When your building faces persistent water leakage after every rainstorm or your energy bills continue to climb despite climate control upgrades, the problem often starts from above. Traditional roofing solutions no longer meet the demanding performance standards required by modern commercial and industrial projects in 2025. The answer lies in understanding the three primary metal roofing configurations that combine advanced engineering with proven waterproofing technology. Among these options, Metal Standing Seam Roofing Systems have emerged as the industry's most sophisticated solution, offering unparalleled protection through concealed fastening technology, superior drainage capacity, and structural integrity that withstands decades of harsh environmental conditions while eliminating the maintenance headaches that plague conventional roofing systems.

Understanding Modern Metal Standing Seam Roofing Systems for Large-Scale Projects

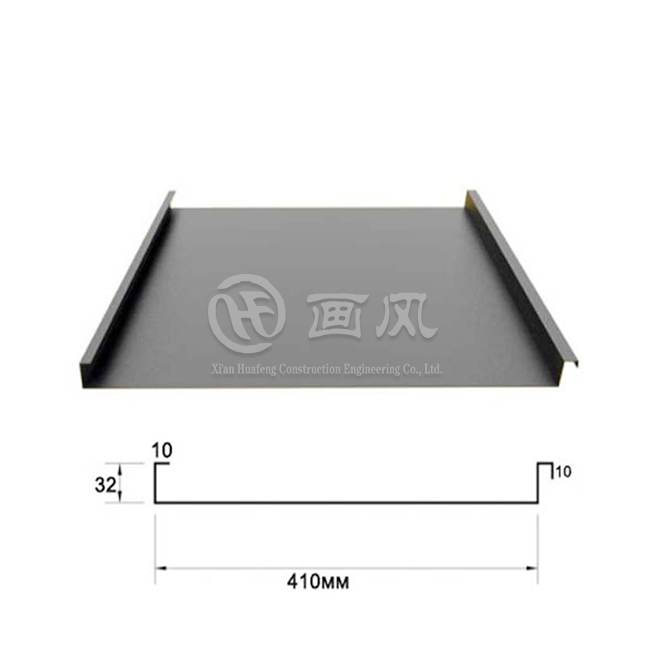

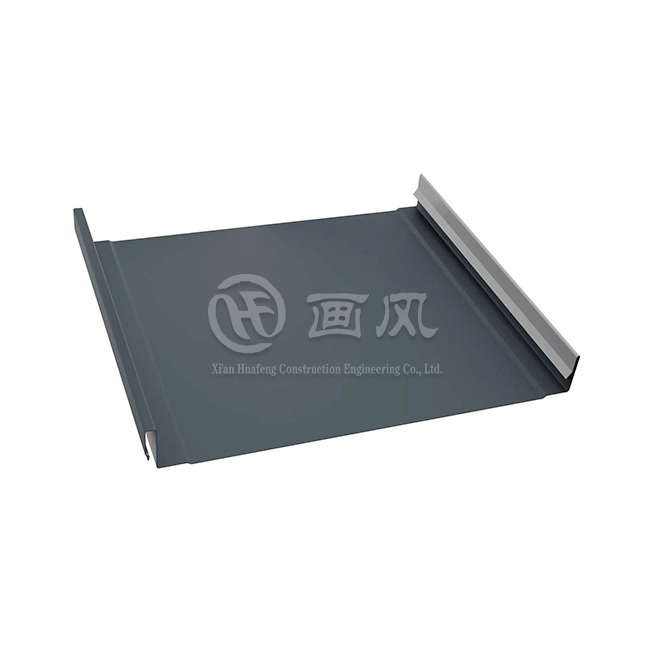

The evolution of Metal Standing Seam Roofing Systems represents a significant breakthrough in building envelope technology, particularly for projects requiring absolute waterproof integrity and long-term durability. Unlike traditional exposed fastener systems that create thousands of potential leak points, standing seam technology employs a sophisticated mechanical interlocking method where vertical metal panels connect through raised seams that run continuously from ridge to eave. This architectural approach fundamentally transforms how buildings manage water, thermal expansion, and structural loads across large roof areas spanning airports, convention centers, sports stadiums, and industrial facilities. The defining characteristic of Metal Standing Seam Roofing Systems lies in the concealed clip attachment mechanism that allows each panel to float independently while maintaining complete weather tightness. Manufactured from premium materials including aluminum alloy grades 3003 and 3004, galvalume steel with AZ150 coating, or specialized titanium-zinc compounds, these panels typically range from 0.6mm to 1.2mm in thickness depending on structural requirements and environmental exposure. The vertical rib height, commonly 65mm for high-performance applications, creates exceptional structural rigidity that resists wind uplift forces exceeding 4.5 kPa—sufficient to withstand category-five typhoon conditions without compromising the building envelope.

-

Technical Specifications and Performance Standards

Metal Standing Seam Roofing Systems manufactured to professional engineering standards incorporate multiple performance layers working synergistically to deliver comprehensive building protection. The primary standing seam roof panel forms the weather-resistant exterior, backed by a waterproof breathable membrane constructed from high-density polyethylene non-woven fabric that blocks external moisture infiltration while permitting interior vapor transmission. This critical vapor management prevents condensation accumulation that leads to structural deterioration and mold formation in conventional roofing assemblies. Beneath the waterproof layer, professional installations integrate rock wool insulation layers with thickness calculations specific to climate zone requirements, providing thermal resistance that minimizes heat transfer and substantially reduces HVAC operational costs. The insulation simultaneously serves acoustic dampening functions, attenuating the impact noise generated during heavy rainfall or hail events—a consideration particularly important for occupied spaces beneath metal roofing. A vapor barrier composed of polyester film or reinforced polyethylene prevents warm, moisture-laden interior air from reaching cold exterior surfaces where condensation would occur, while perforated galvanized structural base plates provide both aesthetic finished appearance and support for the entire roofing assembly across purlin spans extending up to several meters.

Metal Standing Seam Roofing Systems

Comparing Metal Standing Seam Systems with Corrugated and Modular Panel Alternatives

While Metal Standing Seam Roofing Systems represent the premium tier of metal roofing technology, project requirements occasionally necessitate consideration of alternative configurations including corrugated metal panels and modular interlocking systems. Corrugated metal roofing, characterized by its distinctive wavy profile featuring alternating ridges and furrows, offers cost-effective solutions for applications where exposed fastener systems prove acceptable and where the industrial aesthetic complements architectural design intent. These panels, typically manufactured from aluminum, steel, or occasionally copper, derive structural strength from their corrugated geometry rather than material thickness, making them lighter and less expensive than standing seam alternatives. However, corrugated systems introduce fundamental compromises in performance and longevity. The exposed screw-down fastening method creates thousands of penetration points where weatherproof integrity depends entirely on rubber washer gaskets that deteriorate under ultraviolet exposure and thermal cycling. Within five to seven years, these gaskets compress and crack, allowing water infiltration that causes fastener corrosion, substrate rot, and interior leak damage requiring extensive maintenance intervention. The horizontal overlapping seams necessary in corrugated installations create additional vulnerable transition zones where capillary water migration can breach the roofing envelope during wind-driven rain events or ice dam formation.

-

Material Selection and Environmental Performance Considerations

Modern Metal Standing Seam Roofing Systems offer unprecedented material flexibility, allowing project engineers to optimize roofing specification based on precise environmental exposure analysis and performance lifecycle requirements. Aluminum standing seam panels provide exceptional corrosion resistance in coastal environments where salt-laden air would rapidly deteriorate galvanized steel systems. The lightweight characteristics of aluminum—approximately one-third the density of steel—reduce structural loading requirements, potentially eliminating costly reinforcement of existing building frameworks during retrofit applications. Advanced fluorocarbon coating systems containing seventy percent PVDF resin protect aluminum surfaces with coating thickness of 25 to 30 microns, delivering ultraviolet stability and color retention exceeding twenty years in harsh exposure conditions. Galvalume steel panels combine cost-effectiveness with robust mechanical properties, making them ideal for applications requiring high impact resistance and structural performance in moderate climate zones. The proprietary aluminum-zinc alloy coating applied at 150 grams per square meter provides sacrificial protection that significantly extends service life compared to traditional galvanized steel. For ultimate longevity in severe coastal or industrial environments, stainless steel 304 grade standing seam panels deliver corrosion immunity spanning multiple decades, while titanium-zinc systems offer self-healing properties where surface scratches naturally oxidize to restore protective patina, supporting documented service lives exceeding eighty years with essentially zero maintenance requirements.

Installation Excellence and Quality Assurance Protocols for Metal Standing Seam Roofing Systems

The superior performance characteristics inherent in Metal Standing Seam Roofing Systems can only be realized through precision installation methodologies executed by specialized technical teams equipped with advanced roll-forming equipment and comprehensive project management systems. Professional installation begins with detailed structural analysis incorporating three-dimensional building modeling, load calculations accounting for wind uplift and snow accumulation, and drainage system simulation ensuring adequate water removal capacity across the entire roof plane. These engineering studies generate construction documentation including full-scale detail drawings at every transition condition, penetration location, and edge termination where proper execution proves critical to long-term weatherproof integrity. Manufacturing precision represents another critical success factor distinguishing professional Metal Standing Seam Roofing Systems from inferior alternatives. State-of-the-art production facilities employ computer-controlled roll-forming lines that fabricate custom-length panels up to thirteen meters without transverse seams, eliminating horizontal joints that compromise waterproofing in conventional systems. Automated quality control systems continuously monitor panel dimensions, coating integrity, and forming accuracy to tolerances of ±0.02mm, ensuring consistent interlock geometry essential for proper clip engagement and thermal expansion accommodation across thousands of panel connections throughout a project.

-

Comprehensive Material Testing and Certification Requirements

Rigorous incoming material inspection protocols form the foundation of quality assurance in professional Metal Standing Seam Roofing Systems manufacturing. All raw materials including aluminum coil, steel substrate, and coating compounds undergo verification against supplier certifications and third-party laboratory test reports confirming compliance with international specifications including ASTM A924/A755 standards for metallic-coated steel, EN 1991 for structural loading, and GB/T 7106 for weatherproof performance. Physical testing encompasses more than a dozen verification procedures including surface appearance evaluation, dimensional accuracy measurement, salt spray exposure, adhesion pull-off, pencil hardness, impact resistance, film thickness gauging, acid resistance, accelerated weathering, and colorimetric analysis ensuring color consistency across production batches. Production samples manufactured using confirmed parameters including panel profile, material specification, thickness, surface treatment method, and color selection undergo customer approval before full-scale manufacturing commences. These sealed samples establish definitive standards for subsequent product processing, quality inspection, and project acceptance procedures, eliminating ambiguity that often generates disputes during construction completion. Sequential numbering systems applied to each manufactured unit coordinate material flow from production through packaging, shipping, and field installation, ensuring proper panel placement according to shop drawings while preventing costly errors and rework.

Why Metal Standing Seam Roofing Systems Excel in Demanding Applications?

The technical superiority of Metal Standing Seam Roofing Systems becomes immediately apparent when examining their performance across critical building envelope criteria. Watertightness testing conducted under 1000 Pascal negative pressure—simulating severe storm conditions with high-velocity wind-driven rain—demonstrates zero water penetration, validated through compliance with GB/T 7106-2008 international standards. The double-lock mechanical seam connection creates redundant weatherproof barriers that function reliably even as the metal panels expand and contract through temperature differentials exceeding 150 degrees Celsius for aluminum and 260 degrees for steel systems, eliminating the thermal stress failures common in rigidly fastened roof assemblies. Fire safety requirements for major public assembly buildings, transportation terminals, and industrial facilities demand roofing materials that will not contribute fuel to conflagration events or allow fire penetration that threatens building occupants. Metal Standing Seam Roofing Systems manufactured from aluminum, steel, or stainless steel receive A1 non-combustible classification under GB 8624-2012 fire testing protocols, providing essential life-safety protection while potentially reducing property insurance premiums through improved building fire resistance ratings. The complete recyclability of metal roofing materials—approaching one hundred percent for aluminum, steel, and copper—aligns with green building certification requirements and corporate sustainability commitments, while high solar reflectivity values exceeding 0.65 contribute to urban heat island mitigation and reduced cooling energy consumption.

-

Successful Project Implementations Demonstrating Proven Performance

Professional Metal Standing Seam Roofing Systems have demonstrated exceptional performance across diverse high-profile projects worldwide, including the massive commercial complex at Xiongan Station where aluminum-magnesium-manganese panels cover expansive roof planes requiring absolute waterproof reliability for continuous public transportation operations. The Xi'an International Convention and Exhibition Center showcases the architectural versatility of standing seam technology, where custom panel profiles and precision color matching integrate seamlessly with contemporary building aesthetics while delivering the robust performance demanded by large public assembly facilities. Additional successful implementations include the Xi'an Station East Auxiliary Building metal roof project, the Jinghe New City International Culture and Art Center's South Hall, the Liyuanping Highway Station, multiple educational facilities including the Weihua Cadre College complex, critical infrastructure like the Hangzhou Sanpu Drainage Pump Station, and cultural institutions including the archaeological museum design and the Inner Mongolia Tongliao Art Museum, each demonstrating the reliability and longevity achievable through professional engineering and installation excellence.

Conclusion

The three primary metal roofing configurations available in 2025 each serve distinct applications, yet Metal Standing Seam Roofing Systems consistently emerge as the optimal solution for projects demanding maximum performance, longevity, and weatherproof integrity. Superior concealed fastening technology, comprehensive material options, and proven installation methodologies deliver unmatched value across residential, commercial, and industrial applications.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

As a China Metal Standing Seam Roofing Systems manufacturer, China Metal Standing Seam Roofing Systems supplier, and China Metal Standing Seam Roofing Systems factory offering High Quality Metal Standing Seam Roofing Systems for sale at competitive Metal Standing Seam Roofing Systems price points with Metal Standing Seam Roofing Systems wholesale options, Xi'an Huafeng Construction Engineering Co., Ltd. delivers comprehensive solutions backed by extensive engineering design experience, advanced construction capabilities, and state-of-the-art manufacturing facilities. Established in Shaanxi Province in 2018 and recognized as a high-tech enterprise with first-level building curtain wall qualification and third-level steel structure qualification, Huafeng operates a 200,000-square-meter raw material production facility in Anhui plus dedicated processing plants in Hangzhou and Xi'an, equipped with seven color coating lines, one laminating line, ten longitudinal and transverse shearing systems, and over forty specialized fabrication machines producing standing seam panels, aluminum-magnesium-manganese plates, titanium-zinc systems, corrugated profiles, and complete accessory packages. Our one-stop service encompasses project drawing optimization, factory sample production, precision manufacturing with rigorous incoming material inspection following ISO9001 and ISO14000:14001 standards, and seamless on-site installation guidance ensuring zero-leakage performance validated through comprehensive testing protocols. With over twenty registered patents, multiple international certifications, collaboration experience with Fortune 500 companies, customization capabilities for color, pattern, and design specifications, MOQ of 500 square meters, delivery within 15-20 days, 30-year warranty coverage, and monthly production capacity of 1000 tons, Huafeng provides the expertise and resources essential for successful Metal Standing Seam Roofing Systems implementation. Contact our technical team at huafeng@hfmetalroof.com to discuss your project requirements and discover how professional engineering transforms roofing challenges into lasting solutions.

References

1. Standing Seam Metal Roofing Systems: Design, Installation, and Performance Standards for Commercial Applications, National Roofing Contractors Association Technical Guidelines Committee, 2024

2. Comparative Analysis of Metal Roofing Technologies for High-Performance Building Envelopes, Journal of Architectural Engineering and Design, Volume 18, Chen, Wei and Zhang, Ming, 2024

3. Advanced Coating Systems for Metal Roofing: PVDF Technology and Long-Term Weathering Performance, American Society for Testing and Materials Technical Report, Davidson, Robert, 2023

4. Sustainable Building Practices: Metal Roofing Materials Selection and Lifecycle Assessment, International Green Building Council Research Division, Thompson, Sarah and Liu, Xiaoming, 2024