Are you struggling with outdated building facades that compromise both aesthetics and structural integrity? Modern commercial and industrial projects demand wall solutions that deliver seamless appearance without sacrificing weather protection or installation efficiency. Metal wall panel systems, particularly flat lock seam metal wall panels, offer the perfect balance between architectural elegance and functional performance, transforming ordinary building exteriors into sophisticated, long-lasting investments that enhance property value while reducing maintenance costs.

Understanding Flat Lock Seam Metal Wall Panel Technology

Flat lock seam metal wall panels represent a revolutionary approach to building envelope design, combining precision engineering with aesthetic versatility. These sophisticated wall systems utilize concealed fastening mechanisms that create continuous, flush surfaces without visible hardware interruptions. The flat lock wall panels employ interlocking edge profiles that mechanically join adjacent panels, forming watertight seals while maintaining the desired smooth appearance. This technology addresses critical challenges in modern construction, including thermal expansion accommodation, moisture management, and long-term dimensional stability. The engineering behind flat lock seam metal wall panels focuses on creating robust connections that withstand environmental stresses while preserving visual continuity. Each panel features specially formed edges that interlock with neighboring units through precisely manufactured male and female profiles. The concealed fastening system anchors panels securely to structural substrates without penetrating the exposed surface, eliminating potential water infiltration points and enhancing weather resistance. Advanced roll-forming equipment produces these panels with exceptional dimensional accuracy, ensuring consistent fit and finish across entire building facades. Material selection plays a crucial role in performance, with options including aluminum alloys, stainless steel, copper, and titanium-zinc, each offering distinct advantages in corrosion resistance, weight, formability, and aesthetic characteristics.

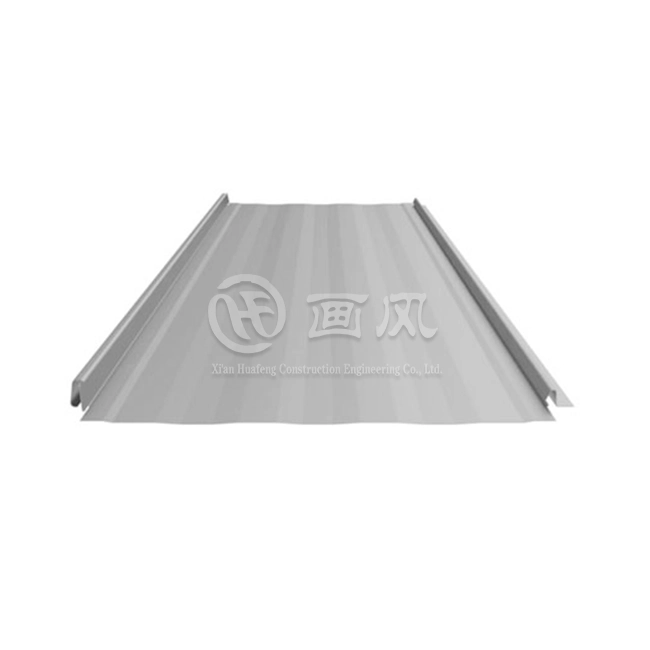

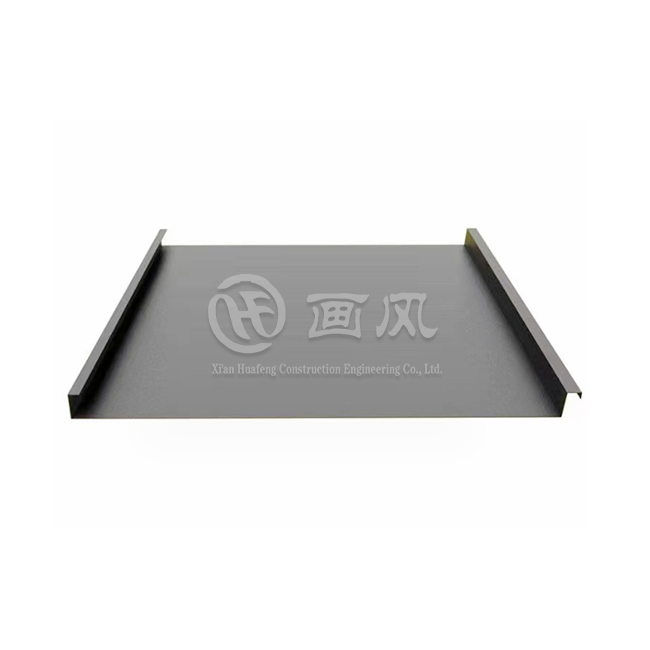

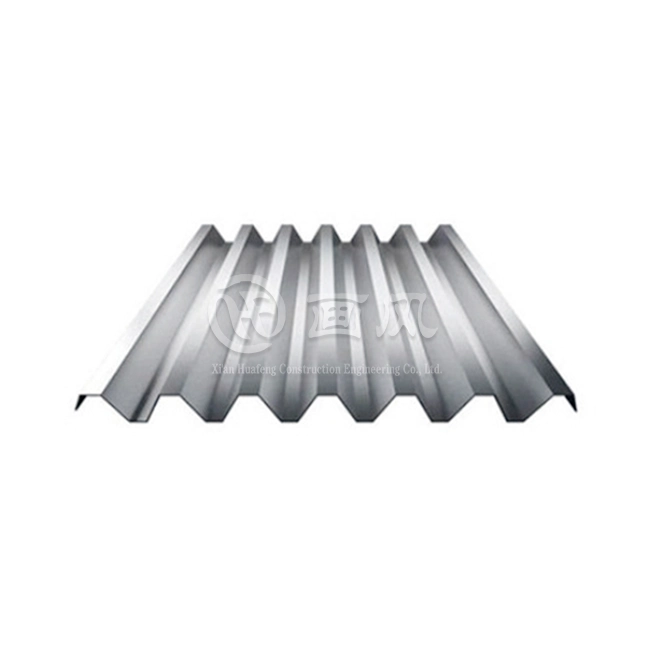

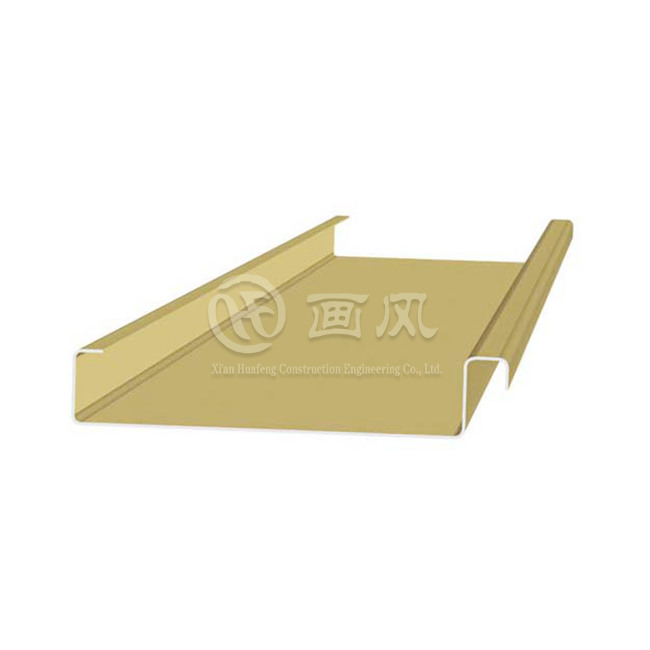

flat lock seam metal wall panels

-

Key Performance Advantages of Flat Lock Wall Panels

Flat lock seam metal wall panels deliver measurable performance benefits that directly impact project outcomes and lifecycle costs. The concealed fastening approach eliminates thermal bridging associated with exposed fastener systems, improving overall envelope thermal performance. Panel interlocking creates redundant weather barriers that shed water effectively even under wind-driven rain conditions. The system's inherent flexibility accommodates building movement from thermal cycling, seismic activity, or structural settlement without compromising weather-tightness or creating stress concentrations that lead to premature failure. Material efficiency represents another significant advantage, as flat lock wall panels typically require less substrate preparation compared to alternative cladding systems. The panels can span between structural supports at wider intervals, reducing framing requirements and associated labor costs. Installation productivity improves through standardized panel profiles and repetitive assembly procedures that minimize field measurement and custom fabrication. Quality control benefits from factory-controlled manufacturing processes that produce consistent panel geometry, finish quality, and performance characteristics, reducing field defects and warranty claims.

-

Material Options and Their Specific Applications

Selecting appropriate materials for flat lock seam metal wall panels requires understanding each metal's properties and performance characteristics. Aluminum alloys, particularly 3003 and 3004 grades, offer excellent corrosion resistance, light weight at approximately three to five kilograms per square meter, and superior formability for complex panel geometries. The material naturally forms a protective oxide layer that prevents progressive corrosion even when surface finishes are compromised. Aluminum's thermal conductivity must be considered in energy-sensitive applications, though proper insulation strategies effectively address this characteristic. Stainless steel provides exceptional durability in harsh environments, with 304 and 316 grades offering progressively higher corrosion resistance for coastal or industrial settings. The material's inherent strength allows thinner gauges ranging from 0.6 to 1.2 millimeters, reducing material costs while maintaining structural performance. Copper develops distinctive patina finishes over time, creating unique aesthetic effects valued in architectural applications. Titanium-zinc combines corrosion resistance with self-healing properties, making it ideal for installations requiring minimal maintenance over extended service lives. Each material accepts various surface treatments including fluorocarbon coatings, powder coating, anodizing, and mill finishes, expanding design possibilities to match specific architectural visions.

Installation Methods and Technical Considerations

Professional installation of flat lock seam metal wall panels requires specialized knowledge of material handling, substrate preparation, and assembly techniques. Successful projects begin with thorough substrate evaluation to ensure adequate structural support, proper moisture management detailing, and appropriate thermal bridging mitigation. The substrate must provide a continuous, flat mounting surface with deviations limited to industry-accepted tolerances, typically less than six millimeters over three meters. Air and water-resistive barriers require careful integration with panel edge conditions, penetrations, and terminations to maintain continuous environmental protection. Panel installation follows systematic sequences that progress from foundation to roofline, maintaining proper alignment through continuous monitoring and adjustment. Starting courses establish critical alignment references that influence all subsequent panel placement. Each flat lock wall panel connects to its neighbor through the interlocking seam, which requires precise engagement to ensure weather-tightness and structural performance. Fastening schedules vary based on wind exposure, building height, and panel dimensions, with engineering analysis determining appropriate fastener spacing and anchor capacity requirements. Corner conditions, openings, and transitions to dissimilar materials demand careful detailing to maintain both functional performance and aesthetic continuity across the building envelope.

-

Quality Control During Installation Process

Quality assurance protocols throughout installation protect project investments and ensure specified performance levels. Pre-installation meetings establish clear understanding of installation sequences, quality standards, inspection procedures, and documentation requirements among all project participants. Material verification upon delivery confirms conformance with specified alloys, thicknesses, finishes, and panel geometries before installation begins. Progressive inspection at key milestones identifies and corrects deviations before they propagate through subsequent work, minimizing costly remediation. Specific inspection points include substrate flatness verification, moisture barrier continuity testing, fastener installation confirmation, seam engagement verification, and finish protection maintenance. Weather monitoring ensures installation occurs within acceptable temperature and precipitation conditions that prevent material damage or improper adhesive curing. Final inspections document completed installation quality through comprehensive visual examination, water testing at critical details, and performance verification testing where specified. Proper documentation creates records supporting warranty claims and provides valuable reference for future maintenance activities.

-

Common Installation Challenges and Solutions

Even experienced installation teams encounter challenges that require problem-solving skills and technical knowledge. Panel alignment issues often stem from accumulated tolerances in structural framing or substrate installation. Addressing these challenges requires strategic placement of adjustment opportunities at natural break points like corners or material transitions where dimensional adjustments can be accommodated without compromising appearance. Thermal movement considerations demand proper expansion joint placement at intervals determined by panel material, local climate conditions, and panel configuration. Weather protection during installation prevents moisture intrusion into wall assemblies that could compromise insulation performance or create conditions supporting biological growth. Temporary protection systems shield partially completed installations from precipitation while maintaining construction progress. Coordination with other trades ensures proper sequencing of mechanical penetrations, electrical installations, and finish work to prevent damage to completed flat lock seam metal wall panels. Specialized tools including panel lifters, seaming equipment, and cutting tools designed specifically for architectural metals ensure quality results while maintaining productivity.

Design Flexibility and Aesthetic Options

Flat lock seam metal wall panels offer extraordinary design flexibility that enables architects to realize diverse aesthetic visions while maintaining functional performance. The panels accommodate various geometric patterns including rectangular, rhomboid, trapezoidal, and hexagonal configurations that create distinctive visual effects through shadow lines and surface articulation. Panel dimensions can be customized within manufacturing constraints, typically ranging from 100 to 600 millimeters in width and extending up to three meters in length, allowing designers to establish specific module systems that align with building proportions and design intent. Color selection dramatically influences building appearance, with options spanning standard RAL color systems and custom color matching capabilities. Fluorocarbon coatings provide superior color retention and chalk resistance, maintaining vibrant appearance throughout extended service lives. Metallic finishes including brushed, polished, and mill finish options create sophisticated aesthetic effects that interact dynamically with natural light conditions throughout the day. Textured finishes add depth and visual interest while potentially concealing minor surface irregularities. Mixed material applications combining different metals or finishes within single projects create rich, complex elevations that establish strong architectural identities.

-

Integrating Flat Lock Wall Panels with Building Systems

Successful building envelope design requires careful integration of flat lock seam metal wall panels with other building components and systems. Window and door openings demand precise coordination to ensure weather-tight transitions between dissimilar materials while maintaining aesthetic continuity. Flashing systems at these interfaces must accommodate differential movement between rigid fenestration components and flexible metal panel assemblies. Proper detailing creates drainage paths that direct moisture away from sensitive building components while maintaining the intended visual expression. Mechanical system integration presents both challenges and opportunities, as equipment penetrations, louvers, and service access panels must be incorporated without compromising envelope performance or appearance. Strategic placement of these elements during design development minimizes visual disruption while ensuring adequate equipment access for maintenance and replacement. Building lighting systems can be integrated with flat lock wall panels to create dramatic nighttime effects that enhance building identity and urban environments. Photovoltaic integration opportunities allow panels to contribute to building energy generation, though careful engineering ensures electrical system safety and maintains panel system warranties.

Performance Testing and Quality Assurance Standards

Rigorous testing protocols validate flat lock seam metal wall panel performance against industry standards and project-specific requirements. Water penetration resistance testing per ASTM E331 and E1646 subjects panel assemblies to simulated wind-driven rain conditions, verifying weather-tightness under challenging environmental exposures. Air infiltration testing following ASTM E283 and E1680 quantifies panel system air leakage characteristics, essential information for energy modeling and building envelope commissioning. Structural performance testing determines panel load capacities, deflection characteristics, and failure modes under both positive and negative pressure loading representing wind conditions. Material-specific testing addresses durability concerns including salt spray resistance per ASTM B117, coating adhesion per ASTM D3359, and accelerated weathering per ASTM G155. These tests predict long-term performance under actual service conditions, supporting material selection decisions and warranty determinations. Fire performance testing establishes material combustibility ratings and contribution to flame spread, critical information for code compliance and life safety system design. Thermal performance testing quantifies panel assembly U-values and thermal bridging effects, enabling accurate building energy simulations and optimization of insulation strategies.

-

Certification and Compliance Documentation

Comprehensive certification documentation demonstrates flat lock wall panels meet applicable building codes, industry standards, and project specifications. ISO 9001 quality management system certification indicates manufacturers maintain consistent production processes and quality control procedures. ISO 14001 environmental management certification demonstrates commitment to sustainable manufacturing practices and environmental responsibility. Product-specific certifications including CE marking for European markets and SGS testing reports provide third-party verification of performance claims. Patent documentation for proprietary panel profiles and fastening systems protects intellectual property while demonstrating innovative engineering approaches. Material certifications from metal suppliers confirm alloy compositions, mechanical properties, and coating specifications meet project requirements. Installation guidelines developed by manufacturers based on extensive field experience and testing provide critical information ensuring proper system performance. Warranty documentation clearly defines coverage terms, maintenance requirements, and claim procedures, protecting owner investments throughout panel service lives.

Maintenance Requirements and Lifecycle Considerations

Proper maintenance preserves flat lock seam metal wall panel appearance and performance throughout extended service lives, protecting building investments and minimizing lifecycle costs. Regular inspection schedules identify developing issues before they progress to costly failures, with inspection frequency varying based on environmental exposure, building use, and local conditions. Visual examinations assess panel condition, fastener integrity, sealant adhesion, and finish quality, documenting observations through photographs and written reports. Early detection of corrosion initiation, coating degradation, or mechanical damage enables timely intervention that prevents accelerated deterioration. Cleaning procedures remove accumulated dirt, biological growth, and atmospheric pollutants that can degrade panel finishes and compromise aesthetic appearance. Gentle cleaning methods using mild detergents and soft brushes preserve coating integrity while restoring original appearance. Avoid abrasive cleaners, high-pressure washing, or aggressive chemicals that damage protective coatings and accelerate panel degradation. Cleaning frequency depends on environmental conditions, with urban or industrial locations requiring more frequent attention than rural settings. Specialized cleaning products formulated for architectural metals provide optimal results without risking panel damage.

-

Long-term Performance and Sustainability Benefits

Flat lock seam metal wall panels deliver exceptional long-term performance that supports sustainable building practices and reduces environmental impact. Metal materials achieve typical service lives exceeding 30 years with proper installation and maintenance, significantly outperforming many alternative cladding systems. Material recyclability at end of service life recovers embodied energy and reduces landfill waste, with aluminum and steel readily accepted by recycling facilities maintaining high scrap values. The panels' durability reduces replacement frequency, minimizing lifetime material consumption and associated environmental impacts from manufacturing and transportation. Energy performance benefits arise from highly reflective finishes that reduce cooling loads in warm climates and optional insulated panel configurations that improve envelope thermal resistance. The lightweight panels reduce structural loading, potentially allowing lighter building frames with reduced material consumption. Local sourcing opportunities through manufacturers with distributed production facilities minimize transportation impacts while supporting regional economies. Low maintenance requirements reduce cleaning chemical usage and eliminate frequent repainting associated with alternative materials, further improving environmental profiles.

Conclusion

Metal wall panel systems featuring flat lock seam technology deliver unmatched combination of aesthetic sophistication, functional performance, and long-term value for modern building projects.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Partner with Xi'an Huafeng Construction Engineering Co., Ltd., a certified China flat lock seam metal wall panels factory, China flat lock seam metal wall panels supplier, and China flat lock seam metal wall panels manufacturer offering premium China flat lock seam metal wall panels wholesale solutions. Our flat lock seam metal wall panels for sale feature competitive flat lock seam metal wall panels price points without compromising on high quality flat lock seam metal wall panels standards. Established in 2018 with recognition as a Shaanxi Province high-tech enterprise in 2020, we operate three factories with seven color coating production lines and over forty specialized machines producing 1000 tons monthly. Our 200,000 square meter Anhui raw material plant and processing facilities in Hangzhou and Xi'an ensure comprehensive one-stop service from custom design and precision manufacturing through expert installation. With over twenty patents, ISO9001, ISO14001, and SGS certifications, we've partnered with Fortune 500 companies delivering landmark projects including Xiongan Station, Xi'an International Convention Center, and Inner Mongolia Tongliao Art Museum. Contact us at huafeng@hfmetalroof.com for customized solutions backed by engineering expertise, quality testing, and 30-year warranty protection.

References

1. Architectural Metal Systems Design Manual - American Architectural Manufacturers Association (AAMA), Technical Standards Committee

2. Metal Wall Panel Installation Guidelines - Metal Construction Association, Engineering Standards Division

3. Performance Testing Standards for Building Envelope Systems - ASTM International Committee E06 on Performance of Buildings

4. Sustainable Metal Building Envelopes: Design and Performance - National Institute of Building Sciences, Building Envelope Technology and Applications Center

_1757558889992.webp)