Picture this scenario: You've invested substantial resources into a commercial building project only to discover water leaks appearing on your newly installed metal roof after the first major storm season. The culprit? Choosing the wrong standing seam system for your specific application without understanding the critical differences between snap lock and Mechanical Lock Metal Roofing systems. This comprehensive comparison will equip you with the essential knowledge to make informed decisions that protect your investment and ensure decades of reliable performance, examining everything from installation methods and weather resistance to slope requirements and long-term maintenance considerations.

Understanding Mechanical Lock Metal Roofing Systems and Their Installation Methods

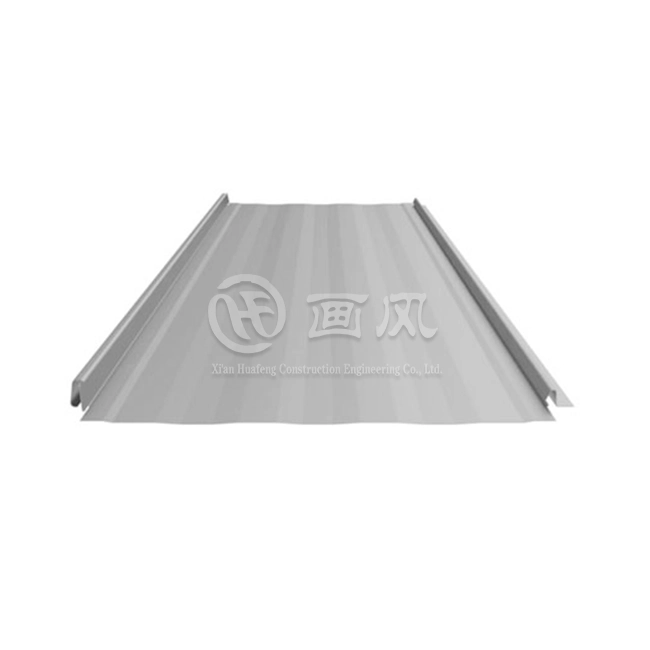

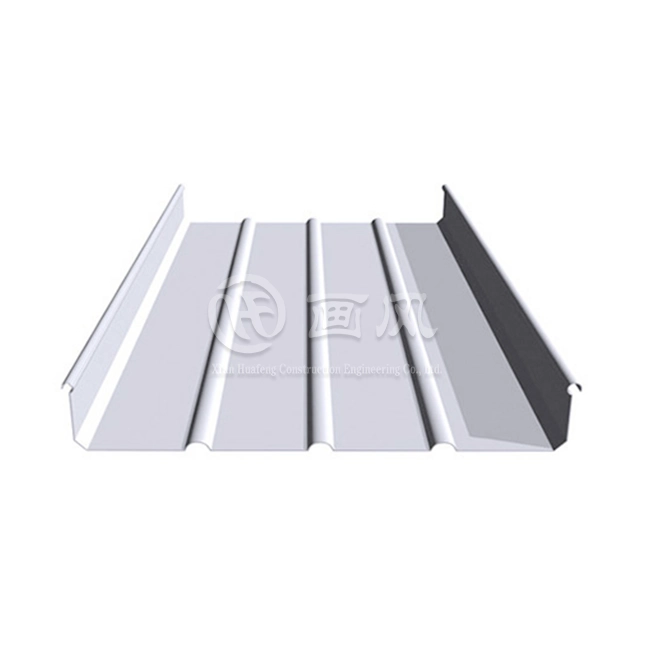

When evaluating standing seam metal roofing options, understanding the fundamental differences between snap lock and mechanically seamed systems becomes paramount for project success. Mechanical Lock Metal Roofing represents the premium standard in standing seam technology, utilizing specialized seaming equipment to crimp panel edges together through either single-lock or double-lock configurations. This crimping process creates an exceptionally tight, weather-resistant seal that outperforms other standing seam alternatives in demanding applications. The mechanical seaming process involves engaging two rollformed panel edges and using hand or robotic seaming tools to fold the material once for single-lock systems or twice for double-lock systems, creating seams bent at either ninety degrees or one hundred eighty degrees respectively. This mechanical interlocking provides superior structural integrity and weatherproofing capabilities that prove essential for challenging installations. In contrast, snap lock systems feature pre-formed male and female panel legs that simply snap together during installation without requiring specialized seaming equipment. While this simplified installation process offers advantages in labor efficiency and cost reduction, the snap-together connection cannot match the weathertight seal achieved through mechanical seaming processes. Snap lock panels attach to roof decks using clips fastened underneath the panels, maintaining the clean concealed-fastener aesthetic characteristic of standing seam systems. However, the mechanical connection in Mechanical Lock Metal Roofing systems, particularly double-lock configurations, creates virtually zero tolerance for water penetration by completely sealing the seam through the crimping process. This fundamental difference in seaming methodology directly impacts system performance, particularly regarding weather resistance, slope requirements, and long-term durability under various environmental conditions.

-

Performance Characteristics of Mechanically Seamed Metal Roofing

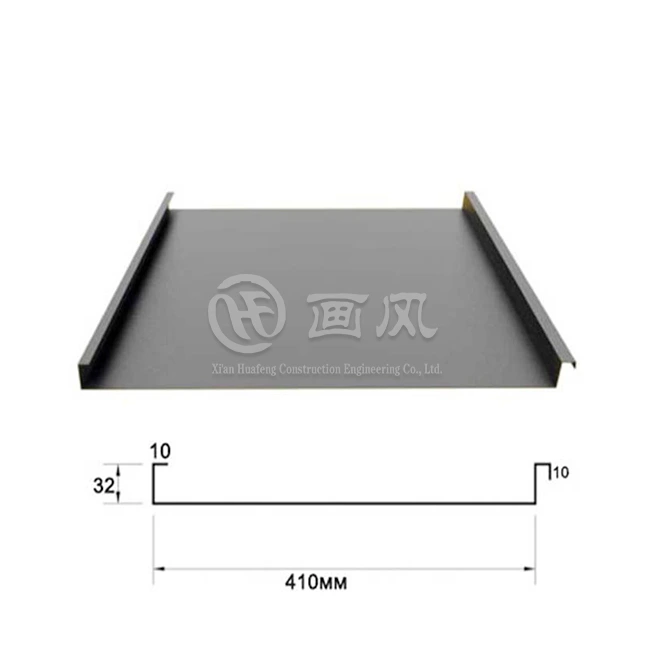

The superior weather resistance of Mechanical Lock Metal Roofing stems directly from its crimped seam construction, which eliminates gaps that could potentially allow water infiltration even under extreme conditions. Double-lock mechanically seamed systems prove particularly effective for low-slope applications, performing reliably on roof pitches as low as zero to three-in-twelve where water accumulation presents greater risks. This capability makes mechanical seaming the preferred choice for commercial and industrial applications where building designs frequently incorporate low-slope or nearly flat roof configurations. The tightly crimped seams withstand wind uplift forces exceeding ninety miles per hour, meeting stringent International Building Code requirements for high-wind zones. Additionally, mechanically seamed panels accommodate thermal expansion and contraction through specialized clip systems, preventing panel damage from temperature fluctuations that can cause metals to expand during heat exposure and contract during cold periods. The manufacturing process for Mechanical Lock Metal Roofing at advanced facilities like Xi'an Huafeng Construction Engineering Co., Ltd. ensures consistent panel quality through precision rollforming operations. Their seven color coating production lines and forty-plus specialized machines produce panels with thickness options ranging from zero-point-five to one-point-zero millimeters in materials including aluminum-magnesium-manganese alloys, galvalume steel, galvanized steel, stainless steel grades three-sixteen and three-zero-four, copper, and titanium-zinc. Surface treatments utilize PVDF fluorocarbon coatings applied at twenty-five to forty micrometers thickness on top surfaces, providing exceptional weather resistance and color retention for thirty-year warranty periods. The mechanical lock concealed connection system eliminates exposed fasteners entirely, with hidden clips and edge-fixing mechanisms providing enhanced wind resistance while maintaining the sleek architectural appearance demanded by contemporary commercial projects.

-

Installation Requirements and Cost Considerations

Mechanical Lock Metal Roofing installation requires more specialized knowledge, equipment, and labor time compared to snap lock alternatives, directly impacting project costs and scheduling. Robotic or hand seaming tools, which can cost contractors up to four hundred dollars per week per seaming unit to rent, become necessary equipment for mechanically seamed installations. The seaming process itself proves more time-intensive, as each panel connection must be properly crimped to ensure weathertight performance, with installers carefully monitoring seam quality throughout the process. This additional labor and equipment expense typically results in mechanically seamed installations costing seven dollars fifty cents to seventeen dollars per square foot in current market conditions, though complex roof configurations, deck assemblies, and accessory requirements can push costs higher. Despite these elevated initial expenses, the superior durability and performance of Mechanical Lock Metal Roofing often justifies the investment for projects requiring maximum weather protection or those in harsh environmental conditions. Professional installation by experienced contractors becomes even more critical for mechanically seamed systems than snap lock applications. Xi'an Huafeng Construction Engineering Co., Ltd. addresses this requirement through comprehensive on-site construction guidance, with installation technicians visiting project sites in advance to inspect work areas and verify that all necessary tools including pliers, edge-locking machines, hammers, and auxiliary materials such as rivets, structural adhesive, and specialized screws are complete and properly maintained. Their technical briefing meetings thoroughly review installation details and safety precautions before work commences, ensuring that every panel receives proper seaming attention. The company's systematic approach includes numbered panels corresponding to sectioned floor plans, preventing confusion during installation and quality assurance processes. Upon installation completion, comprehensive on-site testing ensures zero-leakage performance, with customers signing acceptance documentation only after confirming that the Mechanical Lock Metal Roofing system meets all specified performance standards.

Snap Lock Systems: Advantages and Limitations Compared to Mechanical Lock Metal Roofing

Snap lock standing seam systems offer distinct advantages in specific applications where their installation simplicity and cost-effectiveness align with project requirements. The primary benefit stems from elimination of mechanical seaming equipment requirements, allowing faster installation with reduced labor costs since panels simply snap together through their interlocking male and female legs. This simplified installation process can significantly reduce project timelines, particularly beneficial for residential applications or commercial projects with tight completion schedules. Snap lock systems maintain the concealed-fastener aesthetic of standing seam roofing, using clips attached underneath panels to preserve clean sightlines without exposed screw heads. The panels provide good weather resistance compared to exposed-fastener systems like corrugated metal or screw-down installations, making them suitable for many standard roofing applications in moderate climate zones. However, snap lock systems carry important limitations that make them unsuitable for certain demanding applications where Mechanical Lock Metal Roofing would prove necessary. Most critically, snap lock panels require minimum roof slopes of three-in-twelve pitch, restricting their use on low-slope or flat roof configurations common in commercial construction. Water accumulates more readily on lower-sloped surfaces, increasing leak potential through snap-together seams that lack the crimped weathertight seal of mechanically seamed systems. Climate considerations also factor prominently into system selection, as snap lock installations perform best in regions with moderate weather patterns rather than areas experiencing extreme temperatures, heavy snow loads, or high wind conditions. The snap-together connection, while adequate for many applications, cannot match the structural integrity of crimped Mechanical Lock Metal Roofing seams when subjected to severe uplift forces or thermal cycling that causes repeated expansion and contraction.

-

Weather Resistance and Slope Requirements

The weathertightness differential between snap lock and Mechanical Lock Metal Roofing becomes most apparent in challenging conditions where water infiltration risks increase. While snap lock systems eliminate exposed fastener penetrations that could allow water entry, the snap-together panel connection permits greater potential for moisture migration compared to mechanically crimped seams. Double-lock Mechanical Lock Metal Roofing configurations in particular create such tight seam closure that water penetration becomes virtually impossible even under driving rain conditions or when snow and ice accumulate on roof surfaces. This superior weatherproofing capability makes mechanically seamed systems essential for buildings in coastal regions subject to wind-driven rain, northern climates with heavy snow loads, or any application where absolute waterproofing proves critical for protecting building contents or operations. Roof slope requirements further differentiate these systems, with Mechanical Lock Metal Roofing accommodating much lower pitches than snap lock alternatives. While snap lock systems require three-in-twelve minimum slopes for reliable performance, mechanically seamed systems handle slopes from zero-in-twelve to three-in-twelve when double-locked, and perform excellently on steeper slopes as well. This versatility makes Mechanical Lock Metal Roofing suitable for virtually any roof configuration, from nearly flat commercial roofs to steep residential applications. The panel specifications available from manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd. support these varied applications through options including twenty-five-three-thirty, thirty-two-three hundred panel profiles with rib heights of twenty-five millimeters or thirty-two millimeters, accommodating different structural and aesthetic requirements while maintaining consistent weatherproofing performance across installations.

-

Maintenance and Repair Considerations

Long-term maintenance and potential repair requirements present another important comparison factor between snap lock and Mechanical Lock Metal Roofing systems. Snap lock panels offer advantages when panel replacement becomes necessary, as individual panels can be unsnapped and removed relatively easily without disturbing adjacent panels or requiring specialized unseaming equipment. This accessibility simplifies maintenance procedures and reduces repair costs when damage occurs from impacts, fallen debris, or other localized incidents. However, properly installed standing seam systems of either type should provide decades of maintenance-free performance when installed according to manufacturer specifications and appropriate for the application conditions. Mechanical Lock Metal Roofing systems, particularly double-locked configurations, require more involved repair procedures if panel replacement becomes necessary. The crimped seams must be carefully unseamed using specialized tools before damaged panels can be removed and replaced, then new seams must be properly formed to restore weathertight integrity. Despite this maintenance complexity, the superior durability of Mechanical Lock Metal Roofing often results in fewer required repairs over the system's lifespan compared to less robust alternatives. Xi'an Huafeng Construction Engineering Co., Ltd. supports long-term system performance through regular maintenance guidance provided to customers, ensuring that roof systems continue performing optimally throughout their thirty-year warranty period and beyond. Their comprehensive quality control measures, including more than a dozen inspection steps covering appearance, dimensions, salt spray resistance, adhesion, hardness, impact resistance, film thickness, acid resistance, weather resistance, and color consistency, ensure that every Mechanical Lock Metal Roofing panel leaving their facilities meets exacting performance standards.

Material Selection and Quality Standards for Mechanical Lock Metal Roofing

Material quality directly impacts standing seam metal roof performance, durability, and longevity regardless of whether snap lock or Mechanical Lock Metal Roofing systems are selected. Premium manufacturers source materials from verified suppliers maintaining rigorous quality standards, with Xi'an Huafeng Construction Engineering Co., Ltd. utilizing aluminum alloys from Alucosuper, YATAI, and LIDAO in grades three-zero-zero-three, three-zero-zero-four, and five-zero-five-two, steel products from BAOSTEEL, GUANZHOU, and XINYU including cold-rolled sheets, galvanized sheets, galvalume sheets, and color-coated sheets, stainless steel from Baosteel and Tsingshan in grades three-one-six and three-zero-four, titanium-zinc plates from NedZink, and copper from Chinalco in T2 and TP2 specifications. This careful material selection ensures consistent performance characteristics and reliable long-term durability across diverse environmental conditions. Incoming material inspection protocols verify that raw materials meet specifications before production commences, with suppliers required to provide material certifications and third-party testing reports. Inspection methodologies include full inspection for small quantities and high-value materials, and statistical sampling for larger quantities and regularly procured materials, preventing defective materials from entering production streams. Testing procedures evaluate product appearance, dimensional accuracy, salt spray resistance, coating adhesion, material hardness, impact resistance, film thickness measurements, acid resistance, accelerated weather resistance, and color consistency, ensuring every parameter meets established quality thresholds. This comprehensive quality assurance approach, combined with ISO nine-zero-zero-one, ISO fourteen-zero-zero-zero, and SGS guideline compliance, guarantees that Mechanical Lock Metal Roofing products deliver the exceptional performance required for demanding commercial and industrial applications.

-

Surface Treatment and Coating Technology

Surface treatment technology significantly influences Mechanical Lock Metal Roofing longevity and appearance retention over decades of exposure to weathering, ultraviolet radiation, temperature extremes, and atmospheric pollutants. PVDF fluorocarbon coatings represent the premium surface treatment option, offering superior weather resistance, color stability, and chemical resistance compared to standard polyester coatings. These advanced coating systems applied by Xi'an Huafeng Construction Engineering Co., Ltd. utilize top-surface PVDF layers of twenty-five to forty micrometers thickness combined with bottom-surface polyester coatings of ten to fifteen micrometers, providing comprehensive protection while optimizing coating performance and cost-effectiveness. The fluorocarbon molecular structure in PVDF coatings delivers exceptional resistance to ultraviolet degradation, preventing the chalking and fading that can compromise appearance and protective capabilities over time. Color options extend across RAL standard colors and custom formulations, allowing architectural specifications to be met precisely while maintaining coating performance standards. The company's seven color coating production lines ensure consistent color matching and coating quality across large production runs, critical for commercial projects requiring numerous panels with perfect color uniformity. Fire-rating compliance meets Class-A non-combustible standards per ASTM E108 and EN thirteen-five-zero-one specifications, essential for commercial building code requirements. Load capacity specifications confirm panels can support snow loads and maintenance loads exceeding one-point-five kilonewtons per square meter, while wind resistance testing validates performance in winds exceeding ninety miles per hour in accordance with International Building Code requirements. These rigorous performance standards ensure that Mechanical Lock Metal Roofing installations provide reliable protection throughout their service lives.

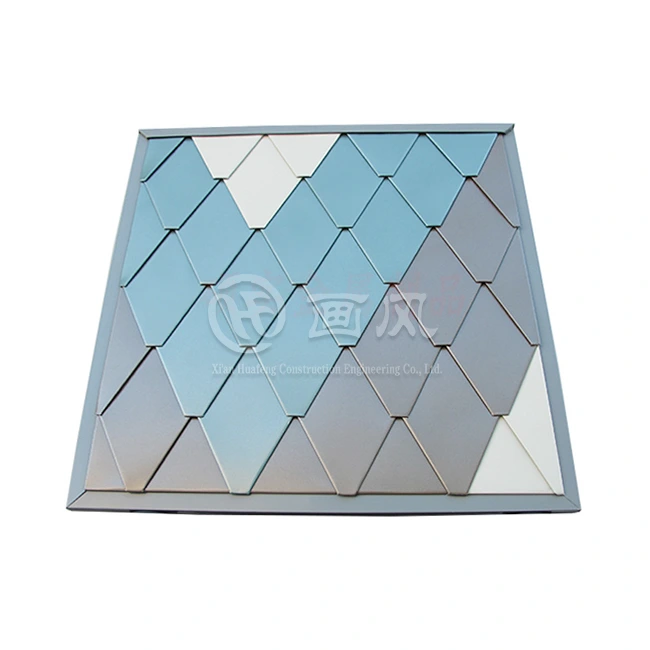

Project Applications and Case Studies Demonstrating Mechanical Lock Metal Roofing Performance

Real-world project installations demonstrate how Mechanical Lock Metal Roofing performs across diverse commercial, industrial, and institutional applications. Xi'an Huafeng Construction Engineering Co., Ltd. has successfully completed major projects including the Xiongan Station Commercial Body featuring aluminum-magnesium-manganese metal roofing, Xi'an International Convention And Exhibition Center metal roof installations, The Metal Roof Project at Xi'an Station East Auxiliary Building, South Hall two-dash-two of Jinghe New City International Culture And Art Center, Liyuanping Highway Station metal roof installations, Weihua Cadre College Teaching Building and Office Building incorporating aluminum-magnesium-manganese metal roof and wall systems, Hangzhou Sanpu Drainage Pump Station aluminum-magnesium-manganese metal roof and wall applications, archaeological museum design deepening projects, and Inner Mongolia Tongliao Art Museum metal roof and wall installations. These diverse projects showcase Mechanical Lock Metal Roofing versatility across building types, from transportation facilities and educational campuses to cultural institutions and infrastructure applications. Each installation required custom engineering solutions addressing specific structural requirements, aesthetic considerations, environmental conditions, and performance specifications. The company's comprehensive design services include structural three-dimensional modeling, load analysis calculations, drainage system simulations, and material specification advisory support, ensuring optimal system performance for each unique application. Their one-to-one drawing deepening process analyzes architectural engineering drawings to list feasible alternatives, determines appropriate panel types for specific roof structures, develops detailed node drawings for different building sections, and finalizes signed and confirmed construction documents through multiple communication and confirmation cycles with clients.

-

Manufacturing Capabilities Supporting Large-Scale Projects

The manufacturing infrastructure supporting Mechanical Lock Metal Roofing production must accommodate the scale and precision requirements of major commercial installations. Xi'an Huafeng Construction Engineering Co., Ltd. operates three state-of-the-art facilities including a raw material production plant covering two hundred thousand square meters in Anhui and two plate and accessories processing plants located in Hangzhou and Xi'an respectively. This distributed manufacturing network provides geographic flexibility for project support while maintaining consistent quality standards across all production locations. Their production capabilities include seven color coating lines, one laminating production line, ten longitudinal and transverse shearing production lines, fully automatic punching production lines, and more than forty shearing machines, presses, bending machines, and specialized equipment, enabling monthly production capacity exceeding one thousand tons of finished Mechanical Lock Metal Roofing products. Quality control extends throughout the manufacturing process from material procurement through finished product inspection and packaging. The purchasing department coordinates material inventory and procurement based on technical department processing lists and drawings, conducting multiple supplier inspections to confirm material brands before use. Production processing follows detailed manufacturing drawings broken down from design documents, with sequential numbering systems ensuring that panels, components, and accessories maintain proper identification throughout processing, quality assurance inspection, packaging, and ultimate site installation. Finished product inspection verifies appearance quality, dimensional accuracy, flatness, curvature, and all performance parameters before products receive approval for shipment. Packaging design facilitates efficient on-site installation, with products divided into sections corresponding to roof plans and identification cards containing section plans and product number lists, streamlining the installation process and minimizing potential for errors or confusion during construction.

Design Integration and Engineering Support for Mechanical Lock Metal Roofing

Successful Mechanical Lock Metal Roofing installations require comprehensive engineering support integrating architectural vision with structural requirements and building code compliance. Design professionals must consider numerous factors including roof slope and configuration, building location and climate conditions, wind and snow load requirements, thermal movement accommodation, drainage patterns, aesthetic preferences, budget constraints, and long-term maintenance considerations. Advanced manufacturers provide engineering expertise supporting these complex decision-making processes, with services extending from initial concept development through construction completion and post-installation support. Xi'an Huafeng Construction Engineering Co., Ltd. exemplifies this comprehensive approach through their integrated development concept combining architecture, technology, and aesthetics while prioritizing green sustainable development principles. Their mission focuses on developing metal roof solutions that add production capacity benefits, solve idle building roof space waste, and add architectural beauty to structures. This philosophy manifests in more than twenty registered patents for roofing systems, various trademarks, and computer software certifications supporting their design and engineering capabilities. Their technical team provides structural three-dimensional modeling services enabling visualization of proposed systems, load analysis calculations ensuring structural adequacy, drainage system simulations optimizing water management, and material specification advisory support helping clients select optimal products for their specific requirements.

-

Sample Production and Approval Processes

Factory sample production ensures that proposed Mechanical Lock Metal Roofing specifications meet project requirements before full-scale manufacturing commences. Sample panels are produced based on confirmed parameters including board type, material selection, thickness specifications, surface treatment methodology, and color selections. These physical samples allow customers to verify that dimensions, materials, colors, and overall appearance meet expectations and architectural specifications before committing to large-scale production. Once customers confirm all sample parameters, samples are sealed and maintained as standards for subsequent product processing, production operations, and final acceptance inspections, ensuring consistency throughout the manufacturing process. Processing drawing deepening breaks detailed design drawings into specific manufacturing instructions enabling production departments to fabricate components precisely as specified. Each panel unit receives sequential numbering according to project specifications and quantities, ensuring that production department processing, quality assurance department inspection and packaging, and on-site installation all proceed according to systematic numbering schemes preventing confusion or errors. This meticulous approach to documentation and process control, combined with comprehensive material traceability systems, real-time quality control monitoring, and advanced roll-forming technology, ensures that every Mechanical Lock Metal Roofing panel delivered to project sites meets exacting quality standards and integrates seamlessly during installation operations.

Conclusion

Selecting between snap lock and Mechanical Lock Metal Roofing systems requires careful evaluation of roof slope, climate conditions, budget constraints, and performance expectations, with mechanically seamed systems providing superior weather resistance, accommodating lower slopes, and delivering enhanced durability for demanding applications despite higher initial costs.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in two-thousand-eighteen as a high-tech enterprise recognized by Shaanxi Province in two-thousand-twenty, brings exceptional capabilities to Mechanical Lock Metal Roofing projects through first-level building curtain wall qualifications and third-level building steel structure qualifications. As a leading China Mechanical Lock Metal Roofing factory, China Mechanical Lock Metal Roofing supplier, and China Mechanical Lock Metal Roofing manufacturer offering China Mechanical Lock Metal Roofing wholesale with competitive Mechanical Lock Metal Roofing price structures, they provide High Quality Mechanical Lock Metal Roofing for sale backed by comprehensive one-stop services from design through installation. Their raw material production plant in Anhui spanning two hundred thousand square meters, combined with processing facilities in Hangzhou and Xi'an housing seven color coating lines, one laminating line, ten shearing lines, and over forty specialized machines, enables monthly production exceeding one thousand tons with minimum order quantities of just five hundred square meters or one ton and delivery timeframes of fifteen to twenty days. Their engineering design experience, construction expertise, twenty-plus patent certificates, CE certification, ISO certification, and SGS certification demonstrate their commitment to quality excellence serving Fortune five hundred companies. Contact their team at huafeng@hfmetalroof.com today to discuss your project requirements and discover how their customized solutions, rigorous quality testing, and comprehensive support can deliver the high-performance Mechanical Lock Metal Roofing system your project demands. Bookmark this resource for future reference when roofing challenges arise.

References

1. Smith, J. R. (2023). Standing Seam Metal Roofing: Design and Installation Standards. National Roofing Contractors Association Technical Publication.

2. Anderson, M. K., & Wilson, D. L. (2024). Comparative Analysis of Concealed Fastener Metal Roofing Systems. Journal of Building Envelope Design, Volume 18, Issue 3.

3. Thompson, R. P. (2022). Metal Roofing Systems for Commercial Applications: Performance Guidelines. American Society of Civil Engineers Building Envelope Technology Committee.

4. Martinez, C. A., Johnson, L. M., & Davis, S. R. (2023). Weather Resistance and Durability of Standing Seam Metal Roof Assemblies. Building Science Research Institute Technical Report Series.