Are you tired of replacing your roof every decade due to weather damage, leaks, and constant maintenance costs? Traditional roofing materials often fail to withstand extreme weather conditions, leaving property owners frustrated with frequent repairs and replacements. The solution lies in upgrading to a Snap Lock Standing Seam Roof system that combines innovative engineering with proven durability to protect your investment for decades to come.

Why Snap Lock Standing Seam Roof Systems Outperform Traditional Roofing?

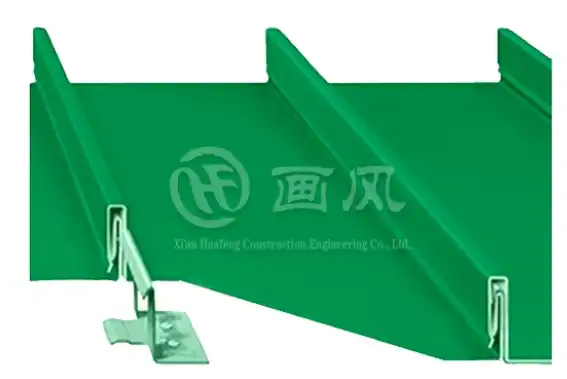

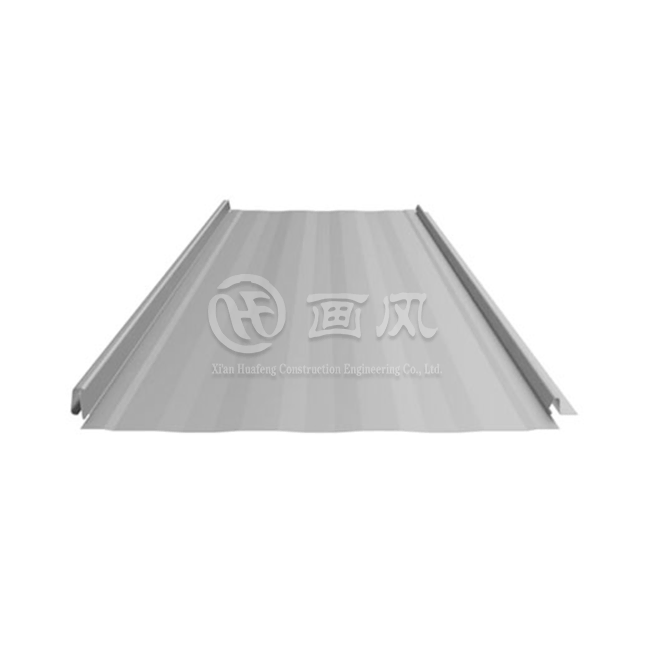

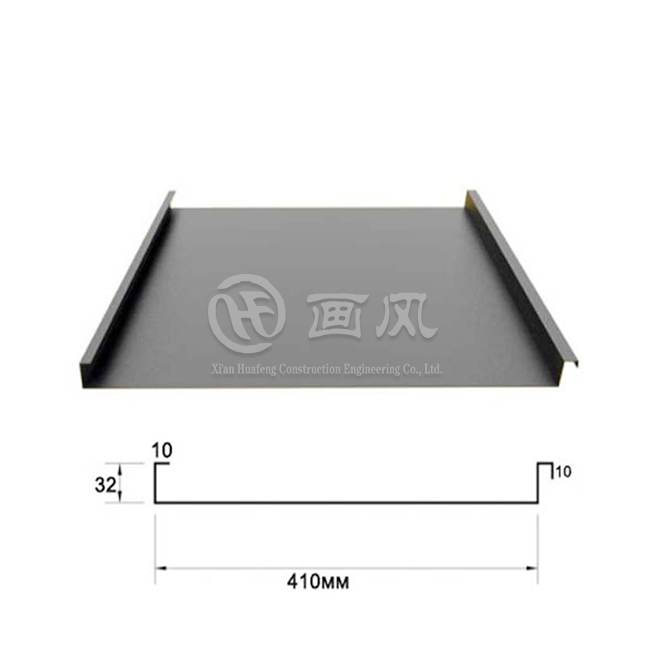

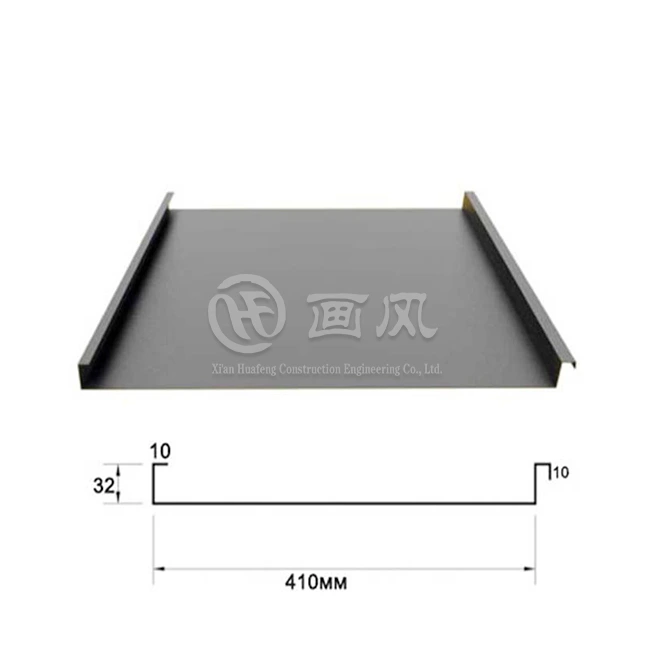

Metal roofing technology has evolved dramatically over the past decade, and the Snap Lock Standing Seam Roof represents the pinnacle of this innovation. Unlike conventional roofing materials that deteriorate within fifteen to twenty years, these advanced metal roofing systems deliver exceptional performance for forty to seventy years or more. The standing seam design features raised interlocking seams that create a watertight barrier while allowing for thermal expansion and contraction, preventing the stress fractures common in traditional roofing materials. The snap-lock mechanism eliminates the need for exposed fasteners, which are the primary source of leaks in conventional metal roofs. This hidden fastener system not only enhances waterproofing capabilities but also creates a sleek, modern aesthetic that complements both commercial and residential architecture. The forty-five millimeter standard height of the standing seams provides superior water channeling, ensuring that even during heavy rainfall or rapid snowmelt, moisture is efficiently directed away from vulnerable roof penetrations and edge details.

-

Understanding the Engineering Behind Snap Lock Standing Seam Roof Performance

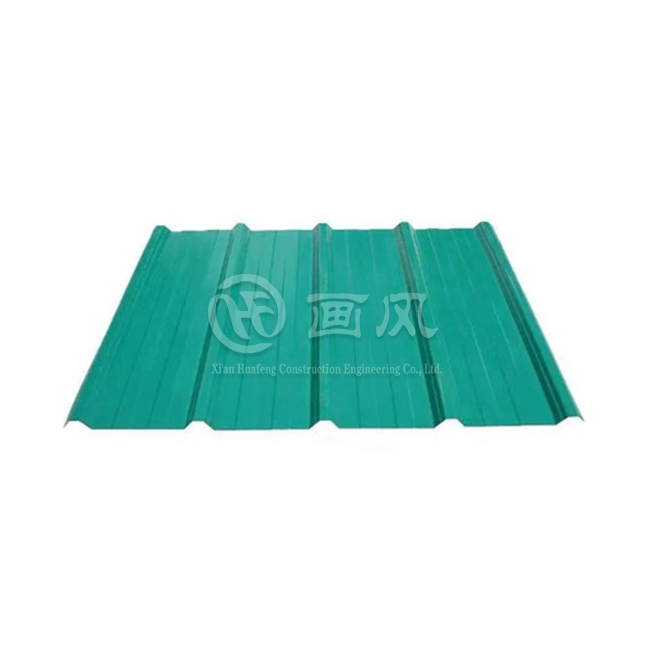

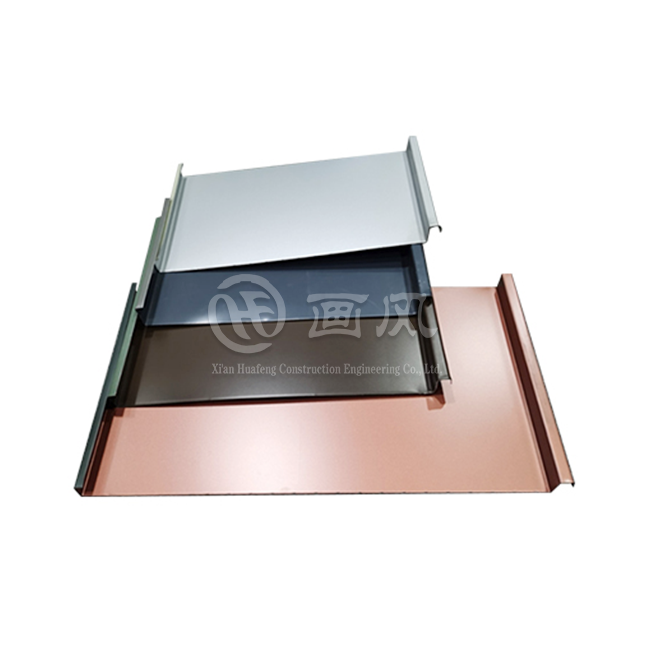

The engineering principles that make Snap Lock Standing Seam Roof systems so effective revolve around material science and structural design. These roofing systems utilize high-grade substrates including galvalume steel, aluminum alloy, stainless steel, and even premium materials like copper and titanium zinc. Galvalume steel, composed of fifty-five percent aluminum, forty-three point four percent zinc, and one point six percent silicon, offers corrosion resistance approximately two to six times greater than ordinary galvanized steel. This substrate forms the foundation for a roofing system capable of withstanding wind speeds exceeding sixty meters per second and snow loads of up to two kilonewtons per square meter. The surface coatings applied to these substrates further enhance performance and longevity. PVDF coatings provide the best weather resistance available, maintaining color retention for more than twenty years while offering exceptional ultraviolet resistance. For projects with budget constraints, PE coatings deliver economical protection suitable for less demanding environments, though they sacrifice some longevity compared to premium PVDF finishes.

-

Material Selection: Choosing the Right Snap Lock Standing Seam Roof for Your Climate

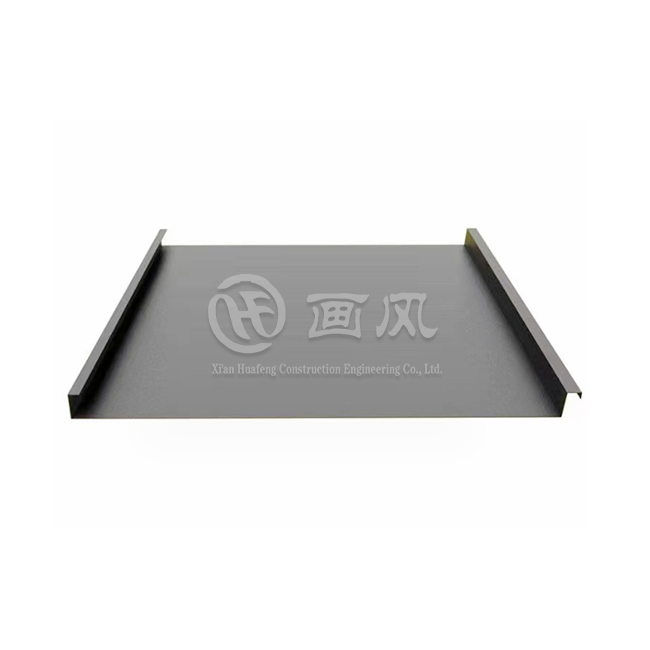

Geographic location and environmental conditions significantly impact roofing material selection, making it essential to match your Snap Lock Standing Seam Roof substrate to local climate challenges. Aluminum alloy roofing panels excel in coastal and high-humidity environments due to their natural resistance to salt spray corrosion. With a density of just two point seven grams per cubic centimeter, aluminum panels reduce structural load while maintaining strength, and their complete recyclability makes them an environmentally responsible choice for sustainability-focused projects. These panels typically feature thicknesses ranging from zero point seven to one point two millimeters, providing robust protection with lifespans exceeding fifty years in harsh maritime conditions. For inland and dry climate applications, galvalume steel represents the optimal balance of performance and value. These panels, available in thicknesses from zero point five to one point zero millimeters, deliver exceptional durability with service lives of thirty to fifty years. The standard panel width ranges from three hundred to six hundred millimeters, with custom lengths up to thirteen meters available to minimize horizontal seams and potential leak points. Stainless steel options, particularly three hundred four and three hundred sixteen L grades, serve specialized applications in chemical processing facilities and extreme industrial environments where standard materials would fail prematurely, though their higher cost limits widespread residential adoption.

Snap Lock Standing Seam Roof

Installation Advantages That Reduce Project Costs and Timeline

One of the most compelling reasons to upgrade to a Snap Lock Standing Seam Roof involves the dramatic installation efficiency improvements over traditional mechanical seam systems. The snap-lock design increases installation speed by thirty to fifty percent compared to systems requiring on-site mechanical seaming equipment. This efficiency translates directly into labor cost savings and reduced project timelines, allowing buildings to achieve weather-tight protection faster. Ordinary construction workers can achieve professional-quality installation after just one day of training, eliminating the need for specialized seaming machine operators and expensive equipment rentals. The hidden clip fastening system completely avoids roof membrane penetrations that create potential leak points in exposed fastener systems. Each panel snaps securely onto concealed clips attached to the structural purlins, with the subsequent panel's seam covering and protecting the connection point. This ingenious design maintains watertight integrity even as the metal expands and contracts with temperature fluctuations, accommodating movements of plus or minus fifteen millimeters without compromising performance. The flexible connection system also provides seismic resistance, allowing the roofing membrane to move independently of the building structure during earthquakes without tearing or creating gaps.

-

Quality Control and Manufacturing Excellence in Snap Lock Standing Seam Roof Production

Manufacturing precision directly impacts the long-term performance of any Snap Lock Standing Seam Roof installation, making supplier selection critical to project success. Xi'an Huafeng Construction Engineering Co., Ltd. operates three state-of-the-art production facilities featuring seven color coating production lines, one laminating production line, and ten longitudinal and transverse shearing lines. This manufacturing infrastructure supports monthly production capacity exceeding one thousand tons while maintaining strict quality standards throughout the fabrication process. The company's raw material production plant in Anhui Province covers two hundred thousand square meters, with additional plate and accessories processing facilities located strategically in Hangzhou and Xi'an. More than forty specialized machines including shearing equipment, presses, and bending machines ensure consistent dimensional accuracy and surface finish quality. Incoming material inspection protocols verify substrate composition, coating thickness, adhesion strength, hardness, impact resistance, salt spray tolerance, acid resistance, weather resistance, and color consistency before materials enter production. This rigorous quality control prevents defective materials from compromising finished products and ensures every panel meets international standards including ASTM, DIN, JIS, BS, and GB/T specifications.

-

Structural Performance: Wind, Snow, and Seismic Resistance

The structural capabilities of Snap Lock Standing Seam Roof systems far exceed conventional roofing materials across all critical performance metrics. Wind resistance testing conducted according to EN fifteen six zero one standards demonstrates these systems can withstand wind pressures exceeding three kilonewtons per square meter when fixing clips are spaced at one point five meter intervals or less. This translates to survival in wind speeds of two hundred sixteen kilometers per hour, providing reliable protection even in hurricane-prone regions. The key factors influencing wind resistance include clip strength, panel thickness, and the tightness of the standing seam bite connection, all of which must be properly specified during design and carefully executed during installation. Snow load capacity varies based on substrate material and purlin spacing, with zero point seven millimeter aluminum panels on six hundred millimeter purlin spacing rated for one point five kilonewtons per square meter, while one millimeter galvanized steel panels achieve two kilonewtons per square meter under identical conditions. The substrate yield strength and purlin support density determine ultimate load capacity, requiring careful structural analysis during project planning. The sliding clip design that enables thermal movement also provides crucial seismic resistance, allowing metal panels to accommodate structural deformation without tearing or creating openings. This allowable displacement of fifteen millimeters in any direction means the roofing membrane can flex with building movements during earthquakes, preventing catastrophic failures that plague more rigid roofing systems.

Long-Term Value: Calculating the True Cost of Roof Ownership

Financial analysis of roofing investments must extend beyond initial installation costs to encompass total lifecycle expenses including maintenance, repairs, and eventual replacement. While Snap Lock Standing Seam Roof systems command higher upfront investment compared to asphalt shingles, their superior longevity and minimal maintenance requirements deliver substantially lower total cost of ownership. Asphalt shingle roofs typically require replacement every twelve to twenty years, meaning a building owner will likely install three to four complete roof systems over a sixty-year period. Each replacement involves removal and disposal of the failed roofing material, creating landfill waste and project disruption beyond just material and labor costs. In contrast, a properly installed Snap Lock Standing Seam Roof with premium substrates and coatings can provide reliable service for fifty to seventy years, often representing the last roof a property owner will ever purchase. The thirty-year warranty backing these systems reflects manufacturer confidence in product durability and provides additional financial protection. Maintenance requirements consist primarily of annual visual inspections to verify fastener tightness and clear any debris accumulation, with no need for the frequent repairs demanded by shingle roofs suffering from wind damage, missing components, or deteriorated waterproofing. Energy efficiency benefits further enhance financial returns, as reflective metal surfaces reduce cooling loads by up to twelve degrees compared to dark asphalt shingles, translating to measurable reductions in electricity consumption during summer months.

-

Sustainability and Environmental Benefits

Modern construction increasingly prioritizes environmental responsibility, and Snap Lock Standing Seam Roof systems deliver exceptional sustainability credentials throughout their lifecycle. Metal roofing materials contain twenty-five to ninety-five percent recycled content depending on the specific substrate, dramatically reducing dependence on virgin raw materials and the environmental impacts of mining and refining operations. At the end of their extended service life, metal roofing panels are one hundred percent recyclable without quality degradation, creating a true closed-loop material cycle. This stands in stark contrast to asphalt shingles, which contribute millions of tons of waste to landfills annually with essentially no recycling infrastructure available. The longevity of metal roofing systems also reduces environmental impact by minimizing the frequency of replacement cycles and associated transportation emissions, manufacturing energy consumption, and construction waste generation. The reflective properties of metal roofing surfaces contribute to urban heat island mitigation in densely developed areas, while their compatibility with solar panel installations makes them ideal for buildings pursuing net-zero energy goals. Metal roofs typically outlast solar panel systems by twenty to forty-five years, eliminating concerns about needing roof replacement before solar equipment reaches end of life and enabling seamless integration of renewable energy systems.

Comprehensive Design and Engineering Support

Successful metal roofing projects require more than quality materials; they demand expert engineering analysis and detailed planning to address site-specific challenges. Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive design services including structural three-dimensional modeling, load analysis, drainage system simulation, and material specification advisory. The design process begins with thorough analysis of architectural drawings including floor plans, elevations, and node diagrams to identify feasible alternatives for each roof section. Following client consultation to determine optimal panel types for specific structural conditions, the design department conducts one-to-one drawing deepening of nodes throughout the project based on confirmed models. Multiple communication rounds ensure all technical details receive proper attention before both parties sign final deepening drawings. Factory processing sample production follows confirmed parameters including panel type, material specifications, thickness dimensions, surface treatment methods, and color selections. After client verification and approval, samples are sealed as production standards for subsequent manufacturing, quality assurance inspection, and final acceptance procedures. Processing drawings break down detailed shop drawings into fabrication instructions for production teams, with each component numbered sequentially according to project specifications and quantities. This systematic approach ensures manufacturing, quality inspection, packaging, and on-site installation proceed according to numbered sequences, eliminating confusion and reducing error rates that plague less organized construction operations.

-

On-Site Installation Excellence and Project Management

The transition from factory production to field installation represents a critical phase where attention to detail determines project success. Based on actual site conditions, installation teams consult with clients to confirm construction layouts including product storage locations, accessory staging areas, and on-site processing zones. Upon product arrival, verification procedures confirm packaging identification corresponds to sectioned floor plans and product number lists, ensuring materials are positioned correctly for efficient installation sequencing. Installation technicians conduct mandatory pre-construction site visits one day before work commences to inspect work areas and verify that all required tools including pliers, edge-locking machines, and hammers are available alongside auxiliary materials like rivets, structural adhesive, screws, and specialized accessories. Technical briefing meetings thoroughly review installation procedures and safety protocols before work begins, ensuring all team members understand their responsibilities and potential hazards. Throughout installation, quality control personnel monitor workmanship to maintain standards and address any issues immediately rather than discovering problems during final inspection. Upon completion, comprehensive testing verifies zero-leakage performance before inviting clients to review installation interfaces. After confirmation and acceptance signature collection, the project team provides maintenance guidance to building owners or facility management staff, ensuring they understand proper care procedures to maximize roofing system longevity.

Proven Performance in Demanding Applications

Real-world project experience demonstrates the versatility and reliability of Snap Lock Standing Seam Roof systems across diverse building types and challenging environmental conditions. Xi'an Huafeng Construction Engineering Co., Ltd. has successfully completed prominent installations including the Xiongan Station Commercial Body, where aluminum-magnesium-manganese metal roofing protects this high-profile transportation hub serving thousands of daily passengers. The Xi'an International Convention and Exhibition Center metal roof project showcases the aesthetic possibilities of standing seam systems on large-scale architectural landmarks. Transportation infrastructure projects like the Xi'an Station East Auxiliary Building and Liyuanping Highway Station demonstrate metal roofing performance in applications requiring exceptional durability and minimal maintenance accessibility. Cultural facilities including the South Hall two dash two of Jinghe New City International Culture and Art Center and the Inner Mongolia Tongliao Art Museum highlight how metal roofing systems complement prestigious public architecture while delivering practical performance benefits. Educational facilities like Weihua Cadre College teaching and office buildings benefit from the long service life and low maintenance requirements that maximize budget efficiency for institutional clients. Industrial applications such as the Hangzhou Sanpu Drainage Pump Station illustrate metal roofing effectiveness in demanding environments with exposure to moisture, chemicals, and operational vibrations that would rapidly degrade conventional roofing materials.

Conclusion

Upgrading to a Snap Lock Standing Seam Roof delivers unmatched durability, performance, and value through advanced engineering, premium materials, and expert installation, protecting your investment for decades while minimizing lifecycle costs.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in Shaanxi Province, China in 2018, stands as a recognized high-tech enterprise specializing in metal roofing systems, building curtain wall systems, and steel structure enclosure solutions. With first-level qualification for building curtain walls and third-level qualification for building steel structures, the company integrates green sustainable development principles throughout its operations. The company's manufacturing infrastructure includes a two-hundred-thousand-square-meter raw material production plant in Anhui Province and two strategically located plate and accessories processing facilities in Hangzhou and Xi'an. Seven color coating production lines, one laminating production line, and ten longitudinal and transverse shearing lines support production capacity exceeding one thousand tons monthly. More than forty specialized machines ensure precision manufacturing while maintaining ISO nine zero zero one and ISO fourteen zero zero one certification standards along with SGS quality verification. With over twenty registered patents for roofing systems and comprehensive quality control protocols, the company delivers customized solutions tailored to specific project requirements from design through construction completion.

As a China Snap Lock Standing Seam Roof factory, China Snap Lock Standing Seam Roof supplier, and China Snap Lock Standing Seam Roof manufacturer offering China Snap Lock Standing Seam Roof wholesale, we provide Snap Lock Standing Seam Roof for sale at competitive Snap Lock Standing Seam Roof price points. Our High Quality Snap Lock Standing Seam Roof systems backed by thirty-year warranties represent the optimal choice for demanding applications. Engineering design experience, extensive construction capabilities, seven raw material production lines, and more than twenty plate production machines combined with over twenty patent certificates, CE certification, ISO certification, and SGS certification demonstrate our commitment to excellence. We cooperate with Fortune 500 companies delivering customized production and one-stop procurement from raw materials through accessories. Our services include design optimization, raw material quality testing, customized products, multiple packaging options, and flexible transportation methods ensuring your project success. Contact us at huafeng@hfmetalroof.com to discuss your roofing requirements and discover how our comprehensive solutions can protect your investment while delivering exceptional long-term value. Bookmark this resource for future reference when planning your next roofing project.

References

1. Metal Roofing Alliance. "Longevity and Performance Standards for Metal Roofing Systems." Technical Report on Metal Roof Durability and Life Cycle Assessment.

2. National Roofing Contractors Association. "Standing Seam Metal Roof Installation Guidelines." Professional Standards Manual for Commercial and Residential Applications.

3. American Society for Testing and Materials. "ASTM E1592 Standard Test Method for Structural Performance of Sheet Metal Roof and Siding Systems by Uniform Static Air Pressure Difference." Materials Testing Standards for Metal Roofing.

4. Building Research Establishment. "Wind Resistance and Weather Performance of Metal Roofing Systems." European Standards Documentation EN 15601 for Metal Roof Testing and Certification.