Picture this: a commercial building owner watching water stains spread across their ceiling after a storm, facing costly repairs and business disruptions. This nightmare scenario highlights why choosing the right roofing system matters. Weathertight Commercial Roof Systems, particularly Metal Standing Seam Roofing Systems, offer the ultimate solution for protecting your investment against water infiltration, extreme weather, and premature deterioration. This comprehensive guide explores how advanced metal roofing technology delivers uncompromising weather protection for commercial applications.

Metal Standing Seam Roofing Systems

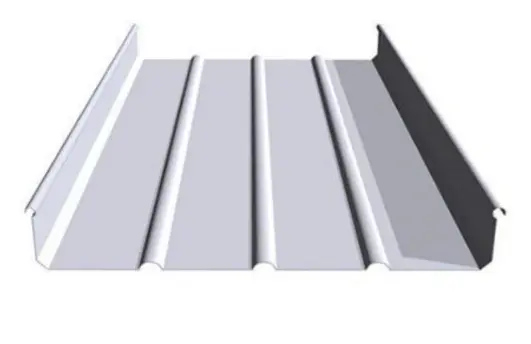

Understanding Metal Standing Seam Roofing Systems for Weather Protection

Metal Standing Seam Roofing Systems represent the pinnacle of weathertight commercial roofing technology, engineered specifically to withstand the harshest environmental conditions while maintaining structural integrity over decades. These sophisticated systems utilize raised interlocking seams that create an impenetrable barrier against water, wind, and debris, making them ideal for large-scale commercial projects where weather protection cannot be compromised. The fundamental design of Metal Standing Seam Roofing Systems centers on concealed fastening technology combined with vertical panel orientation that naturally channels water away from the building envelope. Unlike traditional roofing systems with exposed fasteners that create potential leak points, standing seam panels feature hidden clips and mechanical seaming that lock panels together without penetrating the weather barrier. This innovative approach eliminates the most common failure points in commercial roofing systems, ensuring long-term weathertight performance even under extreme conditions.

-

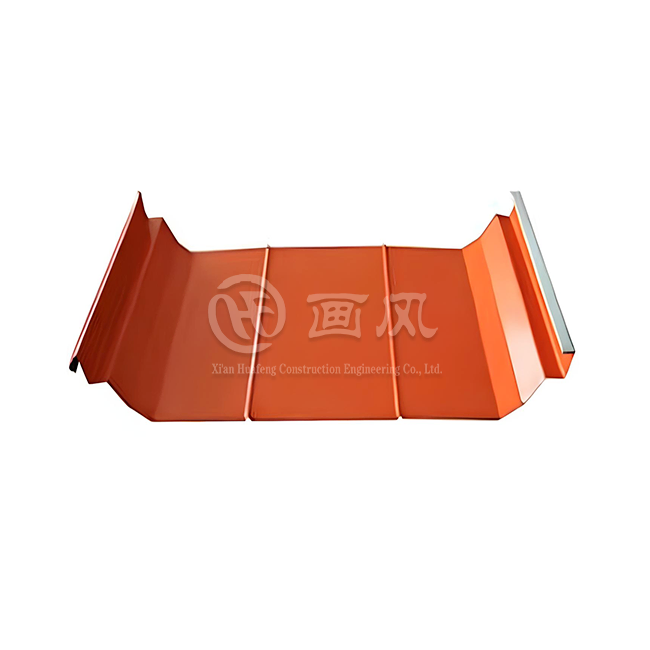

High-Performance Material Options for Demanding Environments

Modern Metal Standing Seam Roofing Systems offer diverse material specifications tailored to specific environmental challenges and performance requirements. Aluminum panels ranging from 0.9 to 1.2 millimeters thickness provide exceptional corrosion resistance for coastal installations where salt spray threatens conventional roofing materials. The 3003 and 3004 series aluminum alloys in H44 hardened state deliver optimal strength-to-weight ratios while maintaining excellent formability for complex architectural designs. These aluminum systems excel in environments where weight restrictions or corrosive atmospheres demand lightweight yet durable solutions. Galvalume steel panels offer superior cost-effectiveness without sacrificing performance, featuring AZ150 aluminum-zinc coating that provides robust protection against atmospheric corrosion. When combined with PVDF coatings containing 70 percent fluororesin, these systems deliver color retention exceeding twenty years alongside exceptional UV resistance. The 0.6 to 1.0 millimeter thickness range accommodates various structural requirements while maintaining the flexibility needed for efficient installation across diverse building geometries. For ultimate longevity in harsh industrial environments or coastal regions with extreme exposure, stainless steel and titanium-zinc options provide unmatched durability. Stainless steel panels in 304 grade offer superior resistance to chemical exposure and high humidity, while titanium-zinc plates feature remarkable self-repairing properties that extend service life beyond eighty years. These premium materials justify their investment through minimal maintenance requirements and exceptional aesthetic aging characteristics.

-

Advanced Seam Height Technology and Structural Performance

The 65-millimeter seam height specification distinguishes professional-grade Metal Standing Seam Roofing Systems from standard commercial roofing products, providing enhanced structural rigidity and superior drainage capacity. This ultra-high rib design creates substantial vertical clearance that prevents water pooling even during intense rainfall events, while simultaneously increasing the panel's moment of inertia for improved wind uplift resistance. The raised profile accommodates thermal expansion and contraction without compromising weathertight integrity, critical for maintaining seal quality across seasonal temperature variations. Structural performance testing confirms these systems withstand wind pressure exceeding 4.5 kilopascals, equivalent to Category 5 hurricane conditions, while maintaining snow load capacity of 1.5 kilonewtons per square meter for installations in heavy snowfall regions. Impact resistance testing demonstrates these panels survive direct strikes from one-kilogram steel balls dropped from three-meter heights without penetration or permanent deformation, confirming their durability against hail damage and falling debris.

Comprehensive Waterproofing Architecture in Commercial Applications

Weathertight Commercial Roof Systems require sophisticated multi-layer construction that addresses water management at every level of the building envelope. The standing seam metal panels form only the outermost defense layer, working in concert with integrated waterproof membranes, vapor barriers, and drainage management systems that collectively ensure zero water infiltration under all operating conditions.

-

Multi-Layer Protection Strategy

The waterproof and breathable membrane installed beneath standing seam panels represents critical secondary protection against wind-driven rain and condensation management. High-density polyethylene non-woven fabrics block liquid water penetration while permitting water vapor transmission, preventing moisture accumulation within the roof assembly that leads to insulation degradation and structural damage. This breathability proves essential in climate-controlled commercial buildings where interior humidity levels exceed exterior conditions, allowing moisture to escape rather than condensing within the roof system. Vapor barriers positioned on the warm side of insulation layers limit water vapor migration from interior spaces into the roof assembly, minimizing condensation risk during cold weather operation. Polyester film or high-density spunbond polyethylene materials provide effective vapor retardation while maintaining sufficient flexibility to accommodate structural movement. The strategic placement of vapor barriers combined with proper ventilation design ensures optimal moisture management throughout all seasons, critical for maintaining long-term weathertight performance in commercial applications.

-

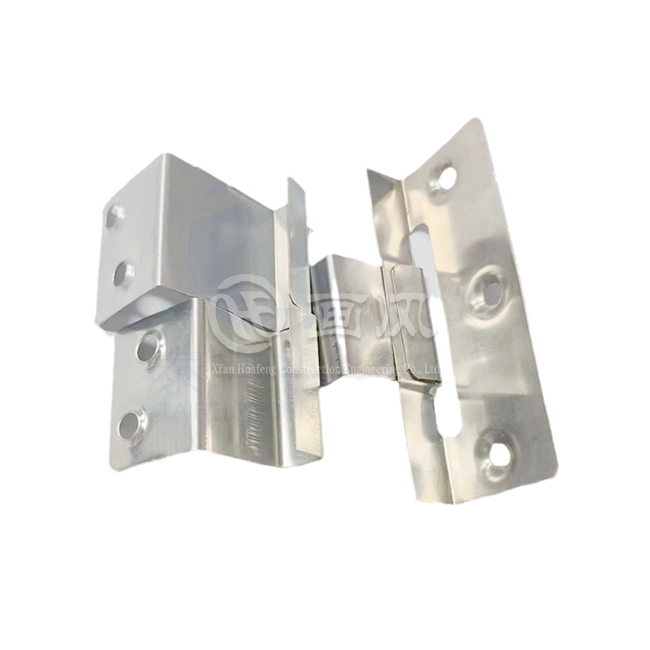

Mechanical Seaming Technology for Superior Water Resistance

Double-lock seam construction represents the gold standard in Metal Standing Seam Roofing Systems, creating mechanically interlocked joints that resist water infiltration even under sustained negative pressure conditions. Professional installation equipment forms precise 180-degree folds that compress weatherstripping gaskets while creating labyrinth-style barriers against wind-driven rain. This mechanical seaming process eliminates reliance on sealants that degrade over time, ensuring weathertight performance throughout the system's multi-decade service life. Testing protocols verify these mechanically seamed systems maintain complete watertightness under 1000 pascal negative pressure, simulating extreme wind conditions that create suction forces attempting to draw water through roofing joints. The airtightness performance of 0.1 cubic meters per square meter per hour confirms these systems provide energy-efficient building envelopes that minimize conditioned air loss, contributing to reduced operational costs alongside superior weather protection.

Engineering Specifications for Long-Term Durability

Professional-grade Weathertight Commercial Roof Systems incorporate precise engineering specifications that ensure reliable performance across diverse climate zones and application requirements. Material thickness tolerances maintained within plus-or-minus 0.02 millimeters guarantee consistent mechanical properties and uniform appearance throughout large-scale installations. These tight manufacturing tolerances comply with ASTM A924 and A755 standards, providing architects and building owners confidence in product consistency regardless of order size or delivery schedule.

-

Surface Treatment Systems for Extended Service Life

PVDF coating technology delivers exceptional protection against UV degradation and atmospheric pollutants, maintaining color integrity and surface gloss for twenty years or more in harsh exposure conditions. The 25 to 30 micrometer coating thickness containing 70 percent fluororesin provides superior chemical resistance compared to polyester alternatives, justifying the premium investment for projects requiring long-term aesthetic appearance alongside weather protection. Cool roof formulations with solar reflectivity exceeding 0.65 reduce heat absorption, lowering cooling costs while extending material service life through reduced thermal cycling stress. PE polyester coatings offer economical solutions for applications where budget constraints outweigh longevity requirements, providing adequate protection in moderate climate zones. The 20 to 25 micrometer coating thickness delivers reliable performance for fifteen to twenty years under normal exposure conditions, making polyester-coated systems attractive for industrial buildings and agricultural structures where aesthetics take secondary importance to functional weather protection.

-

Customization Capabilities for Unique Project Requirements

Panel width customization from 300 to 600 millimeters effective coverage allows optimization for specific structural bay spacing and architectural proportions. The ability to manufacture continuous panel lengths up to thirteen meters eliminates horizontal seams that represent potential leak points, particularly critical for low-slope applications where water drainage relies primarily on panel length rather than roof pitch. Custom color matching ensures Metal Standing Seam Roofing Systems integrate seamlessly with existing architectural elements or corporate branding requirements, providing aesthetic cohesion alongside technical performance. Specialized perforation patterns in structural base plates optimize acoustic performance for noise-sensitive applications like convention centers and performing arts venues. The perforated galvanized steel substrate supports sound-absorbing insulation layers while providing structural support for the complete roof assembly, balancing acoustic control with structural efficiency.

Integrated Building Systems and Future-Ready Design

Modern Weathertight Commercial Roof Systems extend beyond simple weather protection to accommodate evolving building requirements including photovoltaic integration, daylighting solutions, and advanced building automation systems. The 65-millimeter rib height in Metal Standing Seam Roofing Systems provides clearance for photovoltaic mounting hardware without compromising weathertight integrity, enabling commercial buildings to generate renewable energy while maintaining roof warranty coverage. This future-ready design philosophy ensures roofing investments remain relevant as building energy requirements evolve.

-

Quality Assurance Through Manufacturing Excellence

Comprehensive incoming material inspection protocols verify all raw materials meet specified chemical composition, mechanical properties, and coating specifications before entering production. Supplier certification requirements include third-party material testing reports confirming compliance with international standards, while internal quality control procedures conduct verification testing on random samples from each delivery. This rigorous material qualification process includes salt spray resistance testing, coating adhesion evaluation, hardness measurement, impact resistance verification, and weathering simulation to ensure consistent quality regardless of raw material supplier or production batch. Finished product inspection encompasses appearance evaluation, dimensional verification, flatness measurement, and curvature assessment to confirm every panel meets specification before packaging. Sequential numbering systems coordinate manufacturing, quality control, packaging, and installation activities, ensuring products arrive at construction sites in optimal sequence for efficient installation while minimizing handling damage risk.

Conclusion

Weathertight Commercial Roof Systems using Metal Standing Seam Roofing technology deliver unmatched protection against water infiltration, extreme weather, and long-term degradation. The combination of advanced materials, precision engineering, and professional installation creates building envelopes that maintain integrity for decades while supporting sustainable building practices and future expansion requirements.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a leading China Metal Standing Seam Roofing Systems manufacturer and China Metal Standing Seam Roofing Systems supplier, offering comprehensive solutions from design through construction. Established in 2018 and recognized as a Shaanxi Province high-tech enterprise in 2020, our company maintains first-level building curtain wall qualification and third-level steel structure qualification, demonstrating our technical capabilities and industry expertise.

Our manufacturing infrastructure includes a 200,000-square-meter raw material production facility in Anhui plus specialized processing plants in Hangzhou and Xi'an, equipped with seven color coating production lines, one laminating line, ten shearing production lines, and over forty precision processing machines. This comprehensive equipment portfolio enables us to serve as your trusted China Metal Standing Seam Roofing Systems factory, delivering High Quality Metal Standing Seam Roofing Systems with competitive Metal Standing Seam Roofing Systems price points. We offer China Metal Standing Seam Roofing Systems wholesale opportunities alongside customized solutions for unique project requirements, with Metal Standing Seam Roofing Systems for sale meeting ISO9001, ISO14000:14001, and SGS certification standards.

Our one-stop service model encompasses structural 3D modeling, load analysis, drainage simulation, material specification advisory, precision manufacturing with real-time quality control, and seamless installation with on-site project management. Contact us at huafeng@hfmetalroof.com to discuss your weathertight roofing requirements and discover why Fortune 500 companies trust our expertise for their critical infrastructure projects.

References

1. "Metal Roofing Performance Standards and Testing Protocols" - American Society for Testing and Materials (ASTM) Technical Committee, Published by ASTM International Standards Organization

2. "Standing Seam Metal Roof Systems: Design and Installation Guidelines" - National Roofing Contractors Association (NRCA) Technical Services Department

3. "Weathertight Building Envelope Design for Commercial Structures" - Building Science Corporation Research Team, Building Science Press

4. "Long-Term Performance Evaluation of Metal Roofing Systems in Severe Weather Conditions" - Construction Research Institute, Journal of Building Performance Analysis