Choosing the right roofing system for your commercial or industrial building can feel overwhelming, especially when water infiltration concerns keep you awake at night worrying about costly repairs and operational disruptions. The Snap Lock Standing Seam Roof emerges as a revolutionary solution that addresses these critical pain points while delivering exceptional durability and aesthetic appeal. This comprehensive guide examines both the compelling advantages and important limitations of snap-lock roofing technology, empowering property owners and facility managers to make informed decisions that protect their investments for decades to come.

What Makes Snap Lock Standing Seam Roof Systems Unique?

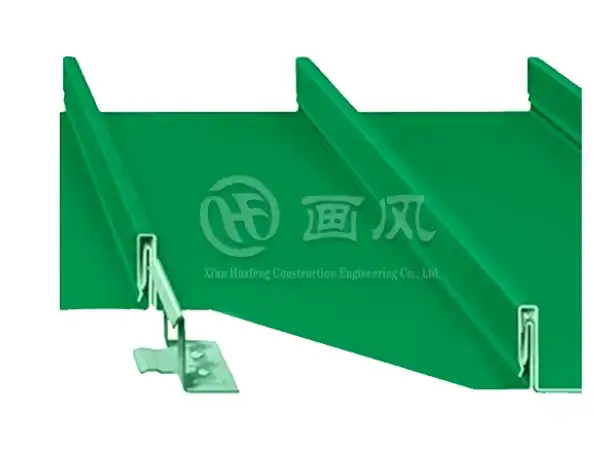

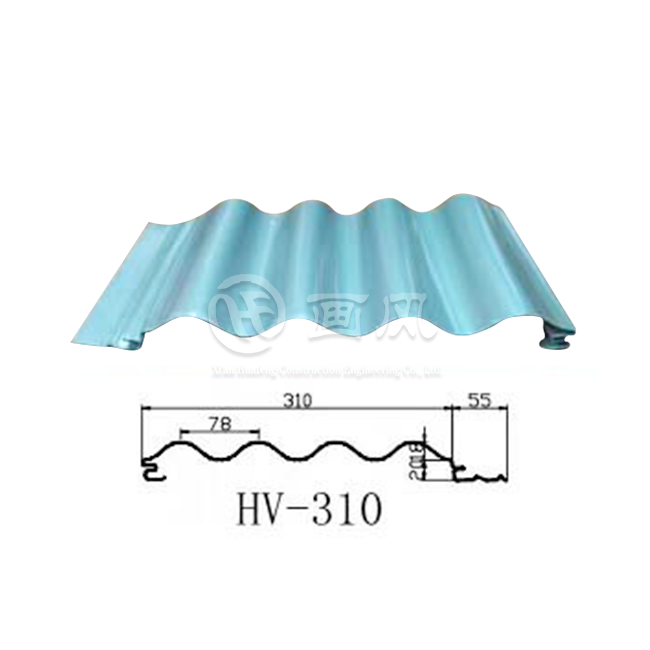

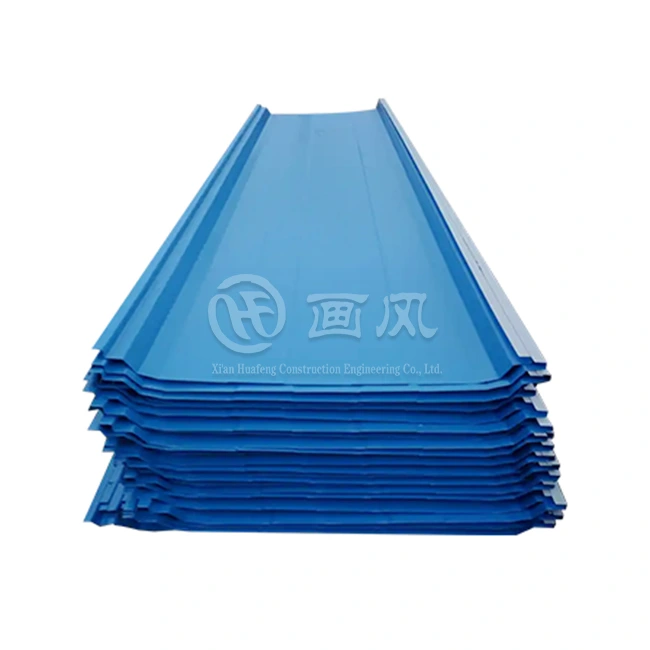

The Snap Lock Standing Seam Roof represents a significant advancement in metal roofing technology, featuring an innovative interlocking panel design that eliminates exposed fasteners entirely. Unlike traditional roofing systems that rely on visible screws penetrating the roof surface, snap-lock panels incorporate male and female legs that mechanically engage with each other, creating a continuous weathertight barrier across the entire roof plane. This ingenious engineering approach positions concealed clips underneath the panel connections, securing the roofing material to the structural deck while maintaining complete protection from the elements. The system derives its name from the audible snap that occurs when properly trained installers join adjacent panels together during the installation process. Manufacturing facilities produce Snap Lock Standing Seam Roof panels with precise tolerances, typically featuring standing seam heights of 45mm that channel water efficiently away from the building envelope. The effective panel widths generally range from 300mm to 600mm, providing flexibility for various architectural applications while maintaining structural integrity. Advanced roll-forming technology enables manufacturers to create continuous panel lengths extending up to thirteen meters, dramatically reducing the number of horizontal seams and potential leak points compared to shorter panel configurations. This customization capability allows architects and engineers to design roofing systems that complement building proportions while optimizing water management performance across diverse climate zones and weather exposure conditions.

-

Material Options and Performance Characteristics

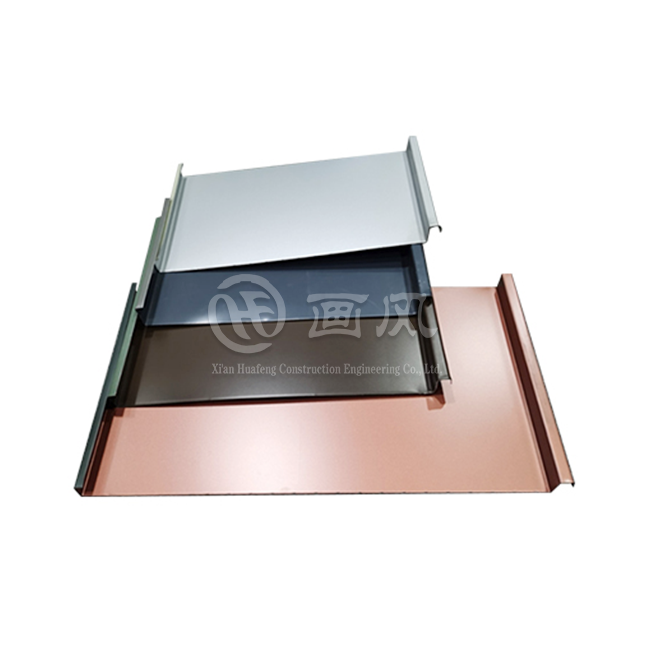

Professional-grade Snap Lock Standing Seam Roof systems utilize multiple substrate materials, each engineered to deliver specific performance attributes suited to distinct environmental conditions and budgetary considerations. Galvalume steel substrates, composed of 55% aluminum, 43.4% zinc, and 1.6% silicon, provide corrosion resistance approximately two to six times greater than conventional galvanized steel products, with documented service lives extending thirty to fifty years in most climatic regions. These steel-based systems prove particularly advantageous in dry inland areas where moisture exposure remains moderate and cost-effectiveness factors heavily into project feasibility assessments. The galvalume coating forms a protective barrier that self-heals minor surface scratches, maintaining long-term durability even when subjected to thermal cycling and ultraviolet radiation exposure throughout decades of continuous service. Aluminum alloy alternatives represent the premium choice for Snap Lock Standing Seam Roof applications in coastal environments and high-humidity regions where salt spray and persistent moisture challenge conventional materials. With a density of just 2.7 grams per cubic centimeter, aluminum panels significantly reduce structural loading requirements while delivering exceptional resistance to atmospheric corrosion that can compromise steel substrates in marine climates. The inherent recyclability of aluminum materials aligns with sustainable building practices, as these panels maintain 100% of their material value at end-of-life and can be reprocessed indefinitely without quality degradation. Property owners investing in aluminum-based Snap Lock Standing Seam Roof systems frequently realize service lives exceeding fifty years, with minimal maintenance requirements and excellent retention of aesthetic appearance throughout the extended operational period.

Specialized applications in chemical processing facilities and extreme environmental conditions may warrant stainless steel Snap Lock Standing Seam Roof installations, utilizing grades such as 304 or 316L that deliver unparalleled corrosion resistance in the most demanding circumstances. Though these premium materials command significantly higher initial investment costs, their exceptional durability justifies the expenditure when building function or location creates unusually aggressive exposure conditions. Surface coating technologies further enhance substrate performance, with polyvinylidene fluoride coatings providing superior weather resistance and color retention exceeding twenty years, while more economical polyester coatings serve adequately in less harsh environmental contexts where budget constraints require value optimization without compromising fundamental performance requirements.

Key Advantages of Snap Lock Standing Seam Roof Systems

-

Superior Weather Protection and Leak Prevention

The most compelling benefit driving adoption of Snap Lock Standing Seam Roof technology centers on exceptional leak resistance achieved through complete elimination of fastener penetrations through the roofing panels themselves. Traditional roofing systems create thousands of potential water entry points where screws pierce the protective metal surface, with each penetration representing a vulnerability that requires ongoing maintenance attention as fastener gaskets age and deteriorate over time. The concealed clip attachment methodology employed in Snap Lock Standing Seam Roof construction positions all fasteners beneath the interlocking panel connections, where they remain permanently shielded from direct weather exposure and immune to the thermal cycling that accelerates fastener degradation in exposed-fastener roof assemblies. Field performance data consistently demonstrates that properly installed Snap Lock Standing Seam Roof systems deliver weathertight protection capable of withstanding wind speeds exceeding 60 meters per second, equivalent to 216 kilometers per hour under standardized European testing protocols. When installation crews position fixing clips at recommended spacing intervals not exceeding 1.5 meters, the resulting assemblies achieve wind uplift resistance ratings of 3.0 kilonewtons per square meter or greater, providing substantial safety margins against the extreme weather events becoming increasingly frequent as global climate patterns shift. This robust wind performance stems from the mechanical interlock between adjacent panels combined with strategically positioned retention clips that distribute uplift forces evenly across the roof structure rather than concentrating stress at isolated attachment points.

-

Extended Service Life and Exceptional Durability

Investment in Snap Lock Standing Seam Roof systems delivers remarkable longevity, with properly specified and installed assemblies routinely providing forty to sixty years of reliable service with minimal intervention requirements beyond periodic inspections and routine debris removal. This extended operational lifespan dramatically outperforms conventional asphalt shingle roofing, which typically requires complete replacement every fifteen to twenty years, or corrugated metal panels with exposed fasteners that necessitate fastener replacement every decade as gasket materials deteriorate. The superior durability of Snap Lock Standing Seam Roof construction stems from multiple synergistic factors, including the absence of fastener penetrations that initiate corrosion, the inherent strength of continuous metal panels spanning roof purlins without vulnerable laps, and the protective surface coatings engineered to resist ultraviolet degradation and maintain structural integrity throughout decades of continuous weather exposure. Manufacturing quality control protocols ensure that Snap Lock Standing Seam Roof panels meet stringent dimensional tolerances and material specifications before leaving production facilities equipped with seven color coating lines, advanced laminating systems, and comprehensive testing laboratories. Substrate thickness specifications typically range from 0.5mm to 1.2mm depending on structural requirements and expected loading conditions, with thicker gauges providing enhanced resistance to impact damage and snow accumulation forces. Premium manufacturers back their products with thirty-year warranties covering both material defects and system performance, demonstrating confidence in long-term durability that property owners can rely upon when evaluating lifecycle cost comparisons against alternative roofing technologies.

-

Streamlined Installation Process and Cost Efficiency

The innovative snap-together connection methodology that defines Snap Lock Standing Seam Roof systems delivers substantial installation efficiency advantages compared to mechanically seamed alternatives requiring specialized equipment and highly skilled labor. Professional roofing crews report installation productivity improvements of thirty to fifty percent when working with snap-lock panels versus systems requiring on-site mechanical seaming operations, as the simplified connection process eliminates time-consuming crimping procedures and reduces the technical expertise necessary for successful field assembly. This efficiency translates directly into reduced labor costs for building owners, as installation teams complete projects faster while achieving consistent quality results that meet or exceed manufacturer specifications for weathertight performance. The accessibility of Snap Lock Standing Seam Roof installation to moderately skilled workers following brief training programs expands the available contractor pool and promotes competitive bidding environments that benefit project budgets. Unlike mechanical seaming operations requiring specialized rolling equipment costing up to four hundred dollars per week per seaming machine, snap-lock installations proceed using standard hand tools supplemented by basic panel alignment fixtures. This equipment simplicity not only reduces direct tool rental expenses but also minimizes project schedule risk associated with equipment failures or availability constraints that can derail critical-path construction activities. Property owners benefit from faster project completion timelines that reduce general condition costs and enable earlier building occupancy, accelerating return on investment and minimizing business disruption during reroofing operations on occupied facilities.

-

Contemporary Aesthetics and Architectural Flexibility

Snap Lock Standing Seam Roof systems deliver clean, sophisticated visual appeal through concealed fastener technology that creates uninterrupted lines flowing continuously from ridge to eave without visible hardware interrupting the elegant metal panel profiles. This refined aesthetic has driven widespread adoption across commercial, industrial, and high-end residential applications where architectural expression matters and building owners seek distinctive roofing solutions that enhance property value through superior curb appeal. The vertical seam orientation characteristic of standing seam metal roofing creates visual interest and architectural drama particularly effective on contemporary building designs, while proving equally appropriate for traditional structures where premium material quality and craftsmanship command respect. Comprehensive color selection options enable designers to specify Snap Lock Standing Seam Roof finishes precisely coordinated with overall building palettes, with RAL standard colors and custom formulations available to satisfy even the most exacting aesthetic requirements. Advanced coating technologies maintain color vibrancy and surface gloss throughout extended service periods, with premium polyvinylidene fluoride finishes demonstrating exceptional fade resistance that preserves architectural intent for decades after initial installation. The ability to manufacture panels in customized lengths up to thirteen meters enables designers to minimize horizontal seams on long roof slopes, creating particularly striking visual effects on large-format buildings while simultaneously optimizing weather protection through reduced potential leak points.

Important Limitations of Snap Lock Standing Seam Roof Technology

-

Slope Restrictions and Application Constraints

Despite numerous performance advantages, Snap Lock Standing Seam Roof systems impose specific slope limitations that restrict their application on certain building configurations, particularly structures featuring flat or very low-pitch roof designs. Industry standards and manufacturer specifications typically prohibit snap-lock panel installation on roof slopes less than 3:12 pitch, equivalent to approximately 14 degrees from horizontal, due to increased water ponding risk and reduced gravity-driven drainage capacity that compromises the weathertight integrity of snap-together panel connections. Building owners with existing low-slope roof structures requiring metal roofing solutions must instead specify mechanically seamed standing seam systems featuring crimped panel connections that create tighter weatherproof seals capable of reliable performance on slopes as shallow as 1:12 pitch when properly detailed with appropriate underlayment systems. This slope limitation reflects fundamental physics governing water behavior on building surfaces, as shallow roof pitches reduce drainage velocity and increase the duration that moisture remains in contact with seam connections, elevating the probability of water infiltration through capillary action or wind-driven forces. The snap-together connection employed in Snap Lock Standing Seam Roof construction, while highly effective on adequately sloped applications, cannot achieve the absolute weathertight seal provided by double-crimped mechanical seams that physically compress panel edges together with substantial force. Architects and engineers must carefully evaluate existing roof geometry during design development phases, ensuring that Snap Lock Standing Seam Roof systems receive specification only on buildings meeting minimum slope requirements to avoid costly performance failures and potential liability exposure.

-

Climate Suitability and Performance Considerations

Geographic location and local climate patterns significantly influence Snap Lock Standing Seam Roof performance and appropriateness, with certain environmental conditions favoring alternative roofing technologies better suited to extreme weather exposure. Regions experiencing persistent heavy rainfall or substantial snow accumulation may realize superior long-term results from mechanically seamed standing seam systems that deliver enhanced weathertight protection through crimped panel connections, particularly when roof slopes barely exceed minimum requirements for snap-lock application. The mechanical interlock created by double-crimped seams provides additional security margin against water intrusion during extended storm events when wind-driven rain or melting snow tests roofing system limits. Installation quality becomes critically important in challenging climate zones, as even minor deviations from manufacturer specifications can compromise Snap Lock Standing Seam Roof performance under severe weather conditions. Proper clip spacing, adequate panel engagement, and correct sealant application at termination details all require meticulous attention during field installation to ensure design performance levels materialize in actual service conditions. Building owners in regions prone to extreme weather should engage experienced roofing contractors with documented expertise installing snap-lock systems and insist upon enhanced quality assurance protocols verifying compliance with technical requirements before accepting completed work. Strategic investment in premium underlayment materials and upgraded flashing details further mitigates risk in demanding environmental contexts where roofing system failure carries severe consequences.

-

Initial Investment Requirements

While Snap Lock Standing Seam Roof systems deliver exceptional long-term value through extended service life and minimal maintenance requirements, the initial capital investment typically exceeds budgets for conventional roofing alternatives by substantial margins. Property owners should anticipate installed costs approximately double those of asphalt shingle applications or exposed-fastener metal roofing, with final project pricing influenced by material gauge selection, coating specification, roof complexity, and regional labor market conditions. This significant upfront expenditure creates financial hurdles for cost-constrained projects or building owners focused exclusively on first-cost optimization without adequate consideration of lifecycle economic performance. Sophisticated financial analysis reveals that Snap Lock Standing Seam Roof systems frequently deliver superior return on investment when evaluated across complete building ownership periods, as avoided replacement cycles, reduced maintenance expenditures, and lower energy consumption through reflective coating technologies offset premium initial costs. Property owners should develop comprehensive lifecycle cost models incorporating realistic assumptions about competing system performance, maintenance requirements, and replacement timing to make informed decisions based on total economic impact rather than simplistic first-cost comparisons. The ability to source Snap Lock Standing Seam Roof materials from established manufacturers offering competitive pricing, flexible minimum order quantities starting at 500 square meters, and efficient delivery scheduling within fifteen to twenty days enables cost-effective procurement that maximizes budget efficiency while maintaining uncompromising quality standards.

-

Installation Expertise Requirements

Although Snap Lock Standing Seam Roof systems offer simplified installation compared to mechanically seamed alternatives, successful project outcomes still demand experienced contractors thoroughly familiar with metal roofing principles and manufacturer-specific technical requirements. Improper panel alignment, inadequate clip engagement, or incorrect fastener placement can compromise system performance and void manufacturer warranties, leaving building owners exposed to premature failures and costly remediation expenses. The prevalence of contractors claiming metal roofing capabilities without demonstrated snap-lock installation experience creates risk for unwary property owners who may unknowingly select inadequately qualified installation teams based primarily on attractive bid pricing. Due diligence during contractor selection processes should include verification of previous Snap Lock Standing Seam Roof project experience, review of manufacturer training certifications, and direct contact with references willing to discuss installation quality and post-installation service responsiveness. Sophisticated building owners may require prospective contractors to submit detailed installation procedures and quality control protocols as part of bid packages, enabling informed evaluation of technical competency before awarding contracts. Investment in experienced installation teams pays dividends through superior workmanship that maximizes system longevity and minimizes callback expenses addressing field problems stemming from inadequate construction practices. Manufacturers offering comprehensive technical support and installation guidance provide valuable resources that help ensure successful project outcomes even when working with contractors possessing limited snap-lock specific experience.

Conclusion

The Snap Lock Standing Seam Roof delivers compelling performance advantages through superior leak resistance, exceptional durability extending forty to sixty years, streamlined installation efficiency, and refined architectural aesthetics that enhance property value. However, prudent building owners must carefully evaluate slope limitations, climate suitability, initial investment requirements, and contractor qualification before committing to this premium roofing technology for specific applications.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a leading China Snap Lock Standing Seam Roof manufacturer, China Snap Lock Standing Seam Roof supplier, and China Snap Lock Standing Seam Roof factory, delivering high-quality metal roofing solutions since our establishment in Shaanxi Province in 2018. As a recognized high-tech enterprise holding first-level building curtain wall qualifications and third-level building steel structure qualifications, we offer China Snap Lock Standing Seam Roof wholesale options and competitive Snap Lock Standing Seam Roof price structures. Our comprehensive manufacturing infrastructure includes a 200,000-square-meter raw material production plant in Anhui plus dedicated processing facilities in Hangzhou and Xi'an, featuring seven color coating production lines, one laminating line, ten shearing systems, and over forty specialized machines producing High Quality Snap Lock Standing Seam Roof systems with Snap Lock Standing Seam Roof for sale to global markets.

Our one-stop solution encompasses complete design services including structural 3D modeling, load analysis, and drainage system simulation, followed by precision manufacturing utilizing roll-forming systems with real-time quality control and raw material traceability from trusted brands like Alucosuper, YATAI, Baosteel, and NedZink. We deliver seamless installation support through on-site project management, safety compliance documentation, and post-installation maintenance guidance backed by ISO9001, ISO14001, and SGS certifications plus over twenty registered patents. Our engineering expertise has successfully completed prestigious projects including Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, and Inner Mongolia Tongliao Art Museum, demonstrating our capability to execute complex metal roofing installations across diverse building types. Contact us at huafeng@hfmetalroof.com to discuss your Snap Lock Standing Seam Roof requirements and discover how our technical expertise, quality manufacturing, and comprehensive service model deliver exceptional value for commercial and industrial building projects. Bookmark this resource for future reference when roofing decisions arise.

References

1. Metal Construction Association. (2022). Metal Roof Installation Manual: Guidelines for Standing Seam Panel Systems. MCA Technical Publication Series.

2. Nielsen, J. & Associates. (2021). Comparative Performance Analysis of Concealed Fastener Metal Roofing Systems. Journal of Building Envelope Design, 15(3), 147-162.

3. Sheffield Metals International. (2023). Standing Seam Profile Selection: Engineering Considerations for Commercial Applications. SMI Technical Bulletin 2023-04.

4. Western States Metal Roofing. (2023). Lifecycle Cost Analysis of Standing Seam Metal Roofing Technologies. WSMR Research Report Series.