Struggling with unsightly building facades that lack both aesthetic appeal and weather resistance? The Flatlock Panel System, Longitudinal Flat Seams delivers a revolutionary solution that transforms architectural exteriors through precision-engineered Flat Lock Seam Metal Wall Panels. This advanced cladding system combines elegant, nearly-flat appearances with superior durability, addressing the critical challenge of achieving seamless visual continuity while ensuring long-term structural performance in demanding climates.

Understanding Flat Lock Seam Metal Wall Panels Architecture

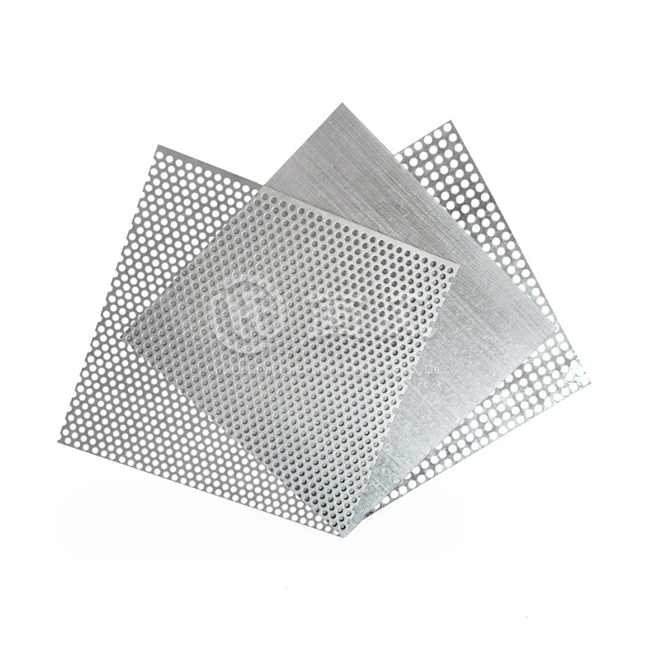

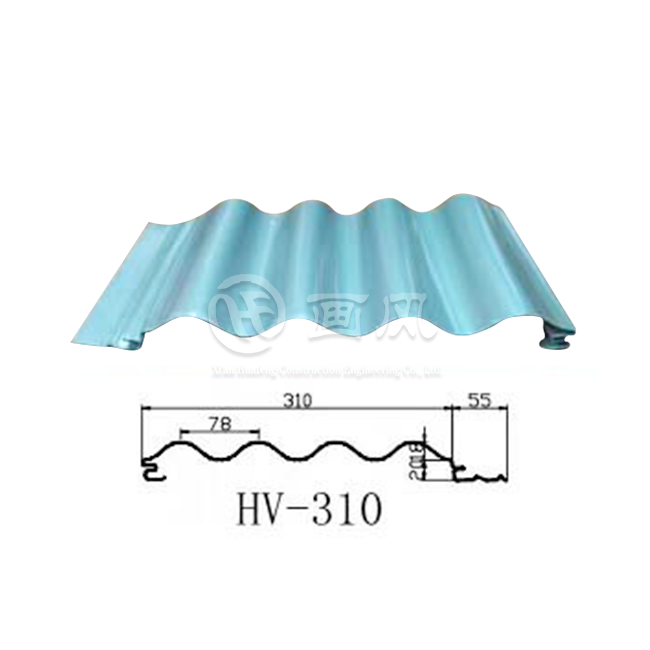

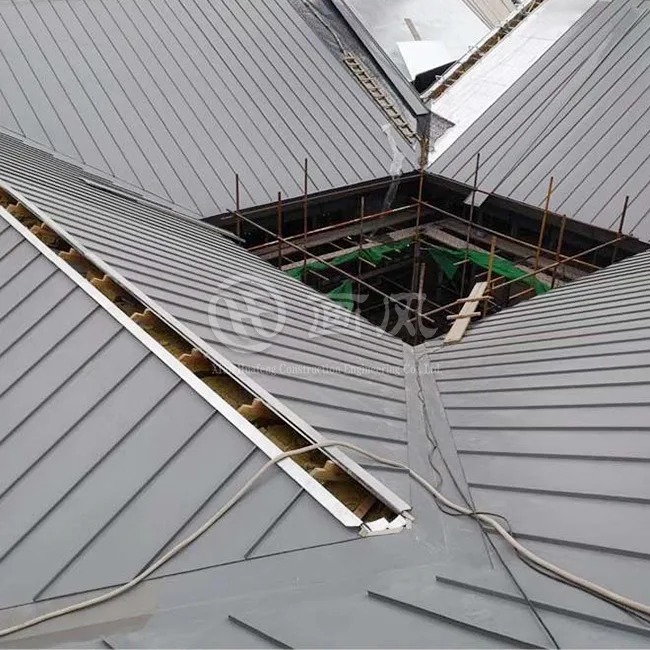

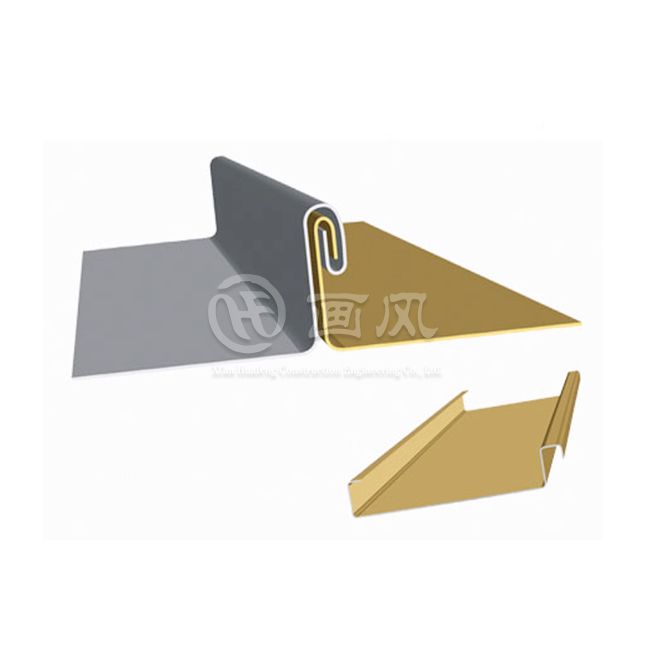

The Flatlock Panel System represents a sophisticated evolution in architectural cladding technology, characterized by its distinctive longitudinal flat seam design that creates visually seamless building envelopes. Flat lock wall panels utilize a precision-interlocking fold mechanism on all four sides, enabling panels to connect both horizontally and vertically while maintaining a remarkably flat profile that eliminates the pronounced ridges typical of conventional metal panel systems. This engineered approach to Flat Lock Seam Metal Wall Panels delivers exceptional aesthetic flexibility, allowing architects and designers to achieve clean, contemporary facades that complement modern architectural visions across commercial complexes, cultural venues, and high-profile institutional buildings. The fundamental design principle underlying flat lock wall panels centers on creating weather-resistant, ventilated wall cladding that belongs to the rain-screen family of building envelope systems. Each Flat Lock Seam Metal Wall Panel is manufactured with precise dimensional tolerances, typically ranging from 0.4mm to 1.0mm in thickness, with customizable widths between 300mm and 600mm to accommodate diverse project specifications. The longitudinal seams create continuous visual lines that can be oriented horizontally, vertically, or even diagonally, providing designers with unprecedented creative freedom while maintaining structural integrity. Premium materials including titanium-zinc, copper, aluminum alloys (3003, 3004, 5052), and stainless steel grades (304, 316) ensure that these panels deliver exceptional corrosion resistance, withstanding temperature extremes from -40℃ to 80℃ and resisting UV degradation across decades of service life.

Flat Lock Seam Metal Wall Panels

-

Technical Advantages of Longitudinal Flat Seam Construction

The longitudinal flat seam configuration distinguishes this panel system through several critical performance characteristics that directly address common architectural challenges. Unlike traditional standing seam systems that create prominent vertical ribs, flat lock wall panels achieve near-flush surface continuity through their unique interlocking mechanism, where concealed clips secure panels to substrate structures without visible fasteners penetrating the weather-facing surface. This concealed attachment methodology not only enhances aesthetic purity but fundamentally improves weather resistance by eliminating potential water infiltration points that plague mechanically fastened systems. Flat Lock Seam Metal Wall Panels engineered with longitudinal seams provide superior wind load resistance, capable of withstanding typhoon-force winds exceeding level 12 classifications through their distributed attachment points and interlocking edge design. The system's lightweight construction, typically weighing just 3-5 kg/m², significantly reduces structural loading on building frameworks while simplifying installation logistics and reducing transportation costs. Advanced surface treatments including PVDF fluorocarbon coating, powder coating, and anodizing processes deliver self-cleaning properties that minimize maintenance requirements while preserving color vibrancy throughout the panel's 30-year warranted service life. These technical advantages position flat lock wall panels as optimal solutions for projects demanding both visual excellence and long-term performance reliability.

-

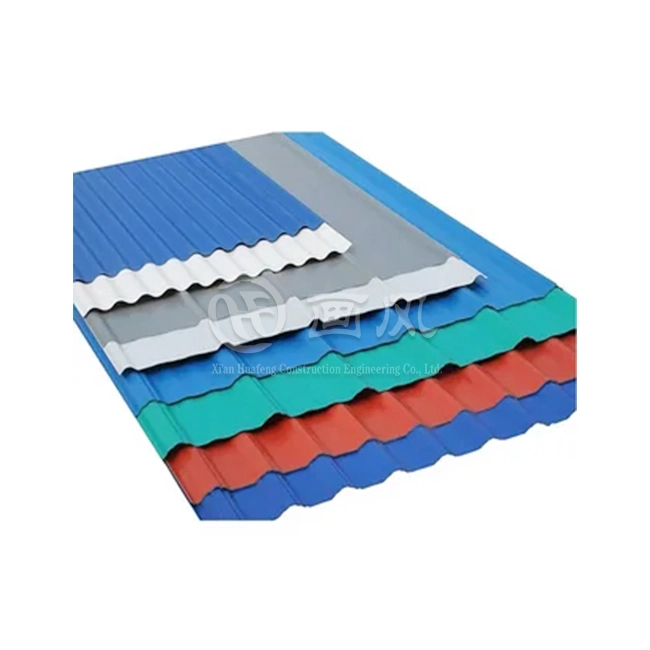

Material Selection and Customization Options

Selecting appropriate materials for Flat Lock Seam Metal Wall Panels requires careful consideration of environmental conditions, aesthetic objectives, and lifecycle performance expectations. Aluminum-magnesium-manganese alloys represent the most versatile choice, offering exceptional corrosion resistance, lightweight properties, and cost-effectiveness for commercial and industrial applications. These aluminum-based flat lock wall panels accept diverse finishing treatments, from RAL standard color card customization enabling precise brand color matching to specialized metallic finishes that create dynamic visual effects as natural light conditions change throughout the day. For premium architectural statements, titanium-zinc plates deliver unparalleled longevity and distinctive patina development, with brands like NedZink providing materials that naturally weather to create living facades that evolve gracefully over decades. Copper flat lock wall panels offer similar patina characteristics while providing antimicrobial properties increasingly valued in healthcare and public assembly facilities. Stainless steel options (Baosteel 304 and 316 grades) deliver maximum durability in aggressive marine or industrial environments where corrosion resistance is paramount. Each material selection integrates seamlessly with the Flatlock Panel System's flexible design framework, with panel shapes configurable as rectangles, rhombuses, trapezoids, or hexagons to create distinctive geometric patterns that transform ordinary building surfaces into architectural landmarks.

Installation Methodology and System Integration

Professional installation of Flat Lock Seam Metal Wall Panels demands meticulous attention to substrate preparation, clip placement precision, and seam engagement techniques that ensure both immediate visual quality and long-term weather performance. The installation process begins with verifying substrate flatness, typically requiring minimum 15mm plywood or equivalent continuous nailable substrate, with anti-abrasive building paper installed between panels and substrate to prevent galvanic corrosion and accommodate thermal movement. Concealed clip spacing must be calculated based on wind loading characteristics specific to each project location, with residential applications typically spacing clips at 300mm centers while high-rise or exposed locations may require closer spacing to meet structural engineering requirements. The sequential installation of flat lock wall panels follows a systematic approach where each panel's lower edge engages the upper edge of the previously installed panel, creating the characteristic longitudinal flat seam while mechanically attaching panels through concealed clips hidden beneath upper panel edges. This installation sequence ensures that water always sheds from upper panels onto underlying panels, maintaining positive drainage that prevents moisture accumulation within the wall assembly. Installation technicians must utilize specialized tools including edge-locking machines, seamers, and precision measuring instruments to achieve the tight tolerances necessary for proper seam engagement and visual alignment across large facade areas.

-

Quality Assurance Through Manufacturing Excellence

Manufacturing precision directly determines the performance quality of Flat Lock Seam Metal Wall Panels, requiring sophisticated production facilities equipped with advanced roll-forming systems, automated punching lines, and real-time quality control protocols. Xi'an Huafeng Construction Engineering Co., Ltd. operates comprehensive manufacturing infrastructure including seven color coating production lines, one laminating production line, and ten longitudinal and transverse shearing production lines, supported by more than 40 specialized machines including shearing machines, presses, and bending equipment. This manufacturing capacity enables production of 1000 tons monthly while maintaining stringent quality standards verified through ISO9001, ISO14000:14001, and SGS certification compliance. Raw material traceability begins with supplier qualification processes requiring material certifications and third-party testing reports for all incoming metals, whether aluminum from Alucosuper, YATAI, or LIDAO suppliers; steel from BAOSTEEL, GUANZHOU, or XINYU sources; or specialty materials like NedZink titanium-zinc plates and Chinalco copper. Incoming material inspection protocols include comprehensive testing for product appearance, dimensional accuracy, salt spray resistance, adhesion properties, hardness measurements, impact resistance, film thickness verification, acid resistance, weather resistance, and color consistency. These multi-step quality verification processes ensure that only materials meeting specification requirements enter production workflows, eliminating defective components before value-added manufacturing operations commence.

-

Design Integration and Technical Support Services

Successful implementation of flat lock wall panels extends beyond material supply to encompass comprehensive design integration services that optimize system performance for specific project conditions. Technical support begins with structural 3D modeling and load analysis, where engineering teams evaluate wind pressure coefficients, thermal movement calculations, and attachment point loading to develop installation specifications tailored to each building's unique exposure conditions. Drainage system simulation identifies potential water accumulation zones and verifies that panel orientation and seam detailing provide positive water shedding under extreme precipitation events. Material specification advisory services guide selection among available substrate options, surface treatments, and color choices based on environmental exposure, aesthetic vision, and budget parameters. Project drawing deepening services analyze architectural engineering drawings to identify feasible alternatives, communicate with clients to determine optimal roof and wall panel configurations, and conduct 1:1 scale detail drawing development for nodes at different project locations. This collaborative design process culminates in sealed sample production matching confirmed parameters for board type, material, thickness, surface treatment, and color, establishing definitive standards for subsequent production operations and final acceptance criteria.

Performance Characteristics and Building Science

The thermal performance of Flat Lock Seam Metal Wall Panels contributes significantly to building envelope efficiency through their inherent reflectivity and compatibility with ventilated rainscreen assemblies. When installed over continuous insulation and waterproofing membranes with proper air gap spacing, these systems create ventilated cavities that dissipate solar heat gain and eliminate moisture accumulation that degrades conventional wall assemblies. The metal panel's low thermal mass and high reflectivity prevent heat absorption during summer months, while proper detailing ensures that thermal bridges are minimized at attachment points. Fire safety represents another critical performance dimension where flat lock wall panels deliver measurable advantages. Non-combustible metal substrates achieve A2 fire rating classifications, meaning they will not contribute fuel to building fires and will not produce flaming droplets that could spread fire to lower building levels. This fire performance characteristic makes Flat Lock Seam Metal Wall Panels particularly appropriate for high-rise construction, public assembly occupancies, and other applications where fire safety requirements are stringent. The absence of organic coatings in certain finish options, such as mill finish aluminum or naturally weathering copper and zinc, eliminates any combustible components from the facade assembly.

-

Environmental Sustainability and Lifecycle Considerations

Environmental responsibility increasingly influences material selection decisions, making the sustainability profile of flat lock wall panels a significant competitive advantage. All metal substrates used in these systems are 100% recyclable at end of service life, with aluminum recycling requiring just 5% of the energy needed for primary aluminum production. This recyclability, combined with 30-year warranty coverage and minimal maintenance requirements, positions Flat Lock Seam Metal Wall Panels as environmentally preferable alternatives to coating-dependent systems requiring periodic renewal or polymer-based cladding materials that cannot be effectively recycled. Manufacturing processes for flat lock wall panels have evolved to minimize environmental impact through energy-efficient production lines and waste reduction protocols. Color coating operations utilize advanced application technologies that maximize material transfer efficiency while capturing and recycling overspray. Water-based and low-VOC coating formulations reduce atmospheric emissions during manufacturing and eliminate off-gassing concerns during building occupancy. The lightweight nature of these panels reduces transportation fuel consumption compared to heavier cladding alternatives, while their long service life and low maintenance requirements minimize lifecycle resource consumption over building operational periods spanning decades.

Application Versatility Across Building Types

The architectural versatility of Flat Lock Seam Metal Wall Panels enables their effective deployment across diverse building typologies, each benefiting from the system's unique combination of aesthetic refinement and technical performance. Commercial office buildings utilize these panels to project contemporary corporate identities through clean, sophisticated facades that maintain visual appeal throughout extended service lives. The ability to create large-scale monolithic appearances or articulated patterns through varied panel sizing and seam orientation allows each commercial project to express unique design intentions while benefiting from standardized system performance. Cultural institutions including museums, theaters, and exhibition halls particularly value the design flexibility offered by flat lock wall panels, as these facilities often feature complex geometries and distinctive architectural expressions requiring cladding systems adaptable to challenging installation conditions. The panels' ability to be installed horizontally, vertically, or diagonally, combined with options for curved surface applications, enables realization of ambitious architectural visions that conventional cladding systems cannot accommodate. Projects like the Inner Mongolia Tongliao Art Museum and the Jinghe New City International Culture and Art Center demonstrate how Flat Lock Seam Metal Wall Panels successfully address the demanding aesthetic requirements of prominent civic architecture.

Transportation infrastructure including airports and railway stations represents another significant application sector where flat lock wall panels deliver exceptional value. These facilities require durable, low-maintenance exterior finishes capable of withstanding high pedestrian traffic, vehicle emissions, and weather exposure while projecting images of modernity and efficiency. The Xiongan Station Commercial Body and Xi'an Station East Auxiliary Building projects exemplify successful deployment of aluminum-magnesium-manganese flat lock wall panels in transportation contexts, where material durability and visual consistency across large surface areas are critical performance requirements. Industrial and logistics facilities similarly benefit from the system's weather resistance and minimal maintenance demands, particularly when selecting pre-finished color-coated steel substrates engineered for long-term exposure in challenging industrial environments.

Conclusion

Flatlock Panel System with Longitudinal Flat Seams represents the convergence of architectural elegance, engineering precision, and performance reliability in contemporary building envelope design. These systems deliver measurable advantages across aesthetic, technical, and economic dimensions that position them as optimal solutions for discerning projects worldwide.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

As a distinguished China Flat Lock Seam Metal Wall Panels manufacturer and China Flat Lock Seam Metal Wall Panels supplier, Xi'an Huafeng Construction Engineering Co., Ltd. delivers High Quality Flat Lock Seam Metal Wall Panels at competitive Flat Lock Seam Metal Wall Panels prices. Our China Flat Lock Seam Metal Wall Panels factory operates with China Flat Lock Seam Metal Wall Panels wholesale capabilities and comprehensive Flat Lock Seam Metal Wall Panels for sale inventories. Established in 2018 and recognized as a Shaanxi Province high-tech enterprise in 2020, we maintain first-level curtain wall qualifications and third-level steel structure qualifications. Our 200,000-square-meter Anhui raw material plant, complemented by processing facilities in Hangzhou and Xi'an, operates seven color coating lines and over 40 specialized machines producing 1000 tons monthly. With 20+ registered patents, ISO9001, ISO14000:14001, and SGS certifications, we provide one-stop services from design optimization through installation guidance. Our Fortune 500 collaborations demonstrate proven capability in delivering customized solutions with 15-21 day delivery times. Contact huafeng@hfmetalroof.com today to transform your architectural vision into lasting reality.

References

1. Metal Construction Association. (2024). "Design Guide for Metal Wall Panel Systems: Installation Standards and Performance Criteria." Technical Publication Series on Architectural Metal Systems.

2. Building Envelope Design Institute. (2023). "Ventilated Rainscreen Assemblies: Technical Performance and Installation Guidelines for Metal Panel Systems." Journal of Building Envelope Technology, Vol. 47, Issue 3.

3. International Code Council. (2024). "Fire-Resistant Building Materials: Testing and Classification of Non-Combustible Metal Cladding Systems." ICC Evaluation Service Report on Metal Building Components.

4. Architectural Metal Systems Association. (2023). "Flat-Lock Metal Panel Technology: Design Principles, Material Selection, and Application Best Practices." Professional Reference Guide for Architects and Specifiers.