Are you struggling with roof leaks, high maintenance costs, or finding a roofing solution that balances durability with aesthetic appeal? Modern construction demands more than just basic weather protection. Today's building owners face challenges including extreme weather conditions, thermal expansion issues, and the need for sustainable materials that deliver long-term value. Trapezoidal standing seam roofing systems offer comprehensive solutions to these pain points, combining advanced engineering with practical functionality. This guide explores how trapezoidal, corrugated and standing seam aluminium sheets address real-world roofing challenges while providing design flexibility for industrial, commercial and residential applications.

Understanding Trapezoidal Standing Seam Roofing Systems

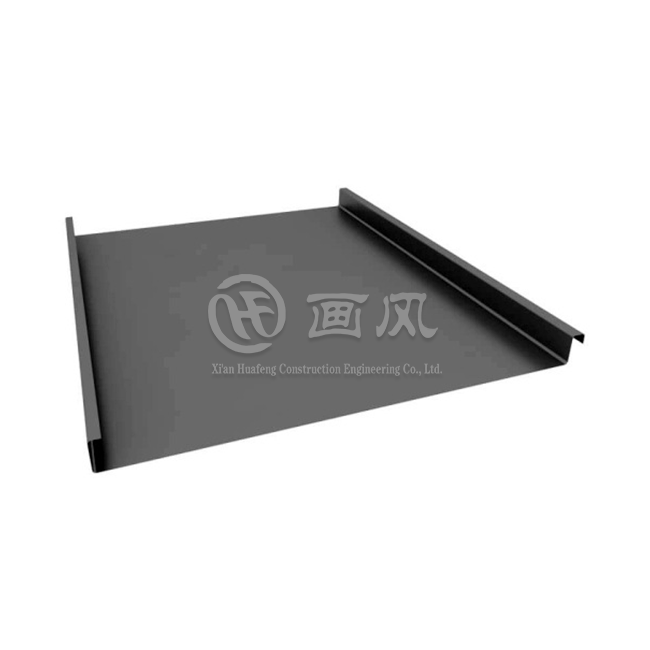

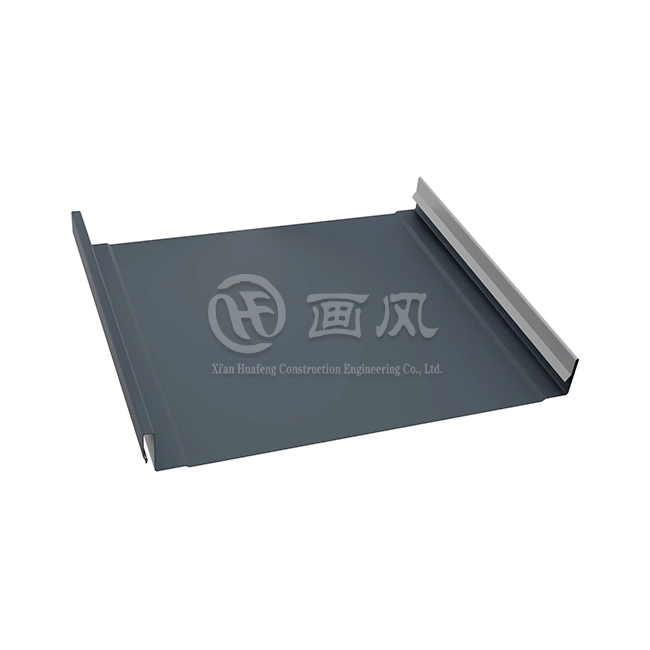

Trapezoidal standing seam roofing represents an evolution in metal roofing technology, featuring angular profiles that provide superior structural integrity compared to traditional roofing materials. The trapezoidal design incorporates raised seams that run vertically along the roof panels, creating a distinctive architectural profile while serving critical functional purposes. These systems utilize non-penetrating fixation methods, meaning fasteners are concealed beneath the panel surface rather than exposed to weather elements. This fundamental design principle eliminates the primary source of roof leaks in conventional roofing systems where screws penetrate the weatherproof surface. The engineering behind trapezoidal standing seam roofing addresses thermal expansion and contraction, a challenge that causes premature failure in many roofing systems. Metal naturally expands in heat and contracts in cold temperatures. Traditional fixed roofing systems fight against this natural movement, creating stress points that lead to fastener failure, panel distortion and eventual leaks. Trapezoidal standing seam roofing incorporates floating clip systems that allow panels to move independently along their length while maintaining watertight seals at the seams. This accommodation of thermal movement extends system lifespan significantly, with properly installed systems lasting thirty to fifty years depending on material selection and environmental conditions.

-

Material Composition and Performance Characteristics

The performance of trapezoidal standing seam roofing depends heavily on material selection. Aluminum alloys including 3003, 3004 and 5052 grades offer exceptional corrosion resistance, making them ideal for coastal environments and areas with high atmospheric pollution. These aluminum grades contain magnesium and manganese additions that enhance strength while maintaining the metal's natural resistance to oxidation. When aluminum is exposed to air, it forms a protective oxide layer that prevents further corrosion, unlike steel which continues rusting once the protective coating is compromised. This self-healing characteristic makes aluminum particularly valuable in applications where long-term maintenance access is difficult or costly. Galvanized steel and galvalume steel alternatives provide higher strength-to-weight ratios than aluminum, suitable for applications requiring greater load-bearing capacity. Modern pre-painted finishes including polyester and PVDF coatings add additional weather protection while offering extensive color options. PVDF coatings, in particular, demonstrate exceptional resistance to ultraviolet degradation, maintaining color integrity for twenty-five years or more in most climates. The coating selection directly impacts the system's thermal performance, with lighter colors reflecting more solar radiation and reducing cooling loads in warm climates.

Comparing Corrugated, Trapezoidal and Standing Seam Profiles

Building owners often face confusion when selecting between corrugated sheets, trapezoidal profiles and standing seam systems. Each profile type serves specific applications and performance requirements. Corrugated sheets feature rounded, sinusoidal waves that provide good strength-to-weight ratios and are economical for basic weather protection. These profiles work well for agricultural buildings, storage facilities and temporary structures where aesthetic considerations are secondary to functionality and cost. However, corrugated profiles use exposed fastener systems, making them more susceptible to leaks over time as fastener washers degrade and holes elongate through thermal cycling. Trapezoidal profiles incorporate angular ridges rather than rounded corrugations, creating a more contemporary appearance while delivering superior structural rigidity. The trapezoidal shape with its vertical ribs and horizontal pans distributes loads more efficiently than corrugated profiles, allowing longer spans between purlins and reducing overall structural costs. These profiles are extensively used in commercial and industrial applications where appearance matters but extreme weather performance is the priority. Modern trapezoidal standing seam roofing systems combine the structural advantages of trapezoidal geometry with the leak-resistance of concealed fastener technology.

-

Standing Seam Technology Advantages

Standing seam systems represent the premium tier of metal roofing technology, utilizing vertical leg seams that interlock adjacent panels while concealing all fasteners beneath the weather surface. The standing seam design creates continuous water-shedding ridges running from ridge to eave, eliminating horizontal joints where water can accumulate. This vertical drainage principle works with gravity rather than relying solely on sealants or overlapping joints. Properly designed standing seam systems can perform on slopes as low as one-quarter inch per foot, whereas conventional roofing typically requires minimum slopes of three inches per twelve inches. The snap-lock and mechanical seam variants of standing seam systems offer different advantages. Snap-lock systems allow faster installation without specialized seaming equipment, reducing labor costs while maintaining excellent weather performance. Mechanical seam systems require portable seaming machines that fold the panel edges together, creating a more secure connection better suited for extreme wind zones and applications requiring additional security. Both systems accommodate thermal movement through concealed clips that grip the panel seams while allowing longitudinal sliding. This movement accommodation is critical for long panel runs where thermal expansion can exceed several inches over the panel length.

Installation Considerations and Best Practices

Successful trapezoidal standing seam roofing installation requires careful attention to substrate preparation, panel handling and seaming techniques. The roof deck must provide adequate support and flatness, as undulations in the substrate will telegraph through metal panels, creating visual irregularities and potential water pooling areas. Most installations utilize structural purlins or solid decking with appropriate spacing based on panel profile, gauge and design loads. Thermal barrier insulation can be incorporated either beneath the deck or as rigid board insulation between purlins, with proper consideration for condensation control. Panel handling during installation requires care to prevent damage to pre-finished surfaces. Protective films should remain in place until installation is complete, and panels should be lifted rather than dragged across surfaces. Storage at the jobsite must protect panels from ground moisture and allow air circulation to prevent condensation damage to coatings. Installation sequencing typically begins at one rake edge, proceeding across the roof width while ensuring proper alignment and seam engagement. Each panel must be independently secured with the appropriate clip spacing, typically sixteen to twenty-four inches on center depending on wind zone requirements.

-

Quality Control and Testing Protocols

Professional installation includes systematic quality control measures to ensure long-term performance. Clip installation requires verification that clips are properly centered on the panel seam and engaged with the structural substrate. Under-driven or over-driven fasteners can compromise clip function, either allowing panel lift-off in high winds or restricting thermal movement. Seam integrity must be verified along the entire panel length, with mechanical seams achieving complete folding without gaps or incomplete engagement. Water testing after installation confirms system integrity, typically involving controlled water application while inspecting interior surfaces for leakage. Modern trapezoidal standing seam roofing systems incorporate advanced accessories including eave closures, ridge caps and penetration flashings that integrate with the panel system. These components must be installed following manufacturer specifications to maintain system warranties and weather performance. Penetrations for vents, pipes and equipment supports require special attention, utilizing prefabricated boots and curbs designed specifically for standing seam applications. Proper flashing details around chimneys, walls and other roof projections are critical, following the fundamental principle that water must be directed away from vulnerable areas through overlapping and properly sealed components.

Durability and Maintenance Requirements

The service life of trapezoidal standing seam roofing systems significantly exceeds conventional roofing materials when properly specified and installed. Aluminum systems commonly achieve forty to fifty-year lifespans in most environments, with some installations exceeding seventy years in benign conditions. Steel systems with quality pre-painted finishes typically deliver thirty to forty years of service, with coastal environments potentially reducing lifespan depending on atmospheric salinity and maintenance frequency. The concealed fastener design eliminates the primary failure mode of exposed fastener systems, where weathering degrades fastener washers and creates leak points. Maintenance requirements for standing seam systems are minimal compared to alternative roofing types. Regular inspections should verify seam integrity, check for loose panels or damaged accessories, and ensure drainage systems remain clear of debris. Panel surfaces can be cleaned using mild detergents and low-pressure water to maintain appearance, though the natural self-cleaning effect of rain typically keeps roofs reasonably clean without intervention. Unlike asphaltic or membrane roofing systems that require periodic recoating or replacement of deteriorated sections, metal roofing maintains its fundamental weather protection indefinitely as long as the protective finish remains intact.

-

Environmental Performance and Sustainability

Trapezoidal standing seam roofing excels in environmental performance metrics that increasingly influence material selection decisions. Aluminum and steel are infinitely recyclable without degradation of material properties, and most metal roofing contains substantial recycled content. At end-of-service life, panels can be removed and recycled, avoiding landfill disposal required for most alternative roofing materials. The high reflectivity of metal roofing surfaces reduces cooling loads in warm climates, with light-colored finishes reflecting seventy percent or more of solar radiation. This thermal performance can significantly reduce air conditioning costs and urban heat island effects in cities. The longevity of metal roofing systems contributes to sustainability by avoiding the resource consumption and waste generation associated with frequent roof replacement. A building with a fifty-year metal roof avoids two to three reroof cycles typically required with conventional materials, saving the embodied energy of manufacturing replacement materials and eliminating disposal costs and environmental impacts. Additionally, standing seam roofs provide ideal platforms for solar panel installation, with many clip manufacturers offering photovoltaic mounting systems that integrate with the roofing without penetrating the weather surface.

Design Flexibility and Architectural Applications

Contemporary architecture increasingly features trapezoidal standing seam roofing as a prominent design element rather than simply functional weather protection. The clean, linear appearance of standing seam profiles complements modern architectural styles, with the vertical seam lines creating strong directional emphasis. Architects can specify curved applications where panels are rolled to custom radii during installation, creating dramatic barrel vaults, curved eaves or complex geometric forms impossible with rigid panel systems. Color selection ranges from traditional metallic finishes to bold architectural colors, with some manufacturers offering custom color matching for unique project requirements. The versatility of standing seam systems extends to wall cladding applications where the same profile provides visual continuity between roof and wall surfaces. This design integration creates cohesive building envelopes with superior weather performance, as wall panels shed water effectively while accommodating the same thermal movement considerations as roof applications. Mixed material designs might incorporate different metals on the same building, such as aluminum roofing with zinc or copper accent walls, achieving varied aesthetics while utilizing appropriate materials for each application.

-

Project-Specific Customization Capabilities

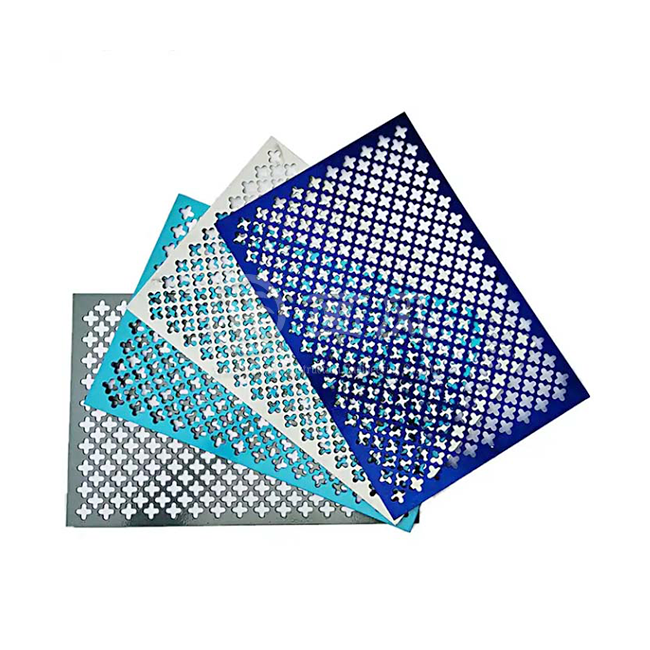

Professional metal roofing manufacturers offer extensive customization capabilities that allow optimal solutions for specific project requirements. Panel widths typically range from twelve to twenty-four inches, with varying rib heights from one inch to over four inches depending on structural requirements and aesthetic preferences. Gauge selection balances weight, strength and cost considerations, with residential applications often using lighter gauges while commercial and industrial projects specify heavier materials for increased durability and wind resistance. Custom panel lengths eliminate horizontal joints on most roof slopes, with some manufacturers producing panels exceeding sixty feet in single lengths. Surface finish options extend beyond basic painted coatings to include specialty treatments like stone-coated steel systems that replicate tile or shake roofing appearances while maintaining metal roofing performance advantages. Perforation patterns can be incorporated for applications requiring acoustic absorption or visual permeability, such as covered walkways or transit facilities. The ability to integrate functional elements including snow retention systems, walkway pads and fall protection anchors during installation creates comprehensive roofing systems that address all building requirements without compromising weather protection.

Cost Analysis and Value Proposition

Initial cost comparisons often show trapezoidal standing seam roofing systems commanding premium pricing compared to conventional roofing materials. However, comprehensive life-cycle cost analysis consistently demonstrates superior value when considering installation, maintenance, energy performance and lifespan factors. While basic asphalt shingle roofing might cost forty percent of a standing seam system initially, the requirement for replacement every fifteen to twenty years combined with ongoing maintenance costs results in higher total ownership costs over typical building lifespans. Additionally, metal roofing adds resale value to properties, an advantage particularly relevant in commercial real estate where building value directly impacts investment returns. Energy cost savings contribute significantly to the value proposition, with reflective metal roofing reducing cooling costs by fifteen to twenty-five percent in warm climates compared to dark absorptive roofing materials. These savings compound over the building lifespan, offsetting initial cost premiums within ten to fifteen years in most applications. Insurance companies recognize the superior wind and fire resistance of metal roofing, often offering premium discounts that further improve economic performance. The elimination of business interruption costs associated with roof failures and emergency repairs provides additional but less quantifiable value.

-

Return on Investment Considerations

Building owners evaluating trapezoidal standing seam roofing should consider both tangible and intangible return factors. Tangible returns include reduced energy costs, lower maintenance expenditures, extended service life and potential insurance savings. Intangible benefits encompass improved building aesthetics, enhanced marketability, reduced operational disruption and occupant comfort improvements from better thermal performance. For industrial and commercial facilities, the ability to install solar panels without roof penetrations adds another dimension to return calculation, as energy generation revenue can significantly impact project economics. Financing options including energy performance contracts and green building loan programs can improve project feasibility by aligning costs with realized savings. Some jurisdictions offer tax incentives or accelerated depreciation for energy-efficient building systems, further enhancing financial performance. The key to maximizing return involves proper system specification matching project requirements, professional installation ensuring full performance realization, and manufacturer selection providing robust warranty coverage protecting the investment.

Conclusion

Trapezoidal standing seam roofing systems deliver comprehensive solutions for modern building challenges through superior weather protection, minimal maintenance requirements, exceptional durability and design versatility that conventional roofing materials cannot match.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 in Shaanxi Province, China, specializes in comprehensive metal roofing solutions including design, manufacturing and installation services. Recognized as a high-tech enterprise with first-level building curtain wall qualification and third-level steel structure qualification, Huafeng operates a two-hundred-thousand-square-meter production facility in Anhui alongside processing plants in Hangzhou and Xi'an. Our manufacturing capabilities include seven color coating production lines, ten shearing production lines and more than forty specialized processing machines, enabling us to deliver customized trapezoidal standing seam roofing solutions for projects of any scale.

As a China Trapezoidal Standing Seam Roofing factory, China Trapezoidal Standing Seam Roofing supplier and China Trapezoidal Standing Seam Roofing manufacturer, we offer China Trapezoidal Standing Seam Roofing wholesale solutions and have Trapezoidal Standing Seam Roofing for sale at competitive Trapezoidal Standing Seam Roofing price points. Our High Quality Trapezoidal Standing Seam Roofing products meet international standards backed by over twenty registered patents, ISO9001, ISO14001 and SGS certifications. We provide one-stop services from structural 3D modeling through installation guidance, with successful projects for Fortune 500 companies including Xiongan Station, Xi'an International Convention Center and Inner Mongolia Tongliao Art Museum. Our customization capabilities include color, pattern and design modifications, with typical delivery within fifteen to twenty days and a thirty-year warranty. Contact us at huafeng@hfmetalroof.com to discuss your project requirements.

References

1. Aluminum Association. "Aluminum Design Manual: Specifications and Guidelines for Aluminum Structures." The Aluminum Association, 2020.

2. Davies, J.M. "Lightweight Sandwich Construction." Blackwell Science, 2001.

3. Metal Construction Association. "Technical Bulletin: Standing Seam Metal Roof Systems Design and Installation Guidelines." Metal Construction Association, 2019.

4. Walker, Alan C. "Metal Building Systems: Design and Specifications." F.W. Dodge Corporation, 2002.