Picture this: water seeping through your commercial building's roof during a storm, panels lifting under high winds, and repair crews unable to access damaged sections without tearing apart entire roof sections. These are the painful realities many facility managers face with traditional Trapezoidal Standing Seam Roofing systems. However, modern metal roofing innovations have emerged to address these critical vulnerabilities, offering building owners peace of mind through enhanced waterproofing, superior wind resistance, and simplified maintenance protocols that extend roof lifespan while reducing long-term operational costs.

Understanding Traditional Trapezoidal Standing Seam Roofing Limitations

Traditional Trapezoidal Standing Seam Roofing systems have served the construction industry for decades as cost-effective solutions for large-span commercial and industrial buildings. The trapezoidal profile, characterized by its angled leg design connecting the male and female panel edges, provides structural rigidity while allowing for thermal expansion and contraction. These systems typically feature wider panel coverage of eighteen to twenty-four inches, making them economically attractive for projects with significant square footage requirements. Installation over open framing or purlins reduces material costs compared to solid deck applications, and the concealed fastener design presents a cleaner aesthetic than through-fastened systems. Manufacturing efficiency allows for competitive pricing, with standard gauge options ranging from twenty-two to twenty-six gauge steel or aluminum materials that balance structural performance with weight considerations. Despite these advantages, facility managers and building owners consistently encounter three fundamental challenges that compromise the long-term performance and reliability of traditional Trapezoidal Standing Seam Roofing installations. Understanding these shortcomings is essential for making informed decisions about roofing system selection and recognizing when advanced metal roofing solutions provide superior value propositions for new construction and retrofit applications.

Trapezoidal Standing Seam Roofing

-

The End Lap Leakage Problem

End lap connections represent the most vulnerable points in traditional Trapezoidal Standing Seam Roofing assemblies where water intrusion commonly occurs. When panel lengths exceed manufacturing or transportation limitations typically around forty to fifty feet, contractors must create overlapping joints between consecutive panels. These end lap details require field-applied sealant tapes and penetrating fasteners to maintain weather tightness, introducing potential failure points into an otherwise concealed fastener system. Over time, thermal cycling causes sealant materials to deteriorate, ultraviolet radiation breaks down adhesive bonds, and differential movement between overlapping panels creates pathways for moisture migration. The screw penetrations required to secure end laps compromise the roof membrane integrity, and improper installation techniques frequently result in inadequate overlap dimensions or insufficient sealant coverage. Water infiltration at end laps leads to concealed deterioration of structural decking, insulation saturation, interior damage to building contents, and costly emergency repairs that disrupt facility operations and tenant activities.

-

Insufficient Wind Uplift Resistance

The trapezoidal leg configuration inherently provides lower wind uplift capacity compared to vertical leg standing seam systems due to geometric limitations in clip engagement and seam strength. Standard clips measuring eight inches in length with sixteen-gauge thickness attach to structural members and engage the panel legs, but the angled geometry of trapezoidal profiles creates mechanical disadvantages when resisting upward wind forces. During severe weather events, negative pressure on roof surfaces generates uplift forces that stress the clip-to-panel connection and the seamed joint between adjacent panels. Traditional Trapezoidal Standing Seam Roofing systems may achieve wind ratings suitable for moderate exposure conditions, but buildings in coastal regions, high-elevation sites, or areas subject to severe weather require enhanced performance specifications. Insufficient wind resistance results in panel displacement, seam separation, complete system failure during hurricanes or tornadic events, and substantial property damage including water intrusion and interior destruction. The economic consequences extend beyond immediate repair costs to include business interruption, inventory losses, and potential liability for inadequate roof performance in predictable severe weather scenarios.

-

Repair and Modification Challenges

The asymmetrical nature of traditional trapezoidal panel designs creates significant obstacles when building owners need to repair damaged sections, accommodate new roof penetrations, or modify existing installations for facility expansions. Each panel features distinct male and female edges that must align in a specific directional sequence during installation, meaning contractors cannot simply remove and replace individual damaged panels without disrupting adjacent sections. Accessing panels in the middle of a roof plane requires progressive disassembly from the roof edge, consuming substantial labor hours and exposing interior spaces to weather during extended repair periods. Adding equipment curbs for HVAC installations, creating new roof penetrations for utility services, or integrating building additions demands extensive panel removal and reinstallation that multiplies project costs and complexity. The directional dependency of Trapezoidal Standing Seam Roofing assemblies also limits design flexibility for complex roof geometries involving valleys, dormers, or intersecting planes where panel direction changes become necessary. These practical limitations frustrate facility managers who require adaptable roof systems capable of accommodating evolving building needs throughout their service life without requiring complete roof replacement for minor modifications.

Advanced Metal Roofing Solutions for Trapezoidal Systems

The metal roofing industry has responded to these traditional Trapezoidal Standing Seam Roofing shortcomings through innovative system designs that preserve the economic advantages of trapezoidal profiles while addressing critical performance vulnerabilities. Modern solutions incorporate site-forming capabilities, enhanced clip technologies, symmetrical panel configurations, and specialized installation methodologies that collectively resolve the three major limitations plaguing conventional systems. These advancements enable building owners to specify Trapezoidal Standing Seam Roofing for projects where previously they might have selected more expensive alternatives, expanding the practical application range for cost-effective metal roofing solutions across industrial warehousing, manufacturing facilities, distribution centers, and large-format retail buildings.

-

Site-Formed Continuous Panel Technology

Site-forming equipment represents a transformative approach to eliminating end lap vulnerabilities in Trapezoidal Standing Seam Roofing installations by producing continuous panels directly at the project site. Portable roll-forming machines mounted on trailers or positioned on rooftops accept coil stock and progressively shape metal into finished panel profiles in lengths up to two hundred fifty feet or more, limited only by practical handling considerations rather than manufacturing constraints. This on-site production capability allows contractors to create custom panel lengths matching actual roof plane dimensions, completely eliminating the need for end lap joints and their associated waterproofing challenges. The continuous panel approach removes hundreds of potential leak points from large roof areas, as each roof section from eave to ridge consists of a single uninterrupted metal panel without field-applied sealants or penetrating fasteners along the panel length. Transportation costs decrease substantially when delivering coil stock rather than finished panels, packaging waste is eliminated, and installation labor productivity improves because crews avoid time-consuming end lap detail execution. Quality control improves dramatically as the only seams requiring attention are the mechanically formed standing seams between adjacent panels, which follow standardized procedures rather than variable field conditions affecting end lap installations.

-

Enhanced Clip Systems and Wind Performance

Specialized clip designs dramatically increase wind uplift capacity for Trapezoidal Standing Seam Roofing applications through geometric optimization and material specification improvements. Extended-length clips measuring sixteen inches rather than standard eight-inch dimensions distribute uplift forces across greater structural member engagement, reducing localized stress concentrations and improving load transfer efficiency. The increased clip footprint creates more robust mechanical connections capable of resisting higher wind pressures without panel displacement or seam separation. Oversized seam profiles measuring two and three-quarter inches tall rather than standard dimensions provide additional material engagement area when mechanically seamed, strengthening the panel-to-panel connection that must resist both uplift and lateral wind forces. Some advanced systems incorporate super clips with enhanced thickness specifications and reinforced attachment zones specifically engineered for high-wind exposure categories. These component improvements enable Trapezoidal Standing Seam Roofing systems to achieve wind ratings previously reserved for more expensive vertical leg panels, making them viable for coastal construction, tall building applications, and facilities in tornado-prone regions. The enhanced performance comes with minimal cost premium compared to standard clip specifications, representing excellent value for building owners prioritizing roof system resilience and long-term durability in challenging wind environments.

-

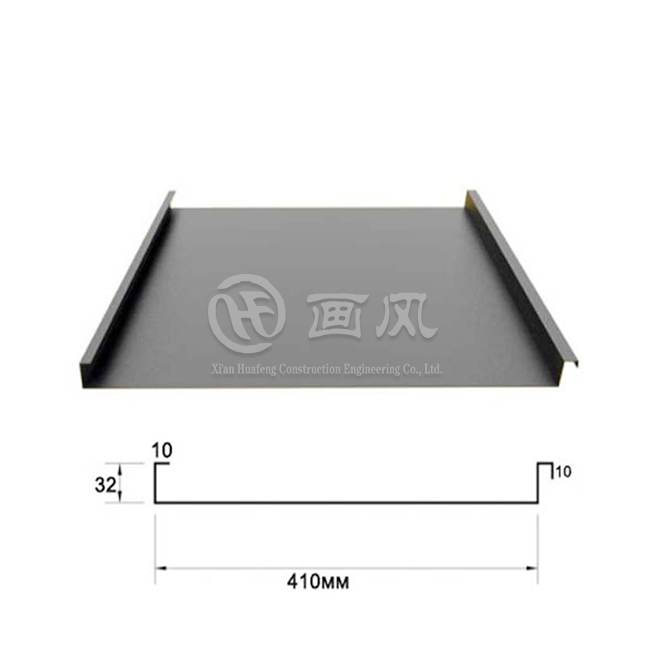

Symmetrical Panel Design Benefits

Symmetrical standing seam configurations revolutionize repair and modification capabilities for metal roofing systems by creating panels with identical left and right edges that eliminate directional dependencies. Unlike traditional Trapezoidal Standing Seam Roofing with distinct male and female legs requiring sequential installation from one roof edge, symmetrical panels feature matching profiles on both sides that allow bidirectional installation and mid-roof access. When damaged panels require replacement, contractors can mechanically unseal the standing seams on both sides of the affected panel, lift it out, and install a new panel without disturbing adjacent roof areas. This surgical repair approach minimizes labor costs, reduces weather exposure during repair activities, and enables rapid response to roof damage events. Building additions and facility expansions become significantly less complex because contractors can access the connection point between existing and new roof sections without progressive panel removal from distant edges. Creating new roof penetrations for mechanical equipment, skylights, or utility services requires only local panel removal and custom flashing fabrication rather than extensive roof disassembly. The operational flexibility of symmetrical Trapezoidal Standing Seam Roofing systems provides building owners with adaptable infrastructure capable of accommodating future modifications without the prohibitive costs and disruptions associated with asymmetrical panel configurations.

Quality Manufacturing and Material Selection

Superior metal roofing performance depends fundamentally on material quality, manufacturing precision, and coating technology selection that determine long-term durability and aesthetic retention. Building owners specifying Trapezoidal Standing Seam Roofing must evaluate substrate materials, finish systems, and manufacturing standards to ensure their roof investments deliver expected service life and performance characteristics throughout decades of exposure to weathering, thermal cycling, and environmental stresses.

-

Premium Substrate Materials and Specifications

Advanced Trapezoidal Standing Seam Roofing systems utilize carefully selected metal substrates optimized for specific application requirements and environmental conditions. Aluminum alloy options including 3003, 3004, and 5052 designations provide excellent corrosion resistance for coastal environments and industrial facilities with exposure to chemical atmospheres, with aluminum's natural oxide layer offering inherent protection against atmospheric oxidation. These aluminum specifications deliver strength-to-weight ratios superior to steel alternatives while maintaining formability for complex panel geometries and field-fabricated trim components. Galvanized steel substrates with zinc coating protection serve general commercial applications where cost considerations prioritize steel's structural efficiency and established supply chain availability. Galvalume steel combining aluminum and zinc coating formulations provides enhanced corrosion protection exceeding standard galvanized performance, particularly along cut edges and formed details where coating damage occurs during fabrication. Stainless steel grades including 304 and 316 specifications offer maximum corrosion resistance for extreme environments but command premium pricing that limits applications to specialized projects with specific performance requirements. Material thickness selection balances structural span capability against weight and cost considerations, with common specifications ranging from 0.7 millimeters to 1.2 millimeters depending on panel width, rib height, and structural loading requirements. Premium manufacturers maintain rigorous incoming material inspection protocols including certification review, dimensional verification, coating weight testing, and mechanical property validation to ensure substrate materials meet design specifications before entering production processes.

-

High-Performance Coating Technologies

Finish systems applied to Trapezoidal Standing Seam Roofing panels determine long-term color retention, weathering resistance, and maintenance requirements throughout the roof service life. Polyester coatings represent economical finish options suitable for projects prioritizing initial cost over maximum durability, providing adequate protection for inland locations with moderate ultraviolet exposure and limited industrial contamination. These PE finishes typically carry manufacturer warranties of fifteen to twenty years depending on application environment and maintenance protocols. PVDF fluoropolymer coatings formulated with seventy percent resin content deliver superior weathering performance through enhanced ultraviolet resistance, chemical stability, and color retention properties that minimize fading and chalking throughout decades of service. Premium PVDF finishes backed by thirty to forty year warranties provide building owners with long-term aesthetic protection and reduced recoating requirements that lower life-cycle costs despite higher initial investment. Advanced coating technologies incorporate infrared-reflective pigments that reduce solar heat absorption, improving building energy efficiency and extending substrate service life by moderating thermal cycling stress. Cool roof coatings meeting Energy Star certification standards deliver measurable energy savings for cooling-dominated climates while contributing toward LEED certification and sustainability objectives. Coating selection must consider project location, building use, aesthetic requirements, budget parameters, and long-term ownership plans to optimize the balance between initial cost and life-cycle value.

Professional Design and Installation Excellence

Even the most advanced Trapezoidal Standing Seam Roofing systems cannot deliver intended performance without proper design integration, installation expertise, and quality control verification. Building owners must engage qualified design professionals and experienced installation contractors who understand the technical requirements, industry standards, and best practices governing metal roofing applications.

-

Comprehensive Design Services and Project Planning

Successful Trapezoidal Standing Seam Roofing installations begin with thorough design services that analyze project requirements, evaluate alternative solutions, and develop detailed specifications and construction documents. Professional design teams conduct structural analysis using three-dimensional modeling software that evaluates roof geometry, identifies load paths, and verifies member sizing for anticipated dead loads, live loads, wind uplift, and snow accumulation specific to project location and building classification. Drainage system simulation using computational fluid dynamics predicts water flow patterns across complex roof surfaces, ensuring adequate slope provisions, proper gutter and downspout sizing, and effective scupper placement that prevents ponding conditions and water infiltration. Material specification advisory services help building owners navigate the extensive options for substrate materials, coating systems, insulation types, and accessory components based on project budget, performance requirements, aesthetic preferences, and long-term maintenance considerations. Detailed construction documents including plans, elevations, sections, and enlarged details communicate design intent to contractors and facilitate accurate pricing, efficient installation, and quality verification throughout construction. Design professionals coordinate penetrations, equipment supports, and expansion joint locations during the planning phase, avoiding costly field modifications and ensuring proper integration of roofing, structural, mechanical, and electrical building systems.

-

Precision Manufacturing and Quality Assurance

Advanced manufacturing facilities supporting Trapezoidal Standing Seam Roofing production incorporate multiple quality control checkpoints that verify dimensional accuracy, surface finish integrity, and component performance before materials ship to project sites. Incoming material inspection protocols verify substrate thickness, coating specification, color accuracy, and mechanical properties through sampling and testing procedures that prevent defective materials from entering production. Production equipment including roll-forming lines, slitting machines, and CNC-controlled fabrication centers maintain tight dimensional tolerances that ensure proper panel fit-up and seam engagement during field installation. Real-time quality monitoring systems track production parameters including forming speeds, roller pressures, and dimension verification at multiple stations along manufacturing lines, triggering automatic adjustments or production stops when parameters drift outside specification windows. Finished panel inspection procedures examine surface condition for coating damage, verify dimensional accuracy against shop drawings, and confirm proper packaging and labeling for shipment tracking and field organization. Material traceability systems maintain documentation linking finished panels to specific coil lots, production runs, and test results, enabling rapid identification and resolution of any quality issues discovered during installation or subsequent service. Manufacturers operating under ISO 9001 quality management systems and ISO 14001 environmental management standards demonstrate organizational commitment to consistent quality and continuous improvement that benefit building owners through reliable product performance and reduced construction defects.

Conclusion

Modern metal roofing innovations have successfully resolved the three critical shortcomings that historically limited Trapezoidal Standing Seam Roofing applications through site-forming technology, enhanced clips, and symmetrical designs that improve waterproofing, wind resistance, and repair accessibility.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a leading China Trapezoidal Standing Seam Roofing manufacturer and China Trapezoidal Standing Seam Roofing supplier, established in 2018 with comprehensive capabilities in metal roofing system design, production, and construction. Our recognition as a Shaanxi Province high-tech enterprise and certifications including first-level building curtain wall qualification and third-level steel structure qualification demonstrate our technical expertise and industry leadership. With a 200,000 square meter raw material production facility in Anhui and processing plants in Hangzhou and Xi'an, we operate seven color coating lines, one laminating line, and ten shearing production lines supported by over forty pieces of specialized equipment. We maintain more than twenty registered patents, ISO9001 and ISO14000:14001 certifications, and SGS compliance, ensuring High Quality Trapezoidal Standing Seam Roofing that meets the most demanding international standards. Our China Trapezoidal Standing Seam Roofing factory delivers customized solutions for industrial, commercial, and public buildings with competitive Trapezoidal Standing Seam Roofing price structures and Trapezoidal Standing Seam Roofing for sale through our one-stop service model. As a trusted China Trapezoidal Standing Seam Roofing wholesale partner for Fortune 500 companies, we provide design optimization, material testing, precision manufacturing, and professional installation guidance. Contact our team today at huafeng@hfmetalroof.com to discuss your project requirements and discover how our engineering expertise, manufacturing capacity, and quality certifications deliver exceptional value for your metal roofing investment.

References

1. Griffin, C.W. & Fricklas, R.L. "Manual of Low-Slope Roof Systems: Fourth Edition." McGraw-Hill Education, 2019.

2. Revie, R.W. & Uhlig, H.H. "Corrosion and Corrosion Control: An Introduction to Corrosion Science and Engineering." John Wiley & Sons, 2008.

3. Metal Construction Association. "Technical Bulletin: Standing Seam Roof System Design and Installation Guidelines." Metal Construction Association, 2022.

4. American Society of Civil Engineers. "ASCE 7: Minimum Design Loads and Associated Criteria for Buildings and Other Structures." American Society of Civil Engineers, 2022.