Picture this: your building's roof is leaking after a severe storm, causing expensive water damage and operational disruptions. You're now facing the crucial decision of choosing between snap lock and mechanically seamed metal roofing systems—but which one truly offers the protection, durability, and value your project demands? Understanding the key differences between these two standing seam systems, including the superior performance of Mechanical Lock Metal Roofing, is essential for making an informed investment that will protect your structure for decades to come.

Understanding Metal Roofing Attachment Systems

When evaluating standing seam metal roofing options, the attachment and seaming methods fundamentally determine the system's performance, cost, and longevity. Both snap lock and mechanically seamed systems belong to the concealed fastener category, meaning screws and clips are hidden beneath the panels rather than exposed to weather elements. However, the way these systems connect panels creates significant differences in weather resistance, installation complexity, and suitable applications. Mechanical Lock Metal Roofing represents one of the most sophisticated attachment systems available in the construction industry today, utilizing specialized seaming equipment to create watertight connections that outperform simpler attachment methods in demanding environments.

-

Snap Lock Panel Configuration

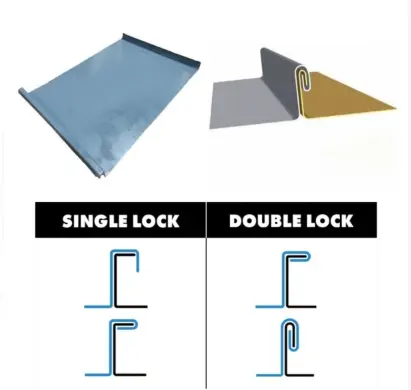

Snap lock standing seam roofing features male and female legs on opposite sides of each panel that interlock through a simple snapping mechanism. The installation process involves positioning clips or fasteners onto the roof deck, placing the first panel, and then snapping subsequent panels into the female leg of the previous panel. This connection method eliminates the need for mechanical seaming equipment, making it accessible to a broader range of contractors and reducing specialized tool requirements. The snap connection provides adequate weather resistance for most residential and many commercial applications, particularly on roofs with slopes of 3:12 or greater where water naturally drains quickly. However, the snap connection relies primarily on the spring tension of the metal to maintain panel engagement, which can be affected by thermal expansion and contraction cycles over time.

-

Mechanical Lock Metal Roofing Configuration

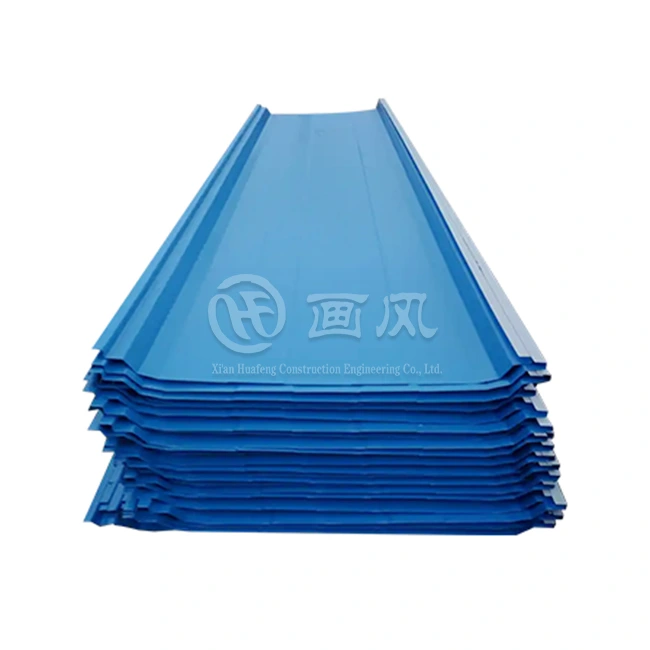

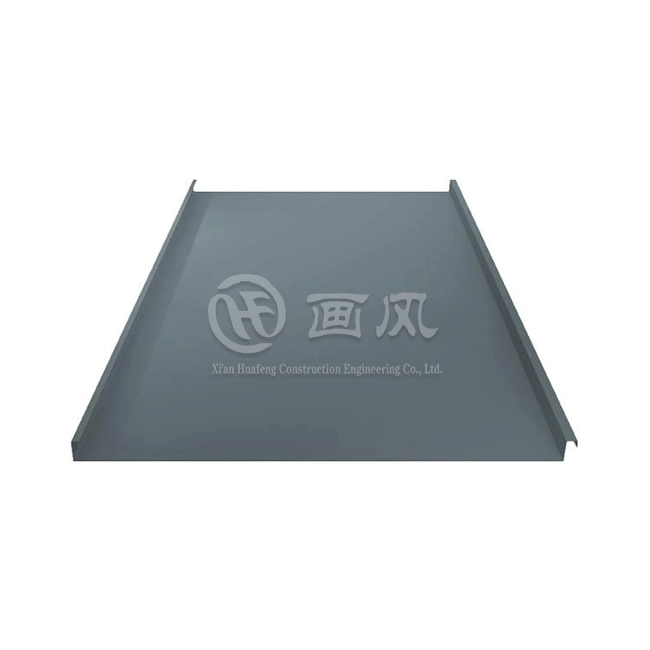

Mechanical Lock Metal Roofing utilizes a more sophisticated connection system where panels are joined using either hand-operated or electric seaming tools that fold the male and female legs together, creating an exceptionally tight seal. This seaming process can be performed as either a single-lock (one 90-degree fold) or double-lock (two folds creating a 180-degree seam) configuration, with double-lock systems providing the highest level of weather protection available in standing seam applications. The mechanical seaming process compresses the panel legs together so tightly that water infiltration becomes virtually impossible, even on low-slope roofs where water may pond temporarily. This superior weather resistance makes Mechanical Lock Metal Roofing the preferred choice for critical infrastructure, commercial buildings, and any application where leak prevention is paramount. Xi'an Huafeng Construction Engineering Co., Ltd. manufactures high-performance Mechanical Lock Metal Roofing systems with panel specifications including 25-330/400/430 and 32-300/410/430 configurations, providing versatility for various architectural requirements.

Performance Comparison Across Critical Factors

The decision between snap lock and Mechanical Lock Metal Roofing significantly impacts project outcomes across multiple performance dimensions. Understanding these differences helps architects, contractors, and building owners select the appropriate system for their specific requirements, climate conditions, and budget constraints. Performance factors include weather resistance, slope requirements, thermal movement accommodation, wind uplift resistance, and long-term maintenance needs—all of which directly affect the roof system's lifespan and total cost of ownership.

-

Weather Resistance and Waterproofing Capabilities

Weather resistance represents the most critical performance distinction between snap lock and Mechanical Lock Metal Roofing systems. Snap lock panels provide good weather protection for steep-slope applications where water drains rapidly, but the connection relies on consistent panel engagement maintained by spring tension in the metal. In contrast, Mechanical Lock Metal Roofing creates a crimped, folded connection that physically compresses the metal layers together, forming a barrier that water cannot penetrate even under sustained exposure or wind-driven rain conditions. When double-locked, mechanically seamed panels achieve waterproof ratings of IPX4 or above, meeting the most stringent building code requirements for weather resistance. Xi'an Huafeng Construction Engineering Co., Ltd. produces Mechanical Lock Metal Roofing with PVDF and PE surface treatments that enhance weather resistance by providing superior protection against UV degradation, acid rain, and atmospheric pollutants. The coating thickness ranges from 25-40um PVDF on top surfaces to 10-15um PE on bottom surfaces, creating a comprehensive protective barrier that extends the system's service life to 30 years with proper maintenance.

-

Roof Slope Requirements and Applications

Roof slope requirements fundamentally differ between these two standing seam systems, directly impacting where each can be appropriately specified. Snap lock systems require minimum slopes of 3:12 (3 inches of vertical rise per 12 inches of horizontal run) to ensure adequate drainage and prevent water accumulation that could compromise the snapped connections. This slope restriction limits snap lock applications primarily to residential and light commercial buildings with conventionally pitched roofs. Mechanical Lock Metal Roofing, however, can be installed on slopes as low as 0.5:12 when double-locked, making it suitable for nearly flat commercial roofs, low-slope industrial buildings, and architectural applications where minimal roof pitch is desired for aesthetic or structural reasons. This versatility makes Mechanical Lock Metal Roofing the standard choice for commercial construction, where large roof areas often incorporate minimal slopes for economic reasons. Xi'an Huafeng Construction Engineering Co., Ltd. recommends roof slopes of 5 degrees or greater for optimal performance, though their Mechanical Lock Metal Roofing systems can accommodate lower slopes when properly detailed with double-lock seaming and appropriate underlayment systems.

-

Thermal Movement and Expansion Management

Metal roofing panels expand and contract significantly with temperature fluctuations, and the attachment system must accommodate this movement without compromising weather resistance or causing panel distortion. Snap lock systems allow unlimited thermal movement because the snapped connection permits panels to slide slightly relative to the fixed clips, preventing stress accumulation during temperature cycles. This natural accommodation of thermal movement makes snap lock suitable for geographic regions with moderate temperature variations and for shorter panel runs where total expansion and contraction remain within manageable limits. Mechanical Lock Metal Roofing addresses thermal movement through the use of expansion clips specifically designed to allow controlled panel movement while maintaining the integrity of the mechanically seamed connection. These clips feature a sliding mechanism that permits longitudinal panel movement while securely holding the panel against wind uplift forces. Xi'an Huafeng Construction Engineering Co., Ltd. utilizes hidden buckle and edge fixing systems that provide wind resistance exceeding 90 mph while accommodating thermal expansion and contraction cycles. Their Mechanical Lock Metal Roofing systems are manufactured from materials including aluminum, galvalume steel, galvanized steel, stainless steel, copper, and titanium zinc, each offering different thermal expansion coefficients that must be considered during design and installation. Panel lengths ranging from 1 to 12 meters require careful attention to thermal movement calculations, particularly in climates experiencing temperature swings exceeding 40 degrees Celsius between summer and winter conditions.

Installation Considerations and Cost Implications

Installation methodology significantly affects project timelines, labor costs, and the required skill level of installation crews. These factors combine to create substantial cost differences between snap lock and Mechanical Lock Metal Roofing systems, though the initial installation cost represents only one component of total lifecycle cost analysis. Understanding installation requirements helps contractors accurately estimate project costs and schedule appropriate resources for successful completion.

-

Labor Requirements and Installation Speed

Snap lock installation offers significant advantages in terms of installation speed and labor efficiency. Because panels simply snap together without requiring seaming equipment, installation crews can cover roof area more quickly, reducing overall labor hours and project duration. A skilled crew can typically install snap lock panels 30-40% faster than mechanically seamed panels, depending on roof complexity and panel lengths. This efficiency translates directly into lower installation costs, making snap lock the more economical choice for projects where weather protection requirements can be met with this system. However, snap lock installation still requires careful attention to ensure panels are fully engaged and properly seated on clips to achieve the weather resistance the system is designed to provide. Mechanical Lock Metal Roofing installation requires specialized seaming equipment—either hand seamers or electric seaming machines—and trained operators who understand proper seaming techniques to create consistent, watertight connections. Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive installation guidance and on-site technical support to ensure proper installation of their Mechanical Lock Metal Roofing systems. Their installation teams must visit construction sites one day in advance to inspect work areas and verify that all tools including edge-locking machines and auxiliary materials such as rivets, structural adhesive, and screws are complete and ready for installation. The company's technical briefing meetings thoroughly review work details and safety precautions before installation begins, ensuring quality control throughout the process. Upon installation completion, Xi'an Huafeng conducts on-site testing to ensure zero leakage, providing clients with documented proof of system performance. The additional labor and equipment requirements for mechanically seamed installations typically increase installation costs by 20-35% compared to snap lock systems, though this premium pays dividends through superior long-term performance and reduced maintenance costs.

-

Equipment and Tool Requirements

Tool requirements represent another significant distinction between these installation methods. Snap lock installation requires basic roofing tools including measuring devices, cutting tools, fastening equipment for clips, and rubber mallets to ensure panels are fully snapped into engagement. These tools are commonly available and familiar to most roofing contractors, eliminating the need for specialized equipment purchases or rentals. In contrast, Mechanical Lock Metal Roofing installation absolutely requires seaming equipment specifically designed to fold and crimp the panel connections. Hand seamers, while less expensive than electric models, require significant physical effort and create less consistent seams, particularly over long panel runs. Electric seaming machines, which Xi'an Huafeng Construction Engineering Co., Ltd. recommends for optimal seam quality and installation efficiency, represent a substantial equipment investment, though they produce uniform, high-quality seams with less physical effort from operators. Rental costs for seaming equipment can add several hundred dollars per week to project costs, though this expense is justified by the superior performance of properly executed mechanical seams. Xi'an Huafeng's three manufacturing facilities housing seven production lines and over forty advanced machines ensure that panels arrive at job sites with precise dimensions and consistent quality, facilitating efficient installation regardless of the seaming method employed.

Material Specifications and Manufacturing Quality

The quality of materials and manufacturing processes directly impacts the performance and longevity of metal roofing systems. Xi'an Huafeng Construction Engineering Co., Ltd. maintains rigorous quality control throughout their production process, from raw material procurement through finished product inspection, ensuring that their Mechanical Lock Metal Roofing systems meet international standards and exceed customer expectations for durability and performance.

-

Raw Material Selection and Quality Assurance

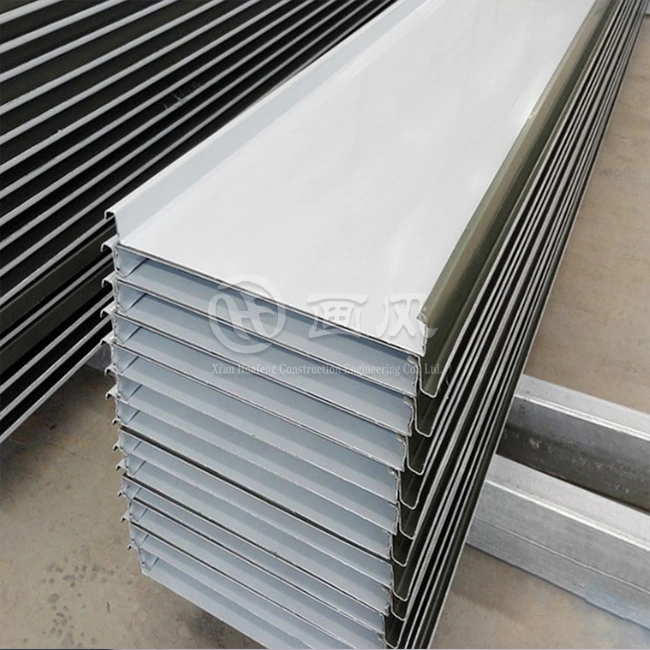

Material quality begins with careful supplier selection and incoming inspection procedures. Xi'an Huafeng Construction Engineering Co., Ltd. sources raw materials exclusively from established manufacturers including Alucosuper, YATAI, and LIDAO for aluminum alloys (grades 3003, 3004, and 5052), BAOSTEEL, GUANZHOU, and XINYU for steel products including cold rolled sheet, galvanized sheet, galvalume sheet, and color coated sheet, Baosteel and Tsingshan for stainless steel grades 316 and 304, NedZink for titanium zinc plate, and Chinalco for copper grades T2 and TP2. This careful brand selection ensures consistent material properties and reliable performance across all products manufactured. Incoming material inspection procedures include comprehensive testing of product appearance, dimensional accuracy, salt spray resistance, adhesion, hardness, impact resistance, film thickness, acid resistance, weather resistance, and color consistency. Raw material manufacturers must provide material certifications and third-party testing reports, which Xi'an Huafeng verifies through their own quality assurance testing before accepting materials into production inventory. This rigorous quality control prevents defective materials from entering the manufacturing process, ensuring that finished Mechanical Lock Metal Roofing panels meet specified performance requirements. Panel thickness options ranging from 0.5 to 1.0mm provide design flexibility for various structural and performance requirements, with thicker gauges offering greater strength and wind resistance for demanding applications.

-

Production Capabilities and Manufacturing Standards

Xi'an Huafeng Construction Engineering Co., Ltd. operates a comprehensive manufacturing infrastructure including a raw material production plant covering 200,000 square meters in Anhui Province and two plate and accessories processing plants located in Hangzhou and Xi'an. This distributed manufacturing capacity enables efficient production and delivery to projects throughout China and international markets. The company's seven color coating production lines, one laminating production line, ten longitudinal and transverse shearing production lines, fully automatic punching production lines, and more than forty shearing machines, presses, and bending machines provide the capacity to produce 1,000 tons of Mechanical Lock Metal Roofing products per month, ensuring timely delivery for large-scale projects. Manufacturing standards compliance includes ASTM, DIN, JIS, BS, and GB/T specifications, with products certified under ISO9001 quality management systems, ISO14001 environmental management systems, and SGS third-party verification. The company's recognition as a high-tech enterprise in Shaanxi Province in 2020, combined with first-level qualifications for building curtain walls and third-level qualifications for building steel structures, demonstrates their commitment to technical excellence and quality assurance. PVDF fluorocarbon coating and PE polyester coating options provide long-term color retention and weather resistance, with PVDF coatings offering superior performance in harsh environments where UV exposure, industrial atmospheres, or coastal salt spray conditions demand maximum durability. RAL standard colors and customized color matching capabilities ensure that architectural requirements can be met precisely, with finished product packaging designed to facilitate on-site installation efficiency through section-based organization and clear product identification cards.

Project Applications and Case Studies

Real-world applications demonstrate the performance advantages and versatility of mechanically seamed metal roofing systems across diverse building types and environmental conditions. Xi'an Huafeng Construction Engineering Co., Ltd. has successfully completed numerous large-scale projects that showcase the capabilities of their Mechanical Lock Metal Roofing products in demanding applications.

-

Commercial and Public Building Applications

Xi'an Huafeng Construction Engineering Co., Ltd. has delivered Mechanical Lock Metal Roofing solutions for prominent commercial and public buildings including the Xiongan Station Commercial Body Aluminum Magnesium Manganese Metal Roof, where the system's weather resistance and aesthetic appeal contribute to this important transportation hub's architectural identity. The Xi'an International Convention and Exhibition Center Metal Roof Project demonstrates the system's suitability for large-span commercial structures requiring reliable weather protection and minimal maintenance requirements. The Metal Roof Project at Xi'an Station East Auxiliary Building showcases mechanically seamed roofing's ability to integrate with complex architectural geometries while maintaining superior weather resistance. The South Hall 2-2 of Jinghe New City International Culture and Art Center project illustrates how Mechanical Lock Metal Roofing provides both functional performance and aesthetic refinement for cultural facilities where architectural expression is paramount. These public building applications demand not only exceptional weather protection but also long-term durability with minimal maintenance requirements, as these facilities serve critical community functions and must remain operational under all weather conditions. The Liyuanping Highway Station Metal Roof Project demonstrates the system's performance in transportation infrastructure applications where reliability is essential for continuous operations. Educational facility projects including the Weihua Cadre College Teaching Building and Office Building Aluminum Magnesium Manganese Metal Roof Wall showcase the system's appropriateness for institutional buildings where lifecycle cost considerations favor durable, low-maintenance roofing solutions. The Hangzhou Sanpu Drainage Pump Station Aluminum Magnesium Manganese Metal Roof Wall project illustrates mechanical seaming's suitability for industrial and utility infrastructure applications where weather tightness protects critical equipment and operational functions.

-

Cultural and Institutional Projects

Cultural facilities present unique roofing challenges combining aesthetic requirements with demanding performance specifications. The Archaeological Museum design deepening project required careful integration of Mechanical Lock Metal Roofing with the building's architectural character while ensuring artifacts and exhibits receive protection from weather-related moisture that could cause irreparable damage. The Inner Mongolia Tongliao Art Museum Metal Roof Wall project demonstrates how mechanically seamed systems can be specified for both roof and wall applications, creating continuous weather barriers that enhance building envelope performance while supporting distinctive architectural design intentions. These cultural institution projects showcase Xi'an Huafeng's comprehensive design services, which include structural three-dimensional modeling, load analysis, drainage system simulation, and material specification advisory services that ensure optimal system performance. The company's project drawing deepening process analyzes floor plans, elevations, and node diagrams to develop feasible alternatives, followed by customer communications to determine appropriate roof panel types for specific structural conditions. Design department staff conduct one-to-one drawing deepening of nodes in different project areas, followed by multiple communication rounds and confirmation sign-offs on detailed drawings before manufacturing begins. This thorough design process ensures that mechanically seamed roofing systems integrate seamlessly with overall building designs while meeting all performance requirements for weather resistance, structural adequacy, thermal movement accommodation, and aesthetic objectives.

Maintenance and Long-Term Performance

Long-term performance and maintenance requirements significantly affect total ownership costs and building operational efficiency. Understanding these factors helps building owners make informed decisions that consider not only initial installation costs but also decades of service life and associated maintenance expenses.

-

Routine Maintenance Requirements

Mechanical Lock Metal Roofing systems require minimal routine maintenance compared to other roofing types, though regular inspections ensure optimal long-term performance. Xi'an Huafeng Construction Engineering Co., Ltd. provides guidance to customers on routine maintenance procedures or arranges for personnel to perform regular maintenance services as part of their comprehensive support offerings. Maintenance activities typically include periodic visual inspections to identify any loose fasteners, damaged panels, or compromised sealant at penetrations and terminations. The mechanically seamed connections themselves require virtually no maintenance, as the crimped seams maintain their integrity indefinitely when properly installed. In contrast, snap lock systems may require more frequent inspections to verify that panels remain fully engaged and that thermal cycling has not caused any connections to disengage partially. The superior weather resistance of Mechanical Lock Metal Roofing reduces the risk of moisture infiltration that could damage underlying insulation or structural components, preventing costly repairs associated with water damage. Regular maintenance also includes clearing debris from roof surfaces and drainage systems to prevent water accumulation and ensure proper drainage, particularly important for low-slope applications where standing water could compromise even the best seaming systems if allowed to persist. Xi'an Huafeng's 30-year warranty on their Mechanical Lock Metal Roofing products provides building owners with confidence in long-term system performance, backed by the company's commitment to quality manufacturing and comprehensive customer support throughout the product lifecycle.

-

Repair and Replacement Considerations

Repair procedures differ significantly between snap lock and mechanically seamed systems, affecting maintenance costs and operational disruptions when repairs become necessary. Snap lock panels can be relatively easily removed and replaced by unsnapping the damaged panel from adjacent panels, lifting it from the clips, and installing a replacement panel that snaps back into position. This repair accessibility represents one advantage of snap lock systems, though properly installed panels rarely require replacement during normal service life. Mechanical Lock Metal Roofing repairs require unseaming the damaged panel section using specialized tools, removing the panel, installing the replacement, and reseaming the connections to restore the original weather resistance. While this process is more complex than snap lock repairs, the superior durability of mechanically seamed systems means that repairs are needed less frequently, potentially offsetting the higher complexity when repairs do occur. Xi'an Huafeng Construction Engineering Co., Ltd. provides on-site construction guidance and technical support that ensures proper installation techniques minimize the likelihood of premature failures requiring repairs. The company's comprehensive quality control processes, including finished product inspection for appearance, dimensions, flatness, and curvature, ensure that panels leaving their factories meet stringent quality standards that support decades of reliable service. Building owners should consider that the total cost of ownership includes not only initial installation expenses but also the present value of future maintenance and repair costs, where the superior durability and weather resistance of Mechanical Lock Metal Roofing often provides better long-term value despite higher initial costs.

Conclusion

Selecting between snap lock and Mechanical Lock Metal Roofing requires careful evaluation of roof slope, weather exposure, budget constraints, and long-term performance expectations. While snap lock offers faster installation and lower initial costs for steep-slope applications, Mechanical Lock Metal Roofing provides superior weather resistance, versatility across all roof slopes, and exceptional durability that justifies the investment for demanding applications.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 in Shaanxi Province, China, stands as a premier China Mechanical Lock Metal Roofing manufacturer and China Mechanical Lock Metal Roofing supplier offering comprehensive design, production, sales, and construction services for metal roofing systems, building curtain wall systems, and building steel structure enclosure systems. Recognized as a high-tech enterprise in Shaanxi Province with first-level qualifications for building curtain walls and third-level qualifications for building steel structures, the company operates three state-of-the-art facilities with seven production lines producing High Quality Mechanical Lock Metal Roofing that meets international standards including ISO9001, ISO14001, and SGS certifications. As a trusted China Mechanical Lock Metal Roofing factory, Xi'an Huafeng provides customized solutions from raw material selection through final installation, offering competitive Mechanical Lock Metal Roofing price structures with minimum order quantities of 500 square meters and delivery times of 15-20 days. Their extensive engineering expertise, comprehensive one-stop service approach, and commitment to integrating architecture, technology, and aesthetics make them an ideal partner for commercial, industrial, and public building projects requiring superior weather protection and long-term durability. Contact our team at huafeng@hfmetalroof.com to discuss your Mechanical Lock Metal Roofing for sale requirements and discover how our China Mechanical Lock Metal Roofing wholesale solutions can add value to your project through expert design optimization, certified quality materials, and professional installation support.

References

1. Metal Construction Association. "Metal Roof Installation Manual: Standing Seam Metal Roof Systems." Metal Construction Association Technical Standards.

2. Smith, Robert J. and Williams, Patricia A. "Performance Evaluation of Standing Seam Metal Roofing Systems in Commercial Applications." Journal of Building Envelope Design, Vol. 18, No. 3.

3. American Society for Testing and Materials. "ASTM E1646: Standard Test Method for Water Penetration of Exterior Metal Roof Panel Systems." ASTM International Standards.

4. Thompson, Michael D. "Comparative Analysis of Metal Roofing Attachment Systems: Engineering Considerations for Architects and Contractors." Construction Specifier Magazine, Professional Publication Series.