Improper drip edge installation causes water infiltration beneath roofing panels, leading to structural damage, mold growth, and premature system failure costing thousands in repairs. Installing drip edge correctly on your Snap Lock Standing Seam Roof creates a watertight barrier that protects your investment, prevents costly damage, and ensures decades of reliable performance through proper water management and edge protection.

Understanding Drip Edge Installation for Snap Lock Standing Seam Roofs

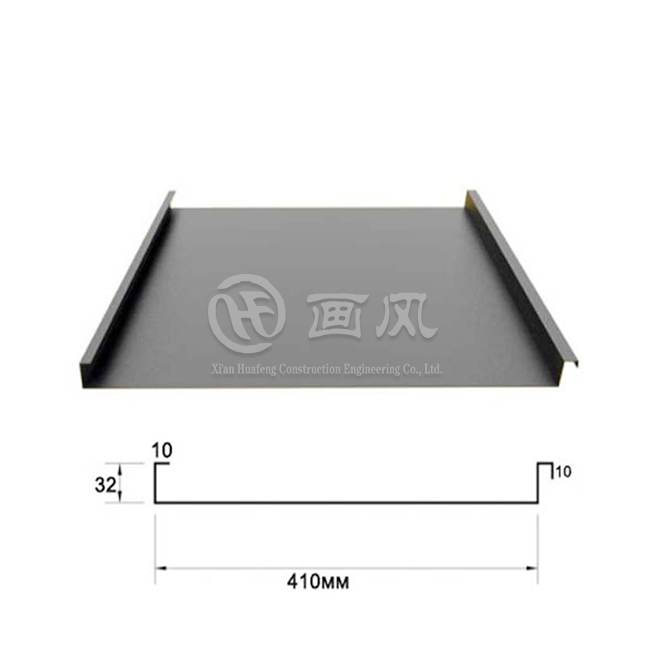

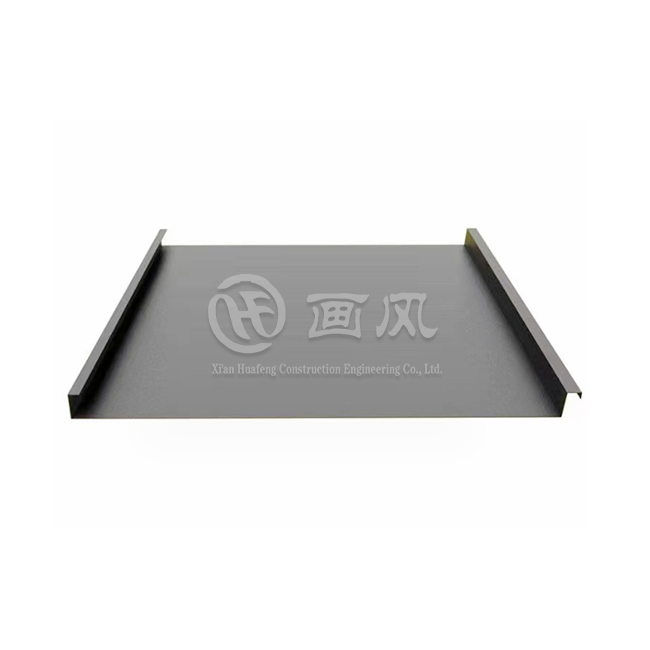

The drip edge represents one of the most critical components in any standing seam metal roofing system, yet it remains frequently misunderstood or improperly installed. When you install a Snap Lock Standing Seam Roof, the drip edge serves multiple essential functions that extend far beyond simple aesthetics. This metal flashing component creates a mechanical barrier between your roofing panels and the building structure, directing water away from fascia boards, preventing moisture intrusion into the roof deck, and providing a secure attachment point for the lower edge of your metal panels. The drip edge acts as both a protective shield and a functional cleat system that locks the hemmed edge of standing seam panels in place, preventing wind uplift and ensuring the entire roofing system performs as designed. Understanding the specific requirements for drip edge installation on snap lock systems differs significantly from traditional roofing applications. Unlike mechanically seamed or screw-down metal roofing, Snap Lock Standing Seam Roof systems utilize hidden fasteners and a specialized clip mechanism that requires precise alignment with the drip edge. The installation sequence begins with proper measurement and layout, ensuring the drip edge sits at the correct elevation to accommodate the panel hem while maintaining adequate overhang for water drainage. Professional installers recognize that the drip edge must be positioned to allow the lower hem of each panel to hook securely around the extended lip, creating a positive lock that resists both wind pressure and thermal movement. This integration between drip edge and panel system represents the foundation of a successful installation, making proper technique essential for long-term performance.

-

Critical Pre-Installation Preparation Steps

Before installing any drip edge components, comprehensive roof preparation ensures optimal results and prevents future complications. The substrate must be thoroughly inspected for structural integrity, with all damaged decking replaced and fasteners secured. A high-quality underlayment system should be installed according to manufacturer specifications, with particular attention paid to the eave area where water concentration occurs. When working with Snap Lock Standing Seam Roof installations, the underlayment typically extends over the drip edge to provide maximum protection against ice damming and wind-driven rain. This configuration allows easier drip edge replacement during future maintenance while ensuring water cannot wick upward beneath the flashing. The preparation phase also includes installing fascia wrap when specified, creating an additional protective layer that enhances both durability and aesthetic appeal. Material selection for drip edge components should match or exceed the corrosion resistance of your standing seam panels. For coastal installations or high-humidity environments, aluminum alloy drip edge provides superior salt spray resistance and extended service life. Inland applications often utilize galvalume steel with appropriate gauge thickness to ensure structural rigidity. The profile of the drip edge must be specifically designed for standing seam applications, featuring an extended lip dimension that accommodates the panel hem depth while providing adequate clearance for proper engagement. Standard residential drip edge profiles typically will not function correctly with Snap Lock Standing Seam Roof systems, making it essential to source components specifically engineered for standing seam applications.

-

Precise Drip Edge Installation Methodology

Installing drip edge for standing seam systems requires meticulous attention to alignment and fastening patterns. Begin at one corner of the eave, positioning the first section with the lower edge aligned to your predetermined layout line. The drip edge should extend approximately one inch beyond the fascia face to ensure proper water discharge into gutters without back-splash onto building components. Fasten the drip edge using appropriate substrate fasteners at eight-inch centers in a staggered pattern, ensuring penetrations occur through solid decking rather than into gaps between boards. This staggered fastening pattern distributes stress evenly across the flashing, preventing oil-canning or distortion under thermal expansion cycles. Overlapping adjacent drip edge sections requires specific techniques to maintain waterproof integrity. Each overlap should measure a minimum of six inches, with the upslope section positioned over the downslope piece to shed water effectively. Apply a continuous bead of high-quality silicone sealant three inches from the overlap edge before positioning the overlapping section, then compress firmly to create a weathertight seal. When approaching corners or transitions, custom cutting becomes necessary to maintain clean lines and proper function. Mark the drip edge at a 45-degree angle from the corner point, then use metal-cutting snips to create a clean cut that allows proper folding and overlap. The tab created at corners should be folded downward 90 degrees using a hand seamer, ensuring it sits flush against the perpendicular fascia face.

Integrating Metal Panels with Installed Drip Edge

Once drip edge installation is complete and verified for proper alignment, the critical process of panel integration begins. This phase determines whether your Snap Lock Standing Seam Roof will perform optimally or experience problems with water infiltration and panel security. The first panel, often called the starter panel, sets the stage for the entire roof installation. Position this panel with its lower hem extended approximately two inches beyond the drip edge lip initially, allowing for proper engagement without forcing. The hemmed edge of the panel must be carefully aligned with the drip edge channel, then the panel is pressed downward with hand pressure to snap the hem around the extended lip of the drip edge. This creates a mechanical lock that resists wind uplift while allowing controlled thermal movement along the panel length. After the lower edge engages properly with the drip edge, carefully slide the panel upslope to fully seat the hem around the drip edge lip while establishing the correct expansion gap at the ridge. This expansion gap, typically 15 millimeters, accommodates thermal expansion and contraction without causing buckling or panel distortion. The snap-lock mechanism on the opposite side of the panel receives the hidden fastener clips that secure it to the roof deck. These clips should be positioned with two within the first eight inches from the eave to resist wind pressure, then spaced at two-foot intervals up the slope according to engineering specifications. Never use hammers or mallets to snap panels together, as this can damage the ribs or cause denting at fastener locations.

-

Panel Layout and Alignment Verification

Maintaining proper modularity across the entire roof surface ensures professional appearance and optimal performance. As each Snap Lock Standing Seam Roof panel is installed, measure across multiple ribs at both eave and ridge ends to verify square alignment. Any deviation from parallel creates a saw-tooth effect at the eave that appears unprofessional and may indicate improper installation that could compromise weathertightness. Establish reference lines before beginning panel installation by snapping chalk lines that create a perpendicular layout to the drip edge. The traditional 12-16-20 triangle method provides accurate right-angle verification: measure 12 feet horizontally along the drip edge, 16 feet vertically up the roof slope, and verify that the diagonal distance between these points measures exactly 20 feet. This geometric verification ensures the first panel installs perfectly square, establishing accurate alignment for all subsequent panels. Continuous monitoring throughout the installation process catches problems before they compound across the entire roof surface. Check panel alignment after every third or fourth panel, making micro-adjustments as necessary to maintain consistent spacing and perpendicular orientation. When working with large roof areas requiring dozens of panels, even small angular deviations multiply across the width, potentially resulting in significant alignment problems at the opposite rake edge. The hidden fastener system of Snap Lock Standing Seam Roof designs allows for minor adjustments during installation, but only if problems are identified early. Once multiple panels are locked together, making corrections becomes exponentially more difficult and may require removing and reinstalling numerous panels.

Advanced Trim and Flashing Integration

Beyond basic drip edge installation, comprehensive weatherproofing requires proper integration of all trim components and flashings. Rake edges, where sloped roof planes terminate at vertical gable ends, require specific trim profiles that coordinate with the drip edge system. Box gable trim or zee closure systems create clean transitions while maintaining the concealed fastener aesthetic of standing seam roofing. These components install after panels are in place, covering the cut edges while providing secure attachment through hidden cleats. The trim overlaps the top flange of the zee closure, which is bedded in continuous sealant tape to prevent water infiltration behind the trim face. Ridge caps represent the most visible termination detail on gable roofs, requiring careful installation to maintain both weather resistance and visual appeal. For Snap Lock Standing Seam Roof applications, zee-flashing or closure strips install between each standing seam rib, providing solid backing for ridge cap attachment. These closures must extend fully to the roof edge at both ends, preventing any gaps where wind-driven moisture could penetrate. Cut zee-flashing sections to fit precisely between ribs, then fasten through the panel flats using pancake-head screws that maintain low profiles. The ridge cap then installs over these closures, attached with color-matched trim screws that penetrate through the cap into the zee-flashing beneath. End walls, sidewalls, valleys, and transition flashings all require similarly careful integration, with each component layered to shed water effectively while maintaining the hidden fastener aesthetic.

-

Quality Control and Performance Verification

After completing all panel and trim installation, comprehensive inspection verifies proper installation and weatherproof integrity. Walk the entire roof surface, checking that all panels are fully engaged at the drip edge with consistent overhang. Inspect every standing seam to ensure complete engagement from eave to ridge without gaps or incomplete snaps. All fastener clips should sit fully engaged with panels, showing no signs of incomplete seating or missed connections. Trim components require inspection for proper overlap, adequate sealant application, and secure fastening. Any gaps or potential water entry points should be addressed immediately, as problems identified during final inspection are far easier to correct than issues discovered after weather exposure. Water testing provides definitive verification of installation quality for critical roof areas. Using a garden hose, apply water above suspect areas or complex flashing details, then observe from beneath to verify no water penetration occurs. This testing proves particularly valuable around valley flashings, sidewall transitions, and penetration flashings where multiple components must integrate perfectly. For Snap Lock Standing Seam Roof systems manufactured by Xi'an Huafeng Construction Engineering Co., Ltd., the company's quality control standards require zero-leakage verification before project completion. This commitment to performance ensures that installations meet the highest industry standards while providing the expected 30-year service life with minimal maintenance requirements.

Material Specifications and Performance Characteristics

Selecting appropriate materials for your Snap Lock Standing Seam Roof installation directly impacts long-term performance and maintenance requirements. Substrate options include galvalume steel, aluminum alloy, stainless steel, copper, and titanium-zinc, each offering distinct advantages for specific applications. Galvalume steel, composed of 55 percent aluminum, 43.4 percent zinc, and 1.6 percent silicon, provides corrosion resistance approximately two to six times greater than conventional galvanized steel. This substrate option suits most climate conditions, particularly dry inland areas, and offers expected service life of 30 to 50 years when properly maintained. Material thickness for steel substrates typically ranges from 0.5mm to 1.0mm, with heavier gauges providing enhanced structural performance for regions experiencing high wind or snow loads. Aluminum alloy substrates offer distinct advantages for coastal installations and high-humidity environments where salt spray accelerates corrosion of ferrous metals. With a density of 2.7 grams per cubic centimeter, aluminum provides lightweight performance while maintaining excellent structural properties. The material resists salt spray corrosion naturally and is 100 percent recyclable, supporting sustainable building practices. Service life for aluminum Snap Lock Standing Seam Roof systems exceeds 50 years in most applications, making it ideal for projects requiring minimal lifecycle costs. Thickness ranges from 0.7mm to 1.2mm, with specific gauge selection depending on panel width, purlin spacing, and design load requirements.

-

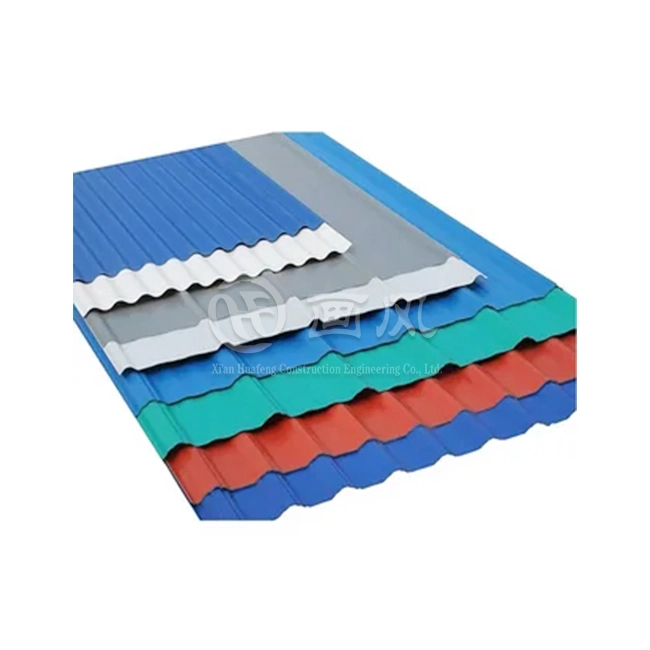

Surface Coating Systems and Protection

Beyond substrate selection, surface coating systems dramatically affect both appearance retention and weathering performance. PVDF coatings represent the premium choice for Snap Lock Standing Seam Roof applications, providing exceptional weather resistance with color retention exceeding 20 years under normal exposure conditions. These fluoropolymer coatings resist UV degradation, chemical exposure, and chalking far better than conventional paint systems. Available in extensive color ranges meeting RAL and custom specifications, PVDF coatings maintain gloss and color integrity throughout their service life. PE coatings offer economical alternatives for applications where budget constraints exist and environmental exposure remains moderate. While PE coatings provide good initial appearance and adequate weather resistance, they show more significant color change and chalking over extended timeframes compared to PVDF systems. Some premium installations utilize uncoated metal substrates that develop protective oxide layers naturally. Copper panels develop the classic verdigris patina over time, creating distinctive appearance while providing excellent corrosion resistance. Titanium-zinc materials form stable zinc carbonate surface layers that protect the underlying substrate indefinitely. These natural weathering systems require no coating maintenance and often suit historical restoration projects or architectural designs emphasizing authentic material expression. Xi'an Huafeng Construction Engineering Co., Ltd. sources premium materials from recognized industry manufacturers including Alucosuper, YATAI, and LIDAO for aluminum alloys; BAOSTEEL, GUANZHOU, and XINYU for steel substrates; and NedZink for titanium-zinc applications, ensuring consistent quality and performance.

Structural Performance and Load Management

Understanding load-bearing capabilities ensures your Snap Lock Standing Seam Roof performs safely under all anticipated conditions. Wind pressure resistance represents a critical performance parameter, particularly for buildings in hurricane-prone regions or exposed hilltop locations. Quality snap-lock systems withstand wind speeds of 60 meters per second or greater when properly installed, meeting EN 15601 standard requirements. With fixing clip spacing maintained at 1.5 meters or less, wind resistance reaches 3.0 kilonewtons per square meter, providing substantial safety margins for most applications. Clip strength, panel thickness, and seam tightness all influence overall wind resistance, making proper installation technique essential for achieving rated performance. Snow loads and live loads require consideration during system design, with performance capabilities varying based on substrate thickness and purlin support density. A 0.7mm aluminum panel system installed over 600mm purlin spacing typically supports 1.5 kilonewtons per square meter, while 1.0mm galvanized steel construction increases capacity to 2.0 kilonewtons per square meter or more. These values account for the substrate yield strength combined with the panel profile geometry that provides structural stiffness. Seismic resistance represents another important performance characteristic, particularly for buildings in earthquake-prone regions. The flexible connection system inherent in Snap Lock Standing Seam Roof designs accommodates building movement, allowing panel displacement of ±15mm to adapt to structural deformation without damage or leakage. Sliding clip designs enable this controlled movement while maintaining weatherproof integrity.

-

Installation Efficiency and Skill Requirements

Snap-Lock technology dramatically improves installation efficiency compared to traditional mechanically-seamed standing seam systems. The snap-together panel connection eliminates the need for specialized mechanical seaming equipment and skilled operators, reducing installation time by 30 to 50 percent while maintaining equivalent or superior weather performance. Ordinary construction workers receive adequate training in one day to perform quality snap-lock installations, expanding the available workforce and reducing labor costs substantially. The hidden fixing clip system conceals all fastener penetrations beneath the standing seam, eliminating potential water entry points while creating clean aesthetic appearance. This design approach proves particularly valuable for commercial and institutional projects where roof visibility from surrounding buildings makes appearance a priority consideration. The elimination of on-site rolling operations reduces installation complexity while improving consistency and quality. Traditional mechanical seaming requires careful operator technique to achieve uniform seam height and tightness across the entire roof area, with variations potentially creating both visual and performance problems. Snap-Lock systems manufactured by Xi'an Huafeng Construction Engineering Co., Ltd. achieve consistent seam profiles through precision roll-forming in controlled factory conditions, then deliver to the jobsite ready for immediate installation. This factory fabrication approach ensures dimensional accuracy, material consistency, and quality control that field operations cannot match. With three state-of-the-art factories, seven production lines, and over 40 advanced machines, Huafeng maintains production capacity of 1000 tons monthly while meeting demanding delivery schedules of 15 to 20 days.

Conclusion

Proper drip edge installation forms the foundation of successful Snap Lock Standing Seam Roof performance, protecting building structures from water damage while ensuring secure panel attachment and decades of reliable service when executed correctly.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

As a China Snap Lock Standing Seam Roof manufacturer and China Snap Lock Standing Seam Roof supplier, Xi'an Huafeng Construction Engineering Co., Ltd. delivers exceptional value through comprehensive engineering expertise, advanced manufacturing capabilities, and customer-focused service. Recognized as a high-tech enterprise in Shaanxi Province since 2020, with first-level building curtain wall qualifications and third-level steel structure credentials, Huafeng provides complete one-stop solutions from initial design through final installation. Our 200,000 square meter raw material production facility in Anhui, combined with processing plants in Hangzhou and Xi'an, ensures consistent quality and timely delivery for projects worldwide. With over 20 registered patents, ISO9001 and ISO14000:14001 certifications, and SGS quality verification, we manufacture High Quality Snap Lock Standing Seam Roof systems that meet the most demanding specifications. Our China Snap Lock Standing Seam Roof wholesale programs offer competitive Snap Lock Standing Seam Roof price structures, with Snap Lock Standing Seam Roof for sale meeting minimum order quantities of 500 square meters. As a trusted China Snap Lock Standing Seam Roof factory partner to Fortune 500 companies, we customize production to your exact requirements while providing design optimization, material testing, specialized packaging, and flexible transportation solutions. Contact our technical team at huafeng@hfmetalroof.com to discuss your project requirements and discover how our engineering excellence transforms your roofing vision into lasting reality.

References

1. Metal Construction Association. Metal Roofing Installation Guidelines and Best Practices. Technical Standards Committee.

2. National Roofing Contractors Association. The NRCA Roofing Manual: Metal Panel and Standing Seam Roof Systems. NRCA Publications.

3. American Society for Testing and Materials. ASTM E1592: Standard Test Method for Structural Performance of Sheet Metal Roof and Siding Systems by Uniform Static Air Pressure Difference. ASTM International.

4. Sheet Metal and Air Conditioning Contractors National Association. Architectural Sheet Metal Manual. SMACNA Technical Publications.