Are you struggling with roof systems that fail under harsh weather conditions, leak after just a few years, or require constant maintenance? Traditional roofing solutions often leave building owners frustrated with unexpected repairs and replacement costs. Trapezoidal Standing Seam Roofing emerges as the definitive answer to these persistent challenges, offering a sophisticated blend of engineering excellence and long-term durability that transforms how we approach commercial and industrial building envelopes.

Understanding Trapezoidal Standing Seam Roofing Systems

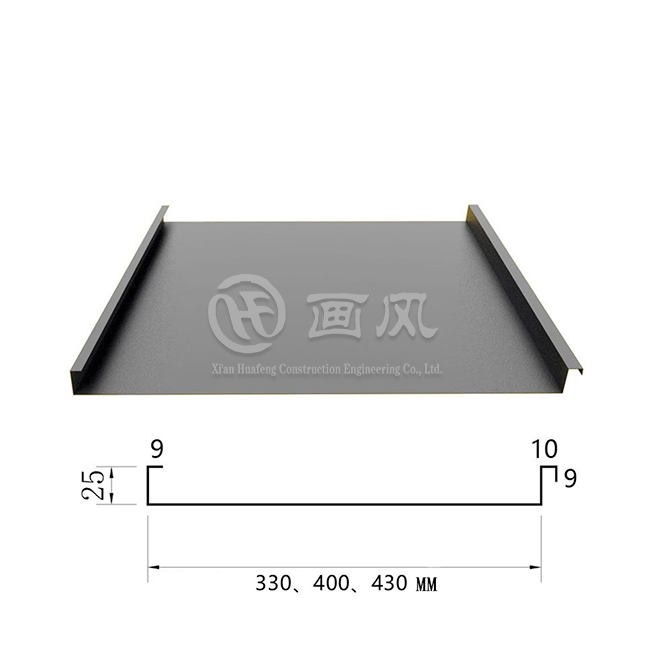

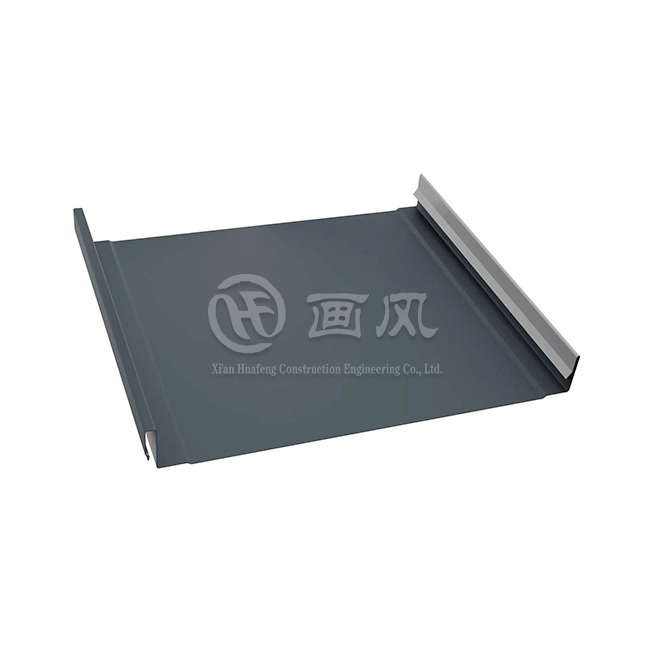

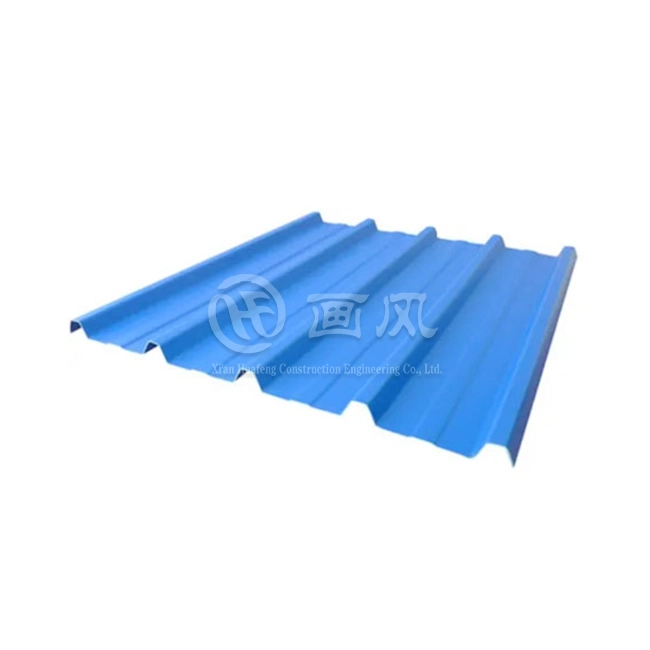

Trapezoidal Standing Seam Roofing represents a revolutionary advancement in metal roofing technology that combines the structural efficiency of trapezoidal profiles with the weather-tight performance of standing seam systems. This innovative approach addresses the fundamental limitations of conventional roofing by creating a continuous, non-penetrating surface that eliminates the primary cause of roof failures across the construction industry. The trapezoidal geometry provides exceptional load-bearing capacity while the standing seam configuration ensures complete waterproofing without exposing fasteners to the elements. At Xi'an Huafeng Construction Engineering Co., Ltd., our Trapezoidal Standing Seam Roofing systems incorporate decades of engineering research and field testing to deliver solutions that exceed international performance standards. The unique profile design features ribs ranging from 50mm to 115mm in height, creating structural depth that allows panels to span greater distances without intermediate support while maintaining rigidity under wind loads exceeding 5.0 kPa. This design philosophy reflects our understanding that modern buildings demand roofing systems capable of performing flawlessly for thirty years or more without significant intervention.

Trapezoidal Standing Seam Roofing

-

The Engineering Excellence Behind Trapezoidal Profiles

The trapezoidal profile configuration inherent in our Trapezoidal Standing Seam Roofing systems delivers structural advantages that flat or minimally profiled panels simply cannot match. The geometric shape creates natural stiffness through its angular form, distributing loads efficiently across the panel width and transferring forces to the supporting structure with minimal deflection. When engineers select panel configurations for large-span applications such as manufacturing facilities, distribution centers, or transportation terminals, the load capacity becomes a critical design parameter. Our trapezoidal panels achieve load capacities exceeding 1.5 kN/m², enabling them to support not only their own weight and snow accumulation but also maintenance traffic and equipment installations. The standing seam connection method further enhances performance by allowing thermal expansion and contraction without creating stress concentrations that could compromise panel integrity. Traditional through-fastened panels create rigid attachment points that resist natural material movement, eventually leading to fastener failure or panel distortion. Our non-penetrating clip system accommodates thermal movement while maintaining complete weather protection, a feature particularly valuable in regions experiencing significant temperature variations. The manufacturing precision we achieve through our seven color coating production lines and advanced roll-forming equipment ensures every panel meets exacting dimensional tolerances, facilitating seamless field installation and long-term performance.

-

Material Science and Surface Protection Technologies

Material selection forms the foundation of any high-performance Trapezoidal Standing Seam Roofing system, and our approach reflects both scientific rigor and practical application experience. We offer aluminum alloy substrates including 3003, 3004, and 5052 grades, each selected for specific performance characteristics ranging from coastal corrosion resistance to exceptional formability. Steel substrates receive galvanized or aluminum-zinc coating protection before applying premium finish systems including PE and PVDF technologies. The PVDF coating system represents the industry's most durable finish option, maintaining color stability and chalking resistance for decades even under intense ultraviolet exposure and industrial atmospheric conditions. Our partnership with leading material suppliers including Alucosuper, YATAI, LIDAO for aluminum, and BAOSTEEL, GUANZHOU, XINYU for steel ensures we source only materials meeting our stringent quality standards. Every incoming material shipment undergoes comprehensive inspection including appearance evaluation, dimensional verification, salt spray resistance testing, adhesion assessment, hardness measurement, impact resistance, film thickness confirmation, acid resistance validation, weather resistance evaluation, and color difference analysis. This rigorous quality control process, supported by material certifications and third-party testing reports, guarantees that every Trapezoidal Standing Seam Roofing panel we produce will deliver the promised thirty-year performance warranty. The stainless steel options we provide through Baosteel and Tsingshan partnerships offer ultimate corrosion resistance for the most demanding coastal or chemical processing environments where even premium coated steel might prove insufficient.

Comprehensive Design and Engineering Services

-

Project-Specific Engineering and Drawing Development

Successful Trapezoidal Standing Seam Roofing installations begin long before the first panel arrives at the construction site, starting with comprehensive design services that transform architectural concepts into constructible reality. Our engineering team analyzes complete architectural drawing packages including floor plans, elevations, and preliminary details to identify potential challenges and develop optimized solutions. This initial feasibility analysis considers factors including structural capacity, drainage patterns, thermal movement accommodation, and interface details with adjacent building systems. Following client consultation to confirm panel selection and system configuration, our design department creates detailed construction documents at full scale, developing node-specific details that address every unique condition within the project. These deepened drawings undergo multiple review cycles with clients and their design teams, ensuring complete alignment with project requirements before construction begins. The collaborative design process we employ reflects our understanding that successful projects result from clear communication and thorough planning rather than field improvisation. Our structural 3D modeling capabilities enable us to visualize complex geometries and verify clearances before fabrication, while drainage system simulation ensures water management strategies will perform as intended. Material specification advisory services help clients navigate the extensive options available in Trapezoidal Standing Seam Roofing systems, balancing performance requirements against budget realities to achieve optimal value.

-

Sample Development and Production Verification

Before committing to full-scale production of any Trapezoidal Standing Seam Roofing project, we manufacture physical samples incorporating all specified parameters including panel profile, substrate material, thickness, surface treatment, and color selection. These factory-processed samples undergo client review and approval, with accepted samples sealed as production standards against which all subsequent manufacturing will be evaluated. This sample approval process eliminates ambiguity regarding appearance expectations and performance characteristics, providing clear benchmarks for quality assurance throughout the project lifecycle. The transition from approved samples to production drawings represents another critical control point in our process, as our design department creates detailed fabrication documents that manufacturing personnel will follow. Each component receives sequential numbering according to its location within the overall roof assembly, creating traceability from production through installation that prevents confusion and ensures proper placement. This systematic approach to project execution reflects methodologies we have refined through numerous large-scale installations including the Xiongan Station Commercial Body project, Xi'an International Convention and Exhibition Center, and Inner Mongolia Tongliao Art Museum, where coordination complexity demanded flawless execution.

Precision Manufacturing and Quality Assurance

-

Advanced Production Capabilities and Equipment

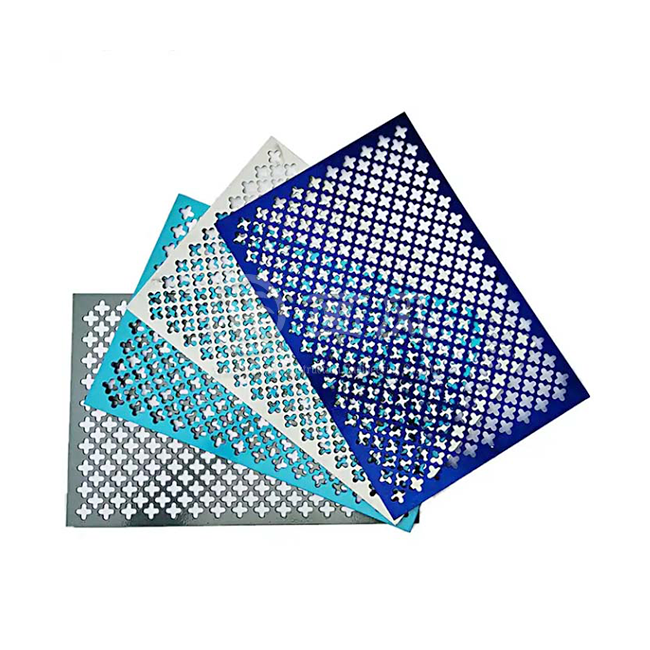

Our manufacturing infrastructure represents significant investment in technologies that enable us to deliver Trapezoidal Standing Seam Roofing systems meeting the highest quality standards while maintaining production efficiency. The raw material production plant in Anhui covers 200,000 square meters and houses seven color coating production lines capable of applying premium finishes to steel and aluminum substrates. A dedicated laminating production line enables us to produce specialty finishes including wood grain and stone patterns when aesthetic requirements demand alternatives to solid colors. Ten longitudinal and transverse shearing production lines provide the flexibility to process materials in various widths and lengths, while fully automatic punching production lines create the precise hole patterns required for clip attachment and ventilation details. More than forty shearing machines, presses, and bending machines distributed across our Hangzhou and Xi'an processing plants enable us to fabricate custom flashings, trims, and accessories that complete each Trapezoidal Standing Seam Roofing installation. Our roll-forming systems produce panels in lengths up to thirteen meters, eliminating intermediate joints on many roof sections and enhancing both appearance and weather resistance. Real-time quality control integrated into our production processes monitors dimensional accuracy, surface quality, and profile consistency, immediately flagging any deviations for correction before defective products can proceed to subsequent operations. This commitment to manufacturing excellence earned us recognition as a high-tech enterprise in Shaanxi Province and supports the certifications we maintain including ISO9001 quality management, ISO14001 environmental management, and SGS product verification.

-

Rigorous Inspection Protocols Throughout Production

Quality assurance for Trapezoidal Standing Seam Roofing systems demands comprehensive inspection at multiple stages throughout the manufacturing process, beginning with incoming material verification and continuing through finished product evaluation. Raw material inspection encompasses both full inspection for small quantities of high-value materials and statistical sampling for large volumes of frequently used components. Suppliers must provide material certifications and independent testing reports documenting compliance with specified properties, which our quality team verifies through additional testing before accepting materials into inventory. Production processes undergo continuous monitoring with inspection steps including appearance evaluation to identify surface defects, dimensional measurement to confirm conformance with drawings, flatness assessment to ensure panels will install properly, and curvature verification to detect any unwanted distortion. Finished Trapezoidal Standing Seam Roofing panels receive final inspection before packaging, with quality personnel checking that each component matches approved samples and meets specification requirements. Our packaging approach facilitates efficient site operations by organizing materials according to roof sections, with identification cards showing sectional floor plans and product number lists that guide installation crews. This systematic approach to quality management ensures that when our Trapezoidal Standing Seam Roofing products arrive at your construction site, they will perform exactly as specified throughout their multi-decade service life.

Professional Installation Support and Maintenance

-

On-Site Construction Management and Technical Guidance

Even the highest quality Trapezoidal Standing Seam Roofing panels will fail to deliver expected performance if installation does not follow proper procedures, which is why we provide comprehensive construction support services. Our site preparation activities begin with consultation regarding material storage, equipment staging, and work area organization to ensure efficient operations. When materials arrive, our team verifies packaging integrity and guides product placement according to sectional plans and sequential numbering systems established during fabrication. Installation technicians conduct pre-construction site inspections one day before work commences, verifying that all required tools including seaming equipment, cutting implements, and fastening devices are available and functional. We confirm that necessary accessories including concealed clips, structural adhesives, rivets, and fasteners are on hand in sufficient quantities to avoid installation delays. Technical briefing sessions review installation sequences, quality standards, safety protocols, and coordination requirements with adjacent trades. Throughout the installation process, our experienced supervisors provide guidance ensuring that every Trapezoidal Standing Seam Roofing panel installs correctly with proper alignment, appropriate seam engagement, and complete weather protection. Upon completion, we conduct comprehensive water testing to verify zero leakage before requesting client acceptance inspection. This thorough approach to installation support reflects our understanding that system performance depends equally on product quality and installation craftsmanship.

-

Long-Term Performance Through Planned Maintenance

While Trapezoidal Standing Seam Roofing systems require minimal maintenance compared to alternative technologies, establishing appropriate care protocols maximizes service life and ensures warranty compliance. We provide clients with detailed maintenance guidelines customized to their specific installation, addressing factors including climate conditions, surrounding environment, and building use patterns. For clients preferring professional maintenance services, we can arrange periodic inspections and necessary interventions to keep systems performing optimally. The combination of premium materials, expert engineering, precision manufacturing, and professional installation support we provide has enabled successful project completion for numerous high-profile facilities. Our project portfolio includes installations at major transportation hubs, cultural institutions, educational facilities, and commercial developments where Trapezoidal Standing Seam Roofing performance directly impacts building operations and user experience. The Hangzhou Sanpu Drainage Pump Station project demonstrates our capability with critical infrastructure requiring absolute weather protection, while the South Hall of Jinghe New City International Culture and Art Center showcases aesthetic possibilities achievable with properly engineered metal roofing systems.

Conclusion

Trapezoidal Standing Seam Roofing from Xi'an Huafeng delivers unmatched durability, engineering excellence, and long-term value for demanding commercial and industrial applications worldwide.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Partner with a leading China Trapezoidal Standing Seam Roofing factory that combines advanced manufacturing capabilities, comprehensive engineering services, and proven project delivery. As a premier China Trapezoidal Standing Seam Roofing supplier and China Trapezoidal Standing Seam Roofing manufacturer, we offer China Trapezoidal Standing Seam Roofing wholesale solutions backed by over twenty patent certifications, CE compliance, ISO quality systems, and SGS verification. Our High Quality Trapezoidal Standing Seam Roofing products deliver competitive Trapezoidal Standing Seam Roofing price points while maintaining premium performance standards. With Trapezoidal Standing Seam Roofing for sale through our global distribution network, we provide one-stop procurement from raw materials through accessories, customized solutions tailored to your specifications, and expert installation guidance. Contact us today at huafeng@hfmetalroof.com to discuss your project requirements and discover how our engineering expertise, manufacturing excellence, and commitment to customer success can transform your next roofing challenge into a showcase installation.

References

1. "Metal Roofing Systems: Design and Installation Guidelines" - American Society of Civil Engineers (ASCE), Structural Engineering Institute

2. "Standing Seam Metal Roof Systems: Performance Requirements" - ASTM International Standards Committee on Metal Building Systems

3. "Architectural Metal Roofing and Wall Systems Manual" - National Roofing Contractors Association (NRCA), Technical Operations Division

4. "Durability and Service Life Prediction of Metal Building Envelopes" - International Building Performance Simulation Association (IBPSA), Building Science Journal