Picture this scenario: you're overseeing a critical commercial building project where roof failure could mean catastrophic water damage, costly repairs, and project delays that spiral into hundreds of thousands of dollars in losses. Traditional roofing systems expose you to risks of leak points at every fastener, thermal movement issues that compromise structural integrity, and maintenance headaches that drain budgets year after year. Metal Standing Seam Roofing Systems eliminate these pain points by offering concealed fastening technology, superior weather resistance, and architectural elegance that transforms vulnerable roof planes into high-performance building envelopes capable of withstanding extreme conditions while delivering decades of maintenance-free service.

Understanding Metal Standing Seam Roofing Systems Architecture

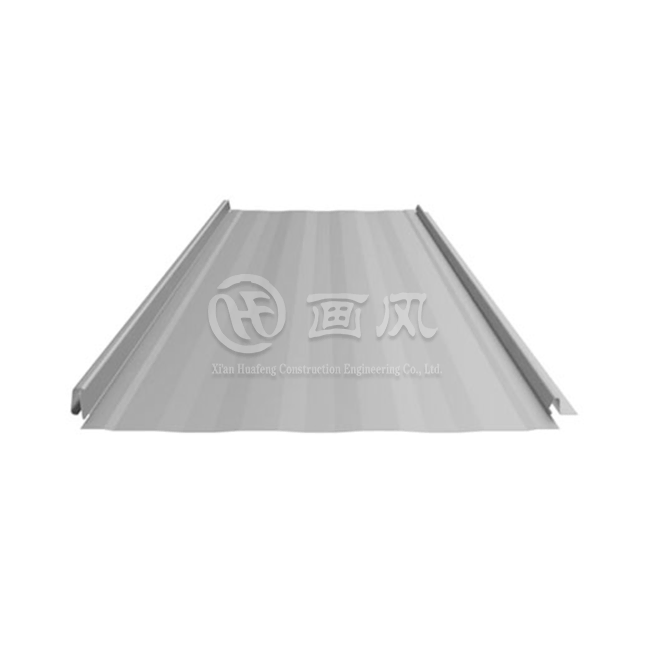

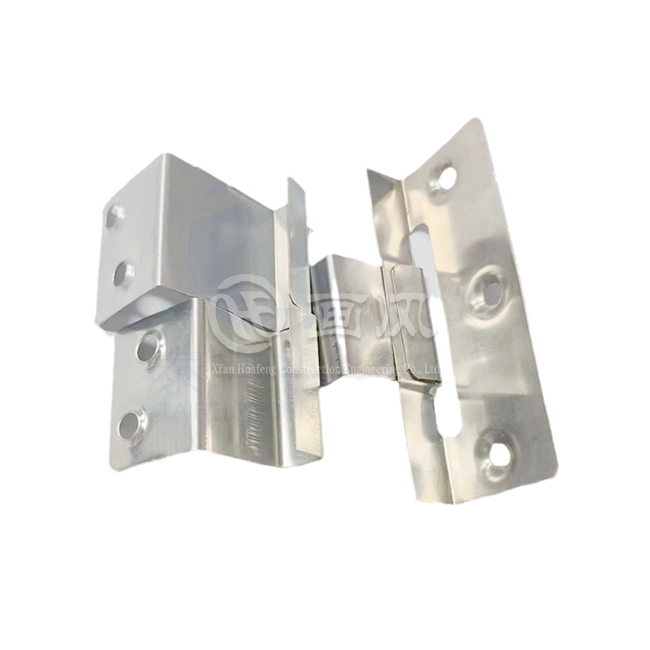

Metal Standing Seam Roofing Systems represent a revolutionary approach to commercial and industrial roof design, combining structural engineering excellence with aesthetic sophistication. These systems feature vertically oriented metal panels that run continuously from ridge to eave, interconnected through raised seams that stand elevated above the roof surface. The fundamental architecture relies on interlocking panel edges that create weathertight connections without penetrating the roofing surface with exposed fasteners. This concealed fastening methodology addresses the primary vulnerability of traditional metal roofing where fastener penetrations become potential leak points subject to thermal cycling, UV degradation, and mechanical stress over time. The structural composition of Metal Standing Seam Roofing Systems incorporates multiple performance layers working synergistically to achieve superior building envelope performance. The standing seam roof panel itself typically ranges from 0.9mm to 1.2mm in thickness, manufactured from premium materials including aluminum alloys, galvalume steel, stainless steel, titanium-zinc, or copper depending on project requirements and environmental conditions. Beneath the metal panels, a waterproof breathable membrane constructed from high-density polyethylene nonwoven fabric blocks wind-driven rain penetration while permitting vapor transmission, preventing condensation accumulation that could compromise insulation effectiveness. The insulation layer, commonly rock wool with calculated thickness based on thermal performance requirements, provides both heat retention and acoustic dampening critical for occupied spaces below metal roofing assemblies. A vapor barrier limits interior moisture migration into the roof assembly, while sound-absorbing cotton, typically glass wool with specified bulk density, further enhances acoustic comfort. The structural base plate, usually perforated galvanized corrugated steel designed according to purlin spacing, supports the assembly while roof purlins provide structural support and slope adjustment necessary for proper drainage performance.

Metal Standing Seam Roofing Systems

-

Technical Specifications of High-Performance Metal Standing Seam Roofing Systems

Metal Standing Seam Roofing Systems deliver exceptional performance through precisely engineered material specifications and dimensional tolerances. Material options include aluminum in 0.9-1.2mm thickness using 3003/3004 series alloys with H44 hardening and fluorocarbon spray finishes, providing lightweight construction with superior salt spray resistance ideal for coastal environments. Galvalume steel panels ranging 0.6-1.0mm thick feature AZ150 coating providing 150g/m² aluminum-zinc protection with PVDF topcoats, delivering robust corrosion resistance at cost-effective pricing suitable for diverse climatic conditions. Stainless steel options in 0.5-0.8mm thickness using 304-grade material with fluorocarbon coatings offer exceptional corrosion resistance for coastal areas, industrial zones, or high-humidity environments. Titanium-zinc plates measuring 0.7-1.0mm thick provide self-repairing surface properties and projected lifespans exceeding 80 years while satisfying environmental sustainability requirements. Copper panels in 0.8-1.0mm thickness using TU1 oxygen-free copper deliver ultra-long service life surpassing 100 years combined with distinctive aesthetic character that develops natural patina over time. Panel dimensional specifications significantly impact both structural performance and aesthetic expression of Metal Standing Seam Roofing Systems. Panel widths ranging from 300mm to 600mm effective coverage width allow adjustment based on seam height and edge-locking methodology selected for specific project conditions. The signature 65mm seam height represents an ultra-high rib design that enhances structural strength and drainage performance substantially compared to lower-profile systems. Panel lengths can be customized up to 13 meters long, eliminating transverse seams that represent potential water infiltration points while creating clean visual lines across expansive roof planes. Thickness tolerances maintained at ±0.02mm comply with ASTM A924/A755 standards, ensuring consistent material performance and predictable structural behavior under load conditions.

-

Surface Treatment Technologies for Metal Standing Seam Roofing Systems

Surface treatment selection critically influences both aesthetic appearance and long-term durability of Metal Standing Seam Roofing Systems. PVDF coatings applied at 25-30μm thickness containing 70% fluororesin provide exceptional UV resistance and chemical corrosion protection with color retention guaranteed for 20+ years even under intense solar exposure and aggressive atmospheric conditions. Polyester coatings at 20-25μm thickness represent economical alternatives suitable for general climatic conditions where extreme weathering resistance is not mandatory. Natural oxidation finishes on copper and zinc materials allow uncoated surfaces to develop protective patinas naturally over time, delivering lifespans ranging from 50 to 100 years with zero maintenance requirements while creating distinctive aged aesthetics valued in certain architectural contexts.

Structural Performance Characteristics of Metal Standing Seam Roofing Systems

Metal Standing Seam Roofing Systems excel across multiple performance metrics critical to commercial and industrial roofing applications. Mechanical properties include wind pressure resistance exceeding 4.5 kPa, enabling these systems to withstand Category 5 hurricane-force winds equivalent to 16-level typhoon conditions as verified through ASTM E1592 and GB 50223 testing protocols. Snow load capacity surpassing 1.5 kN/m² makes these systems appropriate for regions experiencing significant winter precipitation in accordance with EN 1991-1-3 standards. Impact resistance demonstrated through 1kg steel ball drop tests from 3-meter heights without panel perforation confirms durability against hail damage and falling debris per ASTM D3746 specifications. Heat deformation temperatures of 150°C for aluminum and 260°C for steel panels ensure dimensional stability under extreme thermal conditions, though linear expansion coefficients must be calculated for proper expansion joint detailing. Waterproofing and airtightness represent paramount concerns in Metal Standing Seam Roofing Systems design and installation. These assemblies routinely pass 1000Pa negative pressure testing without water infiltration, exceeding requirements specified in GB/T 7106-2008 standards for watertightness performance. Airtightness levels measuring ≤0.1 m³/(m²·h) minimize energy loss through the building envelope while the double-lock seam mechanical bite joint creates redundant weathersealing that maintains integrity even under extreme differential pressure conditions. Fire prevention credentials include A1 non-combustible material classification per GB 8624-2012, critical for insurance compliance and life safety requirements in commercial construction. Environmental attributes feature 100% recyclability of all metal components combined with reflectivity values ≥0.65 meeting cool roof standards that reduce urban heat island effects and building cooling loads.

-

Installation Methodology for Metal Standing Seam Roofing Systems

Proper installation of Metal Standing Seam Roofing Systems requires meticulous planning and execution following systematic protocols to ensure weather-tightness and long-term performance. The process begins with comprehensive project drawing development where engineering teams analyze architectural drawings including floor plans, elevations, and node diagrams to identify feasible installation alternatives. Communication with clients establishes panel type selection appropriate for specific roof structural conditions and architectural design intent. Design departments then conduct full-scale drawing development of connection details for different roof areas based on selected panel systems, with multiple review cycles culminating in signed confirmation drawings that govern subsequent fabrication and installation activities. Factory sample production follows confirmed parameters including panel profile, material specification, thickness, surface treatment methodology, and color selection. Client approval of physical samples covering dimensional accuracy, material quality, and color matching establishes acceptance standards for subsequent production runs and field installation verification. Processing drawings break detailed connection designs into granular fabrication instructions for production teams, with sequential numbering systems applied to each unit according to project specifications and quantities. This systematic approach ensures that manufacturing, quality assurance inspection, packaging, and on-site installation proceed according to numbered sequences that prevent confusion and installation errors during complex roof assemblies.

Material procurement begins with purchasing department inventory completion and acquisition based on processing lists and technical drawings. Supplier qualification procedures involve registration list verification and test report review, with multiple inspection protocols confirming material brands before deployment. The material selection brand library for Metal Standing Seam Roofing Systems includes premium manufacturers such as Alucosuper, YATAI, and LIDAO for aluminum products in 3003, 3004, and 5052 grades, BAOSTEEL, GUANZHOU, and XINYU for steel products including cold rolled sheet, galvanized sheet, galvalume sheet, and color-coated sheet variations, Baosteel and Tsingshan for stainless steel in 316 and 304 grades, NedZink for titanium-zinc plates, and Chinalco for copper materials in T2/TP2 specifications.

Design Integration and Application Scope of Metal Standing Seam Roofing Systems

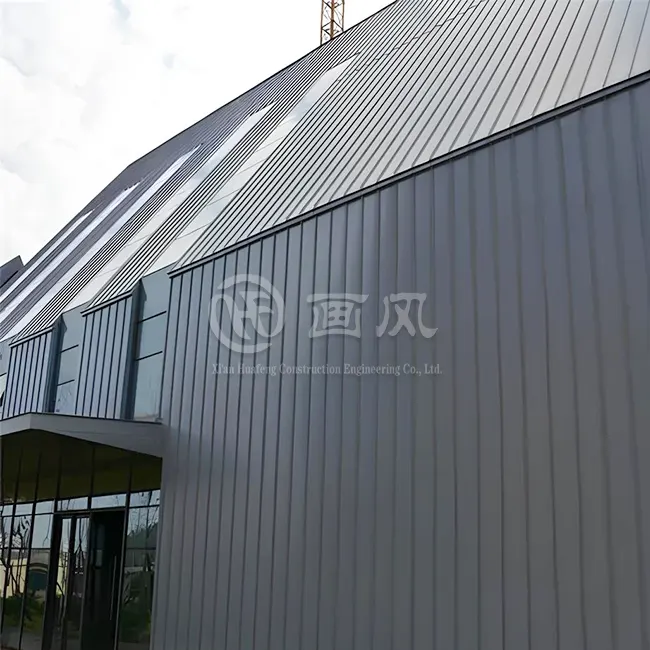

Metal Standing Seam Roofing Systems demonstrate exceptional versatility across diverse building typologies and functional requirements. Large-span structures including airports, high-speed rail stations, and exhibition centers benefit from the structural efficiency and weather protection these systems provide across expansive column-free spaces where conventional roofing materials would require excessive support infrastructure. Stadium applications featuring open roof configurations demand the high drainage performance and wind resistance that Metal Standing Seam Roofing Systems deliver reliably even during extreme weather events. Industrial plants with stringent requirements for corrosion resistance and wind uplift protection find these systems ideal for harsh operating environments where roof failure could compromise production operations and worker safety. Photovoltaic integration represents an increasingly important application for Metal Standing Seam Roofing Systems as building owners seek to maximize renewable energy generation while maintaining roof integrity. The 65mm high-rib profile provides structural compatibility with standard photovoltaic mounting fixtures, allowing solar array installation without compromising the waterproofing membrane or creating additional roof penetrations that could become leak points. This integration creates buildings that function as energy producers rather than merely consumers, advancing sustainability objectives while reducing operational costs over building lifecycles.

-

Quality Assurance Protocols for Metal Standing Seam Roofing Systems

Rigorous quality control throughout material receipt, production, and installation ensures Metal Standing Seam Roofing Systems meet exacting performance standards. Incoming material inspection involves quality verification of raw materials including copper, aluminum, and steel through sampling and testing procedures that determine whether material batches warrant acceptance or rejection. Material manufacturers must provide certification documentation and third-party testing reports confirming compliance with specified grades and properties. Inspection methodologies include full inspection for small quantities and high-value materials alongside statistical sampling for large volumes, preventing defective materials from entering production workflows. Comprehensive testing protocols examine product appearance, dimensional accuracy, salt spray resistance, coating adhesion, hardness values, impact resistance, film thickness uniformity, acid resistance, weathering performance, and color consistency across more than a dozen distinct evaluation criteria. Production processing transforms qualified materials into finished Metal Standing Seam Roofing Systems components through precision manufacturing operations. Finished product inspection verifies appearance quality, dimensional conformance, flatness tolerances, and curvature specifications before packaging approval. Strategic packaging divides products into sections corresponding to roof plan divisions, facilitating efficient on-site unpacking and installation sequencing. Product identification cards affixed to exterior packaging display section plans and product number lists that guide installation crews through systematic assembly procedures that minimize errors and ensure proper component placement throughout roof assemblies.

-

On-Site Installation Management for Metal Standing Seam Roofing Systems

Successful field installation of Metal Standing Seam Roofing Systems depends on comprehensive site management and technical execution. Initial site consultations with clients confirm construction layouts addressing product and accessory storage areas alongside on-site processing zones required for field operations. Product arrival and warehousing procedures verify delivery accuracy and arrange materials in designated locations based on packaging identification cards, sectioned floor plans, and product number lists. Installation technicians conduct advance site inspections one day prior to work commencement, verifying work area readiness and confirming that required tools including pliers, edge-locking machines, and hammers plus auxiliary materials such as rivets, structural adhesives, and screws are complete and properly maintained. Technical briefing meetings thoroughly review installation details and safety protocols before field operations commence. On-site installation follows systematic procedures that maintain quality control throughout the assembly process. Upon installation completion, comprehensive testing verifies zero-leakage performance before client acceptance procedures begin. Customers review installation interfaces and confirm satisfactory completion before signing acceptance documentation. Maintenance guidance provided to clients or arranged periodic service ensures long-term performance preservation of Metal Standing Seam Roofing Systems throughout their extended service lives.

Manufacturing Excellence and Project Delivery for Metal Standing Seam Roofing Systems

Leading manufacturers of Metal Standing Seam Roofing Systems maintain state-of-the-art production facilities capable of delivering premium-quality products at commercial scale. Raw material production plants covering 200,000 square meters provide vertically integrated manufacturing control from base material processing through finished panel fabrication. Multiple plate and accessory processing facilities strategically located near major markets enable efficient project delivery and responsive customer service. Advanced production infrastructure includes seven color coating lines for applying protective and decorative finishes, one laminating line for specialized composite panels, ten longitudinal and transverse shearing lines for precision cutting operations, fully automatic punching lines for fastener hole preparation, and more than forty shearing machines, presses, and bending machines providing flexible forming capabilities for custom profiles and complex geometrical requirements. Manufacturing certifications and intellectual property portfolios demonstrate technical leadership and commitment to innovation in Metal Standing Seam Roofing Systems development. Industry-leading manufacturers hold high-tech enterprise recognition from provincial authorities, first-level qualifications for building curtain wall systems, and third-level qualifications for building steel structures. Patent portfolios exceeding twenty registered inventions covering roofing system innovations plus various trademark registrations and software copyrights protect proprietary technologies and design methodologies. Quality management systems complying with ISO9001 standards, environmental management conforming to ISO14000:14001 specifications, and SGS guideline adherence ensure consistent product quality and responsible manufacturing practices throughout global supply chains serving diverse international markets.

-

Customization Capabilities and Technical Support for Metal Standing Seam Roofing Systems

Comprehensive customization services distinguish premium Metal Standing Seam Roofing Systems suppliers from commodity manufacturers. Engineering design teams provide structural 3D modeling and load analysis services that optimize system performance for specific project conditions. Drainage system simulation ensures adequate water management under design storm conditions while material specification advisory services guide architects and engineers through selection processes considering aesthetic preferences, performance requirements, budget constraints, and environmental factors. Delivery timelines typically range from 15-20 days from order confirmation to product shipment, with minimum order quantities starting at 500 square meters enabling economic feasibility for medium to large-scale projects. Supply capacity exceeding 1000 tons monthly supports simultaneous execution of multiple major projects without compromising delivery schedules or quality standards. Service life warranties extending 30 years demonstrate manufacturer confidence in Metal Standing Seam Roofing Systems durability and long-term performance under real-world conditions. Customization extends beyond dimensional parameters to encompass color selection from extensive palette options, pattern variations creating distinctive visual effects, and complete design customization for signature architectural projects requiring unique aesthetic expressions. This flexibility enables architects to realize creative visions while maintaining the technical performance attributes that make Metal Standing Seam Roofing Systems the preferred choice for demanding commercial and institutional applications worldwide.

Project Case Studies Demonstrating Metal Standing Seam Roofing Systems Performance

Successful implementation of Metal Standing Seam Roofing Systems across high-profile projects worldwide validates their technical capabilities and aesthetic versatility. The Xiongan Station Commercial Body features extensive aluminum-magnesium-manganese metal roofing covering complex geometries and large spans characteristic of modern transportation infrastructure. Xi'an International Convention and Exhibition Center metal roof project demonstrates the systems' suitability for prestigious civic buildings requiring architectural distinction combined with reliable long-term performance. The metal roof installation at Xi'an Station East Auxiliary Building showcases integration with existing historic structures while meeting contemporary performance standards for weather protection and energy efficiency. Cultural facilities including South Hall 2-2 of Jinghe New City International Culture and Art Center employ Metal Standing Seam Roofing Systems to achieve dramatic architectural statements while satisfying stringent acoustic and environmental control requirements essential for performance venues. Transportation infrastructure projects such as Liyuanping Highway Station metal roof installation prove system durability under harsh roadside conditions including vibration, exhaust emissions, and deicing salt exposure. Educational facilities exemplified by Weihua Cadre College teaching building and office building aluminum-magnesium-manganese metal roof and wall installations demonstrate the systems' dual functionality for both horizontal and vertical building envelope applications. The Hangzhou Sanpu Drainage Pump Station aluminum-magnesium-manganese metal roof and wall project illustrates successful deployment in challenging industrial environments where corrosion resistance and maintenance accessibility are paramount. Archaeological museum design development projects and the Inner Mongolia Tongliao Art Museum metal roof and wall installation showcase the aesthetic refinement possible with Metal Standing Seam Roofing Systems in culturally significant institutions where architectural expression must honor contextual sensitivities while incorporating contemporary building technology.

Conclusion

Metal Standing Seam Roofing Systems represent the optimal convergence of structural performance, architectural elegance, and lifecycle value for demanding commercial, industrial, and institutional applications. Their concealed fastening technology, superior weather resistance, extensive material options, and proven track record across diverse project types make them the intelligent choice for architects, engineers, and building owners seeking premium roofing solutions that deliver decades of maintenance-free service while enhancing building aesthetics and supporting sustainability objectives through energy efficiency and complete recyclability.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in Shaanxi Province, China in 2018, stands as a China Metal Standing Seam Roofing Systems factory, China Metal Standing Seam Roofing Systems supplier, and China Metal Standing Seam Roofing Systems manufacturer offering comprehensive design, production, sales, and construction services for metal roofing systems, building curtain wall systems, and steel structure enclosure systems. Recognized as a high-tech enterprise in Shaanxi Province in 2020, holding first-level qualifications for building curtain walls and third-level qualifications for building steel structures, Huafeng operates a 200,000-square-meter raw material production plant in Anhui plus processing facilities in Hangzhou and Xi'an equipped with 7 color coating lines, 1 laminating line, 10 shearing lines, and over 40 precision machines. As a leading China Metal Standing Seam Roofing Systems wholesale provider offering High Quality Metal Standing Seam Roofing Systems, we maintain competitive Metal Standing Seam Roofing Systems price structures with Metal Standing Seam Roofing Systems for sale globally. Our portfolio includes over 20 patents, ISO9001 and ISO14000:14001 certifications, collaboration with Fortune 500 companies, and complete customization from raw materials through installation providing one-stop procurement convenience. Contact huafeng@hfmetalroof.com today to discuss your project requirements and discover why discerning architects worldwide specify Huafeng Metal Standing Seam Roofing Systems for their most demanding applications.

References

1. Standing Seam Metal Roofs: Technical Standards and Installation Guidelines - Metal Construction Association Technical Committee, 2022

2. Architectural Metal Roofing Systems: Design and Performance Criteria - American Society of Civil Engineers Structural Engineering Institute, 2021

3. Sustainable Building Envelope Design: Metal Roofing Solutions for Climate Resilience - International Building Performance Simulation Association, 2023

4. Commercial Roofing Systems: Comparative Analysis of Life Cycle Costs and Performance Metrics - National Roofing Contractors Association Research Division, 2024