Are you frustrated with frequent roof leaks, high maintenance costs, or simply tired of replacing shingles every decade? Installing a Snap Lock Standing Seam Roof offers a transformative solution that eliminates these persistent headaches while delivering exceptional durability and aesthetic appeal. This comprehensive guide breaks down everything you need to know about snap lock standing seam metal roof installation, from essential tools and material selection to professional techniques for handling complex features like skylights, valleys, and dormers. Whether you're a contractor expanding your expertise or a building owner evaluating roofing options, you'll discover why this innovative system has become the preferred choice for residential, commercial, and industrial projects worldwide.

Understanding Snap Lock Standing Seam Roof Systems

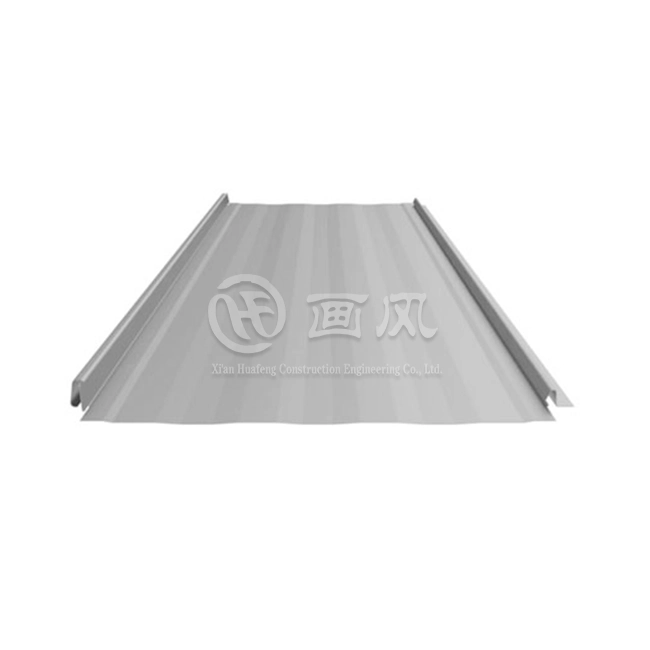

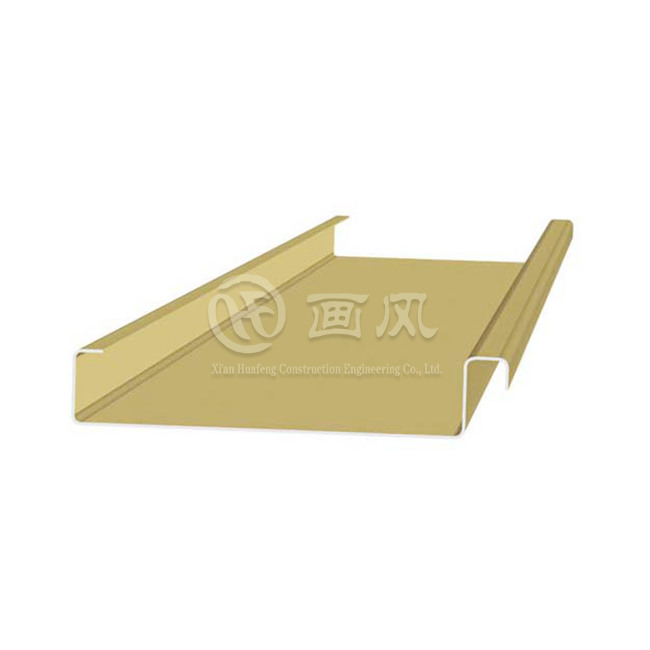

The Snap Lock Standing Seam Roof represents a revolutionary advancement in metal roofing technology, offering superior performance without the complexity and expense of traditional field-seamed systems. Unlike conventional standing seam roofs that require expensive mechanical seamers and specialized crimping tools, snap lock panels feature factory-formed edges that interlock with a simple pressure application, making installation significantly faster and more accessible. This high-performance metal roofing system utilizes snap-on standing seam technology with distinctive raised ribs typically standing forty-five millimeters high, providing exceptional waterproofing, wind resistance, and structural integrity that surpasses traditional roofing materials. The fundamental advantage of Snap Lock Standing Seam Roof systems lies in their hidden fastener design, where concealed clips secure panels to the roof deck while allowing natural thermal expansion and contraction. This engineering innovation eliminates the perforation vulnerabilities inherent in exposed fastener systems, virtually eliminating leak risks at attachment points. Professional installers appreciate that ordinary workers can master snap lock installation techniques after just one day of training, compared to the weeks or months required to develop proficiency with mechanical edge locking equipment. The panels connect through male and female edges that lock together over strategically placed clips, creating perfectly straight standing seams that deliver both structural performance and architectural elegance.

Snap Lock Standing Seam Roof

-

Material Options for Snap Lock Standing Seam Roof Applications

Selecting the appropriate substrate material represents a critical decision that impacts your Snap Lock Standing Seam Roof system's longevity, performance, and cost-effectiveness. Galvalume steel stands as the most popular choice for most climate conditions, featuring a specialized coating composition of fifty-five percent aluminum, forty-three point four percent zinc, and one point six percent silicon that delivers corrosion resistance approximately two to six times greater than ordinary galvanized steel. This advanced metallurgical formulation provides exceptional protection in dry inland areas and moderate coastal environments, with properly installed systems achieving service lives extending thirty to fifty years under normal conditions. Aluminum alloy substrates offer compelling advantages for coastal installations and high-humidity environments where salt spray corrosion poses significant challenges to steel-based systems. With a density of just two point seven grams per cubic centimeter, aluminum panels significantly reduce structural loading while providing inherent resistance to oxidation and electrochemical corrosion. The material's one hundred percent recyclability aligns with sustainable building practices, and aluminum Snap Lock Standing Seam Roof installations commonly exceed fifty years of service life in marine environments. For extreme applications including chemical processing facilities and highly corrosive industrial atmospheres, stainless steel substrates such as 304 or 316L grades deliver unmatched durability despite higher initial investment costs.

Surface coating selection profoundly influences both aesthetic longevity and weather resistance performance. PVDF fluoropolymer coatings represent the premium choice, offering exceptional color retention exceeding twenty years while providing superior resistance to ultraviolet radiation, chemical exposure, and thermal cycling. These high-performance finishes maintain their appearance and protective properties through decades of exposure to harsh environmental conditions. PE polyester coatings provide economical alternatives suitable for non-harsh environments where budget constraints outweigh maximum longevity requirements. Specialty applications may utilize uncoated materials such as copper plates or titanium zinc panels that develop protective natural oxide layers, offering distinctive aesthetics while eliminating coating maintenance concerns entirely.

Essential Tools and Equipment for Snap Lock Installation

Successful Snap Lock Standing Seam Roof installation requires assembling a comprehensive toolkit that balances efficiency with precision. Unlike field-seamed standing seam systems that demand expensive portable seaming machines costing thousands of dollars, snap lock installations utilize relatively accessible hand tools and basic power equipment. Your essential tool collection should include high-quality aviation snips or electric metal shears for panel trimming, a rubber mallet for seam engagement without surface damage, measuring tapes and chalk lines for accurate layout, and cordless drills with appropriate driver bits for clip and trim fastening. Professional installers invest in panel bending equipment for field-fabricating custom trim pieces, though many projects successfully utilize factory-bent accessories supplied by the Snap Lock Standing Seam Roof manufacturer. Safety equipment demands equal attention to installation tools, particularly given the elevated working conditions and sharp metal edges inherent to roofing work. Quality fall protection systems including proper harnesses, anchor points, and lanyards represent non-negotiable requirements for any elevated work. Protective gloves designed for sheet metal handling prevent cuts while maintaining dexterity, safety glasses shield eyes from metal filings and debris, and appropriate footwear with slip-resistant soles provides secure footing on sloped surfaces. Weather monitoring equipment helps contractors schedule installation during optimal conditions, as high winds, precipitation, or extreme temperatures can compromise both worker safety and installation quality for your Snap Lock Standing Seam Roof project.

-

Specialized Equipment for Complex Installation Features

When your Snap Lock Standing Seam Roof project includes architectural complexities such as skylights, dormers, or multiple slope transitions, additional specialized equipment becomes necessary. Skylight installations require precise cutting tools such as nibblers or circular saws equipped with metal-cutting blades that produce clean edges without excessive burring or panel distortion. Custom flashing fabrication for these penetrations often necessitates portable brake equipment that allows on-site bending of trim pieces to match exact field conditions. Valley installations benefit from extended straight edges and specialized folding tools that ensure proper panel termination and water channeling performance. Projects incorporating solar panel mounting systems or snow retention devices require torque-limiting drivers to achieve manufacturer-specified fastener tension without over-tightening that could compromise clip integrity or panel performance. Digital inclinometers help verify minimum slope requirements, as Snap Lock Standing Seam Roof systems typically require minimum slopes of approximately one inch per twelve inches, or roughly four point eight degrees, when properly paired with appropriate waterproofing underlayment. Thermal expansion calculations become particularly important on long panel runs, where panel length measurements combined with expected temperature ranges inform clip spacing and anchor point placement to accommodate dimensional changes without inducing oil canning or fastener failure.

Step-by-Step Snap Lock Standing Seam Roof Installation Process

Proper installation begins long before the first panel reaches the roof deck, starting with comprehensive substrate preparation and accurate measurement. Remove all existing roofing materials completely rather than attempting installation over old shingles, as irregular substrates promote oil canning and compromise the clean appearance characteristic of quality Snap Lock Standing Seam Roof installations. Verify roof deck integrity by replacing any deteriorated sheathing and ensuring proper structural support, with minimum substrates of fifteen thirty-seconds inch structural plywood or five-eighths inch oriented strand board supported on rafters spaced maximum twenty-four inches on center. Install high-quality synthetic underlayment rather than traditional felt paper, working from eaves toward ridge with proper overlap that provides secondary waterproofing protection. Establish accurate roof layout by carefully checking structure squareness and compensating for any out-of-square conditions through strategic drip edge placement. Calculate panel distribution to achieve balanced appearance on both rake edges while ensuring standing seams align properly across valleys and at architectural features. Begin installation at the gable end opposite prevailing weather patterns, measuring one panel width inward from the roof edge and establishing a chalk line from ridge to eave that guides first panel alignment. Install perimeter trim including eave and rake flashings before panel placement, ensuring all trim pieces attach securely with appropriate fasteners that penetrate deck substrate adequately while avoiding over-penetration that could compromise waterproofing membranes.

-

Panel Installation and Seam Engagement Techniques

Position the first Snap Lock Standing Seam Roof panel carefully against established layout lines, verifying squareness and proper overhang at the eave based on selected trim profile requirements. Secure the panel using hidden clips spaced according to manufacturer specifications, typically at intervals not exceeding one point five meters to achieve required wind resistance performance exceeding three point zero kilonewtons per square meter. Modern high-quality systems achieve wind resistance capable of withstanding wind speeds of sixty meters per second or two hundred sixteen kilometers per hour when properly installed according to EN 15601 standards. Engage the male edge of subsequent panels into the female edge of installed panels, starting at eave trim and working upward while ensuring complete seam engagement along the entire panel length. Use rubber mallets or similar soft-faced tools to fully engage seam connections without damaging panel finishes or inducing dents that compromise appearance and potentially affect water shedding performance. The distinctive clicking sound of properly engaged seams provides audible confirmation of correct installation, while visual inspection verifies complete interlock along the full standing seam height. Continue panel installation across the roof plane, maintaining consistent clip spacing and verifying alignment periodically to prevent accumulated angular deviations that could result in sawtooth appearance at eaves or ridges. Field-cut the final panel to proper width, maintaining appropriate clearance from rake trim while ensuring adequate edge protection through proper hemming or trim engagement.

-

Integrating Skylights and Roof Penetrations

Skylight integration represents one of the most challenging aspects of Snap Lock Standing Seam Roof installation, requiring precise measurements and careful flashing details to maintain waterproofing integrity. Position skylights strategically near ridge areas and away from primary snow accumulation zones, as placement decisions significantly impact both water management and snow sliding dynamics. Create rough openings by carefully cutting panels to proper dimensions, with cuts positioned to minimize disruption to standing seam locations and maintaining structural integrity of surrounding panel areas. Install prefabricated skylight curbs according to manufacturer specifications, ensuring proper height above finished roof surface to prevent water intrusion during heavy rainfall or snow melt events. Execute flashing installation in proper sequence, beginning with base flashing that extends beneath upslope panels while integrating with underlayment waterproofing layers. Side flashings must accommodate thermal movement of adjacent Snap Lock Standing Seam Roof panels while maintaining weathertight seals, typically achieved through specialized flexible flashing materials or articulated metal flashings that allow panel movement without compromising water exclusion. Head flashing installations prove most critical, as they must direct water around and past the penetration while integrating seamlessly with overlying panel systems. Apply high-quality butyl sealants or specialized roofing adhesives at all flashing interfaces, creating redundant waterproofing barriers that protect against wind-driven rain and standing water conditions.

Performance Characteristics and Structural Capabilities

The structural performance of Snap Lock Standing Seam Roof systems significantly exceeds traditional roofing materials across multiple critical loading scenarios. Wind uplift resistance represents perhaps the most demanding performance requirement, particularly in coastal regions and high-elevation applications exposed to severe weather events. Properly installed systems with clip spacing maintained at one point five meters or less consistently achieve wind resistance ratings of three point zero kilonewtons per square meter or higher, translating to survival in extreme wind events exceeding category three hurricane intensity. The hidden clip attachment system distributes wind loads more effectively than exposed fastener systems, as each clip functions as an independent load-bearing element while allowing controlled panel movement that dissipates rather than concentrates stress forces. Snow load and live load capacity depends primarily on substrate material selection and supporting purlin or rafter spacing. Aluminum panels with zero point seven millimeter thickness installed over purlins spaced six hundred millimeters on center typically support loads of one point five kilonewtons per square meter, adequate for moderate snow accumulation zones. Upgrading to one point zero millimeter galvanized steel increases capacity to two point zero kilonewtons per square meter or greater, suitable for heavy snow regions. The Snap Lock Standing Seam Roof system's seismic resistance capabilities prove equally impressive, with flexible panel connections allowing displacement of plus or minus fifteen millimeters to accommodate structural deformation during seismic events without inducing panel damage or connection failure. This flexibility results from sliding clip designs that permit controlled movement while maintaining weathertight seals and structural integrity.

-

Long-Term Durability and Maintenance Requirements

Snap Lock Standing Seam Roof installations deliver exceptional longevity with minimal maintenance requirements compared to conventional roofing systems. High-quality installations incorporating galvalume steel substrates with PVDF coating systems routinely achieve thirty-year warranty coverage, with actual service lives frequently extending forty to fifty years when properly maintained. Aluminum substrate systems in favorable environments commonly exceed fifty years of continuous service, while premium stainless steel installations may achieve century-scale performance in appropriate applications. The hidden fastener design eliminates the most common failure mode affecting metal roofing systems, as exposed fastener degradation, backing-out, and seal failure account for the majority of premature metal roof failures. Maintenance protocols for Snap Lock Standing Seam Roof systems remain remarkably minimal, typically requiring only periodic debris removal and occasional rinsing to maintain appearance and prevent organic accumulation in low-slope applications. Annual inspections should verify seam integrity, check for signs of unusual stress or movement, and confirm proper function of all roof penetration flashings and trim pieces. Unlike asphalt shingle systems requiring regular replacement of damaged units and periodic complete re-roofing, metal standing seam roofs maintain their protective and aesthetic qualities through decades of service with only basic custodial care. This dramatic reduction in lifecycle maintenance costs substantially offsets higher initial installation investments, making Snap Lock Standing Seam Roof systems highly cost-effective when evaluated over realistic service life periods.

Conclusion

Snap Lock Standing Seam Roof installation combines advanced engineering with practical accessibility, delivering premium roofing performance without requiring specialized equipment or extensive training. The system's hidden fastener design, thermal movement accommodation, and superior weather resistance make it an ideal choice for projects demanding long-term durability and minimal maintenance.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

As a leading China Snap Lock Standing Seam Roof manufacturer, China Snap Lock Standing Seam Roof supplier, and China Snap Lock Standing Seam Roof factory, Xi'an Huafeng Construction Engineering Co., Ltd. brings exceptional expertise to every project. Established in Shaanxi Province in 2018, our company specializes in comprehensive metal roofing solutions including design, production, sales, and construction services. We offer High Quality Snap Lock Standing Seam Roof systems with competitive Snap Lock Standing Seam Roof price structures, making premium roofing accessible for projects of all scales. Our three state-of-the-art manufacturing facilities spanning over 200,000 square meters house seven color coating production lines and more than forty specialized machines, ensuring superior quality control and efficient delivery for every order.

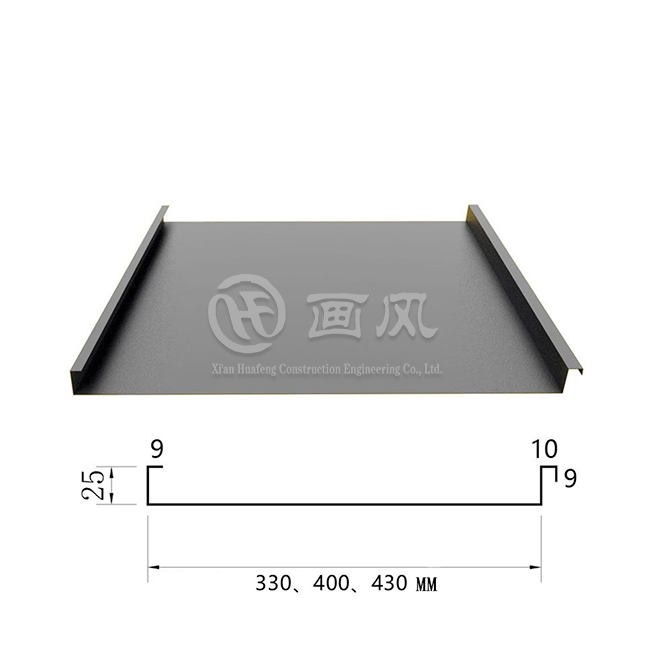

Our China Snap Lock Standing Seam Roof wholesale options provide exceptional value for contractors and developers seeking reliable, certified products backed by comprehensive technical support. With ISO 9001, ISO 14001, CE, and SGS certifications, plus more than twenty registered patents for roofing innovations, we deliver products that meet the highest international standards. Our customizable Snap Lock Standing Seam Roof for sale offerings include aluminum-magnesium-manganese plates, galvanized steel, stainless steel, copper, and titanium zinc substrates in thicknesses from zero point five to one point two millimeters, with standard heights of forty-five millimeters and customizable dimensions to match your exact project requirements. From initial design consultation and 3D structural modeling through precision manufacturing with real-time quality control to seamless on-site installation guidance, we provide complete one-stop solutions that eliminate coordination challenges and ensure optimal results.

Our proven track record includes prestigious projects such as Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, and numerous other high-profile commercial and industrial installations across China and internationally. Whether you need five hundred square meters for a residential project or require production capacity of one thousand tons monthly for large-scale developments, our flexible MOQ and rapid fifteen to twenty day delivery times accommodate projects of all sizes. Contact us today at huafeng@hfmetalroof.com to discuss your Snap Lock Standing Seam Roof requirements and discover how our engineering expertise, manufacturing capabilities, and comprehensive service approach can transform your roofing project. Save this guide for future reference, and reach out whenever questions arise during your planning or installation process.

References

1. Metal Roofing Alliance (2023). "Standing Seam Metal Roofing Systems: Design and Installation Standards." Technical Publication Series, Volume 12.

2. Johnson, Robert M. & Chen, Lisa K. (2022). "Concealed Fastener Metal Roof Systems: Performance Analysis and Best Practices." Journal of Building Envelope Design, 18(3), 145-167.

3. National Roofing Contractors Association (2024). "Metal Roofing Installation Manual: Snap-Lock and Standing Seam Systems." NRCA Technical Operations Division.

4. Patterson, David L. (2021). "Thermal Movement Considerations in Metal Roof Panel Design." Building Science Review Quarterly, 29(2), 78-95.