Are you struggling with outdated building facades that compromise both aesthetics and structural integrity? Traditional wall systems often fail to deliver the seamless, modern appearance that contemporary architecture demands. Flat Lock Seam Metal Wall Panels offer a revolutionary solution that combines exceptional durability, timeless elegance, and versatile design capabilities to transform any building envelope. This comprehensive guide explores how these innovative panels deliver unmatched performance for commercial, industrial, and institutional projects while providing architects and builders with complete design freedom.

Understanding Flat Lock Seam Metal Wall Panel Systems

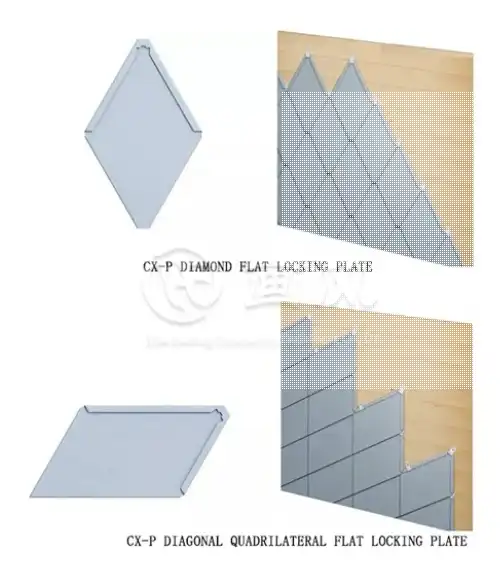

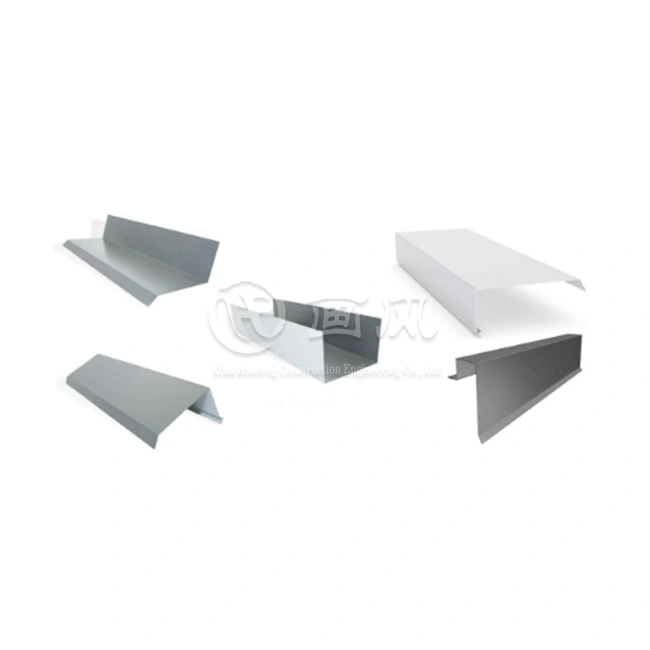

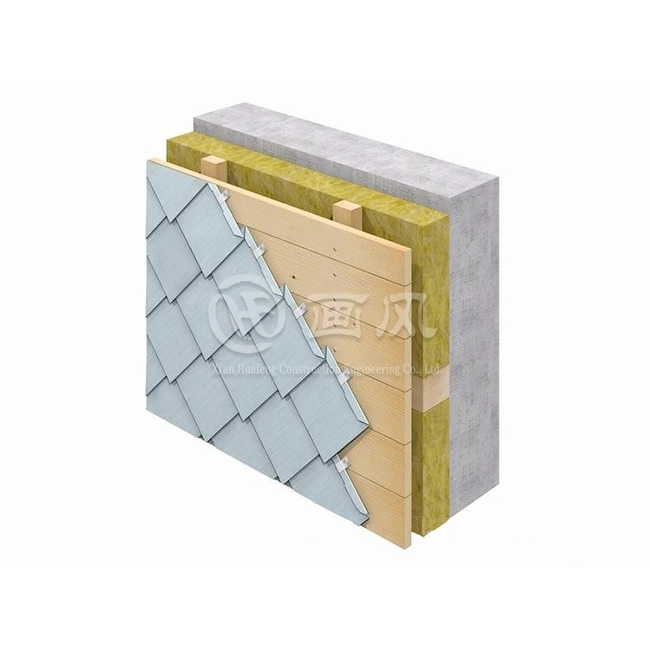

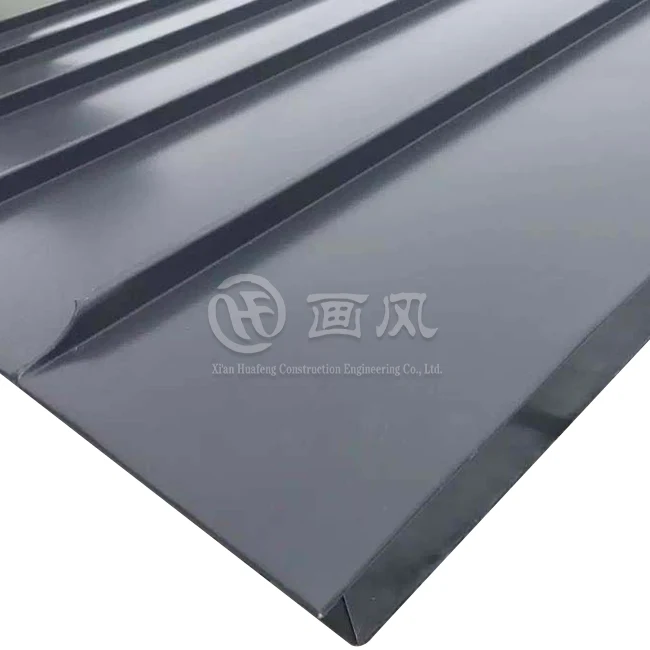

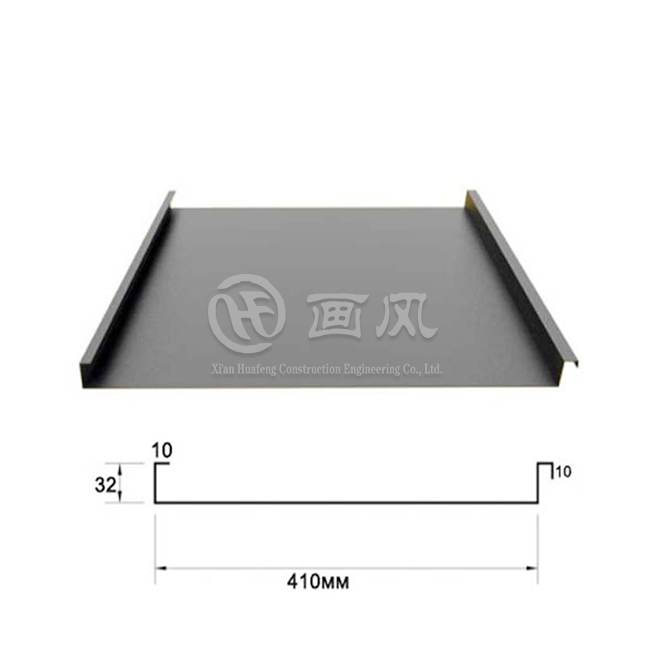

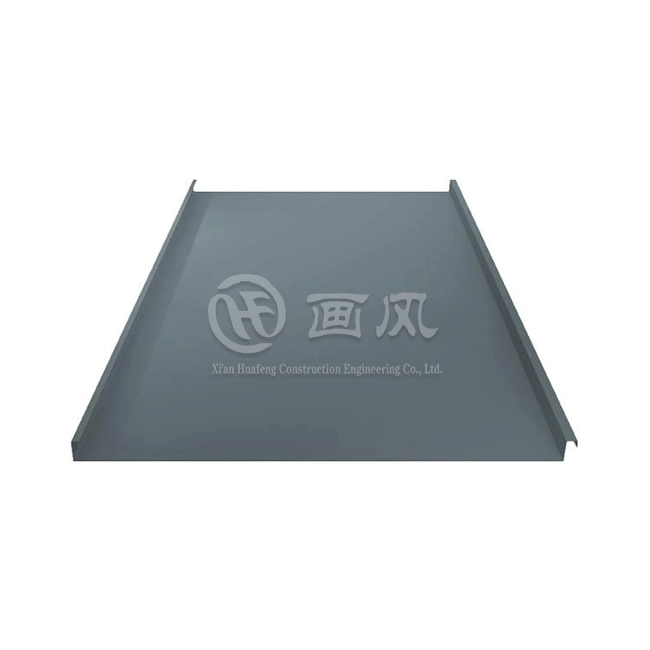

Flat Lock Seam Metal Wall Panels represent a sophisticated architectural solution that has revolutionized building envelope design across multiple industries. These premium wall systems utilize a unique interlocking mechanism where individual panels connect through precisely engineered flat seams, creating a monolithic surface appearance that eliminates visual disruption. Unlike conventional wall cladding systems that rely on exposed fasteners or obvious joint lines, flat lock wall panels achieve their distinctive aesthetic through concealed clip technology that secures each panel while maintaining the seamless facade integrity that modern architecture demands. The manufacturing process behind Flat Lock Seam Metal Wall Panels involves precision roll-forming techniques that ensure consistent dimensions and perfect interlocking capabilities across every panel produced. Each panel undergoes meticulous edge profiling to create the characteristic flat lock seam configuration, typically featuring a lock depth of approximately 0.75 inches that provides both structural connection and weather-resistant overlap. The system's versatility extends to material selection, with manufacturers offering these panels in aluminum alloys, stainless steel grades, copper, titanium-zinc, and various coated steel substrates to accommodate diverse project specifications and performance requirements.

-

Key Technical Specifications and Material Options

Professional specifications for flat lock wall panels demand attention to critical parameters that directly impact system performance and longevity. Material thickness typically ranges from 0.4mm to 1.2mm depending on substrate selection and application requirements, with aluminum panels commonly specified at 0.6mm to 1.0mm thickness, while stainless steel applications may utilize slightly thinner gauges due to superior material strength characteristics. Panel widths vary considerably based on design intent, with standard configurations ranging from 300mm to 600mm, though custom dimensions can be manufactured to accommodate specific architectural visions. The geometric flexibility of Flat Lock Seam Metal Wall Panels distinguishes them from rigid panel systems, offering architects unprecedented design latitude. Panel configurations include traditional rectangular formats for clean contemporary lines, diamond patterns that create dynamic visual interest, trapezoid shapes that add dimensionality to flat surfaces, and hexagonal configurations for distinctive honeycomb aesthetics. This geometric versatility enables designers to create unique building identities while maintaining the system's fundamental performance advantages. Surface treatment options further expand design possibilities, with fluorocarbon PVDF coatings delivering exceptional color retention and weather resistance, powder coating providing economical color variety, and specialized finishes like anodizing for aluminum or natural patination for copper and zinc applications.

Manufacturing Excellence and Quality Control Standards

Xi'an Huafeng Construction Engineering Co., Ltd. operates three strategically positioned manufacturing facilities that collectively demonstrate the company's commitment to production excellence and supply chain efficiency. The primary raw material production plant spans 200,000 square meters in Anhui Province, providing comprehensive material processing capabilities that ensure consistent quality from source materials through finished products. Two additional specialized processing plants located in Hangzhou and Xi'an focus on precision panel fabrication and accessories manufacturing, creating a distributed production network capable of responding rapidly to project demands across China and international markets. The manufacturing infrastructure supporting Flat Lock Seam Metal Wall Panels production includes seven advanced color coating production lines that apply durable finishes with precise thickness control and uniform coverage, one specialized laminating production line for composite panel applications, and ten longitudinal and transverse shearing production lines that process coil stock into precise panel blanks. More than forty pieces of specialized equipment including hydraulic shearing machines, precision press brakes, and computer-controlled bending machines enable the complex forming operations required to create the distinctive flat lock seam profiles. Fully automatic punching production lines ensure consistent hole placement for concealed fastening systems, while automated quality inspection equipment validates dimensional accuracy throughout the manufacturing process.

-

Rigorous Material Procurement and Incoming Inspection Protocols

Quality assurance begins long before panel fabrication commences, with comprehensive material procurement standards that specify approved suppliers and required material certifications. Huafeng maintains an exclusive material selection library featuring premium brands including Alucosuper, YATAI, and LIDAO for aluminum alloys in 3003, 3004, and 5052 specifications, BAOSTEEL, GUANZHOU, and XINYU for steel substrates including cold-rolled, galvanized, galvalume, and pre-coated sheets, Baosteel and Tsingshan for stainless steel grades 316 and 304, NedZink for titanium-zinc plates, and Chinalco copper in T2 and TP2 specifications. These brand partnerships ensure material consistency and traceability throughout the supply chain. Incoming material inspection represents a critical quality control checkpoint where raw materials undergo comprehensive verification before entering production. Inspection protocols include full examination for high-value low-volume materials and statistical sampling for regular production materials, preventing defective substrates from compromising finished panel quality. The inspection regimen encompasses more than a dozen distinct tests including visual appearance assessment, dimensional verification, salt spray corrosion resistance testing, coating adhesion evaluation, hardness measurement, impact resistance testing, film thickness validation, acid resistance confirmation, accelerated weathering simulation, and color consistency verification. All material suppliers must provide factory certifications and independent third-party testing reports documenting compliance with specified material standards including ASTM, DIN, JIS, BS, and GB/T requirements.

Flat Lock Seam Metal Wall Panels

Design Integration and Project Planning Services

The successful implementation of Flat Lock Seam Metal Wall Panels requires comprehensive design coordination that begins during early project conceptualization phases. Huafeng's engineering team specializes in project drawing deepening services that transform conceptual architectural designs into detailed fabrication and installation documentation. This process initiates with thorough analysis of all architectural engineering drawings including floor plans, elevations, and preliminary node details to identify feasible panel configurations and connection strategies. Through collaborative consultation with project stakeholders, the design team determines optimal panel types, dimensions, and layout patterns that align with both aesthetic objectives and structural requirements. Following initial panel type selection, the design department conducts full-scale drawing deepening that creates detailed node drawings at 1:1 scale for every unique condition throughout the project. This meticulous documentation process addresses critical details including panel-to-structure connections, expansion joint accommodation, inside and outside corner transitions, window and door perimeter flashings, base and cap terminations, and penetrations for mechanical systems. Multiple communication cycles with clients ensure comprehensive understanding and agreement before formal drawing approval and signature confirmation, establishing clear fabrication parameters that eliminate field coordination issues during construction.

-

Factory Sample Production and Approval Procedures

Physical sample production bridges the gap between two-dimensional drawings and actual installed appearance, providing stakeholders with tangible references for final approval decisions. Sample panels are manufactured using confirmed specifications including exact panel profile, specified material substrate and thickness, selected surface treatment methodology, and approved color selection. These factory-produced samples undergo the identical manufacturing processes that will be applied to production panels, ensuring representative quality and appearance characteristics. Client review and formal sample approval establish the definitive standard for all subsequent production, with approved samples retained as sealed references throughout fabrication and installation phases. This approval process encompasses verification of panel dimensions and geometry, material substrate and gauge, surface finish quality and appearance, color accuracy and consistency, and edge detail execution. The sealed sample serves multiple purposes including production quality benchmarking for manufacturing personnel, inspection standards for quality assurance departments, and acceptance criteria for final installation verification, creating traceable quality control documentation throughout the entire project lifecycle.

Comprehensive Installation Support and Technical Guidance

Professional installation of flat lock wall panels demands specialized knowledge and meticulous attention to proper techniques that ensure long-term system performance. Huafeng provides comprehensive on-site construction services and technical guidance designed to facilitate successful project completion regardless of contractor experience levels. Installation support begins with pre-construction site evaluation where technical specialists assess actual field conditions and collaborate with clients to confirm optimal construction site organization including designated product staging areas, secure storage zones for panels and accessories, and dedicated space for field fabrication operations when required. Product arrival and warehousing procedures follow systematic protocols that prevent damage and facilitate efficient panel retrieval during installation. Upon delivery, installation teams verify shipment contents against packing documentation, organize panels according to packaging identification cards that reference sectioned floor plans and component number lists, and position materials in designated storage areas that protect panels from weather exposure and physical damage. This organizational framework enables installers to quickly locate specific panels according to the numbered installation sequence, minimizing handling and reducing the risk of damage from repeated movement.

-

On-Site Technical Support and Quality Verification

Installation technicians provide hands-on technical guidance throughout the construction process, conducting mandatory pre-installation site visits to inspect prepared substrate conditions, verify availability of required tools including specialized panel seamers, edge-locking machines, and proper hand tools, and confirm adequate supplies of essential accessories including rivets, structural adhesives, screws, and weatherproofing materials. Pre-installation meetings include thorough review of detailed installation drawings, discussion of critical work sequence requirements, and comprehensive safety briefings that address fall protection, tool safety, and weather-related precautions. During active installation phases, technical specialists monitor work quality and provide real-time problem-solving support for unexpected field conditions. Upon installation completion, comprehensive performance testing validates system integrity through water testing protocols that simulate actual weather conditions and verify zero-leakage performance. Final acceptance procedures include detailed client walkthrough of completed installations, formal documentation of any punch-list items requiring attention, signature confirmation of satisfactory completion, and delivery of maintenance guidelines that inform building owners about recommended care procedures to maximize system service life.

Performance Advantages and Long-Term Value Proposition

Flat Lock Seam Metal Wall Panels deliver exceptional performance characteristics that justify their specification across demanding applications. Weather resistance capabilities extend from extreme cold environments at -40°C through hot climate conditions reaching 80°C, with inherent UV resistance and corrosion protection that maintains appearance and structural integrity throughout decades of service. Wind pressure resistance testing confirms these systems withstand typhoon-force winds exceeding level 12 intensity, providing crucial protection for buildings in coastal regions and areas subject to severe weather events. The lightweight nature of metal panel systems creates significant structural advantages, with typical installed weights ranging from 3 to 5 kilograms per square meter that dramatically reduce dead loads compared to traditional masonry or precast concrete cladding alternatives. This weight reduction enables more efficient structural framing design and may allow building height increases without exceeding foundation capacity limits. Environmental sustainability represents another compelling advantage, with metal panels manufactured from 100% recyclable materials through energy-efficient production processes that minimize environmental impact. The inherent recyclability ensures that panels retain significant value at end-of-service-life, supporting circular economy principles and reducing long-term waste streams.

Conclusion

Flat Lock Seam Metal Wall Panels represent the optimal solution for contemporary building envelope applications demanding superior aesthetics combined with exceptional durability and performance characteristics.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a premier China Flat Lock Seam Metal Wall Panels manufacturer, China Flat Lock Seam Metal Wall Panels supplier, and China Flat Lock Seam Metal Wall Panels factory delivering exceptional High Quality Flat Lock Seam Metal Wall Panels at competitive Flat Lock Seam Metal Wall Panels price points. Established in 2018, our company combines extensive engineering design experience with proven construction expertise, operating 7 raw material production lines and more than 20 plate production machines supported by over 20 patent certificates alongside CE, ISO, and SGS certifications. We proudly collaborate with Fortune 500 companies, offering customized production capabilities and comprehensive one-stop procurement from raw materials through finished accessories. Our services include design optimization, rigorous raw material quality testing, fully customized products, multiple packaging options, and flexible transportation methods. As a trusted China Flat Lock Seam Metal Wall Panels wholesale provider, we deliver complete solutions with Flat Lock Seam Metal Wall Panels for sale that meet the highest international standards. Contact us today at huafeng@hfmetalroof.com to discuss your project requirements and discover how our expertise can elevate your building envelope performance.

References

1. "Architectural Sheet Metal Manual" - Sheet Metal and Air Conditioning Contractors' National Association (SMACNA)

2. "Metal Architecture: Design and Construction" - Thomas Herzog, Julius Natterer, Roland Schweitzer, Michael Volz, Wolfgang Winter

3. "Building Envelope Design Guide - Wall Systems" - National Institute of Building Sciences Whole Building Design Guide Committee

4. "Specification for Metal Roof and Wall Panels" - American Society for Testing and Materials (ASTM) Standards Committee