Are you facing constant roof leaks from exposed fasteners or struggling with roofing systems that can't withstand harsh weather conditions? Mechanical Lock Metal Roofing offers a superior solution with concealed fasteners that eliminate water infiltration points while providing exceptional wind resistance and longevity. This comprehensive guide explores everything you need to know about mechanical lock panels, from technical specifications to installation best practices, helping you make an informed decision for your next commercial or industrial roofing project.

What Are Mechanical Lock Metal Roofing Systems?

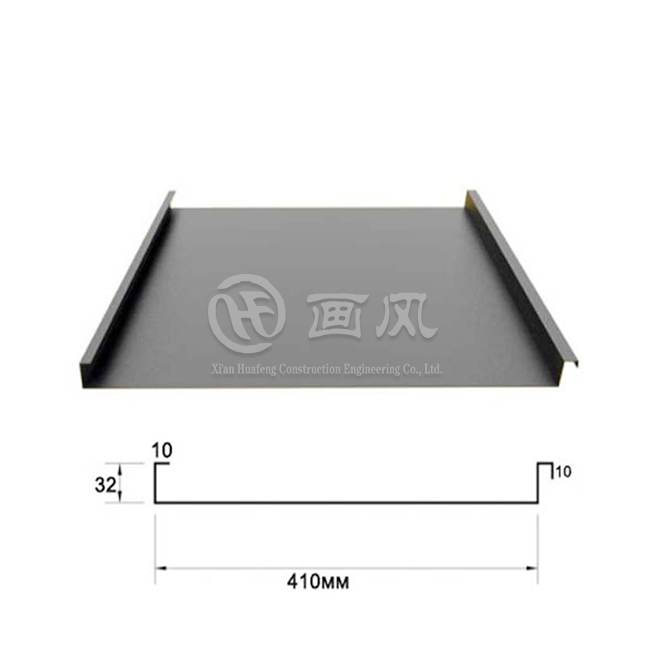

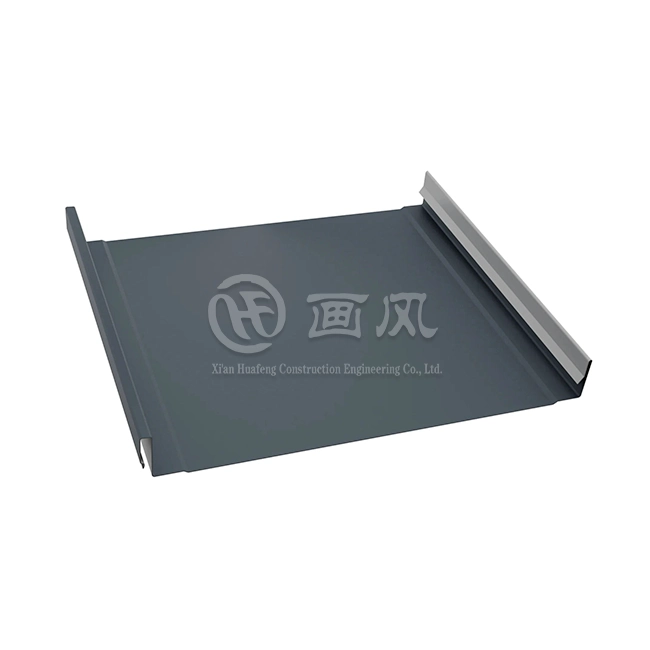

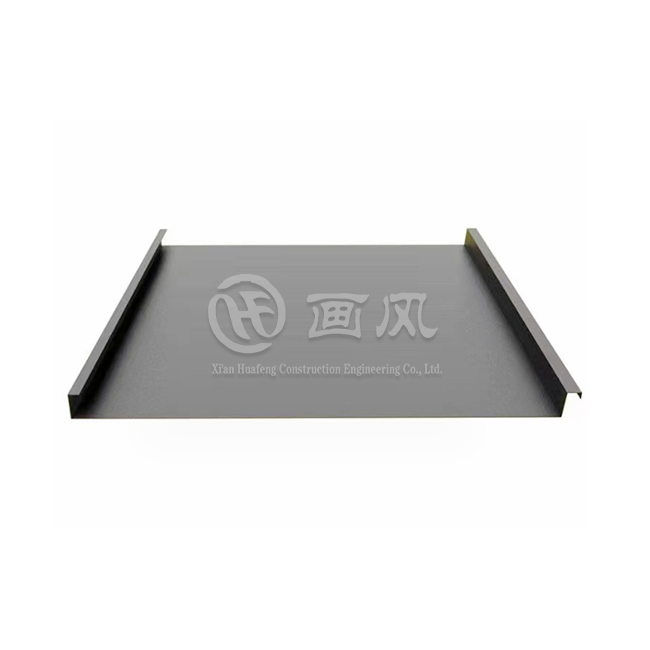

Mechanical Lock Metal Roofing represents a sophisticated standing seam panel system designed specifically for commercial, industrial, and increasingly residential applications where superior weather resistance and durability are paramount. Unlike traditional roofing systems with exposed fasteners that create potential leak points, these panels feature interlocking seams that are mechanically folded together, creating a watertight barrier that protects buildings for decades. The system utilizes concealed clips fastened to the roof deck, with vertical panel legs that align and fold over these clips to create either single lock or double lock seams, depending on project requirements and environmental conditions. The engineering behind Mechanical Lock Metal Roofing systems addresses critical challenges faced by building owners and contractors. Each panel features precision-formed male and female legs manufactured to exacting tolerances, ensuring consistent alignment during installation. The concealed clip system allows for thermal expansion and contraction of the metal panels without compromising the roof's integrity, a crucial consideration in regions experiencing significant temperature fluctuations. Modern mechanical lock systems incorporate advanced metallurgy and coating technologies, with materials ranging from aluminum-magnesium-manganese alloys to galvanized steel, galvalume, stainless steel, copper, and titanium-zinc, each offering distinct advantages for specific applications. With panel widths typically ranging from 300 to 500 millimeters and rib heights between 25 and 32 millimeters, these systems provide architects and engineers with flexibility in achieving both aesthetic goals and performance requirements.

-

Single Lock vs. Double Lock Seam Configurations

The choice between single lock and double lock configurations significantly impacts both the performance characteristics and installation requirements of Mechanical Lock Metal Roofing systems. Single lock seams involve one fold of the panel legs, creating a 90-degree mechanical connection that provides adequate weather protection for buildings in moderate climates with minimal exposure to extreme weather conditions. This configuration offers advantages in terms of installation speed and ease of repair, as the single fold requires less labor and specialized equipment operation. However, single lock seams may not provide sufficient security against water infiltration in low-slope applications or regions experiencing heavy rainfall and snow loads. Double lock seams represent the industry standard for high-performance applications, featuring two complete folds that create a 180-degree mechanical connection. This configuration delivers superior weather resistance, enhanced structural integrity, and improved aesthetic appeal with a cleaner, more vertical seam profile. The double lock system creates redundant barriers against moisture penetration and provides greater wind uplift resistance, making it the preferred choice for commercial warehouses, manufacturing facilities, airport terminals, and other critical infrastructure. While requiring more skilled installation and specialized seaming equipment, double lock Mechanical Lock Metal Roofing systems offer dramatically extended service life, often performing flawlessly for thirty years or more with minimal maintenance requirements.

-

Materials and Specifications for Optimal Performance

Selecting appropriate materials for Mechanical Lock Metal Roofing systems requires careful consideration of environmental exposure, structural requirements, aesthetic preferences, and lifecycle cost analysis. Aluminum-magnesium-manganese alloys, available in 3003, 3004, and 5052 grades, provide exceptional corrosion resistance and lightweight properties, making them ideal for coastal environments and structures with limited load-bearing capacity. These alloys naturally form a protective oxide layer that enhances durability while maintaining malleability for complex architectural forms. Galvanized and galvalume steel options offer superior strength and rigidity, with zinc or aluminum-zinc coatings providing sacrificial protection against rust and corrosion. Premium coatings such as polyvinylidene fluoride, commonly known as PVDF or Kynar 500, deliver outstanding color retention and chalk resistance, maintaining aesthetic appeal for decades even under intense ultraviolet exposure. Stainless steel grades 304 and 316 represent the premium tier of Mechanical Lock Metal Roofing materials, offering unparalleled corrosion resistance and structural integrity for harsh industrial environments or architectural statements requiring distinctive metallic finishes. Copper and titanium-zinc materials provide unique aesthetic evolution over time, developing natural patinas that many architects specify for heritage restoration projects or contemporary designs seeking organic material expression. Panel thickness specifications typically range from 0.5 to 1.0 millimeters, with thicker gauges providing enhanced structural capacity and resistance to impact damage. Surface treatments including polyester and PVDF coatings in thousands of custom colors enable precise matching to corporate branding or architectural vision, while coating thickness specifications of 25 to 40 micrometers on exposed surfaces ensure long-term protection against weathering and chemical exposure.

Installation Requirements and Best Practices

Professional installation of Mechanical Lock Metal Roofing systems demands specialized knowledge, proper equipment, and meticulous attention to detail throughout the construction process. The foundation of successful installation begins with substrate preparation, ensuring that structural decking, whether steel purlins, solid wood sheathing, or insulated metal panels, provides adequate support and proper alignment for panel installation. Roof slopes of at least 5 degrees are typically specified for standard installations, though low-slope applications down to 0.5:12 pitch can be accommodated when combined with appropriate underlayment systems and hot-melt seam sealants that provide additional moisture protection. Installation technicians must account for thermal expansion characteristics of the chosen material, with properly specified expansion clips positioned at calculated intervals to allow panel movement without creating stress concentrations that could compromise seam integrity. The mechanical seaming process represents the critical phase where panel system performance is ultimately determined. Professional contractors utilize either hand-operated or electric seaming tools specifically designed for the panel profile being installed, with electric seamers providing more consistent seam quality and significantly faster installation rates on large projects. Proper seamer adjustment and operation technique directly impact seam tightness and uniformity, with insufficient seaming pressure resulting in inadequate weather seals while excessive force can damage panel coatings or deform metal substrates. Quality control protocols should include regular seam inspections throughout installation, verifying that double lock seams achieve complete 180-degree closure and that concealed clips remain properly engaged. Installation teams working with Mechanical Lock Metal Roofing must possess appropriate training and certification, understanding not only the mechanical aspects of panel installation but also critical safety protocols for working at height and managing large, unwieldy metal components in varying weather conditions.

-

Climate Considerations and Performance Standards

Understanding how Mechanical Lock Metal Roofing systems perform across diverse climate conditions enables informed material selection and installation specification decisions. In regions experiencing heavy snow loads, panel strength calculations must account for accumulated weight, with rib height and material thickness specifications adjusted to maintain structural integrity under maximum expected loads exceeding 1.5 kilonewtons per square meter. The concealed fastener design of mechanical lock systems provides distinct advantages in freeze-thaw cycling conditions, as the absence of penetrations through the panel surface eliminates pathways for ice dam formation and subsequent water infiltration that plagues exposed fastener systems. High wind environments require particular attention to clip spacing and fastener specifications, with properly engineered Mechanical Lock Metal Roofing installations capable of withstanding wind speeds exceeding 90 miles per hour or 144 kilometers per hour, meeting or surpassing International Building Code requirements for hurricane-prone regions. Thermal performance considerations significantly influence the overall building energy efficiency and occupant comfort when specifying Mechanical Lock Metal Roofing systems. Metal's inherent reflectivity can be enhanced through specialized cool roof coatings that reflect solar radiation and reduce heat absorption, potentially decreasing cooling energy consumption by fifteen to twenty-five percent in hot climates. Conversely, the air cavity created between the standing seam panels and roof substrate provides modest insulation value while facilitating ventilation that prevents moisture condensation. Fire resistance represents another critical performance characteristic, with properly specified Mechanical Lock Metal Roofing systems achieving Class A fire ratings under ASTM E108 and EN 13501 testing protocols, providing non-combustible protection for building contents and occupants while potentially qualifying for insurance premium reductions and regulatory compliance advantages.

Design Flexibility and Architectural Applications

Modern Mechanical Lock Metal Roofing systems transcend purely functional considerations, offering architects and designers remarkable creative freedom to realize ambitious aesthetic visions while maintaining rigorous performance standards. The clean, linear geometry of standing seam profiles complements contemporary architectural language, with vertical seam lines creating visual rhythm that emphasizes building proportions and directional flow. Panel lengths extending up to twelve meters or forty feet enable uninterrupted runs from ridge to eave on many structures, eliminating horizontal joints that disrupt visual continuity while simultaneously reducing potential leak points. This capability has made mechanical lock systems increasingly popular for low-slope, long-span roof designs that define modern commercial and institutional architecture, from airport terminals and convention centers to educational facilities and corporate campuses. Color selection and finish options expand design possibilities exponentially, with standard color charts offering hundreds of choices while custom color matching services enable precise coordination with existing building elements or corporate identity requirements. Metallic and textured finishes create visual depth and interest, while matte surfaces provide sophisticated understatement appropriate for contexts where roof visibility necessitates aesthetic sensitivity. The inherent malleability of Mechanical Lock Metal Roofing materials permits curved and radiused applications, allowing architects to incorporate dramatic barrel vaults, wave forms, and sculptural roof geometries that would prove prohibitively expensive or technically impossible with alternative roofing systems. This design flexibility extends to integration with other building systems, as standing seam profiles accommodate photovoltaic panel mounting systems, skylight installations, and rooftop mechanical equipment with minimal roof penetrations when proper planning and specialized accessories are employed.

-

Sustainability and Lifecycle Benefits

Environmental responsibility increasingly drives material selection decisions in contemporary construction, positioning Mechanical Lock Metal Roofing as a sustainable choice that aligns with green building certification requirements and corporate sustainability commitments. Metal roofing materials contain significant recycled content, often exceeding sixty percent for steel products and potentially reaching one hundred percent for aluminum systems, reducing embodied energy and raw material extraction impacts. At end of service life, Mechanical Lock Metal Roofing panels are completely recyclable, unlike asphalt shingles and other petroleum-based roofing products that contribute millions of tons to landfills annually. This circularity represents a fundamental advantage in lifecycle environmental assessment, with metal roofing systems demonstrating lower overall environmental footprints when considering extraction, manufacturing, transportation, installation, maintenance, and disposal phases. Durability and longevity characteristics of Mechanical Lock Metal Roofing deliver both environmental and economic benefits over extended building lifecycles. While initial material and installation costs typically exceed conventional roofing alternatives, properly specified and installed mechanical lock systems routinely provide thirty to fifty years of service with minimal maintenance requirements, compared to fifteen to twenty-year replacement cycles for asphalt composition roofing. This extended service life dramatically reduces lifecycle costs, including avoided replacement material consumption, installation labor, building disruption, and waste disposal expenses. Energy performance advantages further enhance sustainability credentials, with reflective coatings reducing urban heat island effects while decreasing building cooling loads. When combined with facility energy modeling and integrated design approaches, Mechanical Lock Metal Roofing contributes to LEED certification, BREEAM ratings, and other green building recognition programs that increasingly influence commercial real estate valuations and tenant attraction.

Quality Assurance and Manufacturing Excellence

Manufacturing quality directly determines the long-term performance and aesthetic durability of Mechanical Lock Metal Roofing systems, making supplier selection a critical decision factor for architects, contractors, and building owners. Advanced manufacturing facilities employ sophisticated roll-forming equipment capable of producing panels with tolerances measured in tenths of millimeters, ensuring consistent panel geometry that facilitates efficient installation and proper seam formation. Multiple quality control checkpoints throughout the manufacturing process verify coating adhesion, thickness uniformity, color consistency, and dimensional accuracy before panels are released for shipment. Leading manufacturers maintain comprehensive material traceability systems, documenting coil origin, coating specifications, and production parameters for every panel produced, enabling quality investigation and warranty administration should field performance issues emerge. Xi'an Huafeng Construction Engineering Co., Ltd. exemplifies manufacturing excellence in the Mechanical Lock Metal Roofing industry, operating three state-of-the-art production facilities equipped with seven color coating lines, one laminating line, and ten longitudinal and transverse shearing production lines. With over forty specialized machines including shearing equipment, pressing systems, and precision bending apparatus, the company maintains production capacity exceeding one thousand tons monthly while adhering to international quality standards including ISO9001, ISO14001, and SGS certifications. This manufacturing infrastructure supports customized production runs meeting specific project requirements, from panel width and rib height variations to specialized coatings and custom color formulations. Comprehensive testing protocols verify critical performance characteristics including salt spray resistance, coating adhesion, hardness, impact resistance, film thickness, acid resistance, weather resistance, and color consistency, ensuring that every panel meets or exceeds specified performance standards.

-

Technical Support and Project Services

Successful Mechanical Lock Metal Roofing projects require more than quality materials, demanding comprehensive technical support and engineering services throughout design, procurement, and construction phases. Leading suppliers provide structural modeling services utilizing three-dimensional building information modeling software to analyze load distributions, verify structural adequacy, and identify potential installation challenges before fabrication begins. Drainage system simulation ensures adequate roof slope and strategically positioned outlets prevent water ponding that could compromise waterproofing performance or create unacceptable roof loading conditions. Material specification advisory services help architects and engineers navigate complex material selection decisions, considering factors including environmental exposure, structural requirements, aesthetic goals, maintenance capabilities, and budget constraints to identify optimal solutions for specific project contexts. Detailed shop drawing development represents another critical service offering, with experienced engineering teams producing comprehensive installation drawings that break down complex roof geometries into manageable fabrication and installation sequences. These drawings specify panel lengths, clip locations, expansion joint positions, flashing details, and accessory components, providing clear guidance to installation crews while minimizing field questions and potential errors. Sample production capabilities enable stakeholders to physically evaluate proposed panel profiles, materials, colors, and finishes before committing to full production orders, reducing the risk of aesthetic dissatisfaction or performance mismatches. Throughout construction, responsive technical support staff address field conditions, installation questions, and coordination issues, ensuring project continuity and quality outcomes. Post-installation services including acceptance testing, maintenance guidance, and warranty administration complete the comprehensive support framework that distinguishes industry-leading Mechanical Lock Metal Roofing suppliers.

Conclusion

Mechanical Lock Metal Roofing systems deliver unmatched durability, weather resistance, and design versatility for demanding commercial and industrial applications. By understanding panel configurations, material options, installation requirements, and quality considerations, building stakeholders can confidently specify solutions that protect investments for decades.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a China Mechanical Lock Metal Roofing manufacturer and China Mechanical Lock Metal Roofing supplier committed to delivering world-class roofing solutions. Established in 2018, this China Mechanical Lock Metal Roofing factory combines cutting-edge manufacturing technology with comprehensive engineering expertise, recognized as a Shaanxi Province high-tech enterprise holding first-level building curtain wall qualifications and third-level building steel structure qualifications. Our High Quality Mechanical Lock Metal Roofing products include aluminum-magnesium-manganese plates, titanium-zinc plates, color-coated steel, and stainless steel systems, all manufactured at our 200,000 square meter Anhui production facility and processing plants in Hangzhou and Xi'an.

As a trusted China Mechanical Lock Metal Roofing wholesale partner, we provide one-stop solutions from design and 3D structural modeling through precision manufacturing and seamless installation, backed by more than twenty registered patents, ISO9001, ISO14001, and SGS certifications. Our Mechanical Lock Metal Roofing for sale delivers exceptional value with competitive Mechanical Lock Metal Roofing price structures, 30-year warranties, and proven performance in landmark projects including Xiongan Station, Xi'an International Convention Center, and Inner Mongolia Tongliao Art Museum. Partner with us for customized solutions, expert technical support, and the quality assurance that only comes from a dedicated China Mechanical Lock Metal Roofing supplier with extensive Fortune 500 collaboration experience. Contact us at huafeng@hfmetalroof.com to discuss your project requirements and discover how our expertise transforms architectural visions into enduring realities. Bookmark this guide for future reference as you plan your next roofing project.

References

1. Metal Construction Association, "Guidelines for Concealed Attachment Metal Wall and Roof Panel Systems," authored by Technical Advisory Group, Metal Construction Association Technical Bulletin

2. Baker, William C., "Standing Seam Metal Roof Systems: Design, Engineering, and Performance," Journal of Architectural Engineering Technology

3. American Society for Testing and Materials, "Standard Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the Hot-Dip Process," ASTM International Standards Committee

4. National Roofing Contractors Association, "Metal Panel Roof Systems Design Manual," edited by Technical Operations Division, NRCA Publications