When planning your next roofing project, you're likely facing a critical dilemma: invest heavily upfront in a Metal Standing Seam Roofing System or choose a more affordable alternative that might require replacement sooner. This comprehensive guide breaks down exactly how standing seam metal roof costs stack up against traditional roofing materials, helping you make an informed decision that protects both your property and your investment for decades to come.

Understanding Metal Standing Seam Roofing Systems Cost Structure

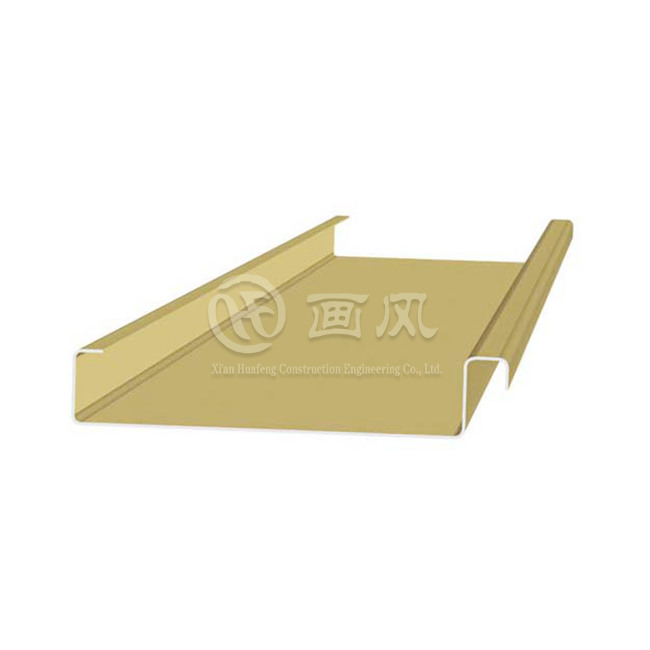

Metal Standing Seam Roofing Systems represent a premium investment in building protection, with costs typically ranging from $10 to $35 per square foot depending on material selection and project specifications. This pricing reflects the sophisticated engineering behind these systems, which feature raised vertical seams that interlock mechanically to create a watertight barrier. Unlike conventional roofing where fasteners penetrate the surface and create potential leak points, standing seam panels utilize hidden fastening technology that eliminates exposed penetrations entirely. The initial cost encompasses not just the metal panels themselves, but also the specialized installation expertise required to achieve proper thermal expansion accommodation, precise panel alignment, and long-term weatherproofing performance. For a typical residential project covering 2,000 square feet, homeowners should budget between $20,000 and $70,000, with the final figure influenced by metal type, gauge thickness, surface coating selection, and architectural complexity. Commercial applications for airports, exhibition centers, and industrial facilities require additional considerations for structural loading, drainage capacity, and integration with building management systems, factors that Xi'an Huafeng Construction Engineering Co., Ltd. addresses through comprehensive engineering analysis and custom fabrication capabilities.

Metal Standing Seam Roofing Systems

-

Initial Investment Breakdown for Standing Seam Systems

The material costs for Metal Standing Seam Roofing Systems vary significantly based on substrate selection and performance specifications. Galvanized steel panels with PVDF coating, the most economical option, typically cost $10-16 per square foot installed, offering excellent corrosion resistance through AZ150 aluminum-zinc coating enhanced with fluoropolymer surface protection. Aluminum panels range from $11-18 per square foot, providing natural corrosion resistance particularly valuable in coastal environments where salt spray accelerates metal deterioration. Premium materials command higher prices: stainless steel 304 grade costs $15-25 per square foot for applications demanding maximum corrosion resistance in industrial atmospheres, while titanium-zinc systems reach $20-30 per square foot with their unique self-healing patina that repairs minor scratches automatically over time. Copper standing seam roofing represents the ultimate investment at $25-40 per square foot, delivering century-long service life with distinctive aesthetic evolution as the metal develops its characteristic verde patina. Xi'an Huafeng Construction Engineering Co., Ltd. manufactures panels in specifications from 65mm to 500mm seam height, with material thickness options from 0.5mm to 1.2mm depending on structural requirements and span distances. The company's 200,000 square meter production facility in Anhui processes premium raw materials from certified suppliers including Alucosuper aluminum alloys, BAOSTEEL galvanized substrates, and NedZink titanium-zinc, ensuring consistent quality that meets ISO9001 and ISO14000:14001 standards.

-

Labor and Installation Cost Factors

Professional installation of Metal Standing Seam Roofing Systems requires specialized skills and equipment, accounting for $150-300 per square (100 square feet) in labor costs. The installation complexity stems from precise panel alignment requirements, mechanical seaming operations that join adjacent panels with specialized locking tools, and integration of thermal expansion clips that allow panels to move with temperature fluctuations without stressing connections. Roof pitch significantly impacts labor pricing, with slopes exceeding 6:12 requiring additional safety equipment, fall protection systems, and worker positioning apparatus that increase installation time by 25-40 percent. Architectural features including dormers, valleys, hips, and penetrations for skylights, chimneys, and mechanical equipment demand custom flashing fabrication and careful weatherproofing details that add $500-2,000 per feature depending on complexity. Geographic location influences labor rates substantially, with metropolitan areas and regions experiencing high construction demand commanding premium pricing. Xi'an Huafeng Construction Engineering Co., Ltd. addresses these cost variables through comprehensive project planning that includes detailed shop drawings, pre-fabricated panel assemblies customized to exact roof dimensions, numbered packaging systems that simplify on-site panel identification, and technical support from experienced installation supervisors who ensure proper execution of critical waterproofing details and quality control checkpoints throughout the construction process.

Comparing Standing Seam Costs to Traditional Roofing Materials

The cost comparison between Metal Standing Seam Roofing Systems and alternative roofing materials reveals important distinctions in both initial investment and lifecycle economics. Asphalt shingle roofing, the most common residential roofing material, costs $3-7 per square foot installed, representing less than half the initial expense of standing seam metal. However, asphalt shingles typically require replacement every 15-20 years due to UV degradation, thermal cycling stress, and granule loss, necessitating multiple reroofing investments over a building's service life. Three-tab asphalt shingles offer minimal wind resistance and basic waterproofing, while architectural shingles provide improved aesthetics and durability at $4-8 per square foot but still face the same fundamental limitation of organic material degradation. Exposed fastener metal roofing panels, commonly used in agricultural and light commercial applications, cost $4-8 per square foot installed, offering metal durability at reduced initial cost compared to standing seam systems. The critical difference lies in the exposed fasteners that penetrate the roofing surface, creating thousands of potential water entry points that require gasket compression and periodic maintenance to prevent leakage as thermal cycling gradually loosens fastener grip and degrades rubber washers over time.

-

Cost Per Year Analysis Across Roofing Types

Lifecycle cost analysis provides crucial perspective on the true economic value of Metal Standing Seam Roofing Systems compared to cheaper alternatives. A standing seam metal roof with proper material selection and professional installation delivers 40-70 years of service life, with premium materials like copper and zinc exceeding 100 years in favorable climates. For a $35,000 standing seam installation lasting 50 years, the annualized cost equals $700 per year. By contrast, asphalt shingle roofing costing $12,000 initially but requiring replacement every 18 years results in three complete reroofing cycles over 50 years at a total cost of $36,000, or $720 per year, slightly exceeding the standing seam annual cost while delivering inferior performance. This calculation excludes the inflation factor affecting future reroofing costs, the labor cost increases expected over decades, and the disposal fees for removing deteriorated asphalt shingles from landfills. Wood shake roofing presents even less favorable economics, with initial costs of $8-12 per square foot, service life of 20-25 years in dry climates but as little as 15 years in humid regions, plus ongoing maintenance requirements for moss treatment, preservative application, and split shake replacement that add $500-1,000 annually in upkeep expenses.

-

Performance Value Beyond Basic Cost Comparison

The economic comparison of Metal Standing Seam Roofing Systems extends beyond simple material and installation costs to encompass performance attributes that generate tangible financial benefits. Energy efficiency represents a significant ongoing advantage, as metal roofing with reflective PVDF coating can reflect 65-70 percent of solar radiation, reducing cooling load by 10-25 percent compared to dark asphalt shingles that absorb heat. In commercial applications, this energy performance translates to thousands of dollars in annual HVAC operating cost reduction. Wind resistance provides another economic benefit, with properly installed standing seam systems tested to withstand 16-level typhoon wind pressures exceeding 4.5 kPa without panel uplift or water infiltration. This superior wind performance reduces property insurance premiums by 10-30 percent in many regions, particularly in coastal areas subject to hurricane risk where insurers recognize the reduced claim probability from metal roofing. Fire resistance certification as A1 non-combustible material further reduces insurance costs while providing invaluable safety protection. Xi'an Huafeng Construction Engineering Co., Ltd. demonstrates these performance advantages through extensive project experience including the Xi'an International Convention and Exhibition Center, Xiongan Station Commercial complex, and Inner Mongolia Tongliao Art Museum, where Metal Standing Seam Roofing Systems protect high-value facilities with architectural significance and long operational life requirements that justify premium roofing investment.

Long-Term Cost Benefits of Metal Standing Seam Roofing Systems

The extended service life of Metal Standing Seam Roofing Systems generates cumulative cost advantages that compound over decades of ownership. While initial installation represents a substantial capital expenditure, the elimination of periodic replacement cycles removes the financial burden, project disruption, and opportunity cost associated with sequential reroofing operations. Building owners avoid the need to budget for major roofing replacement every 15-20 years, eliminating the cash flow impact of large intermittent expenses and providing financial predictability that facilitates long-term planning. The maintenance requirements of standing seam systems remain minimal, typically limited to annual inspections, gutter cleaning, and occasional fastener adjustment, compared to asphalt roofing that may require shingle replacement after storm damage, moss treatment in humid climates, and edge flashing repair as sealants deteriorate. Metal roofing maintains its appearance and performance throughout its service life, avoiding the progressive deterioration visible in aging asphalt roofs where faded colors, curling shingles, and granule loss broadcast the need for replacement to prospective property buyers or tenants. This sustained aesthetic quality preserves property value and eliminates the negative visual impact of deteriorating roofing materials on commercial buildings where professional appearance directly affects tenant attraction and rental rate justification.

-

Resale Value and Return on Investment

Property value appreciation provides another dimension of economic return from Metal Standing Seam Roofing Systems investment. Real estate market data indicates that metal roofing installation generates 70-95 percent return on investment at property resale, with homeowners recovering a substantial portion of their roofing expenditure through increased property valuations. Appraisers recognize the remaining service life of metal roofing as a valuable property attribute, particularly compared to properties with aging asphalt roofs that will require replacement in the near term. Buyer perception plays an equally important role, as metal roofing conveys quality construction, low maintenance requirements, and long-term cost savings that make properties more attractive in competitive markets. Commercial property investors place even greater emphasis on roofing condition and longevity, as roof replacement costs significantly impact net operating income and cap rate calculations used for property valuation. The 30-year warranty provided with Xi'an Huafeng Construction Engineering Co., Ltd. Metal Standing Seam Roofing Systems transfers to subsequent property owners, maintaining the financial protection and performance assurance that enhances property marketability and justifies premium pricing in both sale and lease transactions.

-

Environmental Cost Considerations

The environmental impact of roofing material selection carries both ethical significance and increasingly tangible economic consequences as building codes evolve to address sustainability mandates. Metal Standing Seam Roofing Systems offer 100 percent recyclability at end of service life, with aluminum, steel, copper, and zinc maintaining their material properties through repeated recycling cycles. This stands in sharp contrast to asphalt shingles that generate 11 million tons of landfill waste annually in the United States alone, with disposal fees of $30-50 per ton adding $360-600 to replacement costs for a typical 2,000 square foot residential roof. Green building certification programs including LEED and BREEAM award points for recyclable building materials, metal roofing's solar reflectance properties, and long service life that reduces embodied carbon impact from repeated manufacturing and transportation cycles. Some jurisdictions now mandate cool roof standards requiring minimum solar reflectance values that metal roofing with appropriate coating easily achieves while dark asphalt shingles cannot meet without specialized granule treatments that add cost. Xi'an Huafeng Construction Engineering Co., Ltd. embraces sustainable development principles through efficient manufacturing processes, integration of photovoltaic mounting systems compatible with 65mm high-rib standing seam profiles, and material specifications from suppliers maintaining environmental management system certifications that verify responsible resource utilization and waste minimization throughout the supply chain.

Customization Options and Their Cost Implications

The specification flexibility available with Metal Standing Seam Roofing Systems allows project-specific optimization that balances performance requirements, aesthetic objectives, and budget constraints. Panel width selection affects both material costs and installation labor, with wider panels covering roof area more efficiently but requiring heavier gauge material to maintain structural rigidity across unsupported spans. Standard panel widths of 300-600mm accommodate different architectural scales, from residential applications where narrower profiles provide human-scale proportions to large commercial projects where wider panels accelerate installation progress and reduce seam quantity. Seam height represents another specification variable, with typical options ranging from 65mm providing excellent water shedding and structural depth to lower profiles of 40-50mm used where architectural design priorities favor minimal visual prominence. Surface finish selection dramatically impacts appearance, performance, and cost, with polyester coating offering economical protection at $2-3 per square foot, while PVDF coatings containing 70 percent fluoropolymer resin deliver superior UV resistance and 20-year color retention at $4-6 per square foot premium. Natural mill finish provides the lowest material cost but requires acceptance of the metal's inherent appearance and oxidation characteristics, an aesthetic choice particularly appropriate for zinc and copper that develop attractive patinas as they age.

-

Project-Specific Cost Optimization Strategies

Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive design optimization services that align Metal Standing Seam Roofing Systems specifications with project requirements and budget parameters. The company's engineering team conducts structural analysis considering roof slope, span dimensions, snow load requirements, and wind exposure to determine minimum material thickness and panel configuration that satisfy structural safety while avoiding over-specification that unnecessarily increases costs. Drainage system simulation optimizes roof slope and panel layout to ensure adequate water evacuation capacity without ponding, eliminating the need for costly roof pitch modifications or supplementary drainage infrastructure after installation. Material specification advisory services help clients navigate the cost-performance tradeoffs between different metals, coating systems, and gauge options, presenting lifecycle cost comparisons that reveal how premium material investments generate long-term value through extended service life and reduced maintenance. The company's 7 color coating production lines enable custom color matching for architectural coordination requirements, providing Pantone-specified colors that integrate with building facades and branding elements. Bulk production capacity exceeding 1,000 tons monthly allows competitive pricing for large projects while maintaining 15-20 day delivery schedules that support construction timeline requirements. The 500 square meter minimum order quantity makes standing seam technology accessible for mid-size projects while the company's three strategically located facilities in Anhui, Hangzhou, and Xi'an provide regional proximity that reduces transportation costs and enables responsive technical support throughout project execution.

Conclusion

Standing seam metal roofing initially costs more than alternatives but delivers superior long-term value through multi-decade service life, minimal maintenance requirements, energy efficiency benefits, and strong resale value return. When evaluating your roofing investment, consider total lifecycle costs rather than just upfront expenses to make the most financially sound decision for your property.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

As a China Metal Standing Seam Roofing Systems factory and leading China Metal Standing Seam Roofing Systems manufacturer since 2018, Xi'an Huafeng Construction Engineering Co., Ltd. delivers High Quality Metal Standing Seam Roofing Systems backed by over 20 registered patents and ISO9001, ISO14000:14001, and SGS certifications. Our China Metal Standing Seam Roofing Systems supplier network includes premium materials from Alucosuper, BAOSTEEL, and NedZink, ensuring China Metal Standing Seam Roofing Systems wholesale pricing without compromising performance. With state-of-the-art facilities spanning 200,000 square meters, 7 color coating lines, and proven expertise demonstrated through major projects including Xiongan Station and Xi'an International Convention Center, we provide Metal Standing Seam Roofing Systems for sale with comprehensive one-stop solutions from engineering design through installation guidance. Our competitive Metal Standing Seam Roofing Systems price structure reflects efficient manufacturing while delivering 30-year warranty protection and customizable specifications for color, pattern, and design requirements. Contact our technical team at huafeng@hfmetalroof.com to discuss your project requirements and receive detailed quotations. Bookmark this resource for future reference when planning your roofing investment.

References

1. Metal Roofing Alliance. "Life Cycle Cost Analysis of Residential Roofing Materials." Building Enclosure Science & Technology Conference, 2024.

2. National Roofing Contractors Association. "Comparative Performance Study of Commercial Roofing Systems." Technical Research Report Series, 2023.

3. Lawrence Berkeley National Laboratory. "Cool Roofing Material Database and Energy Performance Modeling." Heat Island Group Research Division, 2024.

4. American Architectural Manufacturers Association. "Standing Seam Metal Roof System Installation and Performance Standards." Technical Document AAMA TIR-A9, 2023.

_1757558889992.webp)