Are you struggling with frequent roof leaks, escalating maintenance costs, or a roofing system that fails to withstand harsh weather conditions? Commercial and industrial building owners face these challenges daily, often resulting in expensive repairs and operational disruptions. Trapezoidal Standing Seam Roofing offers a proven solution that combines exceptional durability, weather resistance, and long-term cost efficiency. This comprehensive guide explores how this innovative roofing technology can transform your building's performance while delivering decades of reliable protection.

Understanding Trapezoidal Standing Seam Roofing Systems

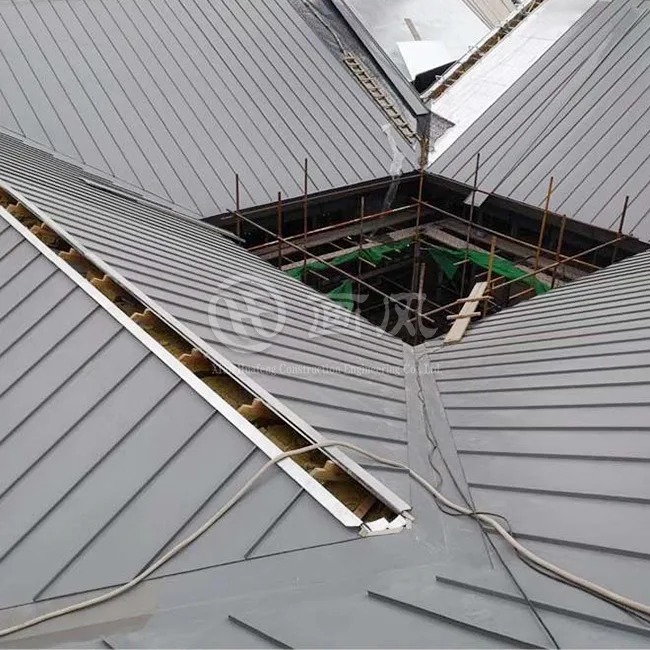

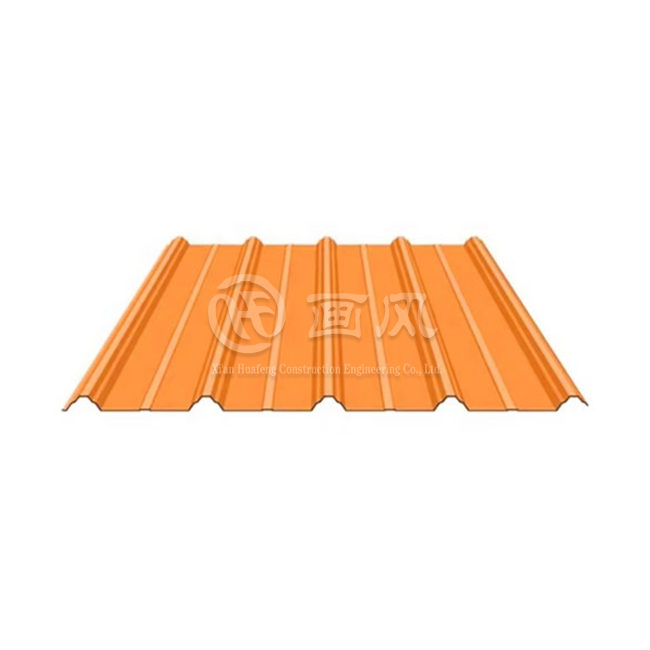

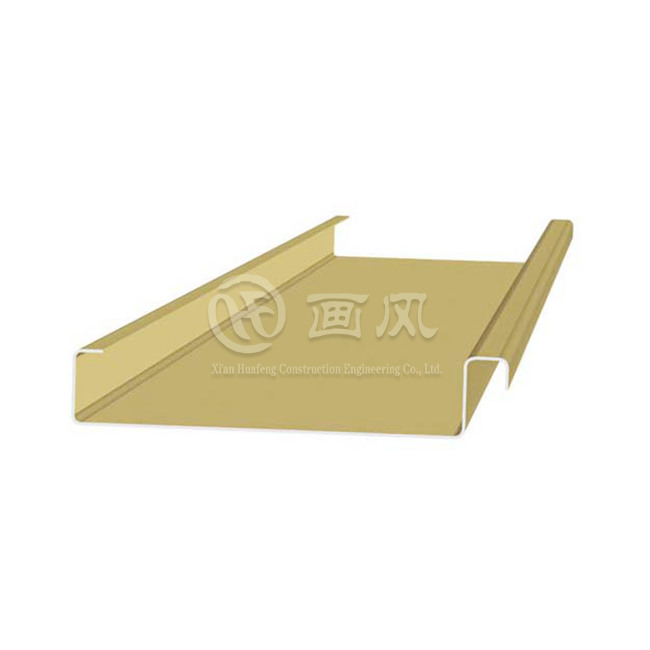

Trapezoidal Standing Seam Roofing represents a significant advancement in metal roofing technology, featuring a distinctive trapezoidal leg profile that provides superior structural integrity compared to traditional roofing systems. The unique design incorporates raised seams that interlock mechanically or through snap-together connections, creating a continuous watertight barrier across the entire roof surface. Unlike conventional roofing materials that rely on exposed fasteners, this system utilizes concealed fastening methods that eliminate penetration points where water infiltration typically occurs. The trapezoidal leg configuration offers enhanced load-bearing capacity, making it ideal for large-span commercial buildings, industrial facilities, and architectural projects requiring both functionality and aesthetic appeal. This roofing solution accommodates thermal expansion and contraction through specially engineered clips, preventing stress-related failures that commonly plague fixed roofing systems.

-

Key Components and Design Features of Trapezoidal Standing Seam Metal Roofing

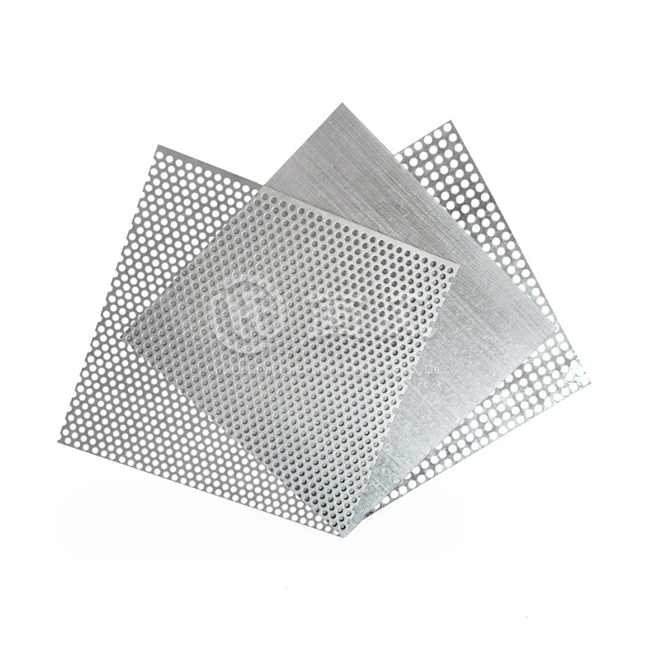

The engineering excellence of Trapezoidal Standing Seam Roofing lies in its sophisticated component integration. Each panel typically ranges from 300mm to 600mm in width, with customizable lengths extending up to 13 meters, allowing for seamless installation across expansive roof areas without problematic horizontal joints. The rib height varies between 50mm and 115mm, providing crucial structural depth that enhances wind resistance ratings up to 5.0 kPa or higher. Premium materials including aluminum alloy grades 3003, 3004, and 5052, galvanized steel, and stainless steel options ensure corrosion resistance in diverse environmental conditions. Advanced surface treatments such as PE and PVDF coatings deliver exceptional weather resistance, with PVDF-coated panels maintaining color integrity and protective properties for 30 years or more. The non-penetrating fixation system represents a fundamental advantage, utilizing concealed clips that attach to the structural deck while allowing panels to move independently, thereby preventing stress concentrations that lead to premature failure.

-

Material Selection and Performance Specifications

Material selection significantly impacts the performance and longevity of Trapezoidal Standing Seam Roofing installations. Aluminum alloy options provide excellent corrosion resistance and lightweight properties, reducing structural load requirements while maintaining strength. The 3003 and 3004 aluminum grades offer superior formability for complex roof geometries, while 5052 grade delivers enhanced strength for high-wind applications. Galvanized and galvalume steel alternatives provide cost-effective solutions with proven performance records spanning multiple decades. Panel thickness selections ranging from 0.7mm to 1.2mm accommodate varying load requirements, with thicker gauges providing Class 4 impact resistance ratings capable of withstanding two-inch diameter hail without visible damage. Waterproofing performance meets or exceeds ASTM D7344 standards, while fire-rated Class A non-combustible classifications ensure compliance with stringent building codes. The load capacity of 1.5 kN/m² or greater supports maintenance equipment access, solar panel installations, and accumulated snow loads in northern climates.

Trapezoidal Standing Seam Roofing

Installation Excellence and Quality Assurance

Professional installation determines the ultimate success of any Trapezoidal Standing Seam Roofing project, requiring specialized expertise and precision execution throughout every phase. The process begins with comprehensive structural assessment and load analysis, utilizing advanced 3D modeling software to identify potential challenges before material procurement. Drainage system simulation ensures proper water management, preventing ponding conditions that accelerate material degradation. Factory-fabricated panels arrive pre-cut to exact specifications, with sequential numbering systems that streamline field installation and minimize errors. Installation technicians must possess thorough knowledge of thermal movement accommodation, seam engagement techniques, and accessory integration to achieve watertight performance. Quality control protocols include rigorous testing at multiple stages, from incoming material verification to final water testing that guarantees zero-leakage performance. This meticulous approach ensures that installed systems deliver the anticipated service life of 30 to 50 years or more, depending on material selection and environmental exposure.

-

Technical Installation Requirements for Standing Seam Systems

Successful Trapezoidal Standing Seam Roofing installation demands strict adherence to manufacturer specifications and industry best practices. Minimum slope requirements typically specify 1/4:12 pitch, though steeper slopes provide enhanced water shedding and extended service life. Substrate preparation includes verifying structural adequacy, installing appropriate underlayment materials, and establishing proper thermal barriers for energy-efficient performance. Clip spacing must be calculated based on wind load criteria, thermal movement coefficients, and panel length to prevent buckling or separation under service conditions. Seam engagement quality directly impacts weather-tightness, requiring proper tooling and technique to achieve consistent interlock strength throughout the installation. Flashing details at roof penetrations, transitions, and terminations represent critical vulnerability points that demand expert fabrication and integration. The installation sequence follows precise protocols, beginning with starter strips, progressing through field panel placement, and concluding with ridge caps and trim components that complete the weather envelope.

Economic Advantages and Long-Term Value Proposition

The financial benefits of Trapezoidal Standing Seam Roofing extend far beyond initial installation costs, delivering substantial lifecycle savings through reduced maintenance requirements and enhanced energy efficiency. Traditional roofing systems typically require replacement every 15 to 20 years, generating recurring capital expenditures and operational disruptions. In contrast, properly installed Trapezoidal Standing Seam Roofing systems routinely achieve 30-year service lives with minimal intervention, effectively eliminating mid-life reroofing expenses. The superior thermal performance characteristics, particularly when combined with reflective coatings, significantly reduce cooling loads in warm climates, generating measurable utility cost reductions. The lightweight nature of metal panels compared to alternative roofing materials may allow reduced structural requirements in new construction, offsetting material premium through foundation and framing savings. Insurance providers frequently offer premium reductions for metal roofing installations due to superior fire resistance, wind performance, and hail damage resistance, providing additional annual savings.

-

Environmental Sustainability and Green Building Benefits

Environmental considerations increasingly influence building design decisions, positioning Trapezoidal Standing Seam Roofing as a preferred sustainable solution. Metal roofing materials typically contain 25% to 95% recycled content, depending on alloy selection, while maintaining 100% recyclability at end of service life. This circular material flow dramatically reduces environmental impact compared to petroleum-based roofing products that contribute to landfill volumes. The exceptional durability minimizes resource consumption by eliminating multiple replacement cycles over typical building lifespans. Reflective roof surfaces meeting ENERGY STAR and Cool Roof Rating Council standards reduce urban heat island effects while lowering building cooling requirements. Many Trapezoidal Standing Seam Roofing installations contribute toward LEED certification through sustainable materials credits, heat island reduction credits, and energy performance improvements. The compatibility with rooftop solar installations transforms previously unused roof areas into renewable energy generation assets, enhancing building sustainability profiles while generating additional economic returns.

Conclusion

Trapezoidal Standing Seam Roofing delivers unmatched performance, combining structural excellence, weather protection, and economic value for commercial and industrial applications requiring long-term reliability.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

As a leading China Trapezoidal Standing Seam Roofing manufacturer and China Trapezoidal Standing Seam Roofing supplier, Xi'an Huafeng Construction Engineering Co., Ltd. brings unparalleled expertise to every project. Established in 2018 and recognized as a high-tech enterprise in Shaanxi Province, we maintain first-level building curtain wall qualifications and third-level steel structure qualifications. Our manufacturing capabilities include a 200,000 square meter raw material production plant in Anhui, plus processing facilities in Hangzhou and Xi'an, featuring 7 color coating production lines and over 40 specialized machines. As a trusted China Trapezoidal Standing Seam Roofing factory offering High Quality Trapezoidal Standing Seam Roofing, we provide comprehensive one-stop solutions from design through installation. Our China Trapezoidal Standing Seam Roofing wholesale services include customized colors, patterns, and specifications with minimum 500 square meter orders and 15-20 day delivery. With over 20 registered patents, CE, ISO9001, ISO14001, and SGS certifications, we deliver Trapezoidal Standing Seam Roofing for sale that meets the highest international standards. For competitive Trapezoidal Standing Seam Roofing price quotations and expert consultation, contact our team at huafeng@hfmetalroof.com today.

References

1. "Metal Roofing Systems: Design, Installation and Performance" by American Society of Civil Engineers (ASCE), Structural Engineering Institute

2. "Standing Seam Metal Roof Systems: Technical Guidelines" by Metal Construction Association (MCA), Technical Committee

3. "Architectural Metal Roofing: Materials, Installation and Maintenance" by National Roofing Contractors Association (NRCA), Technical Services Department

4. "Performance Evaluation of Metal Roofing Systems in Commercial Buildings" by American Society for Testing and Materials (ASTM), Committee E06 on Performance of Buildings