Are you facing challenges selecting the right cladding system for your commercial project that balances aesthetics, durability, and budget constraints? The metal roof and wall cladding industry offers diverse solutions, from standing seam systems to Flat Lock Seam Metal Wall Panels, each designed to address specific architectural requirements. Understanding these different types empowers architects, contractors, and building owners to make informed decisions that enhance building performance while achieving desired visual impact for decades to come.

Understanding Metal Cladding Systems and Their Applications

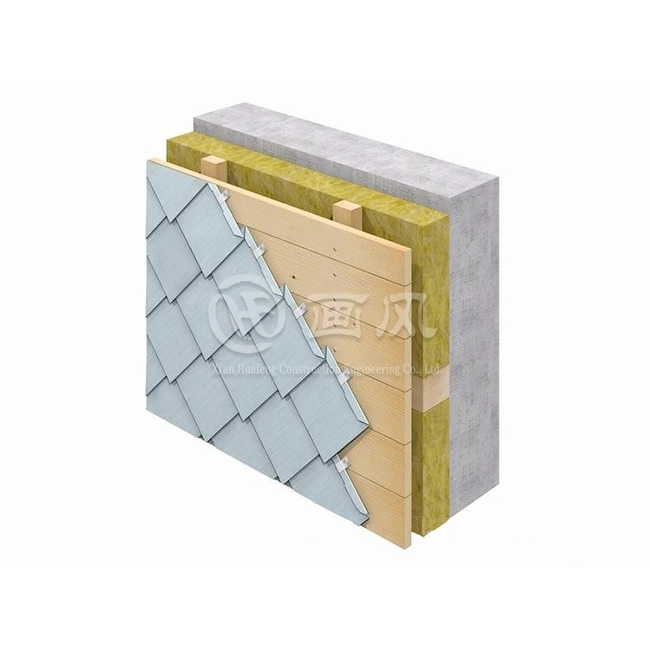

Metal cladding has revolutionized modern construction by providing building envelopes that combine structural protection with architectural expression. These systems serve multiple critical functions including weather resistance, thermal performance, fire protection, and aesthetic enhancement. The selection process requires careful consideration of factors such as building type, environmental conditions, maintenance requirements, and long-term performance expectations. Contemporary metal cladding systems utilize advanced materials including aluminum-magnesium-manganese alloys, stainless steel, titanium-zinc, copper, and color-coated steel sheets, each offering distinct advantages for specific applications. The evolution of metal cladding technology has introduced sophisticated installation methods that ensure watertight performance and accommodate thermal movement. Standing seam systems feature concealed fasteners and raised seams that channel water away from building surfaces. Flat Lock Seam Metal Wall Panels create seamless, refined facades through precision interlocking mechanisms that produce flush surfaces ideal for contemporary architectural designs. Corrugated and profiled sheets provide cost-effective solutions for industrial and agricultural buildings while maintaining excellent structural strength. Understanding these fundamental system types enables proper specification for residential, commercial, cultural, and infrastructure projects ranging from office towers to museums and transportation facilities.

Flat Lock Seam Metal Wall Panels

-

Material Selection for Optimal Performance

Material choice significantly impacts the longevity, maintenance requirements, and visual characteristics of metal cladding installations. Aluminum offers exceptional corrosion resistance, lightweight properties, and malleability, making it ideal for complex geometries and coastal environments where salt exposure presents challenges. Aluminum-magnesium-manganese alloys specifically enhance strength and formability while maintaining natural weather resistance without coating requirements. These materials typically provide service lives exceeding thirty-five years with minimal maintenance interventions. Color options span the RAL standard range, with fluorocarbon coatings offering superior UV resistance and color retention compared to polyester alternatives. Stainless steel presents premium aesthetics with mirror or satin finishes suitable for high-profile projects demanding pristine appearance and exceptional durability. Grades 304 and 316 provide varying levels of corrosion resistance, with 316 recommended for harsh marine or industrial atmospheres. Flat Lock Seam Metal Wall Panels fabricated from stainless steel create striking architectural statements on cultural venues, corporate headquarters, and luxury residential developments. Titanium-zinc develops natural protective patina that self-heals minor scratches while offering fifty-year service life expectations. Copper delivers unmatched longevity exceeding one hundred years, transitioning through distinctive color phases from elemental copper through brown oxidation to iconic green verdigris. Material specifications for flat lock wall panels typically range from 0.4mm to 1.2mm thickness depending on panel dimensions, wind load requirements, and desired acoustic performance characteristics.

-

Installation Methods and System Types

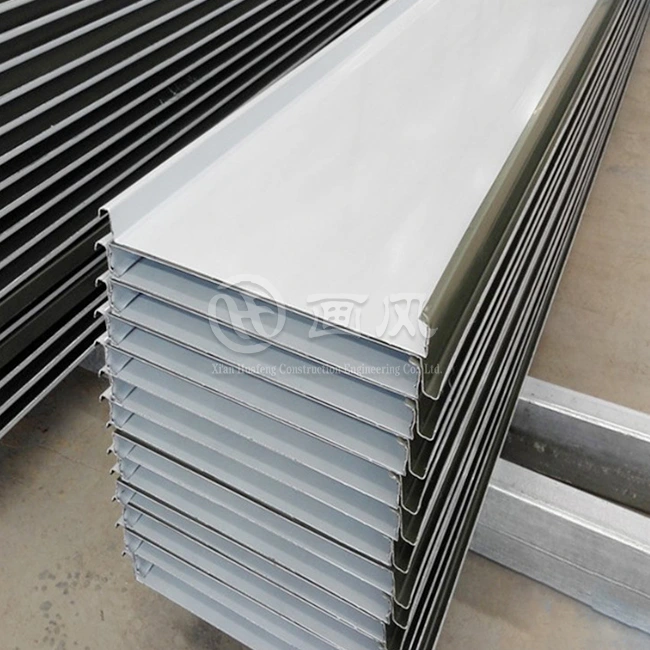

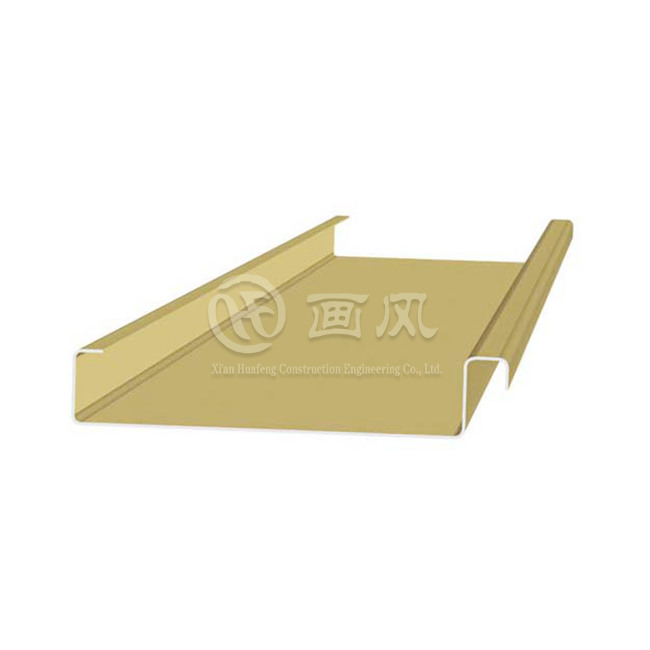

Standing seam systems dominate contemporary metal roofing and wall cladding applications due to their clean lines, concealed fastening, and reliable weather performance. These systems employ clips that secure panels to structural substrates while permitting thermal expansion and contraction without stress damage. Seam heights typically range from 25mm to 65mm, creating shadow lines that emphasize verticality or horizontality depending on installation orientation. Double-lock seams provide maximum weather security for low-slope roofing applications, while single-lock configurations suffice for vertical wall installations. The concealed fastener approach eliminates penetrations through exposed metal surfaces, significantly extending system service life and reducing maintenance requirements. Flat Lock Seam Metal Wall Panels represent specialized cladding technology producing flush, monolithic facades without visible seams or fasteners. This system requires precision fabrication with panels custom-manufactured to project-specific dimensions, typically 300mm to 600mm width and lengths up to three meters. Installation involves interlocking panel edges through flat-lock folding techniques that create weathertight joints flush with the panel surface. The resulting appearance resembles seamless metal skin wrapping building forms, particularly effective for contemporary designs emphasizing minimalist aesthetics. Flat lock wall panels accommodate various geometric configurations including rectangles, rhombuses, trapezoids, and hexagons, enabling creative pattern development across large facade areas. This versatility makes flat lock systems preferred for museums, theaters, exhibition halls, commercial complexes, and signature architectural projects where visual impact drives material selection decisions.

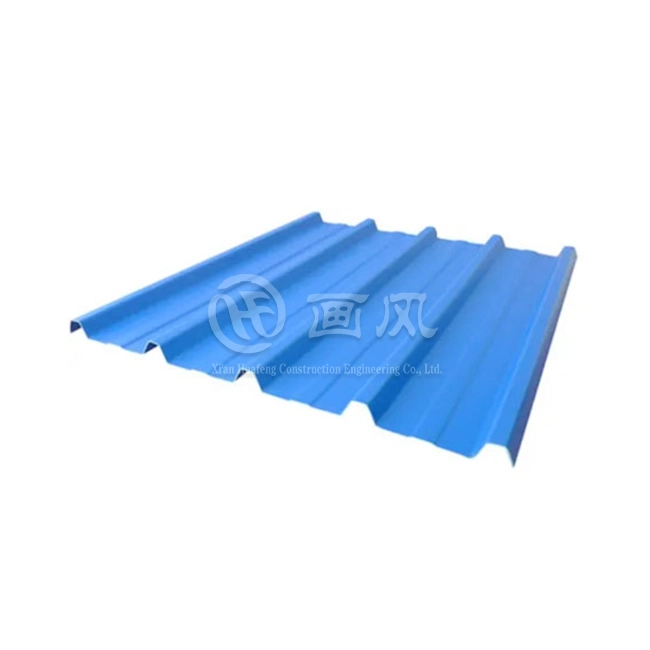

Specialized Panel Profiles and Design Flexibility

Beyond fundamental system categories, metal cladding encompasses numerous profile variations enabling architects to achieve specific design intentions. Corrugated profiles feature repetitive wave patterns providing structural rigidity and traditional industrial character suitable for agricultural buildings, warehouses, and heritage renovation projects. Profile depths typically range from 18mm to 76mm with various pitch dimensions affecting visual scale. Modern corrugated systems incorporate advanced coatings and colors transcending basic utilitarian applications to serve contemporary residential and commercial designs seeking textured, dynamic facades. Cassette panel systems create modular appearances with defined panel borders and express joints producing grid patterns across building elevations. These systems typically employ aluminum panels ranging from 2mm to 4mm thickness, backed by structural substrates or insulation layers. Cassette configurations facilitate rapid installation through clip-fixing systems and accommodate building movement without visible distortion. The flat panel surfaces accept diverse finishes including fluorocarbon coatings, anodizing, natural mill finishes, and specialized textures. This versatility enables cassette systems to serve curtain wall applications, rainscreen assemblies, and architectural feature elements on institutional, commercial, and residential projects.

Flat Lock Seam Metal Wall Panels transcend conventional profile categories by eliminating visible seams entirely, producing continuously smooth surfaces that emphasize building form over cladding articulation. This sophisticated approach requires meticulous fabrication precision and skilled installation expertise to achieve flawless results. Panel edges incorporate carefully engineered folding geometries that interlock securely while maintaining flush alignment across large expanses. Material options for flat lock wall panels include aluminum alloy (3003/3004 specifications), stainless steel (304/316 grades), copper, and titanium-zinc, each contributing distinct aesthetic qualities as surfaces weather and develop patina. Surface treatments encompass fluorocarbon spraying (PVDF), powder coating, and anodizing processes providing customized colors matching specific project requirements or complementing adjacent materials.

-

Color, Finish, and Texture Options

Surface finishing significantly influences metal cladding appearance, durability, and maintenance characteristics. Fluorocarbon coatings represent premium options offering exceptional UV resistance, color stability, and chalking resistance over thirty-year service periods. These coatings employ PVDF or FEVE resin technologies creating molecular bonds that withstand intense solar radiation, temperature cycling, and atmospheric pollutants without degradation. Color selections span full RAL and custom-matched palettes, with metallic and textured finishes adding depth and visual interest. Coating thickness typically ranges from 25 to 35 microns, applied through continuous coil coating processes ensuring consistent quality across large production volumes. Natural metal finishes celebrate inherent material characteristics as surfaces develop distinctive patina through environmental exposure. Weathering steel intentionally oxidizes to form stable rust-colored surfaces requiring no additional coating while providing excellent corrosion resistance. Zinc and copper naturally develop protective layers that change appearance gradually, creating living facades that evolve with building age. These uncoated approaches reduce environmental impact, eliminate coating maintenance, and deliver authentic material expression valued in sustainable and heritage-sensitive contexts. Flat Lock Seam Metal Wall Panels leverage these natural finishing strategies effectively, as flush panel configurations showcase subtle color variations and surface texture evolution across unified facade compositions.

Textured and patterned finishes introduce tactile depth and light-refractive qualities enhancing architectural expression. Embossed patterns ranging from subtle linen textures to pronounced geometric reliefs create shadow play and visual interest at various viewing distances. Perforated panels combine aesthetic considerations with functional benefits including solar shading, acoustic absorption, and natural ventilation. Perforation patterns from simple circular holes to complex customized designs enable architects to develop distinctive building identities while addressing performance requirements. These finishing strategies complement flat lock wall panels particularly well when applied to accent zones, feature walls, or transitional elements within broader cladding assemblies.

Performance Characteristics and Long-Term Value

Metal cladding systems deliver exceptional performance across multiple criteria critical to building envelope success. Weather resistance encompasses protection against rain penetration, wind-driven moisture, UV radiation, thermal cycling, and atmospheric pollutants. Quality metal cladding installations achieve decades of reliable service without leakage or structural degradation when properly specified and installed. Thermal performance depends on system configuration, with insulated metal panels providing integrated R-values while single-skin systems require separate insulation layers. Thermal bridging mitigation through panel support systems and thermal breaks prevents condensation risk and enhances overall building energy efficiency. Structural performance addresses wind loads, seismic movements, and impact resistance throughout building service life. Flat Lock Seam Metal Wall Panels engineered from 0.6mm to 1.2mm material thickness withstand typhoon-level wind pressures exceeding level 12 classifications when properly anchored through tested connection systems. The lightweight nature of metal cladding (typically 3-5 kg per square meter) reduces structural loading compared to masonry or concrete alternatives, enabling economic foundation and framework designs particularly beneficial for renovation projects adding new facades to existing buildings without extensive structural reinforcement. Fire performance varies by material selection and system configuration. Aluminum, stainless steel, and steel-based cladding systems achieve A2 non-combustible ratings meeting stringent fire safety codes for high-rise, institutional, and public assembly occupancies. Proper detailing around openings, behind cladding cavities, and at building transitions ensures fire-resistant assemblies that compartmentalize buildings and prevent flame spread. Many flat lock wall panels incorporate closed-system configurations with optional waterproof backing boards eliminating concealed combustible materials and enhancing overall fire safety performance.

-

Sustainability and Life-Cycle Considerations

Metal cladding exemplifies sustainable construction principles through material efficiency, longevity, and end-of-life recyclability. Aluminum recycling processes consume only five percent of energy required for primary production while maintaining equivalent material properties. Steel recycling similarly achieves near-complete material recovery with minimal quality loss. This circular economy potential positions metal cladding as environmentally responsible choices throughout building lifecycles. Manufacturing processes increasingly incorporate recycled content percentages exceeding fifty percent, reducing embodied carbon impacts while maintaining performance specifications. Service life expectations reaching thirty to fifty years for coated systems and exceeding one hundred years for copper installations minimize replacement cycles and associated environmental burdens. Flat Lock Seam Metal Wall Panels warrant thirty-year performance guarantees when manufactured to international standards (ASTM, DIN, JIS, BS, GB/T specifications) and installed per manufacturer requirements. This longevity eliminates repeated material consumption, waste generation, and disruption associated with shorter-lived cladding alternatives. Low maintenance requirements further enhance sustainability credentials, as self-cleaning surface properties and corrosion-resistant materials rarely require intervention beyond periodic washing. Disassembly and material recovery at building end-of-life proceed efficiently with mechanical fastening systems enabling non-destructive panel removal. Salvaged panels retain value for secondary applications or recycling streams, contrasting with adhered or composite systems requiring disposal. This design-for-deconstruction approach aligns with circular economy principles and resource conservation objectives increasingly mandated through building codes and green building certification programs.

Selecting the Right System for Your Project

Project-specific requirements drive appropriate metal cladding system selection through systematic evaluation of functional, aesthetic, and economic criteria. Building type establishes baseline performance expectations with commercial towers demanding different characteristics than agricultural structures or residential developments. Cultural venues prioritize architectural expression and distinctive identity, making Flat Lock Seam Metal Wall Panels compelling choices for museums, theaters, and exhibition centers seeking unified, sculptural building envelopes. Office buildings balance cost-effectiveness with professional appearance, often selecting standing seam or cassette systems offering proven performance at moderate pricing. Environmental context significantly influences material and system selection. Coastal locations require enhanced corrosion protection through stainless steel, aluminum, or premium coating specifications. Urban environments with high pollution levels benefit from self-cleaning finishes and materials resisting atmospheric contaminants. Climate considerations address thermal expansion characteristics, freeze-thaw durability, and extreme temperature resistance. Flat lock wall panels engineered for -40°C to 80°C operating ranges accommodate diverse global climates while maintaining structural integrity and aesthetic appearance. Budget constraints encompass initial installation costs, maintenance expenses, and lifecycle value considerations. While premium systems like stainless steel flat lock wall panels command higher initial investment, reduced maintenance and extended service life often justify costs through lifecycle analysis. Value engineering should compare total ownership costs rather than focusing exclusively on initial procurement pricing. Delivery timelines ranging from fifteen to twenty-one days for custom-manufactured panels require advance planning coordinating design development, material procurement, and construction scheduling to avoid project delays.

-

Working with Experienced Manufacturers

Successful metal cladding projects depend on partnerships with qualified manufacturers offering comprehensive capabilities from design support through installation guidance. Advanced manufacturing facilities featuring multiple production lines ensure consistent quality and production capacity meeting project demands. Seven color coating production lines, automated punching systems, and more than forty specialized machines enable efficient processing of diverse panel profiles and material specifications. Supply capacity exceeding one thousand tons monthly accommodates large-scale projects and compressed construction schedules. Technical expertise encompassing structural analysis, drainage system design, and material specification advisory services adds significant value during project development phases. Manufacturers providing 3D modeling capabilities facilitate design visualization and coordination with architectural intent. Drawing deepening services translate conceptual designs into fabrication-ready shop drawings ensuring accurate material quantities and minimizing field modifications. Sample production enables design teams to evaluate actual materials, colors, and finishes before full-scale manufacturing proceeds, reducing uncertainty and costly changes during construction. Quality assurance protocols including incoming material inspection, production process monitoring, and finished product testing ensure consistent performance meeting international standards. ISO 9001, ISO 14001, and SGS certifications demonstrate organizational commitment to quality management, environmental responsibility, and product safety. Material certifications and third-party testing reports verify specifications for aluminum alloys (3003, 3004, 5052), stainless steel grades (304, 316), and specialized materials like titanium-zinc. Patent portfolios exceeding twenty registered innovations indicate technological leadership and ongoing development of advanced cladding solutions.

Conclusion

Different types of metal roof and wall cladding systems serve diverse architectural requirements through varied profiles, materials, and installation methods. From standing seam configurations to sophisticated Flat Lock Seam Metal Wall Panels, contemporary options enable performance-driven building envelopes expressing architectural vision while delivering decades of reliable service across commercial, institutional, and residential applications worldwide.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a leading China Flat Lock Seam Metal Wall Panels manufacturer, China Flat Lock Seam Metal Wall Panels supplier, and China Flat Lock Seam Metal Wall Panels factory delivering exceptional metal roofing and wall cladding solutions since 2018. Recognized as a Shaanxi Province high-tech enterprise, Huafeng holds first-level building curtain wall qualifications and third-level steel structure credentials, operating 200,000 square meters of production facilities in Anhui plus specialized processing plants in Hangzhou and Xi'an. Our seven color coating lines, automated production systems, and over forty precision machines produce High Quality Flat Lock Seam Metal Wall Panels with customized dimensions, premium materials, and China Flat Lock Seam Metal Wall Panels wholesale pricing supporting projects worldwide.

Comprehensive one-stop services encompassing design optimization, precision manufacturing, and seamless installation distinguish Huafeng's approach. Our engineering team provides structural 3D modeling, drainage simulations, and material advisory services translating project concepts into detailed fabrication drawings. Rigorous quality control through incoming material inspection, production monitoring, and finished product testing ensures Flat Lock Seam Metal Wall Panels for sale meet international standards (ISO9001, ISO14001, SGS) with thirty-year warranties. Successful installations at Xiongan Station, Xi'an International Convention Center, Inner Mongolia Tongliao Art Museum, and numerous prestigious projects demonstrate proven capabilities delivering architectural excellence across diverse building types.

Partner with Huafeng for competitive Flat Lock Seam Metal Wall Panels price, technical expertise, and reliable execution transforming building visions into enduring architectural achievements. Contact us today at huafeng@hfmetalroof.com to discuss your project requirements and discover why leading architects and contractors choose Huafeng as their trusted metal cladding partner for superior results.

References

1. Walker, Simon and Ramshaw, John. "Metal Cladding and Roofing Selection: Performance and Specification Guidelines for Architectural Applications." Architecture Today Technical Series. 2021.

2. Anderson, Robert M. "Standing Seam and Flatlock Systems: Comparative Analysis of Metal Cladding Installation Methods." Journal of Architectural Engineering Technology. 2022.

3. Thompson, Elizabeth. "Sustainable Metal Building Envelopes: Material Selection and Life-Cycle Performance." Green Building Research Institute. 2023.

4. Mitchell, David and Chen, Wei. "Contemporary Metal Facade Systems: Design Integration and Technical Performance Criteria." International Construction Materials Review. 2024.