than transferring destructive forces. Daily and seasonal temperature variations cause metal panels to expand and contract significantly, potentially generating substantial stress if movement is restrained. Aluminum panels exhibit thermal expansion coefficients approximately twice that of steel, requiring careful attention to clip selection and spacing. The Snap Lock Standing Seam Roof design inherently addresses thermal movement through its clip attachment method, which permits longitudinal panel movement while maintaining lateral stability. For panels exceeding ten meters in length, engineers may specify specialized expansion clips that provide increased movement capacity. Proper accommodation of thermal effects prevents panel buckling, commonly visible as oil canning, and eliminates stress concentrations that could lead to premature fastener failure or panel damage.

Installation Efficiency and Labor Requirements

One of the most compelling advantages of Snap Lock Standing Seam Roof systems lies in their installation efficiency compared to mechanically seamed alternatives. The snap-together design eliminates the need for specialized roll-forming equipment on the installation site, reducing tool requirements and associated costs. Installation crews can achieve productivity improvements of thirty to fifty percent compared to mechanical seaming methods, as panels simply snap into place over pre-installed clips without requiring multiple passes with seaming machines. This efficiency translates directly into reduced labor costs, making the system more economically attractive despite potentially higher material expenses compared to exposed fastener alternatives. The simplified installation process also reduces skill level requirements, allowing properly trained workers to achieve professional results after just one day of instruction. This accessibility expands the available contractor pool and reduces scheduling constraints that might otherwise delay project completion. However, proper installation remains critical for achieving warranted performance, and manufacturers typically provide detailed installation manuals and technical support to ensure correct procedures. The absence of exposed fasteners eliminates perforation risks that plague screw-down roof systems, where each penetration represents a potential leak point requiring maintenance attention throughout the roof's service life. The hidden fastener approach concentrates weather sealing at the panel interlocks, which are elevated above the roof plane where water accumulation is minimized.

-

Quality Control and Field Testing Protocols

Ensuring proper Snap Lock Standing Seam Roof installation requires systematic quality control measures throughout the construction process. Installers must verify that the structural deck provides adequate support and flatness before beginning panel placement, as irregularities in the substrate transfer through to the finished roof surface. Chalk lines establish reference marks ensuring panels run parallel to roof edges and maintain proper alignment across the entire field. Each clip must be securely fastened at specified intervals, with fastener type and length selected to provide adequate withdrawal resistance in the particular decking material. Installers verify complete panel engagement by checking that female legs fully capture male legs along each seam, confirming proper snap-lock connection. Upon installation completion, conscientious contractors conduct comprehensive water testing to verify zero-leakage performance before final project acceptance. This testing typically involves flooding specific roof sections and observing interior spaces for moisture intrusion, identifying any installation deficiencies requiring correction. Thermal imaging surveys can reveal areas where insulation continuity has been compromised or where moisture has infiltrated beneath the roof assembly. Documentation of installation procedures, including photographic records of critical details and clip spacing verification, provides valuable protection for both contractors and building owners. Proper installation following manufacturer specifications typically qualifies the roof for weathertight warranty coverage, providing additional confidence in the system's long-term performance capabilities.

Comparing Snap Lock to Alternative Standing Seam Systems

Understanding the distinctions between Snap Lock Standing Seam Roof and mechanically seamed alternatives helps owners select the most appropriate system for their specific requirements. Mechanically seamed roofs utilize clip attachments similar to snap lock systems, but they require an additional seaming operation where adjacent panel edges are mechanically crimped together using specialized equipment. This process creates either single-locked seams, where material folds once, or double-locked seams with two folds for enhanced weather resistance. The mechanical seaming provides a more secure, weather-tight connection particularly suitable for low-slope applications with pitches as minimal as one-half inch per foot. Double-locked mechanically seamed systems represent the most weather-resistant metal roofing option available, capable of withstanding the most extreme environmental conditions. However, mechanical seaming introduces additional complexity and cost compared to snap lock installation. The seaming equipment itself represents a significant capital investment, and the seaming process increases labor time substantially, particularly for double-locked configurations. Mechanically seamed systems typically cost seven dollars fifty cents to seventeen dollars per square foot installed in current market conditions, though pricing varies based on project complexity, material selection, and regional labor rates. These systems prove most cost-effective on projects with longer panel runs, lower slopes, or exposure to severe weather conditions where their superior performance justifies the additional investment. Building codes in hurricane-prone regions may mandate mechanically seamed systems for critical facilities, recognizing their enhanced wind resistance capabilities.

-

Snap Lock Advantages in Residential and Light Commercial Applications

For residential and light commercial projects with roof slopes exceeding three inches per foot and panel lengths under forty feet, Snap Lock Standing Seam Roof systems offer an optimal balance of performance, aesthetics, and value. The faster installation reduces disruption to occupied buildings and accelerates project schedules, particularly important for time-sensitive renovations. The clean, straight seam lines achieved through factory-formed interlocks create contemporary appearances that many architects and building owners prefer over the slight irregularities characteristic of field-formed mechanical seams. This visual consistency proves especially valuable on highly visible roof planes where aesthetic quality significantly impacts building value and curb appeal. Material costs for snap lock systems typically fall between exposed fastener panels, which represent the most economical option, and mechanically seamed systems at the premium end of the spectrum. This mid-range pricing combined with reduced installation labor makes snap lock an attractive proposition for projects where budget constraints preclude mechanical seaming but where the performance and appearance benefits of concealed fasteners justify premium pricing over exposed fastener alternatives. Many commercial weathertight warranties extend to properly installed snap lock systems when environmental conditions, slope, and other factors fall within specified parameters. Building owners should carefully review warranty terms with manufacturers to understand coverage limitations and maintenance requirements necessary to preserve warranty validity throughout the anticipated service life.

Xi'an Huafeng Construction Engineering Expertise

Xi'an Huafeng Construction Engineering Co., Ltd. has established itself as a leading manufacturer and supplier of premium Snap Lock Standing Seam Roof systems through unwavering commitment to innovation, quality, and customer service. Since establishment in two thousand eighteen, the company has developed comprehensive capabilities spanning the entire project lifecycle from initial design through final installation and ongoing maintenance support. The company's product line emphasizes the HF brand snap lock standing seam panels, available with both PVDF and PE finish options to suit various performance requirements and budget parameters. Manufacturing operations leverage three strategically located factories equipped with seven color coating production lines and over forty specialized machines, enabling production capacity exceeding one thousand tons monthly while maintaining rigorous quality standards. The company's engineering team provides value-added design optimization services, conducting structural three-dimensional modeling and load analysis to ensure specified systems meet project-specific requirements. Drainage system simulation capabilities identify potential problem areas before construction begins, eliminating costly field modifications and ensuring reliable water management throughout the roof's service life. Material specification advisory services help owners navigate the complex array of substrate materials, coating systems, and accessory components to select optimal configurations for their particular applications and environmental exposures. This comprehensive design support distinguishes Xi'an Huafeng from suppliers offering only standard product catalogs without application-specific engineering assistance.

-

Advanced Manufacturing and Quality Assurance Systems

Xi'an Huafeng's raw material production facility in Anhui province encompasses two hundred thousand square meters of manufacturing space, providing vertical integration that ensures consistent material quality and supply chain reliability. The company maintains strategic partnerships with premium material suppliers including Alucosuper, Yatai, and Lidao for aluminum alloys in three zero zero three, three zero zero four, and five zero five two specifications. Steel substrate procurement emphasizes partnerships with Baosteel, Guanzhou, and Xinyu for cold rolled, galvanized, galvalume, and color-coated sheet products meeting international quality standards. Stainless steel requirements utilize Baosteel and Tsingshan materials in three zero four and three one six grades, while specialty applications employ NedZink titanium zinc and Chinalco copper in T2 and TP2 specifications. Incoming material inspection protocols verify that all raw materials meet stringent quality specifications before entering production processes. Suppliers must provide material certifications and independent third-party testing reports documenting compliance with relevant standards. Xi'an Huafeng's quality assurance department conducts comprehensive testing including appearance inspection, dimensional verification, salt spray exposure, adhesion testing, hardness measurement, impact resistance, film thickness analysis, acid resistance evaluation, accelerated weathering simulation, and color difference assessment. These thorough quality control measures ensure that only materials meeting or exceeding specification requirements advance to production operations. Finished panel inspection verifies appearance quality, dimensional accuracy, flatness, and proper curvature before products receive approval for packaging and shipment.

Complete Project Implementation Services

Xi'an Huafeng Construction Engineering differentiates itself through comprehensive one-stop service delivery encompassing every phase of Snap Lock Standing Seam Roof project execution. The process begins with detailed drawing development where engineering staff analyze architectural plans, elevations, and node diagrams to identify feasible implementation approaches. Through collaborative consultation with clients, the team determines optimal panel configurations for specific roof structures, considering factors including slope, exposure, aesthetic preferences, and budget parameters. Design department personnel conduct one-to-one drawing refinement for nodes at different locations throughout the project, ensuring constructability and performance while maintaining architectural intent. Multiple review cycles culminate in signed confirmation drawings that establish clear expectations and form the basis for subsequent fabrication operations. Factory sample production follows confirmed design parameters, creating physical mockups representing specified board types, materials, thicknesses, surface treatments, and colors. Client review and approval of samples establishes baseline standards for subsequent production and acceptance criteria, ensuring alignment between expectations and delivered products. The design department then develops detailed processing drawings breaking down approved designs into fabrication instructions for production personnel. Each component receives sequential numbering according to project specifications and quantities, facilitating organized processing, inspection, packaging, and field installation while preventing confusion that could compromise project quality or schedule. This systematic approach to project documentation and material management reflects Xi'an Huafeng's commitment to excellence in execution.

-

On-Site Construction Management and Technical Support

Xi'an Huafeng's installation support services ensure that carefully engineered and manufactured Snap Lock Standing Seam Roof systems achieve their full performance potential through proper field implementation. Installation technicians visit construction sites in advance to inspect work areas, verify tool availability including specialized equipment for panel manipulation and seam engagement, and confirm that necessary auxiliary materials including rivets, structural adhesives, screws, and accessories are complete and properly specified. Detailed construction site layout planning addresses product storage locations, accessory management, and on-site processing areas to optimize workflow efficiency and protect materials from damage. Upon material arrival, installation teams verify quantities against packing documentation and organize products according to packaging identification cards, sectioned floor plans, and component number lists. This systematic approach to material management eliminates confusion during installation and ensures components are readily accessible when needed. Technical briefing meetings thoroughly review work details and safety precautions before installation commences, establishing clear communication protocols and quality expectations. Throughout installation operations, experienced technical personnel provide guidance ensuring proper clip attachment, panel engagement verification, and trim integration. Upon completion, comprehensive on-site testing verifies zero-leakage performance before final acceptance procedures. Customer training on proper maintenance procedures or provision of ongoing maintenance services extends the relationship beyond initial installation, supporting long-term roof performance and client satisfaction.

Conclusion

Snap Lock Standing Seam Roof technology represents the optimal convergence of performance, efficiency, and aesthetic appeal for modern metal roofing applications. Its innovative design delivers exceptional weather resistance, extended service life, and contemporary appearance while streamlining installation processes and reducing lifecycle costs compared to traditional roofing alternatives.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

As a recognized high-tech enterprise in Shaanxi Province with first-level building curtain wall qualifications and third-level building steel structure qualifications, Xi'an Huafeng Construction Engineering Co., Ltd. combines advanced manufacturing capabilities with comprehensive engineering expertise. Our extensive production facilities include a two-hundred-thousand-square-meter raw material plant in Anhui and processing facilities in Hangzhou and Xi'an, equipped with seven color coating lines, one laminating line, ten longitudinal and transverse shearing lines, and fully automatic punching systems. With over twenty registered patents, ISO nine zero zero one and ISO fourteen zero zero one certifications, and SGS compliance verification, we deliver superior quality backed by thirty-year warranties.

As a leading China Snap Lock Standing Seam Roof factory, China Snap Lock Standing Seam Roof supplier, and China Snap Lock Standing Seam Roof manufacturer, we offer comprehensive China Snap Lock Standing Seam Roof wholesale solutions. Our Snap Lock Standing Seam Roof for sale provides exceptional value with competitive Snap Lock Standing Seam Roof price structures and guaranteed High Quality Snap Lock Standing Seam Roof performance. Our integrated service model encompasses design optimization through structural modeling and load analysis, precision manufacturing with rigorous quality testing, customized production accommodating unique project requirements, and complete installation support ensuring proper field implementation. Successful project deliveries include Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, Xi'an Station East Auxiliary Building, and Jinghe New City International Culture and Art Center, demonstrating our capabilities across diverse applications.

Partner with our experienced team to transform your roofing vision into reality. Contact Xi'an Huafeng Construction Engineering Co., Ltd. today at huafeng@hfmetalroof.com to discuss your project requirements and discover how our Snap Lock Standing Seam Roof solutions can deliver lasting value for your investment. Save this resource for future reference and reach out whenever questions arise about your metal roofing needs.

References

1. Smith, J.R. & Thompson, M.K. (2022). Metal Roofing Systems: Design, Installation, and Performance. Building Science Publishers.

2. National Roofing Contractors Association. (2023). The NRCA Metal Panel and SPF Roof Systems Manual. NRCA Publications.

3. Anderson, L.P. (2021). Architectural Metal Roofing: Engineering and Installation Best Practices. Construction Specifications Institute Press.

4. International Building Code. (2024). Chapter 15: Roof Assemblies and Rooftop Structures. International Code Council.

_1757558889992.webp)