Picture this: heavy rain pounds against your building's roof, wind gusts reach dangerous speeds, and yet inside, everything remains completely dry and secure. This is the promise of Metal Standing Seam Roofing Systems—a roofing solution engineered to withstand nature's harshest conditions while delivering decades of maintenance-free performance. Whether you're an architect designing the next landmark stadium, a facility manager responsible for protecting critical infrastructure, or a developer seeking long-term value, understanding the technical sophistication and practical advantages of standing seam metal roofing is essential for making informed construction decisions that balance performance, aesthetics, and lifecycle costs. Standing seam metal roofing represents a fundamental evolution in building envelope technology. Unlike traditional roofing systems that rely on exposed fasteners vulnerable to weather degradation, Metal Standing Seam Roofing Systems employ concealed mechanical seaming that creates continuous, watertight barriers across entire roof surfaces. This architectural approach has become the gold standard for projects where failure is not an option—airports that must operate through severe weather, exhibition centers with expansive column-free spaces, industrial facilities handling sensitive operations, and sports venues protecting thousands of spectators. The system's adaptability extends beyond performance specifications to encompass aesthetic versatility, with material options ranging from lightweight aluminum alloys to premium copper that develops distinctive patinas over time.

Understanding Metal Standing Seam Roofing Systems Architecture

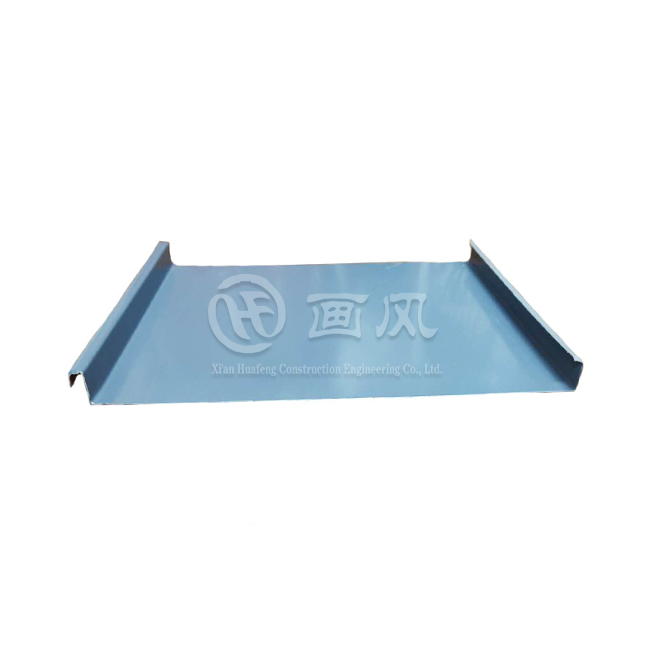

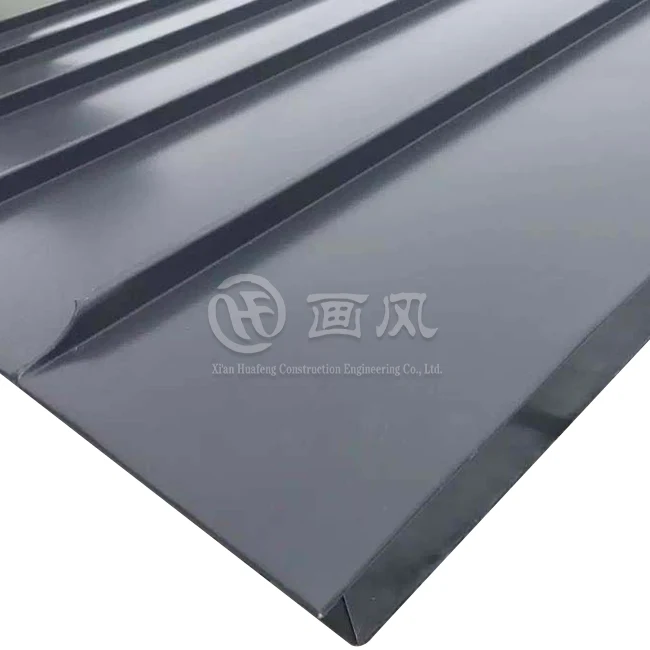

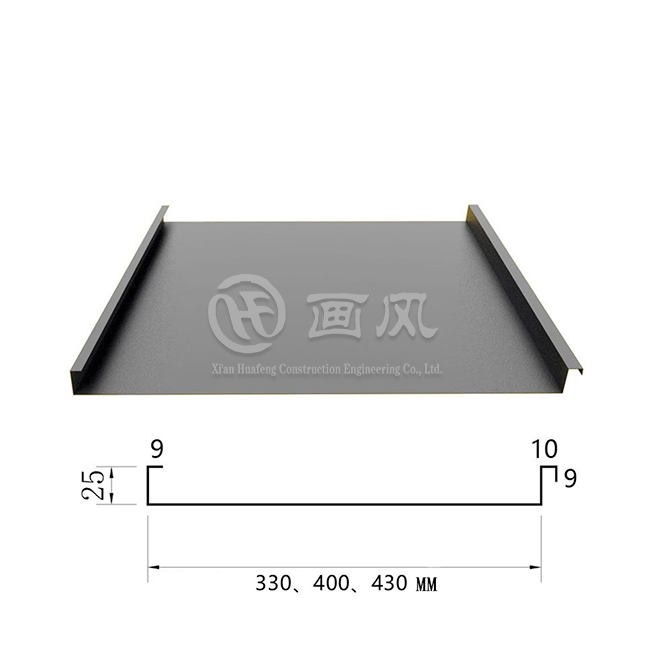

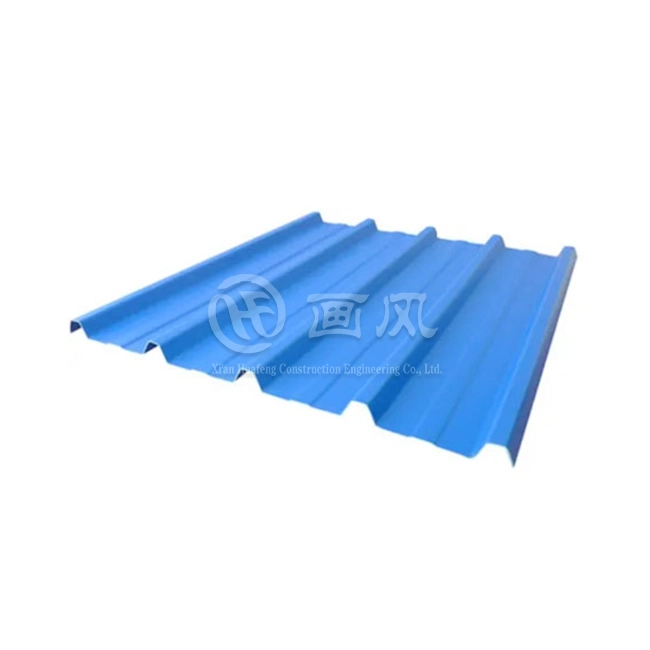

The engineering principles underlying Metal Standing Seam Roofing Systems distinguish them fundamentally from conventional roofing approaches. At the core lies the standing seam profile itself—raised ribs typically 65mm in height that run continuously from ridge to eave, creating structural channels that efficiently manage water drainage while providing exceptional rigidity against wind uplift and snow loads. These vertical seams are formed through specialized roll-forming equipment that shapes flat metal coils into precise panel profiles, with each panel extending the full length of the roof slope to eliminate vulnerable horizontal seams where water intrusion traditionally occurs. The mechanical seaming process represents sophisticated field fabrication where adjacent panel edges interlock and are crimped together using portable seaming machines. This double-lock seam configuration creates joints that exceed the strength of the base metal itself, establishing structural continuity across the entire roof plane. Beneath the visible metal surface, a carefully engineered assembly addresses thermal performance, moisture management, and acoustic control. High-density polyethylene breathable membranes allow interior moisture to escape while blocking external water infiltration, preventing the condensation issues that plague sealed roof assemblies. Rock wool insulation layers provide both thermal resistance and sound attenuation, crucial for spaces beneath metal roofing where rain impact noise can otherwise become problematic.

Vapor barriers positioned on the warm side of the insulation assembly prevent interior humidity from migrating into cooler layers where condensation would compromise thermal performance and potentially damage structural components. Perforated steel substrate panels provide structural support for insulation while contributing acoustic absorption through calculated perforation patterns. This multi-layered approach transforms metal roofing from a simple weather barrier into a sophisticated building system that manages water, heat, sound, and structural loads simultaneously. The purlin support structure beneath allows for precise slope adjustment and accommodates building movement through engineered connection details that permit thermal expansion while maintaining structural integrity.

Material Selection and Performance Specifications in Metal Standing Seam Roofing Systems

Material selection for Metal Standing Seam Roofing Systems demands careful analysis of environmental exposure, structural requirements, aesthetic preferences, and lifecycle budget considerations. Aluminum-magnesium-manganese alloys in 3003 and 3004 series compositions offer exceptional corrosion resistance with weights approximately one-third that of steel alternatives, making them ideal for coastal environments where salt spray accelerates corrosion, or for structures where reduced dead loads provide economic advantages through lighter structural framing. These aluminum alloys typically specify 0.9mm to 1.2mm thickness with H44 hardened temper providing necessary strength and formability. Surface treatments include polyester powder coatings for general applications or premium PVDF fluoropolymer finishes containing 70% Kynar resin that delivers 20-year color retention warranties even in intense UV exposure. Galvalume steel panels represent the most cost-effective option for Metal Standing Seam Roofing Systems requiring excellent corrosion resistance across diverse climate zones. The AZ150 coating specification indicates 150 grams per square meter of aluminum-zinc alloy metallurgically bonded to steel substrate, providing cathodic protection that dramatically extends service life compared to traditional galvanized coatings. At thicknesses ranging from 0.6mm to 1.0mm, galvalume steel offers superior strength-to-weight ratios with material costs significantly below aluminum while maintaining 30-year performance expectations when properly finished with PVDF topcoats. The cost-performance balance makes galvalume the predominant choice for commercial and industrial applications where budget constraints exist alongside demanding performance requirements.

Stainless steel specifications, particularly 304 grade at 0.5mm to 0.8mm thickness, address extreme corrosion environments including chemical processing facilities, wastewater treatment plants, and marine structures directly exposed to salt water. The chromium content in stainless steel forms passive oxide layers that self-repair when scratched, providing corrosion resistance that improves rather than degrades over time. Premium material options include titanium-zinc plates that develop protective patina surfaces requiring no applied finishes, with projected service lives exceeding 80 years, and copper roofing that weathers to distinctive verdigris coloration while delivering century-long performance with virtually no maintenance requirements. These premium materials command significantly higher initial costs but provide unmatched longevity and aesthetic character for landmark projects where roof appearance contributes to architectural identity.

Metal Standing Seam Roofing Systems

Technical Performance and Engineering Standards for Metal Standing Seam Roofing Systems

Understanding the quantified performance characteristics of Metal Standing Seam Roofing Systems enables proper specification for specific project requirements and site conditions. Wind resistance represents perhaps the most critical performance metric for metal roofing, particularly given increasing extreme weather frequency. Properly engineered standing seam systems withstand wind pressures exceeding 4.5 kPa, equivalent to hurricane-force winds approaching 200 kilometers per hour, through the combination of mechanical seaming that distributes loads across panel widths rather than concentrating stress at fastener points, and clip attachment systems that secure panels to structural purlins while permitting thermal movement. Testing protocols defined in ASTM E1592 subject roof assemblies to both positive and negative pressure cycles simulating wind conditions, with negative uplift pressures typically governing design requirements as wind passing over roof surfaces creates suction forces attempting to lift panels away from structures. Snow load capacity addresses accumulation weights in regions experiencing significant winter precipitation, with Metal Standing Seam Roofing Systems engineered to support distributed loads of 1.5 kN per square meter or greater depending on local climate data and building codes. The sloped profile and smooth metal surface facilitate natural snow shedding, reducing actual loads compared to roofs where snow accumulates throughout winter seasons. Impact resistance testing using standardized protocols drops steel balls from specified heights onto roof surfaces, verifying that panels withstand hail impacts and maintenance foot traffic without penetration or permanent deformation. Modern Metal Standing Seam Roofing Systems routinely pass tests involving 1-kilogram projectiles dropped from 3-meter heights, demonstrating robust resistance to both natural hail events and construction-related impacts.

Thermal performance considerations extend beyond basic insulation values to address thermal bridging through structural components, solar heat gain through exposed metal surfaces, and expansion-contraction movements as metal temperatures fluctuate between extreme heat and cold. Aluminum thermal expansion coefficients approximately double those of steel, necessitating careful design of expansion joints and clip attachments that accommodate dimensional changes without inducing panel buckling or seam failures. High solar reflectance values exceeding 0.65 characterize cool roof coatings that reduce heat absorption, lowering building cooling loads while extending roof surface life by minimizing thermal stress cycles. Fire safety classifications achieve A1 non-combustible ratings under GB 8624 standards, providing critical protection for buildings storing flammable materials or requiring enhanced life safety provisions. Watertightness testing subjects installed assemblies to 1000 Pascal negative pressure differentials while spraying water on surfaces, simulating wind-driven rain conditions far exceeding normal weather exposure. Metal Standing Seam Roofing Systems consistently demonstrate zero leakage under these test conditions when properly installed, with the continuous mechanical seams creating redundant water barriers that protect even if individual seam sections experience damage. This waterproofing reliability enables roof warranties extending 30 years on complete systems including both materials and installation workmanship, providing building owners with long-term performance assurance backed by manufacturer guarantees.

Installation Excellence and Project Implementation of Metal Standing Seam Roofing Systems

The sophisticated engineering incorporated into Metal Standing Seam Roofing Systems demands equally sophisticated installation practices to achieve specified performance. Successful projects begin with comprehensive design development where architectural drawings undergo detailed technical review to identify interface conditions, structural coordination requirements, and constructability challenges before fabrication commences. This drawing deepening process creates full-scale node details showing exact material configurations at roof penetrations, expansion joints, perimeter conditions, and transitions to other building elements. Communication between design teams and installation specialists during this phase prevents costly field modifications and ensures that manufactured panels arrive on site ready for efficient installation without requiring cutting or adaptation that compromises waterproofing integrity. Sample panel fabrication provides tangible verification of material selections, finish quality, and profile accuracy before full production begins. Physical samples undergo client review for color confirmation under actual lighting conditions, dimensional verification against specification requirements, and finish quality assessment. These approved samples become contractual standards against which production runs are judged, with sealed samples retained for comparison throughout manufacturing and installation phases. The sequential numbering system applied during fabrication planning assigns unique identification to each roof panel and accessory component, with packaging organized by roof zones and installation sequences. This systematic approach eliminates on-site confusion, reduces handling damage risks, and accelerates installation by ensuring required materials arrive in logical order matching construction progress.

Quality control during manufacturing encompasses incoming material inspection where raw metal coils undergo verification testing including coating thickness measurement, adhesion evaluation, color matching against approved standards, and material certification review. Salt spray testing, impact resistance verification, and weathering simulation provide quantified performance data confirming that materials meet specifications before fabrication begins. Production monitoring tracks panel dimensions, seam formation quality, and surface protection application, with final inspection protocols verifying flatness tolerances, edge straightness, and finish uniformity before packaging for shipment. This multi-stage quality verification ensures that panels arriving on construction sites meet exacting standards required for successful installation and long-term performance. On-site installation management addresses logistics planning for material storage protecting panels from damage, work sequencing that coordinates metal roofing with related trades, and safety compliance ensuring worker protection on elevated work surfaces. Installation crews verify substrate preparation including structural alignment, proper slope achievement, and underlayment installation before beginning panel placement. Specialized seaming equipment crimps adjacent panel edges together following manufacturer-specified procedures that achieve required seam strength and weather tightness. Post-installation testing includes both visual inspection of completed work and physical water testing simulating rain exposure to verify zero-leakage performance before project acceptance.

Comprehensive System Components and Long-Term Value of Metal Standing Seam Roofing Systems

Understanding Metal Standing Seam Roofing Systems requires recognition that visible metal panels represent only the surface layer of integrated assemblies addressing multiple building performance requirements simultaneously. Waterproof breathable membranes installed directly on structural decking provide secondary weather protection while managing moisture vapor transmission, preventing condensation damage that occurs when interior humidity encounters cold surfaces. These technical fabrics combine waterproofing with breathability through microporous structures that block liquid water while permitting vapor passage, maintaining assembly dryness even when construction moisture or building humidity challenges the system. Thermal insulation layers typically employ rock wool or mineral fiber batts selected for both thermal resistance values and fire safety characteristics, with thickness calculations addressing climate zone requirements and energy code compliance. Acoustic performance becomes especially important for Metal Standing Seam Roofing Systems covering occupied spaces, where rain impact noise on metal surfaces requires sound absorption layers to maintain comfortable interior environments. Glass wool acoustic batts positioned beneath perforated metal ceiling panels absorb sound energy, dramatically reducing noise transmission compared to hard roof surfaces. Vapor retarders on the warm side of insulation assemblies control moisture migration, preventing condensation within insulation layers that would compromise thermal performance while potentially damaging structural components or promoting mold growth.

The environmental advantages of Metal Standing Seam Roofing Systems extend throughout product lifecycles from raw material extraction through end-of-service recycling. Metal roofing materials contain high recycled content percentages, with steel and aluminum readily accepting scrap material in production processes without performance degradation. At building end-of-life, metal roofing panels maintain significant scrap value and achieve near-complete recycling rates, contrasting sharply with asphalt shingle or membrane roofing systems destined for landfill disposal. Energy performance benefits include solar reflectance reducing cooling loads, compatibility with photovoltaic mounting systems enabling buildings to generate renewable energy, and exceptional durability eliminating repetitive replacement cycles that consume materials and generate waste. Economic analysis must consider lifecycle costs rather than initial construction expenses alone. While Metal Standing Seam Roofing Systems typically require higher upfront investment compared to conventional roofing alternatives, the 30-year or greater service life with minimal maintenance requirements provides superior value when evaluated over building ownership periods. Avoided replacement costs, reduced maintenance labor, and energy savings from superior thermal performance combine to generate positive return on investment typically within 10-15 years of installation. Insurance considerations may favor metal roofing through reduced premiums reflecting fire resistance and wind damage resilience, further enhancing financial advantages.

Conclusion

Metal Standing Seam Roofing Systems deliver unmatched performance combining structural strength, weather protection, thermal efficiency, and aesthetic versatility for demanding architectural applications requiring decades of reliable service with minimal maintenance intervention across diverse climate conditions and building types.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as your trusted China Metal Standing Seam Roofing Systems factory, China Metal Standing Seam Roofing Systems supplier, and China Metal Standing Seam Roofing Systems manufacturer offering China Metal Standing Seam Roofing Systems wholesale with competitive Metal Standing Seam Roofing Systems price. Our High Quality Metal Standing Seam Roofing Systems for sale combine extensive engineering design experience with state-of-the-art manufacturing capabilities including seven raw material production lines spanning 200,000 square meters, advanced roll-forming equipment, and comprehensive quality control laboratories. Recognized as a Shaanxi Province high-tech enterprise with first-level curtain wall qualifications and third-level steel structure credentials, we hold over 20 registered patents alongside ISO9001, ISO14000, and SGS certifications demonstrating our commitment to manufacturing excellence. Our one-stop service encompasses custom design optimization, precision manufacturing, rigorous quality testing, and professional installation support, backed by 30-year warranties and proven performance in landmark projects including Xiongan Station, Xi'an International Convention Center, and Inner Mongolia Tongliao Art Museum. Contact our technical team at huafeng@hfmetalroof.com to discuss your specific project requirements and receive detailed proposals demonstrating why Fortune 500 companies trust Huafeng for critical roofing applications. Bookmark this guide for future reference as your comprehensive resource for metal roofing solutions.

References

1. Metal Construction Association. "Architectural Sheet Metal Manual: Standing Seam Roof Systems Engineering Guide." Seventh Edition. Metal Construction Association Technical Committee.

2. National Roofing Contractors Association. "The NRCA Roofing Manual: Metal Panel and SPF Roof Systems." NRCA Technical Operations Department.

3. Schittich, Christian, et al. "Building Skins: Concepts, Layers, Materials." Detail Practice Series, Birkhäuser Architecture.

4. Brookes, Alan J. and Grech, Chris. "The Building Envelope and Connections: Concepts and Design." Butterworth Architecture Technical Study.