Are you facing persistent roofing issues with water infiltration, wind uplift failures, or costly maintenance cycles? Mechanical Lock Metal Roofing provides the ultimate solution for building owners who refuse to compromise on durability and performance. This comprehensive guide reveals why mechanical lock standing seam systems outperform conventional roofing methods, delivering unmatched weather resistance and structural integrity for decades.

Superior Weather Protection Through Advanced Seaming Technology

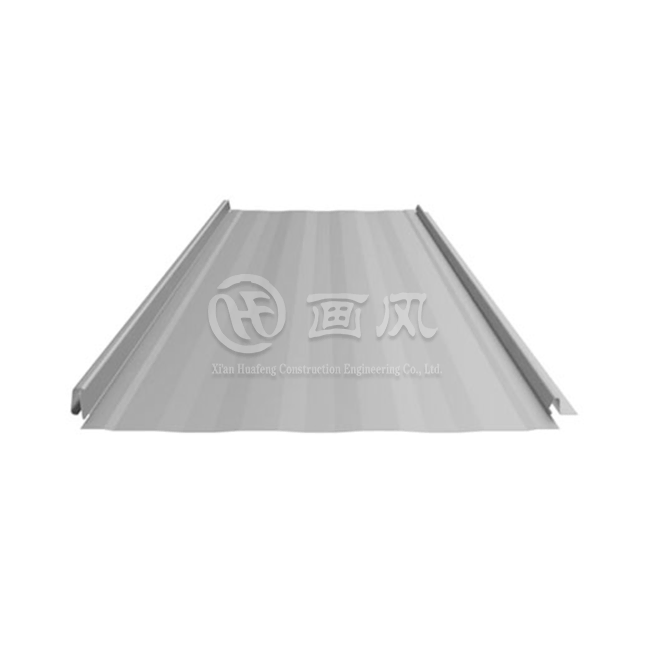

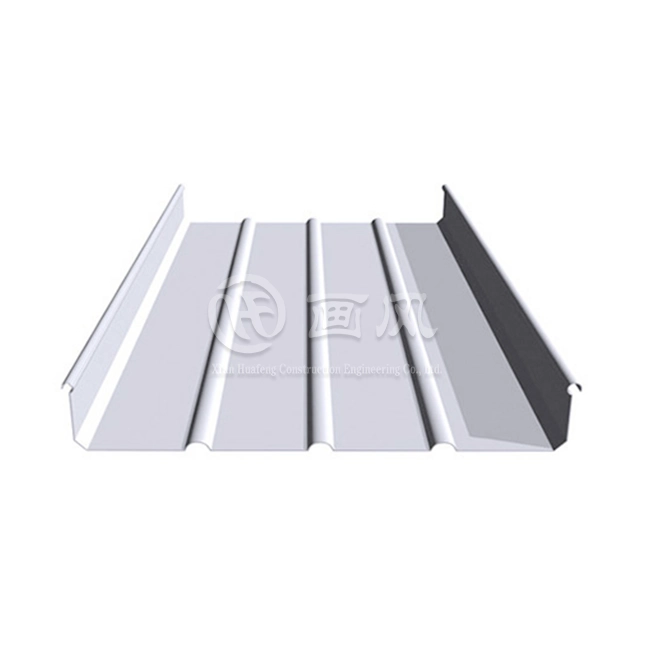

When building professionals demand absolute weather protection, Mechanical Lock Metal Roofing stands as the industry's premier choice. Unlike snap-lock systems that rely on simple interlocking mechanisms, mechanical lock panels feature vertical legs that are folded and crimped together using specialized seaming equipment. This process creates an exceptionally tight seal that prevents water infiltration even under extreme weather conditions. The double-lock configuration, where seams are folded twice creating a 180-degree connection, delivers superior performance in harsh climates with heavy rainfall, wind-driven precipitation, and substantial snow loads. The engineering behind Mechanical Lock Metal Roofing addresses critical vulnerabilities found in alternative roofing systems. Traditional exposed fastener roofs create countless penetration points where moisture can enter, leading to premature failure and expensive repairs. Even snap-lock standing seam systems, while better than through-fastened options, cannot match the watertight integrity of mechanically seamed panels. The crimped connection in mechanical lock systems remains secure through decades of thermal expansion and contraction, maintaining its protective seal when other systems begin to fail.

-

Performance in Low-Slope Applications

One of the most significant advantages of Mechanical Lock Metal Roofing is its exceptional performance on low-slope roofs where other systems struggle. While snap-lock panels typically require minimum slopes of 3:12, mechanical lock systems can be installed on roofs with slopes as low as 2:12, and in some cases even 0.5:12 when continuous in-seam sealant is applied. This versatility makes Mechanical Lock Metal Roofing ideal for commercial and industrial buildings where architectural constraints often result in lower roof pitches. The double-lock seam configuration provides the necessary weather resistance for these challenging applications, preventing water pooling issues that plague less robust roofing systems.

Structural Performance and Engineering Excellence

Mechanical Lock Metal Roofing consistently achieves the highest ratings in industry testing for wind uplift, water penetration, and structural load capacity. When building codes demand maximum structural performance, engineers and architects specify double-seamed mechanical lock panels because they deliver proven results. Independent testing by third-party laboratories demonstrates that these systems can withstand wind speeds exceeding 90 mph while maintaining their weather-tight seal. This performance level is particularly critical for buildings in hurricane-prone regions, mountainous areas with high winds, or any location where extreme weather events occur regularly. The structural advantages of Mechanical Lock Metal Roofing extend beyond wind resistance. These panels provide exceptional load-bearing capacity, supporting snow loads of 1.5 kN/m² or greater without compromising integrity. The raised seam profile adds significant vertical strength to the roofing system, allowing longer panel runs without intermediate support. This structural efficiency reduces overall system costs while providing superior performance compared to lower-profile alternatives. For architects designing large-span structures or buildings with complex geometries, Mechanical Lock Metal Roofing offers the engineering flexibility needed to achieve ambitious design goals without sacrificing performance.

-

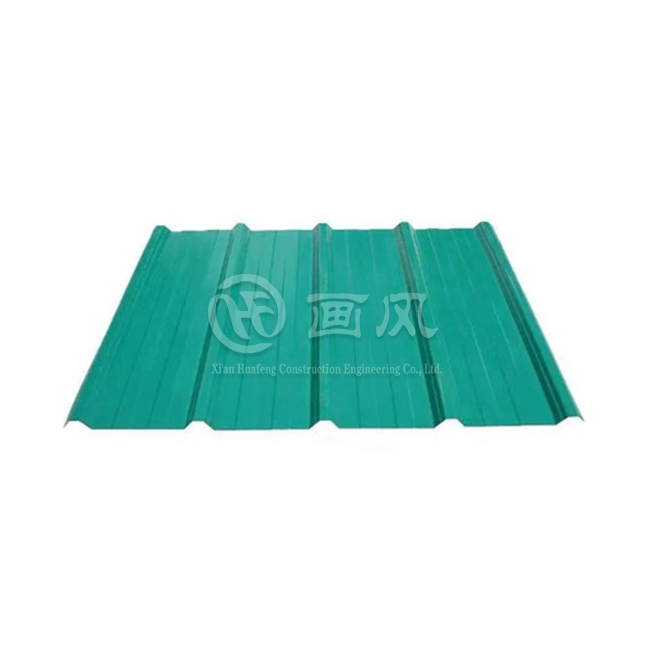

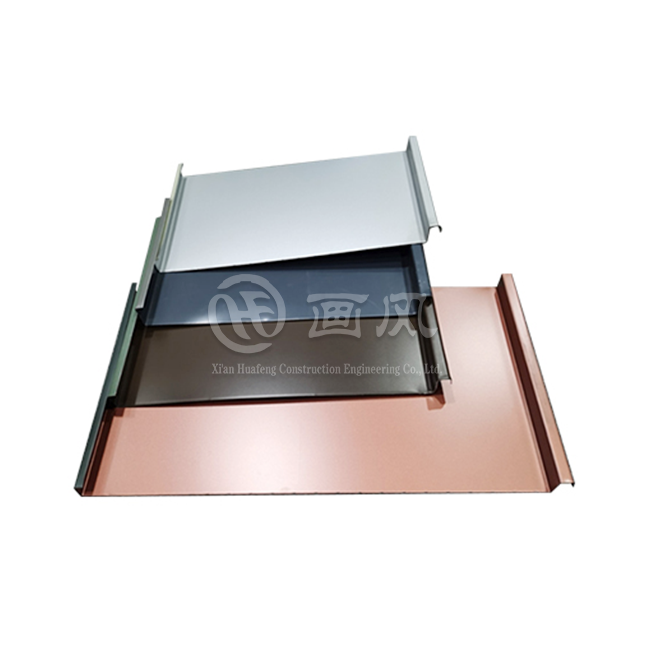

Material Versatility and Customization Options

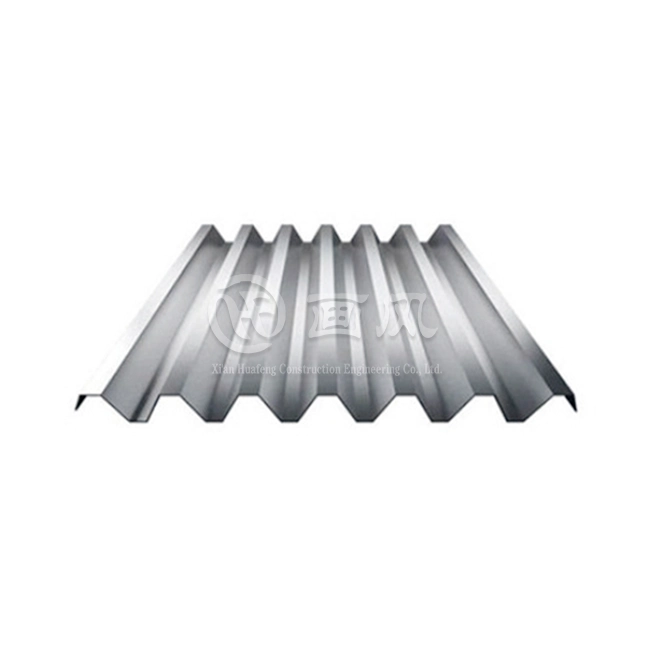

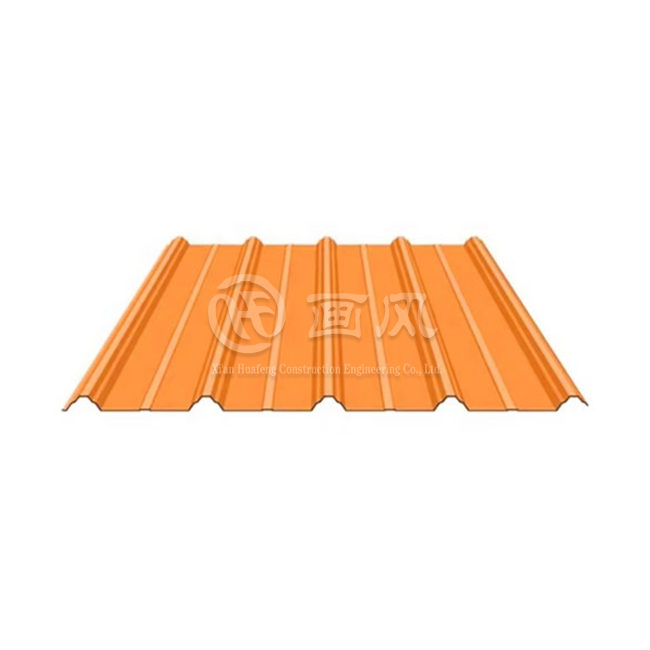

Xi'an Huafeng Construction Engineering Co., Ltd. manufactures Mechanical Lock Metal Roofing systems using premium materials including aluminum, galvalume steel, galvanized steel, stainless steel, copper, and titanium zinc. Each material offers distinct advantages for specific applications. Aluminum panels provide exceptional corrosion resistance and lightweight properties, making them ideal for coastal environments and retrofitting projects. Galvalume steel delivers outstanding longevity with its aluminum-zinc coating that protects against corrosion for decades. Stainless steel grades 304 and 316 offer maximum durability for industrial facilities with aggressive environments, while copper and titanium zinc panels provide distinctive aesthetics that develop beautiful patinas over time. The customization possibilities with Mechanical Lock Metal Roofing extend to multiple dimensions including panel width (300-500mm), rib heights (25mm or 32mm), coating options (PVDF or PE), and virtually unlimited color choices matching RAL standards or custom specifications. This flexibility allows architects to achieve their design vision while specifying a roofing system that meets stringent performance requirements. PVDF coatings with fluorocarbon technology provide superior fade resistance and color retention, maintaining aesthetic appeal for 30 years or more. With coating thicknesses of 25-40 micrometers on exposed surfaces, these panels resist weathering, chemical exposure, and UV degradation far better than conventional painted metal roofing.

Installation Excellence and Long-Term Value

While Mechanical Lock Metal Roofing requires specialized installation expertise and seaming equipment, this complexity translates directly into superior long-term performance. The installation process involves precise alignment of panel legs, proper clip placement, and careful seaming operations that create the weather-tight connections these systems are known for. Professional installers using modern electric seamers can achieve consistent, high-quality seams that meet manufacturer specifications and building code requirements. This installation precision eliminates the common failure points found in simpler roofing systems, providing building owners with genuine peace of mind. The long-term value proposition of Mechanical Lock Metal Roofing becomes apparent when comparing lifecycle costs against alternative systems. While initial installation costs may exceed snap-lock or through-fastened options, the extended service life and minimal maintenance requirements deliver substantial savings over decades. These systems routinely provide 50 years or more of reliable performance with proper installation and minimal maintenance. The absence of exposed fasteners eliminates the need for periodic fastener replacement, a significant maintenance burden with exposed fastener systems. Building owners benefit from reduced maintenance costs, fewer disruptions to building operations, and the confidence that their roofing investment will protect their facility for generations.

-

Fire Resistance and Safety Compliance

Mechanical Lock Metal Roofing provides Class A fire resistance ratings, the highest classification available for roofing materials. These non-combustible panels comply with ASTM E108 and EN 13501 standards, offering critical protection for buildings where fire safety is paramount. In wildfire-prone regions, metal roofing systems have proven their value repeatedly by resisting ember attacks and radiant heat that ignite conventional roofing materials. The inherent fire resistance of Mechanical Lock Metal Roofing also benefits insurance considerations, potentially reducing premiums for buildings in high-risk areas.

Manufacturing Quality and Technical Support

Xi'an Huafeng Construction Engineering Co., Ltd. operates three state-of-the-art manufacturing facilities equipped with seven color coating production lines and over 40 specialized machines for producing Mechanical Lock Metal Roofing systems. This manufacturing capacity enables production of 1000 tons monthly while maintaining stringent quality standards. Every material undergoes comprehensive incoming inspection including appearance assessment, dimensional verification, salt spray testing, adhesion evaluation, hardness testing, impact resistance, film thickness measurement, acid resistance, weather resistance analysis, and color difference assessment. This multi-stage quality control process ensures that only materials meeting international standards (ASTM, DIN, JIS, BS, GB/T) enter production. The company's commitment to quality extends throughout the manufacturing process with real-time quality control monitoring and raw material traceability. Premium material suppliers including Alucosuper, YATAI, Baosteel, Tsingshan, and NedZink provide certified materials with third-party testing documentation. This rigorous material selection and verification process eliminates substandard inputs that compromise performance in inferior roofing products. From panel forming through coating application and finished product inspection, every step follows documented procedures validated through ISO9001 and ISO14000:14001 certification audits.

-

Comprehensive Project Support

Xi'an Huafeng Construction Engineering Co., Ltd. provides complete project support from initial design through final installation and long-term maintenance. The design services include structural 3D modeling, load analysis, drainage system simulation, and material specification advisory to optimize system performance for each project's unique requirements. Technical teams conduct detailed drawing deepening, creating 1:1 scale detailed drawings for complex nodes and connections. This engineering support ensures seamless integration with building structures while meeting all performance specifications and building codes. Factory processing samples allow customers to verify material quality, color accuracy, and dimensional precision before committing to full production runs. Each project's panels are numbered sequentially according to specifications and quantities, streamlining quality assurance inspection, packaging logistics, and on-site installation. This systematic approach eliminates confusion during construction and ensures that every component arrives ready for immediate installation. On-site technical support includes installation guidance, safety briefings, and final testing to verify zero leakage before project acceptance.

Proven Performance Across Major Projects

Xi'an Huafeng Construction Engineering Co., Ltd. has successfully completed numerous prestigious projects demonstrating the versatility and reliability of Mechanical Lock Metal Roofing systems. Notable installations include Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, Xi'an Station East Auxiliary Building, Jinghe New City International Culture and Art Center South Hall, Liyuanping Highway Station, Weihua Cadre College facilities, Hangzhou Sanpu Drainage Pump Station, Archaeological Museum, and Inner Mongolia Tongliao Art Museum. These projects span diverse applications from transportation infrastructure to cultural institutions, proving the system's adaptability to varying architectural requirements and performance demands.

Conclusion

Mechanical Lock Metal Roofing represents the pinnacle of modern roofing technology, combining superior weather resistance, structural performance, and long-term value. For building professionals committed to quality and durability, mechanical lock standing seam systems deliver unmatched protection that justifies the investment through decades of reliable service.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 and recognized as a Shaanxi Province high-tech enterprise in 2020, specializes in comprehensive metal roofing solutions with first-level building curtain wall qualifications and third-level building steel structure qualifications. Our 200,000-square-meter raw material production facility in Anhui, combined with processing plants in Hangzhou and Xi'an, enables us to deliver one-stop solutions from design through installation. With over 20 registered patents, ISO9001, ISO14000:14001, SGS certifications, and Fortune 500 company partnerships, we provide customized High Quality Mechanical Lock Metal Roofing backed by 30-year warranties. As a leading China Mechanical Lock Metal Roofing manufacturer, China Mechanical Lock Metal Roofing supplier, and China Mechanical Lock Metal Roofing factory, we offer competitive Mechanical Lock Metal Roofing for sale with exceptional Mechanical Lock Metal Roofing price points, China Mechanical Lock Metal Roofing wholesale options, and complete technical support. Contact us at huafeng@hfmetalroof.com to discuss your project requirements and discover how our expertise transforms roofing challenges into lasting solutions.

References

1. Metal Construction Association. (2022). Metal Roof Installation Manual: Standing Seam Systems and Best Practices.

2. Sheffield, R. & Northern, G. (2023). Engineering Performance Standards for Mechanical Lock Panel Systems in Commercial Applications.

3. American Society for Testing and Materials. (2021). ASTM E108 Standard Test Methods for Fire Tests of Roof Coverings.

4. International Building Code. (2024). Wind Resistance Requirements for Metal Roofing Systems in High-Performance Applications.