Choosing between mechanical lock and snap-lock standing seam metal roofing systems can mean the difference between a roof that withstands decades of harsh weather or one that requires costly repairs within years. As commercial building managers and architects face increasingly extreme weather patterns, the decision becomes critical for long-term structural integrity and budget management. Understanding the fundamental differences between these two Mechanical Lock Metal Roofing systems will help you select the optimal solution that balances performance, installation efficiency, and lifecycle costs for your specific project requirements.

Understanding Mechanical Lock Metal Roofing Systems

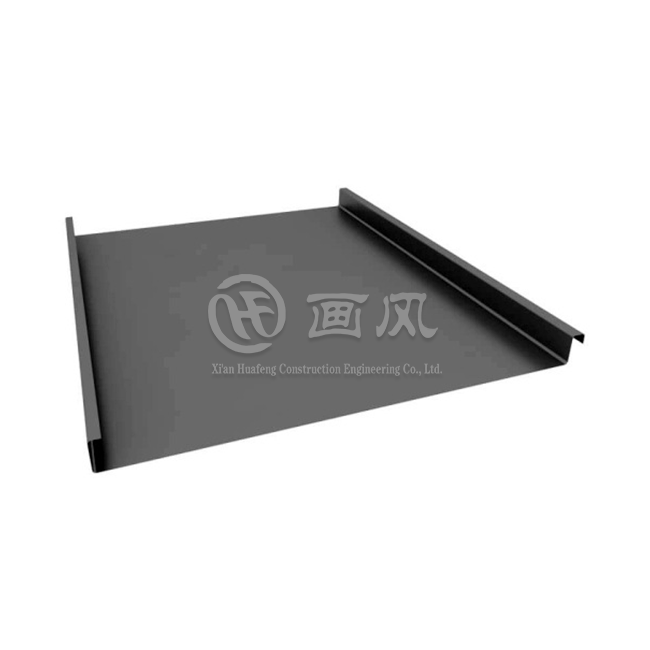

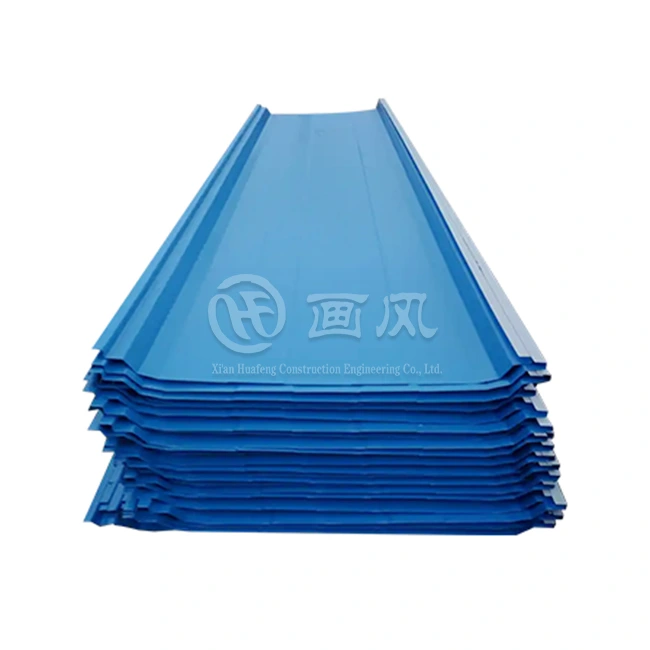

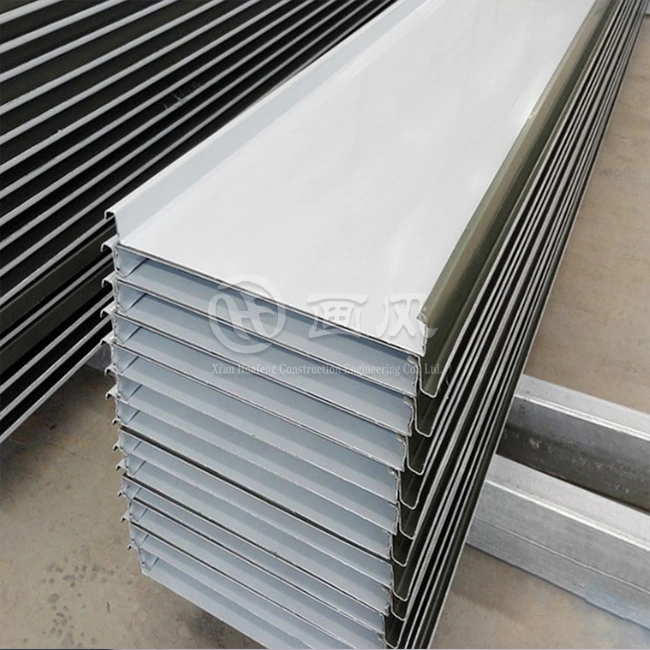

Mechanical Lock Metal Roofing represents the premium tier of standing seam technology, engineered specifically for applications demanding superior weather resistance and structural performance. This system utilizes panels with overlapping edges that are mechanically crimped together using specialized seaming equipment, creating either single-lock or double-lock configurations. The mechanical seaming process folds the metal edges once for single-lock systems or twice for double-lock systems, establishing an exceptionally tight seal that virtually eliminates water infiltration pathways. This concealed fastener approach ensures that no screws penetrate the roofing surface, dramatically reducing potential leak points while maintaining the clean, contemporary aesthetic that defines modern architectural design. The engineering behind Mechanical Lock Metal Roofing systems incorporates floating clip mechanisms that accommodate thermal expansion and contraction, particularly crucial for panel lengths exceeding twenty-five feet. These clips attach to the roof deck substrate and hold the panel ribs in position while permitting controlled longitudinal movement as temperatures fluctuate throughout seasonal cycles. The system's structural integrity comes from the mechanically formed seam itself, which can withstand wind uplift pressures exceeding ninety miles per hour when properly installed according to International Building Code specifications. Manufacturing facilities like those operated by Xi'an Huafeng Construction Engineering Co., Ltd. produce these panels with precision roll-forming equipment, ensuring consistent rib heights of twenty-five millimeters or thirty-two millimeters and panel widths ranging from three hundred to five hundred millimeters to accommodate diverse architectural requirements.

-

Installation Requirements for Mechanical Seaming

Installing Mechanical Lock Metal Roofing demands specialized equipment and trained personnel capable of operating mechanical seaming tools effectively. The installation process begins with careful substrate preparation, followed by precise clip placement at engineered intervals based on structural load calculations and wind uplift requirements. Installers must position each panel accurately before engaging the seaming machine, which travels along the panel length to form the mechanical lock through controlled pressure and folding sequences. Double-lock configurations require two complete seaming passes, significantly extending installation time compared to single-lock alternatives but delivering enhanced weather resistance for low-slope applications or extreme climate zones. The technical complexity of mechanical seaming installation translates directly into labor costs, typically requiring experienced crews familiar with seamer calibration and operation. Temperature conditions during installation must remain within the zero to forty degrees Celsius range to ensure proper material handling and seam formation. Quality control protocols mandate inspection of each seam to verify complete engagement and proper fold geometry, preventing future performance issues. Despite the higher initial labor investment, properly installed Mechanical Lock Metal Roofing systems deliver exceptional long-term value through minimal maintenance requirements and superior resistance to weather-related degradation over their thirty-year-plus service life.

Snap-Lock Standing Seam: The Installation-Efficient Alternative

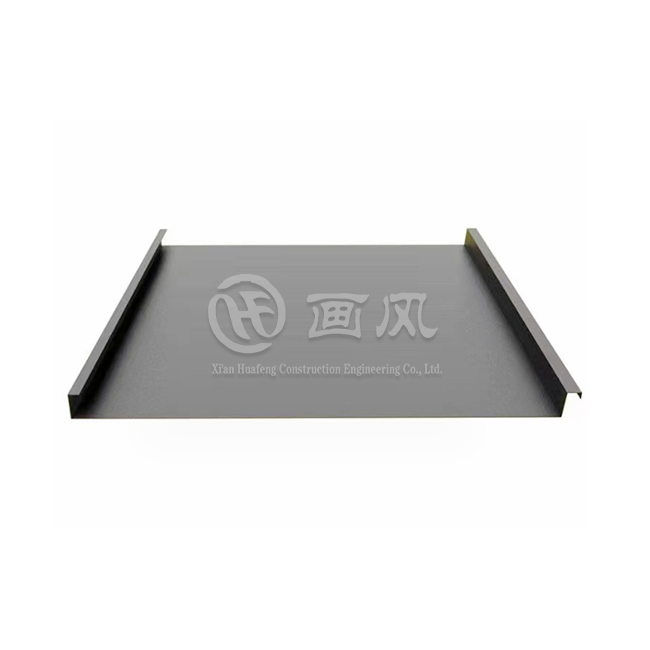

Snap-lock standing seam panels provide an attractive middle-ground solution that maintains concealed fastener benefits while simplifying the installation process considerably. These panels feature male and female legs engineered with interlocking profiles that snap together mechanically without requiring seaming equipment operation. The female leg incorporates a clip attachment point that fastens to the roof deck, while the male leg of the adjacent panel snaps over it to complete the weather-tight connection. This design eliminates the need for specialized seaming tools and reduces installation time substantially compared to Mechanical Lock Metal Roofing alternatives, making snap-lock systems particularly appealing for projects with compressed construction schedules or limited budgets for specialized installation equipment rental. The snap-lock mechanism creates a weather-resistant barrier suitable for most commercial and residential applications, though performance characteristics differ from mechanically seamed alternatives in critical aspects. The snapped connection relies on the panel profile geometry and material spring tension to maintain engagement, which functions effectively under normal loading conditions but may be more susceptible to disengagement under extreme uplift forces or during significant thermal cycling. For this reason, building codes and manufacturer specifications typically restrict snap-lock installations to roof slopes of three-over-twelve pitch or steeper, where gravity assists water drainage and reduces hydrostatic pressure at the seams. Projects with lower slope requirements necessitate mechanical seaming to achieve adequate weather-tightness and code compliance.

-

Performance Characteristics and Limitations

While snap-lock systems deliver reliable performance within their design parameters, understanding their limitations ensures appropriate application selection. The snap-together connection permits unlimited thermal movement as panels expand and contract, an advantage for moderate climate zones experiencing typical seasonal temperature variations. However, this same flexibility means the connection is less rigid than mechanically formed seams, potentially creating slightly larger gaps through which wind-driven moisture might penetrate during severe weather events. The system performs exceptionally well in residential applications and commercial structures located in temperate climates with adequate roof pitch, delivering decades of service when properly installed with appropriate underlayment and flashing details. Material specifications for snap-lock panels mirror those available for Mechanical Lock Metal Roofing, including aluminum alloys, galvanized steel, galvalume steel, stainless steel, copper, and titanium zinc options with PVDF or PE coating systems. Xi'an Huafeng Construction Engineering Co., Ltd. manufactures snap-lock profiles with the same rigorous quality standards applied to mechanical seam products, utilizing thickness ranges from point-five to one-point-zero millimeter and offering extensive color customization through RAL standards. The versatility of material choices ensures that snap-lock systems can meet aesthetic requirements while delivering appropriate performance for their intended application scope, though project specifications must carefully consider slope, climate, and structural requirements when selecting between snap-lock and mechanical seaming approaches.

Comparative Analysis: Weather Resistance and Structural Performance

The weather-tightness differential between Mechanical Lock Metal Roofing and snap-lock systems becomes most apparent in challenging environmental conditions and low-slope applications. Mechanically seamed roofs, particularly double-lock configurations, create such tightly compressed seams that water infiltration becomes virtually impossible even under significant hydrostatic pressure or wind-driven rain conditions. The folded metal seam extends the pathway water must travel to penetrate the roofing system, working in conjunction with gravity to direct moisture safely off the roof surface. This superior weather resistance enables mechanical seaming use on slopes as low as one-over-twelve pitch, expanding design possibilities for contemporary architectural styles favoring low-profile rooflines and maximizing usable interior space in commercial structures. Testing protocols conducted according to ASTM standards demonstrate the performance advantages of mechanical seaming under controlled laboratory conditions and real-world field installations. Wind uplift testing shows that properly installed mechanical seam systems routinely achieve ratings exceeding Class 90, indicating resistance to wind speeds of ninety miles per hour without panel displacement or seam separation. Water infiltration testing under simulated hurricane conditions with wind-driven rain confirms the exceptional weather-tightness of double-lock mechanical seams. These performance characteristics prove essential for coastal installations, high-rise buildings experiencing significant wind pressure, and industrial facilities requiring absolute weather protection for sensitive operations or stored materials.

-

Thermal Movement Accommodation

Both mechanical seam and snap-lock systems address thermal expansion and contraction, though through different mechanical approaches that influence long-term performance. Mechanical Lock Metal Roofing systems employ floating clip designs that permit controlled longitudinal panel movement while maintaining lateral position stability. As temperatures rise, metal panels expand; the floating clips allow this movement without creating stress concentrations that could compromise the seam integrity or fastener connections. This engineering sophistication becomes crucial for panel lengths exceeding twenty-five feet, where thermal movement magnitudes reach levels that could disengage less sophisticated connection systems or damage fixed fastener attachments. Snap-lock connections inherently accommodate thermal movement through their mechanical snap engagement, which permits some relative motion between male and female legs as panels expand and contract. This flexibility represents both an advantage and potential limitation depending on application specifics. In moderate climates with gradual temperature transitions, the snap-lock mechanism performs admirably throughout seasonal cycles. However, in regions experiencing dramatic diurnal temperature swings or extreme seasonal variations, the repeated expansion and contraction cycles may gradually reduce snap engagement tightness over extended service periods, potentially increasing maintenance requirements compared to the more rigidly secured mechanical seam alternative.

Cost Considerations and Project Economics

Initial installation costs differ significantly between Mechanical Lock Metal Roofing and snap-lock alternatives, primarily driven by labor requirements and specialized equipment needs. Mechanical seaming demands trained installation crews capable of operating seaming equipment effectively, along with tool rental or purchase costs that can reach four hundred dollars per week per seaming machine. The installation process itself requires more time per square foot due to the mechanical seaming operation, particularly for double-lock configurations requiring two complete seaming passes along each panel length. These factors combine to position mechanical seam installations at the premium end of the standing seam cost spectrum, typically ranging from twelve to eighteen dollars per square foot including materials and installation labor for commercial applications. Snap-lock systems deliver cost advantages through simplified installation procedures that reduce both labor hours and equipment requirements. Without the need for mechanical seaming operations, installation crews can complete projects more rapidly, translating directly into lower labor costs for building owners. The elimination of specialized seaming equipment rental further reduces project expenses while maintaining the concealed fastener aesthetic and weather protection benefits that differentiate standing seam systems from less expensive through-fastened alternatives. Total installed costs for snap-lock systems typically range from eight to fourteen dollars per square foot, positioning them as an economically attractive option for projects prioritizing value engineering without sacrificing fundamental performance requirements or aesthetic quality.

-

Lifecycle Value and Maintenance Economics

Evaluating true project economics requires consideration of lifecycle costs extending beyond initial installation expenses. Both Mechanical Lock Metal Roofing and snap-lock systems deliver exceptional longevity compared to conventional roofing alternatives, with properly installed metal roofing systems routinely providing forty to sixty years of service life. The virtually maintenance-free nature of concealed fastener systems eliminates the periodic fastener replacement and sealant maintenance required for through-fastened metal roofing or the complete replacement cycles necessary for asphalt shingle roofing every fifteen to twenty years. When lifecycle costs are calculated including maintenance, repair, and eventual replacement expenses, the premium initially paid for standing seam technology generates substantial long-term savings that justify the investment for quality-focused building owners. The slight performance advantage of mechanical seaming may influence lifecycle economics for installations in harsh climate zones or critical-application structures where even minimal maintenance represents significant operational disruption. The enhanced weather-tightness of mechanical seam systems reduces the probability of moisture-related issues that could necessitate premature maintenance intervention or repairs. For pharmaceutical manufacturing facilities, data centers, food processing plants, and other operations intolerant of any weather infiltration, the incremental investment in mechanical seaming delivers risk mitigation value that transcends simple cost-per-square-foot comparisons. Conversely, for standard commercial structures in moderate climates, snap-lock systems provide entirely adequate performance at lower initial cost, optimizing project economics without compromising essential functional requirements.

Application Selection Guidelines and Best Practices

Selecting between Mechanical Lock Metal Roofing and snap-lock systems requires careful analysis of project-specific factors including roof geometry, climate conditions, building use, and budget parameters. Mechanical seaming represents the optimal choice for low-slope applications below three-over-twelve pitch, coastal installations subject to hurricane-force winds or wind-driven rain, and any structure requiring absolute weather-tightness for operational reasons. The system's superior performance characteristics justify the premium installation cost when project requirements demand maximum weather resistance, extended panel lengths necessitate floating clip accommodation of thermal movement, or architectural specifications call for the enhanced visual refinement of tightly compressed mechanical seams. Snap-lock systems excel in residential applications and commercial structures with adequate roof pitch, moderate climate conditions, and value-engineering priorities. The installation efficiency delivers real economic benefits for projects with multiple roof sections or complex geometries where labor cost differentials multiply across large square footage totals. Building owners should consider snap-lock technology for renovation projects requiring rapid installation to minimize building disruption, for structures in temperate inland locations without extreme weather exposure, and for applications where the simplified installation process enables qualified contractors without specialized mechanical seaming equipment to compete for the work, potentially increasing competitive bidding and reducing overall project costs through expanded contractor participation.

-

Material Selection Integration

Both mechanical seam and snap-lock panel profiles accommodate the full range of metal roofing materials, enabling architects to specify appropriate substrates based on aesthetic preferences, corrosion resistance requirements, and budget parameters. Aluminum alloys including 3003, 3004, and 5052 grades provide excellent corrosion resistance for coastal installations while delivering the lightweight characteristics valued in structural weight-sensitive applications. Galvalume steel offers superior corrosion protection compared to traditional galvanized steel through its aluminum-zinc coating, extending service life in moderate corrosive environments while maintaining cost-effectiveness for large-scale commercial projects. Stainless steel grades 304 and 316 deliver premium corrosion resistance for the most demanding exposure conditions, though at material costs that limit applications to projects justifying the investment through extended service life requirements or unique aesthetic objectives. Premium materials including copper and titanium zinc create distinctive architectural statements while providing exceptional durability measured in centuries rather than decades. Xi'an Huafeng Construction Engineering Co., Ltd. sources these specialized materials from leading manufacturers including Chinalco for copper and NedZink for titanium zinc, ensuring material quality meets the demanding performance standards required for successful long-term installation performance. Surface coating selection between PVDF fluoropolymer coatings offering superior color retention and weathering resistance versus more economical PE polyester coatings suitable for less demanding applications further customizes system performance to match project-specific requirements. The comprehensive material flexibility available within both mechanical seam and snap-lock profiles ensures that architects need not compromise aesthetic vision to achieve required functional performance specifications.

Conclusion

The choice between mechanical lock and snap-lock standing seam metal roofing ultimately depends on balancing performance requirements against project economics and installation logistics. Mechanical Lock Metal Roofing delivers unmatched weather resistance and structural capability for demanding applications, while snap-lock systems provide excellent value through simplified installation without sacrificing fundamental quality. Both technologies represent substantial improvements over conventional roofing alternatives, offering decades of low-maintenance service when properly specified and professionally installed according to manufacturer guidelines and building code requirements.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a leading China Mechanical Lock Metal Roofing manufacturer, China Mechanical Lock Metal Roofing supplier, and China Mechanical Lock Metal Roofing factory delivering comprehensive metal roofing solutions since 2018. Our three state-of-the-art manufacturing facilities spanning two hundred thousand square meters in Anhui, with additional processing plants in Hangzhou and Xi'an, house seven color coating production lines and over forty advanced machines producing High Quality Mechanical Lock Metal Roofing systems. As a recognized high-tech enterprise with first-level building curtain wall qualifications and ISO9001, ISO14001, and SGS certifications, we offer Mechanical Lock Metal Roofing for sale with competitive Mechanical Lock Metal Roofing price structures backed by thirty-year warranties. Our one-stop solution encompasses custom engineering design, precision manufacturing with raw material traceability, and seamless installation support for projects worldwide. Contact our technical team at huafeng@hfmetalroof.com for detailed specifications and project consultation. Bookmark this resource for future reference as you evaluate China Mechanical Lock Metal Roofing wholesale options for your next commercial or industrial roofing project.

References

1. Standing Seam Metal Roofing Systems: A Comparative Analysis of Installation Methods and Performance Characteristics - American Society of Civil Engineers, Journal of Architectural Engineering

2. Metal Roofing Design Manual: Technical Guidelines for Concealed Fastener Systems - Metal Construction Association Technical Standards Committee

3. Weather Resistance Testing Protocols for Standing Seam Metal Roof Assemblies - ASTM International, Committee E06 on Performance of Buildings

4. Thermal Movement Accommodation in Metal Roofing Systems: Engineering Design Considerations - National Roofing Contractors Association Research and Technical Services Division