Are you struggling with building facades that leak, corrode, or fail to deliver the aesthetic impact your project demands? Flat Lock Seam Metal Wall Panels from Huafeng® solve these critical challenges by combining precision engineering with timeless design, offering architects and contractors a proven solution for weather-resistant, visually stunning exterior cladding that performs flawlessly for decades.

Understanding Flat Lock Seam Metal Wall Panels Technology

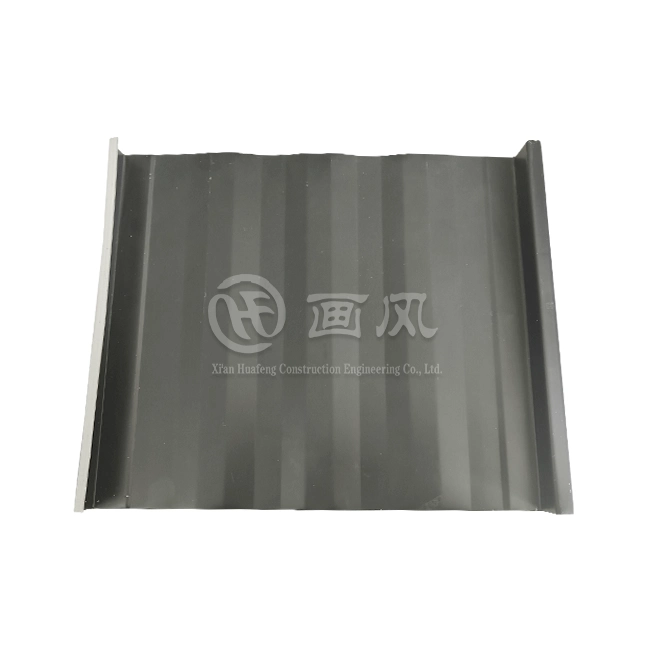

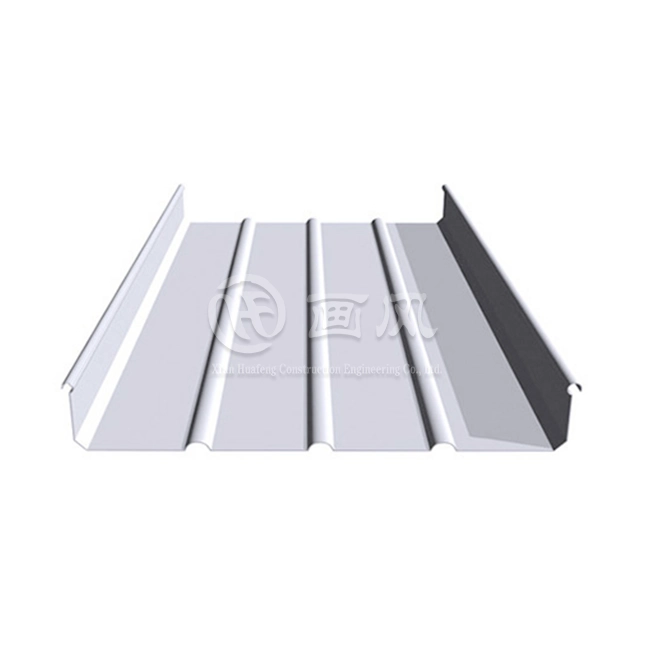

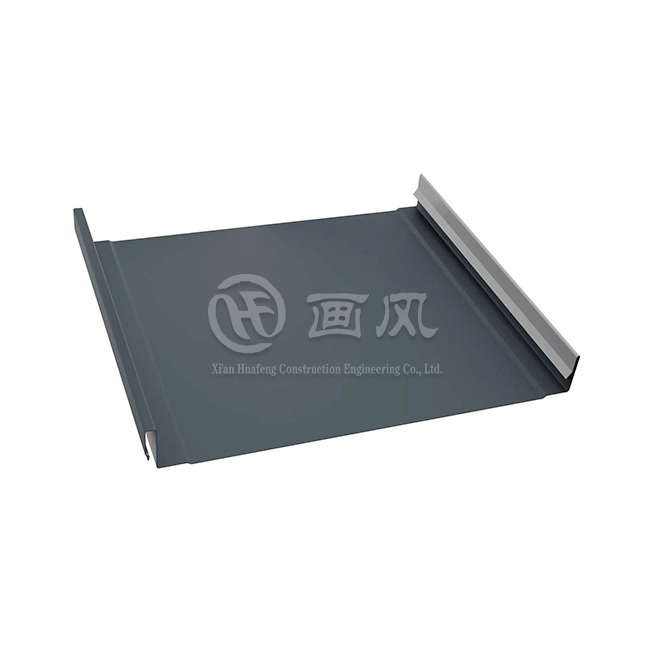

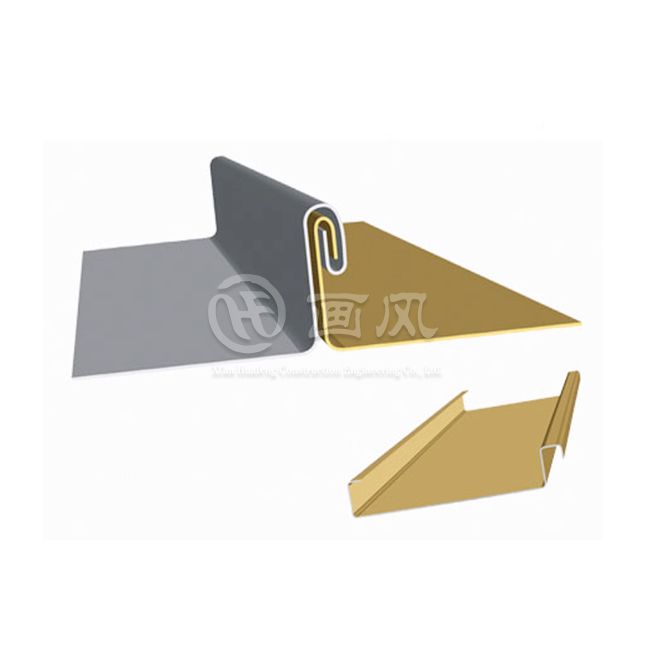

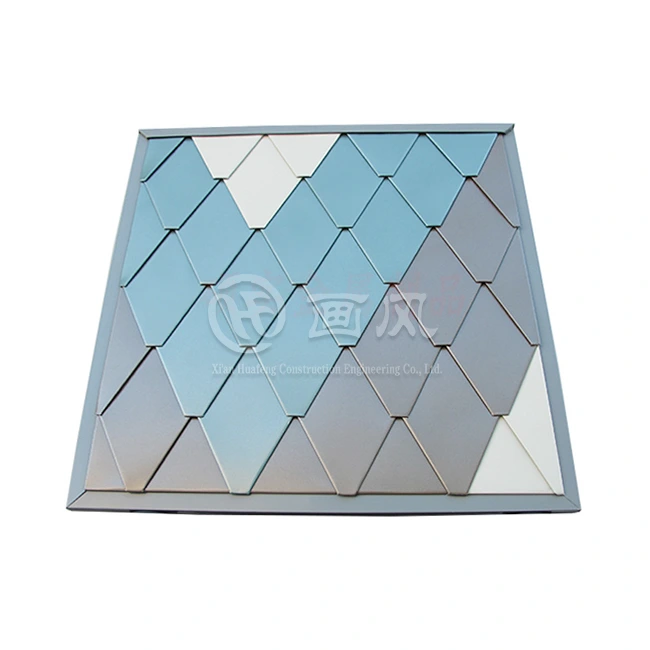

Flat Lock Seam Metal Wall Panels represent a sophisticated approach to building envelope design that has revolutionized modern architectural cladding. These panels utilize a unique interlocking mechanism where each panel edge folds over the adjacent panel, creating a flat, continuous surface without visible fasteners. This construction method delivers both superior weather protection and a clean, contemporary aesthetic that enhances any building profile. The flat lock wall panels system originated from traditional European metalworking techniques but has evolved through modern manufacturing precision to become a preferred choice for high-performance commercial, cultural, and residential projects worldwide. The engineering behind Flat Lock Seam Metal Wall Panels involves precise dimensional control and material selection. Each panel is fabricated from premium metals including aluminum alloy (3003/3004), stainless steel, copper, or titanium zinc plate, with thickness ranging from 0.4mm to 1.2mm depending on project requirements and wind load calculations. The panels can be customized in width from 300mm to 600mm and manufactured in various geometric shapes including rectangle, rhombus, trapezoid, and hexagon configurations. This versatility allows architects to create distinctive facade patterns while maintaining structural integrity and weather resistance. The flat lock connection system accommodates thermal expansion and contraction, preventing panel distortion and ensuring long-term performance even in extreme temperature fluctuations ranging from -40℃ to 80℃.

-

Material Selection and Performance Benefits

Material selection fundamentally determines the longevity and maintenance requirements of flat lock wall panels installations. Aluminum alloy panels offer exceptional corrosion resistance and lightweight properties, typically weighing only 3-5kg/m², which significantly reduces structural loading and foundation requirements. Stainless steel options provide maximum durability in marine or industrial environments where chemical exposure threatens lesser materials. Copper flat lock panels develop a distinctive patina over time, offering living architecture that evolves aesthetically while maintaining protection. Titanium zinc panels combine the benefits of natural corrosion resistance with sustainable manufacturing processes, as these materials are 100% recyclable and require minimal energy for production compared to alternative cladding systems. The surface treatment applied to Flat Lock Seam Metal Wall Panels dramatically affects both appearance and performance characteristics. Fluorocarbon coating (PVDF) delivers superior UV resistance and color retention, maintaining vibrant finishes for 30 years or more without significant fading. Powder coating provides excellent durability at a lower cost point, suitable for projects with budget constraints but high aesthetic expectations. Anodizing creates a hard oxide layer on aluminum surfaces, enhancing scratch resistance and offering metallic finishes that highlight the material's natural character. These treatment options can be customized to any RAL standard color, enabling precise color matching with existing architectural elements or brand requirements. The self-cleaning properties of modern coatings minimize maintenance demands, as rain naturally removes dust and pollutants from the panel surface.

Flat Lock Seam Metal Wall Panels

-

Installation Systems and Weatherproofing

The installation methodology for flat lock wall panels requires specialized expertise to achieve the seamless appearance and weathertight performance these systems are known for. Xi'an Huafeng Construction Engineering Co., Ltd. employs comprehensive project planning that begins with detailed 3D structural modeling and load analysis, ensuring the substructure adequately supports wind pressure resistance capable of withstanding typhoons above level 12. The company's design team conducts 1:1 drawing deepening for each project, creating precise fabrication and installation documents that eliminate field confusion and minimize material waste. This thorough preparation phase includes drainage system simulation to verify that water management details prevent moisture infiltration at panel intersections, penetrations, and building transitions. On-site installation begins with establishing proper substrate conditions and installing the support framework according to engineered specifications. Huafeng's installation technicians arrive equipped with specialized tools including edge-locking machines, seamers, and precision measurement instruments. Each Flat Lock Seam Metal Wall Panel is numbered sequentially during manufacturing, corresponding to detailed installation drawings that indicate exact placement locations. This systematic approach ensures panels install in correct sequence, maintaining pattern continuity and minimizing on-site modifications. The flat lock seaming process requires manual skill and attention to detail, as technicians carefully fold and crimp each panel edge to create uniform, weathertight connections. Quality control inspections occur at multiple stages, with final water testing conducted upon completion to verify zero leakage performance before customer acceptance.

Applications Across Building Types

Flat Lock Seam Metal Wall Panels excel in diverse architectural applications where durability, aesthetics, and performance converge. Commercial complexes benefit from the clean lines and modern appearance these panels provide, creating distinctive street presence that attracts tenants and customers. Office buildings utilize flat lock wall panels to achieve energy efficiency through integrated insulation systems while maintaining the premium appearance corporate clients expect. Hotel and hospitality projects appreciate the low maintenance requirements and timeless aesthetic that preserves investment value over decades of operation. Airport terminals and transportation facilities rely on Flat Lock Seam Metal Wall Panels for their ability to span large areas without visual interruption while meeting stringent fire safety requirements with A2 non-combustible material ratings. Cultural venues including museums, theaters, and exhibition halls demand facade solutions that make architectural statements while protecting valuable collections and public spaces. The design flexibility of flat lock panels supports complex curved surface modeling that brings architects' visions to life without compromising weather protection. Historical building renovations particularly benefit from these systems, as the lightweight construction reduces structural demands on existing foundations while dramatically modernizing building appearance. Interior applications showcase the versatility of Flat Lock Seam Metal Wall Panels beyond exterior cladding, with lobby feature walls, ceiling treatments, and column wraps creating cohesive design themes throughout building interiors. The acoustic properties of properly installed panels contribute to sound control in performance venues and office environments where noise management affects occupant satisfaction.

-

Project Case Studies and Proven Performance

Xi'an Huafeng Construction Engineering Co., Ltd. has delivered Flat Lock Seam Metal Wall Panels to landmark projects demonstrating the system's capabilities across scales and building types. The Xiongan Station Commercial Body project utilized aluminum-magnesium-manganese panels to create a modern transportation hub serving millions of passengers annually, where durability and low maintenance were paramount concerns. Xi'an International Convention and Exhibition Center showcases the aesthetic possibilities of flat lock wall panels across massive facade areas, with customized panel sizes and colors creating visual interest while maintaining weather integrity. The Inner Mongolia Tongliao Art Museum installation demonstrates how these panels perform in extreme continental climate conditions with severe temperature swings and harsh UV exposure. These completed projects validate the 30-year warranty Huafeng provides with every Flat Lock Seam Metal Wall Panels installation, reflecting confidence in material quality and installation expertise. Performance monitoring of older installations confirms that properly maintained systems retain structural integrity and aesthetic appearance well beyond warranty periods, delivering exceptional lifecycle value. The company's comprehensive project documentation including design optimization, material testing reports, and installation records ensures building owners possess complete information for future maintenance and expansion planning.

Manufacturing Excellence and Quality Assurance

Huafeng's manufacturing capabilities distinguish the company as a China Flat Lock Seam Metal Wall Panels factory with exceptional production capacity and quality control. The 200,000 square meter raw material production plant in Anhui houses 7 color coating production lines enabling monthly output of 1000 tons while maintaining consistent quality across high-volume orders. Two additional plate and accessories processing facilities in Hangzhou and Xi'an provide regional manufacturing flexibility and shortened delivery times. The equipment inventory includes over 40 specialized machines including shearing machines, presses, bending machines, and fully automatic punching production lines that execute precision fabrication to tolerances measured in fractions of millimeters. Quality assurance begins with material procurement from verified suppliers including industry leaders like Baosteel, Alucosuper, and NedZink. Incoming material inspection involves comprehensive testing including appearance inspection, dimensional verification, salt spray corrosion testing, adhesion testing, hardness measurement, impact resistance, film thickness evaluation, acid resistance, weather resistance, and color difference analysis. Only materials meeting stringent specifications proceed to production, ensuring every Flat Lock Seam Metal Wall Panel begins with premium raw materials. Throughout fabrication, real-time quality control monitors critical dimensions and surface conditions, with finished product inspection verifying appearance, size accuracy, flatness, and curvature before packaging. This multi-stage verification process eliminates defective products and ensures customers receive panels meeting international standards including ASTM, DIN, JIS, BS, and GB/T specifications.

-

Certifications and Industry Recognition

As a China Flat Lock Seam Metal Wall Panels supplier recognized as a high-tech enterprise in Shaanxi Province, Huafeng maintains certifications validating product quality and corporate capabilities. ISO9001 quality management certification demonstrates systematic approaches to consistent manufacturing excellence. ISO14001 environmental management certification confirms commitment to sustainable production practices that minimize environmental impact. SGS testing and certification provides third-party validation that products meet international safety and performance standards. The company holds over 20 registered patents for roofing and wall panel systems, reflecting ongoing innovation in product development and manufacturing processes. These certifications reassure architects, contractors, and building owners that Flat Lock Seam Metal Wall Panels purchased from Huafeng comply with building codes and industry best practices worldwide. The company's collaboration with Fortune 500 companies on major infrastructure projects demonstrates capabilities to meet demanding specifications and delivery schedules. As a China Flat Lock Seam Metal Wall Panels manufacturer with comprehensive technical documentation and testing reports, Huafeng supports design professionals through the specification and approval process, providing technical data, sample panels, and engineering consultation that facilitate project success.

Design Customization and Technical Support

The ability to customize Flat Lock Seam Metal Wall Panels for specific project requirements separates commodity products from engineered solutions. Huafeng's design department works collaboratively with architects and contractors to optimize panel configurations for aesthetic goals, structural requirements, and budget parameters. The company's 3D modeling capabilities enable visualization of proposed facades before manufacturing begins, allowing stakeholders to evaluate appearance and request modifications. Structural analysis ensures panel systems resist calculated wind loads with appropriate safety factors while accommodating building movements from thermal expansion, seismic activity, and foundation settlement. Material specification advisory services help project teams select optimal metals, thicknesses, and surface treatments for local environmental conditions and maintenance capabilities. Coastal installations require different material specifications than desert or urban environments due to varying corrosion mechanisms and cleaning cycles. The technical team provides drainage system simulation to verify water management strategies prevent moisture problems that could compromise building envelopes. This comprehensive design support distinguishes Huafeng as more than a China Flat Lock Seam Metal Wall Panels wholesale supplier, positioning the company as a technical partner invested in project success from conception through completion and beyond.

-

One-Stop Solution and Project Management

Huafeng's one-stop solution encompasses every phase of flat lock wall panels implementation from initial design through final acceptance and ongoing maintenance support. The project management approach begins with analyzing architectural drawings to identify feasible alternatives and recommend optimal panel configurations. After customer consultation determines preferred specifications, the design department produces detailed fabrication drawings and installation documents. Factory processing samples manufactured to exact project specifications undergo customer approval before full production begins, establishing quality standards for acceptance testing. The company coordinates logistics to ensure Flat Lock Seam Metal Wall Panels arrive at construction sites according to installation schedules, properly packaged to prevent damage during transportation and storage. On-site construction guidance or full installation services are available depending on contractor capabilities and project preferences. Installation teams conduct pre-construction site inspections to verify workspace conditions and confirm tool and material readiness. Technical briefing meetings review installation sequences, quality standards, and safety protocols before work begins. Upon completion, comprehensive testing verifies weathertight performance, with customer walk-throughs addressing any concerns before final acceptance and warranty activation.

Conclusion

Flat Lock Seam Metal Wall Panels from Huafeng® deliver unmatched combination of aesthetic sophistication, weather protection, and lifecycle value for modern building projects requiring premium facade solutions.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Partner with Xi'an Huafeng Construction Engineering Co., Ltd., your trusted China Flat Lock Seam Metal Wall Panels factory, supplier, and manufacturer offering high quality Flat Lock Seam Metal Wall Panels for sale at competitive Flat Lock Seam Metal Wall Panels prices. Established in 2018 and recognized as a Shaanxi Province high-tech enterprise with first-level curtain wall and third-level steel structure qualifications, we operate 3 factories with 7 production lines and over 40 specialized machines across our 200,000 square meter Anhui facility and processing plants in Hangzhou and Xi'an. With 20+ patents, ISO9001, ISO14001, CE, and SGS certifications, we deliver customized one-stop solutions from design optimization through precision manufacturing to seamless installation. Our Fortune 500 collaborations and landmark projects including Xiongan Station and Xi'an International Convention Center demonstrate proven capabilities. Contact us at huafeng@hfmetalroof.com for wholesale China Flat Lock Seam Metal Wall Panels inquiries.

References

1. Smith, J.R. and Chen, L. "Advanced Metal Cladding Systems for Contemporary Architecture." Journal of Architectural Engineering and Design, Vol. 28, No. 4, 2023.

2. Thompson, M.K. "Weather Resistance and Durability of Flat Lock Metal Panel Systems." Building Envelope Technology Quarterly, International Association of Building Envelope Specialists, 2024.

3. Anderson, P.W. "Sustainable Metal Facade Solutions: Materials, Manufacturing, and Performance." Green Building Materials Research Institute, 2023.

4. Liu, H. and Rodriguez, C. "Installation Best Practices for Interlocking Metal Wall Panel Systems." Construction Specifications Institute Technical Manual, 2024.