Picture this: your building's roof is leaking during a critical production cycle, or maintenance costs are eating into your profit margins year after year. Many facility managers and property owners face these challenges because they chose the wrong roofing system. Understanding the different types of metal roofing systems isn't just about construction materials—it's about selecting a solution that protects your investment for decades while meeting specific performance requirements. Metal Standing Seam Roofing Systems have emerged as the premium choice for projects demanding superior waterproofing, wind resistance, and long-term durability, particularly in large-scale commercial and industrial applications where performance cannot be compromised.

Understanding Metal Standing Seam Roofing Systems

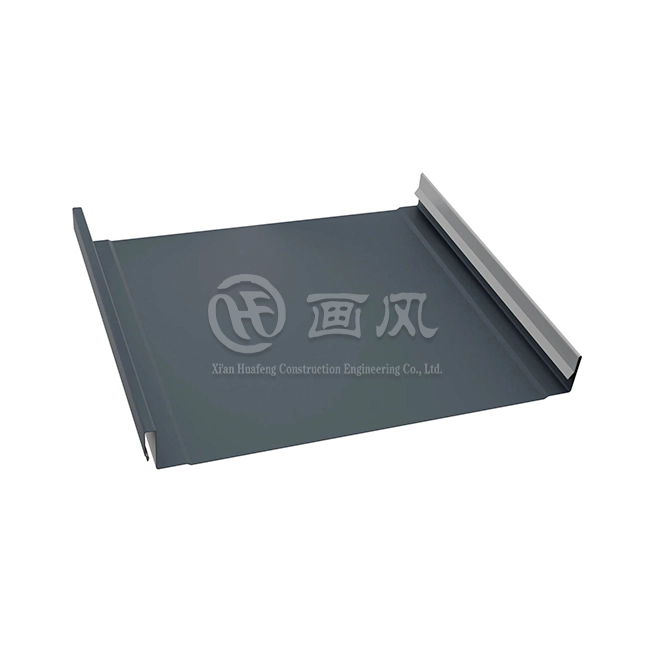

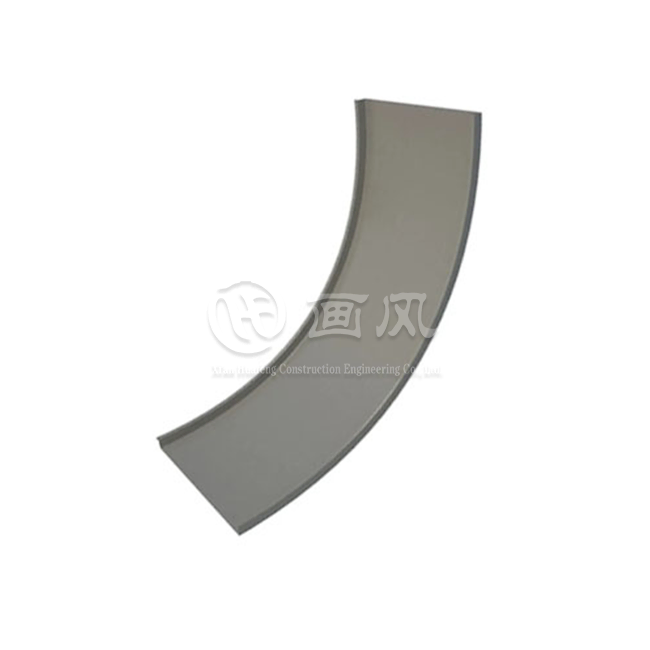

Metal Standing Seam Roofing Systems represent the pinnacle of modern roofing technology, specifically engineered for projects with demanding requirements. These sophisticated systems utilize vertical metal panels connected by raised seams that interlock mechanically, creating a continuous watertight barrier from ridge to eave. The concealed fastener design eliminates penetrations through the roof surface, dramatically reducing leak potential while allowing thermal expansion and contraction without stress on the structural components. Metal Standing Seam Roofing Systems are particularly valued in airports, exhibition centers, stadiums, and industrial facilities where roof failure simply isn't an option. The high-rib design, typically ranging from 65mm to over 100mm in seam height, provides exceptional structural rigidity and enhanced drainage capacity that channels water away efficiently even under extreme weather conditions. The technical sophistication of Metal Standing Seam Roofing Systems extends beyond basic weather protection. These systems incorporate advanced engineering principles including thermal break technology, vapor barrier integration, and acoustic insulation layers that work synergistically to create a complete building envelope solution. Modern installations can accommodate photovoltaic integration, allowing building owners to transform idle roof space into energy-generating assets. The mechanical locking mechanism, whether single-lock or double-lock seam configuration, ensures consistent performance across the entire roof area without relying on sealants that degrade over time. Panel lengths can be customized up to 13 meters without horizontal seams, minimizing potential failure points and creating a streamlined appearance that enhances architectural aesthetics.

-

Material Options for Standing Seam Systems

Material selection fundamentally determines the performance characteristics and lifecycle costs of Metal Standing Seam Roofing Systems. Aluminum alloys, particularly 3003 and 3004 series in H44 hardened state, deliver exceptional corrosion resistance with thicknesses ranging from 0.9mm to 1.2mm, making them ideal for coastal environments where salt spray accelerates degradation of conventional materials. The lightweight nature of aluminum reduces structural load requirements while maintaining strength, and its natural reflectivity contributes to energy efficiency by reducing cooling demands. Galvalume steel, featuring an AZ150 aluminum-zinc coating at 150 grams per square meter combined with PVDF fluoropolymer finish, offers outstanding cost-effectiveness with robust corrosion resistance suitable for most climate zones. This material choice represents the optimal balance between initial investment and long-term performance for the majority of commercial applications. Premium material selections include stainless steel grades 304 and 316, providing unparalleled corrosion resistance for industrial facilities with chemical exposure or extreme coastal conditions where standard materials would fail prematurely. Titanium-zinc plates demonstrate remarkable self-healing properties through natural patina formation, achieving documented lifespans exceeding 80 years with minimal maintenance requirements. Copper roofing systems, utilizing TU1 oxygen-free copper at 0.8mm to 1.0mm thickness, represent the ultimate investment in longevity with verified performance lasting over 100 years while developing the distinctive greenish patina that many architects specifically desire for landmark structures. Each material undergoes rigorous quality control including salt spray testing, adhesion verification, hardness measurement, and weatherability assessment to ensure compliance with ISO9001 and ISO14000:14001 standards that define industry excellence.

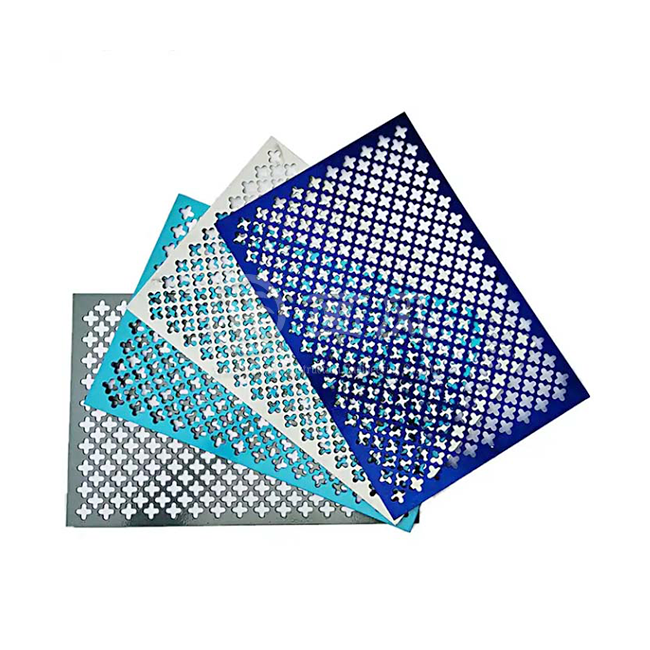

Types of Metal Roofing Panel Configurations

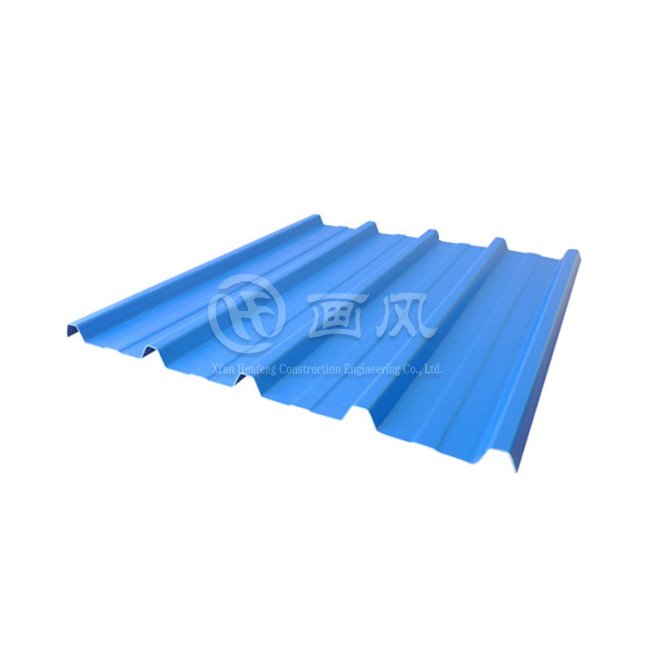

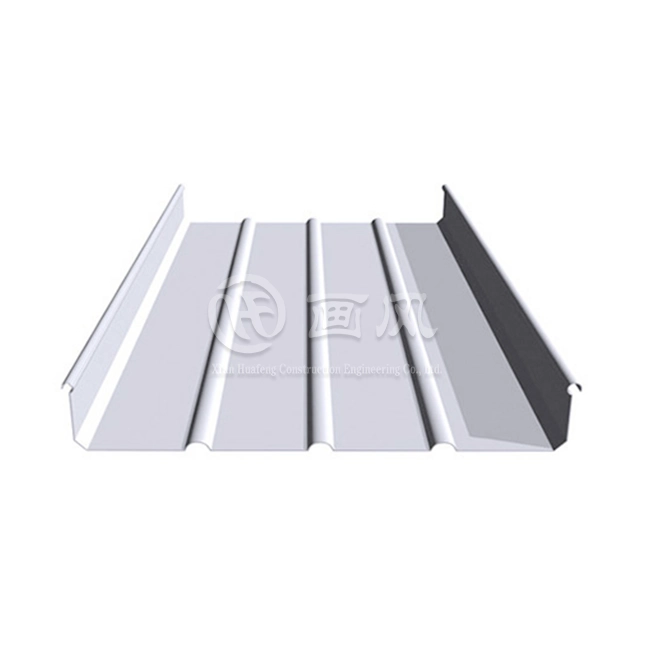

Beyond Metal Standing Seam Roofing Systems, the construction industry utilizes several distinct panel configurations, each optimized for specific applications and performance requirements. Corrugated metal roofing, featuring exposed fastener installation with repeating wave patterns, provides economical coverage for agricultural buildings, warehouses, and structures where aesthetic considerations are secondary to functional protection and budget constraints. The exposed fastener penetrations through panel surfaces require regular maintenance as thermal cycling causes fasteners to loosen over time, potentially creating leak paths that compromise building integrity. While corrugated systems offer initial cost advantages with material pricing between two to four dollars per square foot, the siliconized polyester coatings commonly applied to agricultural panels experience significant UV degradation, resulting in visible fading within five to seven years that necessitates recoating or replacement. Stamped metal roofing systems utilize forming processes to replicate the appearance of traditional materials including clay tiles, wood shakes, slate, and asphalt shingles while delivering the durability advantages inherent to metal construction. These systems appeal to residential markets and historic preservation projects where architectural guidelines mandate specific aesthetic characteristics but property owners desire reduced maintenance burdens and extended service life. Stone-coated metal roofing applies ceramic-coated granules to steel substrates, creating textured surfaces that dissipate sound from rain and hail while providing the visual dimension of conventional roofing materials. The granule attachment process, whether through adhesive bonding or powder coating integration, significantly impacts long-term performance as granule loss exposes underlying metal to accelerated weathering and potential corrosion initiation.

-

Exposed Fastener vs Concealed Fastener Systems

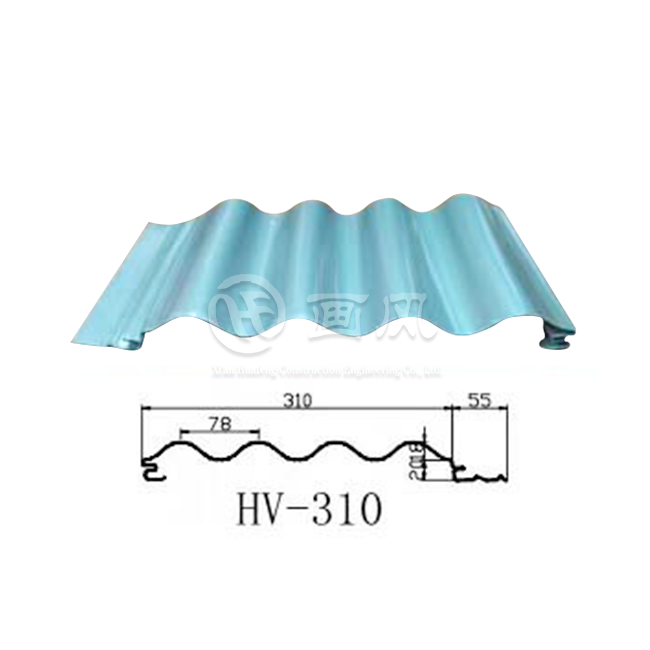

The fundamental distinction between exposed and concealed fastener systems affects virtually every aspect of roof performance, maintenance requirements, and total ownership costs. Exposed fastener panels, including R-panel, PBR panel, and Hi-Rib configurations, penetrate the weathering surface with screws installed through panel peaks, creating thousands of potential leak points that depend entirely on rubber washer integrity for water exclusion. Environmental factors including ultraviolet radiation, ozone exposure, and thermal cycling degrade these elastomeric seals within 15 to 20 years, necessitating comprehensive fastener replacement programs that incur significant labor costs and business disruption. Despite these limitations, exposed fastener systems remain relevant for budget-constrained projects and temporary structures where 20 to 30 year service life expectations align with project economics and functional requirements. Concealed fastener systems, exemplified by Metal Standing Seam Roofing Systems and snap-lock panel variations, eliminate weathering surface penetrations entirely by securing panels to structural supports through hidden clips that allow controlled thermal movement. This design approach fundamentally transforms performance characteristics by removing thousands of potential failure points while creating expansion joints that accommodate thermal coefficient variations without inducing panel stress or fastener withdrawal. The installation complexity and precision requirements of concealed fastener systems demand experienced contractors and specialized equipment including mechanical seamers for double-lock applications, contributing to installed costs approximately 50 to 100 percent higher than exposed fastener alternatives. However, lifecycle analysis consistently demonstrates superior value proposition when evaluating 50 year ownership periods that account for maintenance intervention frequency, replacement timing, and avoided business interruption costs.

Metal Standing Seam Roofing Systems

Technical Specifications and Performance Standards

Professional specification of Metal Standing Seam Roofing Systems requires comprehensive understanding of technical parameters that determine structural adequacy, weather resistance, and regulatory compliance. Panel dimensional specifications including effective coverage width ranging from 300mm to 600mm, seam heights of 65mm or greater, and customizable panel lengths up to 13 meters without transverse joints directly impact installation efficiency and long-term performance reliability. Material thickness tolerances held to ±0.02mm ensure consistent mechanical properties and coating adhesion, meeting stringent requirements established by ASTM A924 and A755 standards that govern metallic-coated steel products. Surface treatment selection between PVDF coating at 25 to 30 micron thickness with 70 percent fluororesin content, PE polyester coating at 20 to 25 microns for moderate climates, or natural oxidation for copper and zinc installations fundamentally determines color retention, chemical resistance, and expected maintenance intervals. Structural performance verification encompasses wind pressure resistance exceeding 4.5 kilopascals to withstand category 5 typhoon conditions per ASTM E1592 testing protocols, snow load capacity of 1.5 kilonewtons per square meter for regions experiencing significant winter precipitation according to EN 1991-1-3 European standards, and impact resistance demonstrated by three-meter drop testing with one-kilogram steel projectiles per ASTM D3746 methodology. Waterproofing performance validated through 1000 pascal negative pressure testing without leakage occurrence, as mandated by GB/T 7106-2008 Chinese national standards, confirms system integrity under extreme weather exposure including wind-driven rain events. Airtightness specifications limiting infiltration to 0.1 cubic meters per square meter per hour ensure energy efficiency and occupant comfort while preventing moisture migration into insulation layers that would compromise thermal performance and create conditions conducive to mold proliferation.

-

Fire Safety and Environmental Credentials

Building code compliance and environmental responsibility drive increasingly stringent requirements for roofing system performance beyond basic weather protection functions. Metal Standing Seam Roofing Systems achieve A1 non-combustible classification under GB 8624-2012 fire testing standards, providing critical life safety protection for occupied buildings and eliminating fire spread concerns that plague organic roofing materials. The inherent non-combustibility of metal roofing eliminates toxic smoke generation during fire events while preventing flame propagation across roof surfaces, characteristics particularly valued for industrial facilities handling flammable materials or high-occupancy public assembly buildings where evacuation timing becomes critical during emergency situations. Fire resistance ratings support lower insurance premiums and regulatory approvals for building occupancies that would face restrictions or prohibitions with combustible roofing assemblies. Environmental performance credentials position Metal Standing Seam Roofing Systems as sustainable building solutions aligned with green construction initiatives and corporate environmental responsibility commitments. The 100 percent recyclability of metal roofing materials eliminates landfill burden at end-of-service life, with aluminum and steel maintaining material value that incentivizes recovery and reprocessing rather than disposal. Solar reflectivity values exceeding 0.65 qualify many metal roofing installations for cool roof designation, reducing urban heat island effects while lowering building cooling loads by 20 to 40 percent compared to darker, absorptive roofing materials. Energy modeling demonstrates that reflective metal roofing can reduce annual cooling costs by $0.50 to $2.00 per square meter in warm climates, creating utility savings that contribute significantly to lifecycle economic performance. The production energy required for metal roofing manufacture, while substantial, distributes across multi-decade service lives that far exceed alternative materials requiring replacement every 15 to 25 years, ultimately resulting in lower embodied carbon per year of service.

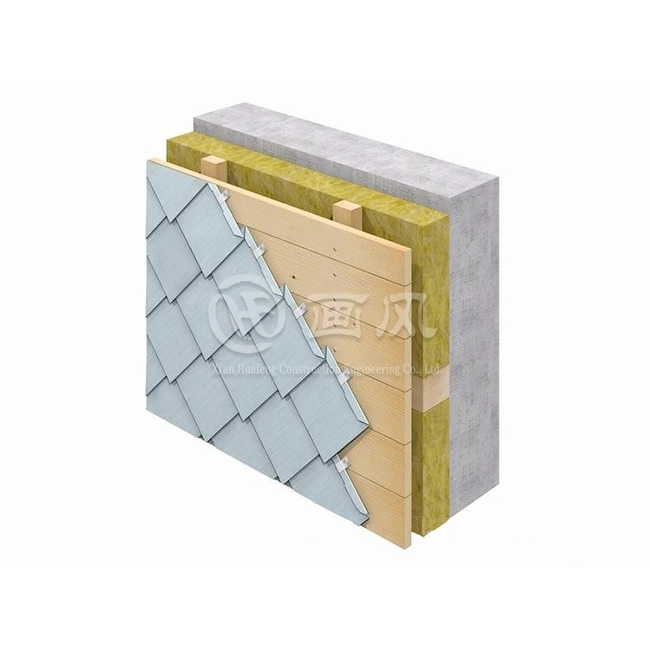

System Integration and Installation Considerations

Successful Metal Standing Seam Roofing Systems installation extends far beyond panel placement, requiring comprehensive attention to underlayment systems, insulation strategies, vapor management, and structural interface details that collectively determine long-term performance and building envelope integrity. Waterproof breathable membranes utilizing high-density polyethylene non-woven fabrics create secondary weather barriers that block wind-driven moisture while permitting vapor transmission that prevents condensation accumulation within roof assemblies. This breathability characteristic proves essential for occupied buildings where interior humidity migrates outward through building envelopes, requiring escape paths that prevent moisture trapping and subsequent structural degradation or mold growth. Proper membrane selection and installation, with careful attention to overlap dimensions and tape sealing at penetrations, establishes reliable backup protection during the inevitable minor roof system breaches that occur during decades of service life. Thermal insulation integration typically employs mineral wool batts with thickness determined through climate-specific heat transfer calculations that balance energy performance against economic optimization and structural depth constraints. Sound attenuation characteristics of mineral wool provide critical acoustic benefits, damping impact noise from rain and hail that otherwise transmits through metal panels, creating interior noise levels that interfere with building functions. Vapor barrier placement below insulation layers, using polyester films or specialized polyethylene membranes, limits moisture migration from conditioned spaces into roof assemblies where temperature gradients could cause condensation formation. The layered assembly sequence—structural decking, vapor barrier, insulation, breathable membrane, and metal panels—creates a sophisticated building envelope system where each component fulfills specific functions while cooperating with adjacent layers to achieve overall performance objectives.

-

Quality Assurance and Project Execution

Manufacturing excellence and installation precision separate superior Metal Standing Seam Roofing Systems installations from marginal performers that fail to deliver anticipated service life and performance characteristics. Raw material procurement following strict supplier qualification protocols ensures consistent quality, with aluminum sourced from certified manufacturers including Alucosuper, YATAI, and LIDAO supplying 3003, 3004, and 5052 alloys meeting specifications. Steel products from BAOSTEEL, GUANZHOU, and XINYU provide cold-rolled, galvanized, galvalume, and color-coated substrates with documented test reports verifying coating weights and mechanical properties. Incoming material inspection programs implementing full inspection for high-value materials and statistical sampling for high-volume commodities prevent defective materials from entering production streams, maintaining quality standards throughout manufacturing processes. Inspection protocols encompassing appearance verification, dimensional measurement, salt spray exposure, adhesion testing, hardness assessment, impact resistance, coating thickness verification, acid resistance, weatherability testing, and color difference evaluation ensure comprehensive quality validation before materials advance to fabrication stages. Production processing utilizing advanced roll-forming equipment with real-time quality monitoring transforms raw coil stock into finished panels meeting exact project specifications for dimensions, profile geometry, and surface finish characteristics. Finished product inspection verifying appearance quality, dimensional accuracy, flatness tolerances, and curvature specifications ensures every panel leaving manufacturing facilities meets stringent acceptance criteria established by quality management systems certified to ISO9001 standards. Strategic packaging dividing products according to roof plan sections, with identification cards detailing section locations and component lists, streamlines site logistics and installation sequencing while minimizing handling damage risks during transportation and storage. This systematic approach to quality assurance, from material procurement through final packaging, establishes the foundation for successful project execution and long-term performance achievement.

Applications and Project Suitability

Metal Standing Seam Roofing Systems demonstrate exceptional versatility across diverse building types and functional requirements, though certain application categories particularly benefit from their unique performance attributes. Large-span structures including airports, high-speed rail stations, and exhibition centers require roofing solutions capable of spanning significant distances between structural supports while maintaining weathertight integrity and accommodating thermal movement across extended panel lengths. The low-slope capability of standing seam systems combined with proven waterproofing performance makes them ideal for these applications where roof drainage becomes critical and leak consequences involve high-value interior spaces or critical operational functions. Sports stadiums and arenas, particularly those featuring retractable roof sections or translucent panel integration for natural daylighting, leverage standing seam technology's structural rigidity and weather sealing to create spectacular architectural features that perform reliably despite extreme exposure conditions. Industrial facilities including manufacturing plants, logistics centers, and processing operations demand roofing systems capable of resisting chemical exposure, accommodating heavy equipment loads for maintenance access and suspended utilities, and integrating with building management systems for environmental monitoring. Metal Standing Seam Roofing Systems fulfill these requirements while offering future adaptability for photovoltaic panel addition as energy costs justify renewable generation investment. The 65mm seam heights common in industrial applications provide compatible mounting surfaces for PV racking systems without roof penetrations, preserving warranty integrity while generating significant energy offsets. Commercial building applications including corporate headquarters, educational institutions, and healthcare facilities appreciate standing seam aesthetics that project quality and permanence while delivering measured energy performance and minimal maintenance demands that reduce total cost of ownership throughout multi-decade building service lives.

Conclusion

Selecting appropriate metal roofing systems demands careful evaluation of performance requirements, budget parameters, aesthetic preferences, and lifecycle cost considerations. Metal Standing Seam Roofing Systems deliver superior weather protection, structural performance, and long-term value for demanding applications.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

As a leading China Metal Standing Seam Roofing Systems manufacturer, Xi'an Huafeng Construction Engineering Co., Ltd. delivers comprehensive solutions from design through installation. Established in 2018 and recognized as a high-tech enterprise in Shaanxi Province in 2020, we maintain first-level building curtain wall qualifications and third-level steel structure certifications that validate our technical capabilities. Our manufacturing infrastructure encompasses a 200,000 square meter raw material production facility in Anhui plus specialized plate and accessory processing plants in Hangzhou and Xi'an, operating seven color coating production lines, one laminating line, ten longitudinal and transverse shearing lines, and fully automated punching systems supported by over 40 precision manufacturing equipment units.

As a trusted China Metal Standing Seam Roofing Systems supplier and China Metal Standing Seam Roofing Systems wholesale provider, we offer High Quality Metal Standing Seam Roofing Systems with competitive Metal Standing Seam Roofing Systems price structures backed by ISO9001, ISO14000:14001, and SGS certifications plus more than 20 registered patents. Our Metal Standing Seam Roofing Systems for sale include customizable specifications—65-300/400/430/500mm widths with PE, HDP, and PVDF coating options, 30-year warranties, 500 square meter minimum orders, and 15-20 day delivery schedules. Our China Metal Standing Seam Roofing Systems factory provides turnkey services including structural 3D modeling, drainage simulation, material specification advisory, precision manufacturing with real-time quality control, and seamless installation with on-site project management. Contact huafeng@hfmetalroof.com to discuss your project requirements and discover why Fortune 500 companies trust Huafeng for critical roofing applications. Bookmark this resource for future reference whenever roofing questions arise.

References

1. Metal Roofing Alliance. "Metal Roofing Design and Installation Guide." Metal Roofing Alliance Technical Manual, 2023.

2. National Roofing Contractors Association. "The NRCA Roofing Manual: Metal Panel and SPF Roof Systems." National Roofing Contractors Association, 2022.

3. American Society for Testing and Materials. "ASTM E1592: Standard Test Method for Structural Performance of Sheet Metal Roof and Siding Systems by Uniform Static Air Pressure Difference." ASTM International Standards, 2021.

4. Cool Roof Rating Council. "Cool Metal Roofing: Energy Efficiency and Thermal Performance Standards." Cool Roof Rating Council Product Rating Program, 2024.