Picture this scenario: a sudden rooftop avalanche damages your property, threatens pedestrian safety, and destroys landscaping below. Without proper snow retention systems on your Trapezoidal Standing Seam Roofing, winter weather creates dangerous liability risks that compromise building integrity and endanger lives. Three-bar snow guard systems provide engineered protection specifically designed for trapezoidal standing seam profiles, preventing catastrophic snow slides while maintaining roof aesthetics and structural warranties throughout severe winter conditions.

Understanding 3 Bar Snow Guard Systems for Metal Roofing

Three-bar snow retention systems represent advanced engineering solutions specifically designed to address the unique challenges posed by metal roofing in snow-prone regions. Unlike traditional single-bar or pad-style retention devices, three-bar configurations distribute snow load across multiple horizontal planes, creating a graduated retention system that controls snow migration without sudden release. When installed on Trapezoidal Standing Seam Roofing, these systems work harmoniously with the roof's natural thermal expansion characteristics, allowing panels to float freely while maintaining secure snow retention capabilities throughout temperature fluctuations. The fundamental mechanics of three-bar systems leverage both mechanical interception and frictional resistance. The lower bar initiates snow retention near the eave line, where gravitational forces concentrate sliding momentum. The middle bar provides secondary reinforcement, catching snow that bypasses the first barrier during heavy accumulation periods. The upper bar serves as final containment, ensuring comprehensive coverage across the entire roof slope. This layered approach proves particularly effective on Trapezoidal Standing Seam Roofing because the pronounced rib geometry creates natural channels that can accelerate snow movement without proper intervention.

-

Design Considerations for Trapezoidal Profiles

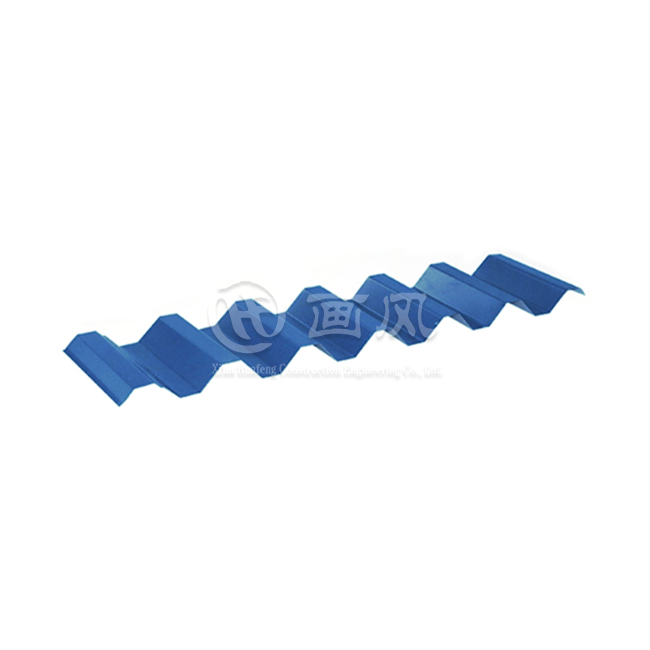

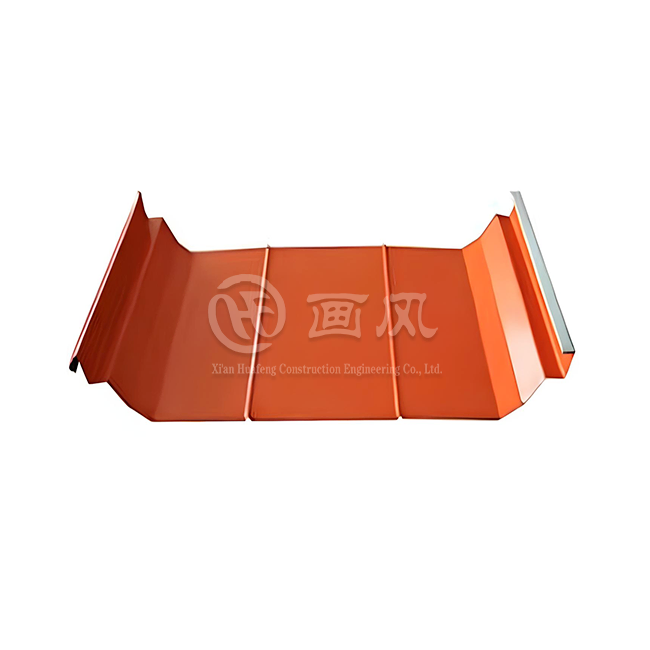

Trapezoidal standing seam profiles present distinct installation challenges that demand specialized mounting solutions. The panel geometry features raised seams with trapezoidal cross-sections, typically measuring between 50mm to 115mm in height, which requires snow guard brackets engineered to accommodate these specific dimensions. Standard attachment methods utilize non-penetrating clamp systems that grip the seam mechanically, distributing retention forces across the seam structure rather than concentrating stress at single fastener points. This approach preserves the integrity of Trapezoidal Standing Seam Roofing while providing the structural capacity necessary to withstand calculated snow loads. The seam spacing on trapezoidal profiles directly influences snow guard placement patterns. Most trapezoidal systems feature seams positioned at 300mm to 600mm intervals, creating a grid pattern that determines optimal bar positioning. Engineers calculate retention requirements based on roof slope, panel length, regional snow load data, and material coefficients of friction. For Trapezoidal Standing Seam Roofing installations, these calculations must account for the reduced friction coefficient of metal surfaces compared to traditional roofing materials, necessitating more frequent bar spacing or increased bar capacity to achieve equivalent retention performance.

-

Material Selection and Durability Standards

Three-bar snow guard systems manufactured for Trapezoidal Standing Seam Roofing applications utilize aircraft-grade aluminum alloys, typically 6005A-T61 or equivalent specifications, providing exceptional strength-to-weight ratios and corrosion resistance. These materials maintain structural integrity across temperature ranges from -40°C to +80°C, accommodating the thermal cycling common in roofing applications without material degradation or connection failure. The aluminum construction eliminates galvanic corrosion concerns when paired with aluminum-magnesium-manganese panels, galvanized steel, or stainless steel substrates through proper material compatibility planning. Surface treatment options significantly impact long-term performance and aesthetic integration. Powder coating processes provide color-matching capabilities that allow snow guards to blend seamlessly with Trapezoidal Standing Seam Roofing finishes, utilizing the same PVDF or polyester coating technologies applied to the panels themselves. This coating integration ensures uniform weathering characteristics and prevents the visual degradation that compromises inferior systems over time. Mill-finished options offer cost-effective alternatives for industrial applications where aesthetic considerations prove secondary to functional performance and budgetary constraints.

Installation Methods for Optimal Performance

Professional installation of three-bar snow guard systems on Trapezoidal Standing Seam Roofing requires comprehensive understanding of both structural engineering principles and roofing system dynamics. The installation sequence begins with thorough roof assessment, identifying panel profiles, seam dimensions, fastening patterns, and substrate conditions that influence mounting strategies. Accurate field measurements ensure proper bracket selection from manufacturer inventories designed to accommodate specific trapezoidal configurations. This preparatory phase prevents costly installation errors and ensures compatibility between retention components and existing roof assemblies. Clamp-style mounting brackets represent the industry standard for Trapezoidal Standing Seam Roofing applications because they eliminate roof penetrations that could compromise waterproofing integrity or void manufacturer warranties. These brackets feature adjustable clamping mechanisms with rounded set screws that apply controlled pressure against seam walls without cutting or deforming the metal substrate. Installation technicians torque these connections to manufacturer specifications, typically ranging from 90 to 120 inch-pounds, balancing adequate retention force against the risk of seam damage through over-tightening.

-

Bar Positioning and Load Distribution

Strategic bar positioning maximizes retention effectiveness while minimizing material costs and installation labor. The primary bar location typically sits approximately 300mm to 450mm above the eave line, intercepting snow at the critical transition zone where gravitational forces overcome static friction. Secondary and tertiary bars follow at calculated intervals, generally spacing bars 1200mm to 1800mm apart vertically, though specific spacing requirements vary based on engineered load calculations. On Trapezoidal Standing Seam Roofing with panel lengths exceeding 8 meters, additional bar rows may prove necessary to prevent mid-span snow accumulation that could exceed design load limits. The horizontal continuity of bar systems significantly influences retention performance. Continuous bars spanning multiple seams provide superior load distribution compared to segmented installations, transferring retention forces across broader roof areas and reducing localized stress concentrations. Splice connections maintain structural continuity between bar sections while accommodating thermal expansion through engineered slip joints that permit linear movement without compromising retention capacity. This expansion accommodation proves critical for Trapezoidal Standing Seam Roofing installations where panel lengths and temperature differentials create significant dimensional changes throughout seasonal cycles.

-

Quality Assurance and Testing Protocols

Verification testing ensures installed snow guard systems meet calculated retention capacities and maintain roof system integrity. Visual inspections confirm proper bracket engagement with seam profiles, adequate set screw penetration without substrate damage, and correct bar alignment throughout the installation. Torque verification using calibrated tools validates connection tightness across all mounting points, ensuring uniform load distribution and preventing premature failure through under-torqued connections. These inspections document compliance with engineering specifications and manufacturer installation guidelines governing Trapezoidal Standing Seam Roofing applications. Advanced installations may incorporate pull testing protocols that apply measured forces to installed brackets, verifying mechanical performance before roof exposure to actual snow loads. These destructive tests sacrifice sample brackets to validate bulk installation quality, providing quantitative performance data that supplements visual inspection results. Non-destructive alternatives utilize strain gauges or deflection measurements to assess connection adequacy without compromising installed components. Such rigorous quality assurance aligns with the precision manufacturing standards maintained throughout Xi'an Huafeng Construction Engineering Co., Ltd. production facilities, ensuring that Trapezoidal Standing Seam Roofing installations deliver predictable long-term performance.

Trapezoidal Standing Seam Roofing

Engineering Calculations and Load Requirements

Proper snow guard system design requires comprehensive engineering analysis incorporating regional climate data, building geometry, and material properties specific to Trapezoidal Standing Seam Roofing configurations. Ground snow load values obtained from meteorological records provide baseline accumulation expectations, which engineers then modify using roof slope factors, thermal factors, exposure categories, and importance factors prescribed by relevant building codes. These calculations determine the total snow weight that retention systems must accommodate, expressed in kilonewtons per square meter or pounds per square foot, establishing the foundation for component selection and spacing determinations. The critical sliding force represents the lateral load that snow guards must resist to prevent rooftop avalanches. This force calculation incorporates the total snow weight, roof slope angle, and the coefficient of friction between snow and the Trapezoidal Standing Seam Roofing surface. Metal roofing typically exhibits friction coefficients between 0.1 and 0.3, significantly lower than asphalt shingles or other rough surfaces, necessitating more robust retention systems to achieve equivalent performance. Engineers factor safety margins into these calculations, typically designing for 150% to 200% of calculated loads to accommodate unpredicted accumulation patterns, ice formation, and installation variability.

-

Seam Capacity and Structural Integration

The load-bearing capacity of trapezoidal seams establishes the upper limit for individual bracket retention forces. Seam strength depends on panel material properties, seam geometry, fastening patterns, and substrate support conditions. Testing protocols established by independent laboratories quantify these capacities through destructive testing that loads seams to failure, documenting both ultimate strength and elastic deformation characteristics. For Trapezoidal Standing Seam Roofing manufactured from aluminum alloys (3003, 3004, 5052) or galvanized steel substrates, typical seam capacities range from 500 to 1500 newtons per bracket, with higher values achieved through enhanced panel thicknesses or specialized seam geometries. Load distribution across multiple seams prevents individual seam overload while maximizing total system capacity. Three-bar configurations with continuous horizontal bars inherently distribute retention forces across all seams intersecting the bar length, effectively multiplying the total system capacity by the number of engaged seams. This distribution advantage proves particularly valuable on wide roof planes where Trapezoidal Standing Seam Roofing panels span 40 to 60 seam positions, creating opportunities for highly efficient retention systems that minimize individual component loading while achieving substantial aggregate capacity.

Maintenance and Long-Term Performance

Professional maintenance protocols extend snow guard system longevity and preserve retention effectiveness throughout the service life of Trapezoidal Standing Seam Roofing installations. Annual inspections scheduled before winter season onset identify potential issues including bracket loosening, bar misalignment, component corrosion, or fastener degradation that could compromise system performance. Visual examination confirms that thermal cycling has not caused set screw relaxation or clamp displacement, while manual testing verifies continued secure engagement between brackets and seam profiles. These proactive assessments prevent minor installation drift from evolving into system failures during critical loading events. Cleaning procedures remove accumulated debris that can accelerate corrosion or interfere with proper snow guard function. Organic material trapped between bars and roof surfaces retains moisture that promotes galvanic reactions between dissimilar metals or supports biological growth that degrades protective coatings. High-pressure washing or manual removal eliminates these contaminants, restoring proper drainage pathways and preventing premature coating breakdown on both retention components and underlying Trapezoidal Standing Seam Roofing panels. Coating inspection identifies areas where mechanical damage or UV degradation has compromised protective finishes, enabling targeted recoating before substrate corrosion initiates.

-

Performance Documentation and Warranty Compliance

Comprehensive documentation maintains warranty coverage and provides reference data for future service interventions. Installation records including bracket locations, bar positions, torque specifications, and component serial numbers create permanent project archives that facilitate maintenance planning and enable accurate replacement part ordering when components reach end-of-service life. Photographic documentation captures as-built conditions, providing visual references that clarify proper configuration details years after original installation completion. These records prove particularly valuable for Trapezoidal Standing Seam Roofing projects involving phased construction or multiple building expansions where consistent system specifications ensure uniform performance across entire facility portfolios. Performance monitoring through winter seasons validates design assumptions and confirms adequate retention capacity under actual loading conditions. Observation protocols document snow accumulation patterns, sliding behavior, and guard interaction with snow masses, generating field data that refines future design approaches. Exceptional performance under design load conditions confirms conservative engineering while unexpected movement or near-failure events identify opportunities for system enhancement through additional bar rows, reduced spacing, or upgraded component capacities.

Conclusion

Three-bar snow guard systems engineered specifically for Trapezoidal Standing Seam Roofing provide comprehensive protection against dangerous rooftop avalanches while preserving roof warranties and aesthetic integrity.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

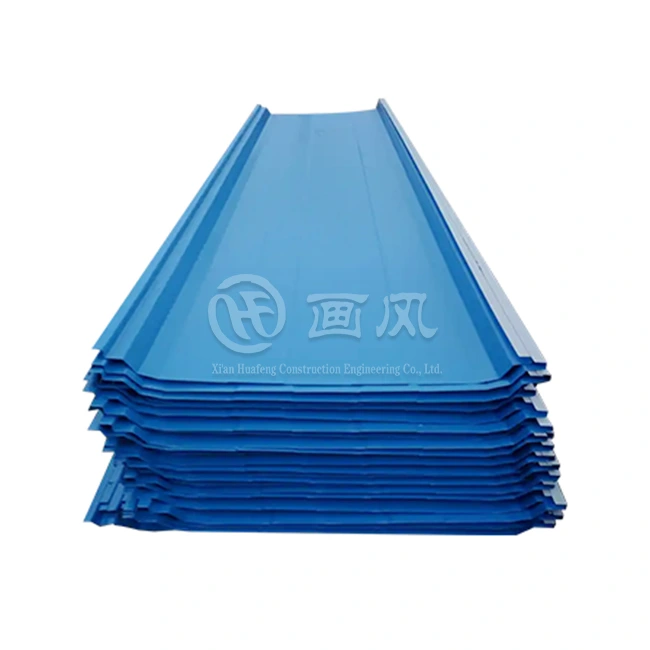

As a leading China Trapezoidal Standing Seam Roofing manufacturer, China Trapezoidal Standing Seam Roofing supplier, and China Trapezoidal Standing Seam Roofing factory, Xi'an Huafeng Construction Engineering Co., Ltd. delivers High Quality Trapezoidal Standing Seam Roofing with competitive Trapezoidal Standing Seam Roofing price and extensive Trapezoidal Standing Seam Roofing for sale through China Trapezoidal Standing Seam Roofing wholesale channels. Established in 2018 and recognized as a Shaanxi Province high-tech enterprise in 2020, we operate a 200,000-square-meter raw material production facility in Anhui plus dedicated processing plants in Hangzhou and Xi'an. Our infrastructure includes seven color coating production lines, one laminating line, ten longitudinal and transverse shearing systems, and over forty specialized machines ensuring precision manufacturing. With more than twenty registered patents, CE certification, ISO9001, ISO14001, and SGS compliance, plus proven collaboration with Fortune 500 companies, we provide customized one-stop solutions from engineering design through material procurement to on-site installation guidance. Contact our team at huafeng@hfmetalroof.com for project-specific quotations and technical consultation.

References

1. American Society of Civil Engineers. "Minimum Design Loads and Associated Criteria for Buildings and Other Structures." ASCE/SEI 7-22, Structural Engineering Institute, 2022.

2. Metal Construction Association. "Snow Retention Systems for Metal Roofing: Design, Testing, and Installation Guidelines." Technical Bulletin 142, MCA Engineering Committee, 2021.

3. Tobiasson, Wayne and Greatorex, Alan. "Database and Methodology for Conducting Site-Specific Snow Load Case Studies for the United States." U.S. Army Corps of Engineers Cold Regions Research and Engineering Laboratory, 2020.

4. Sheet Metal and Air Conditioning Contractors' National Association. "Architectural Sheet Metal Manual." 7th Edition, SMACNA Technical Services, 2019.