Picture this scenario: you've just invested in a beautiful corrugated roofing metal panels system for your coastal property, only to discover rust stains appearing within months, paint fading unevenly across different roof sections, and corrosion eating away at fasteners and panel edges. The salt-laden air, intense UV exposure from both direct sunlight and water reflection, hurricane-force winds, and relentless moisture create a perfect storm that can destroy inadequate roofing materials in record time. Choosing the right corrugated roofing metal panels for coastal climates isn't simply about aesthetics or initial cost; it's about selecting materials, coatings, and installation methods specifically engineered to withstand one of the harshest environments any building material will ever face. This comprehensive guide examines the critical factors you must consider when selecting corrugated metal sheets for oceanfront properties, from base material composition and protective coating systems to proper fastener selection and maintenance protocols, ensuring your investment delivers decades of reliable performance rather than premature failure.

Understanding Coastal Climate Challenges for Corrugated Roofing Metal Panels

Coastal environments present unique and severe challenges that can rapidly degrade improperly specified corrugated roofing metal panels. The primary threat comes from salt spray and airborne chlorides that travel considerable distances inland, sometimes affecting properties up to several miles from the ocean. When saltwater particles settle on metal surfaces, they create electrolytic cells that accelerate corrosion exponentially compared to inland locations. This galvanic corrosion process attacks the base metal substrate, particularly when protective coatings are compromised through scratches, cut edges, or fastener penetrations. Beyond salt exposure, coastal properties face intense ultraviolet radiation that breaks down paint pigments and resin systems, causing premature fading and chalking. The reflective nature of water surfaces effectively doubles UV exposure compared to inland areas, making inferior coating systems fail rapidly in beachfront applications. Hurricane-prone regions add another layer of complexity to corrugated metal sheets selection. Wind uplift forces during tropical storms can exceed 140 miles per hour in designated coastal zones, requiring fastening systems and panel profiles engineered specifically for extreme wind resistance. Many manufacturers void warranties entirely for installations within certain proximities to saltwater sources, recognizing that standard galvanized or galvalume products simply cannot survive these conditions. Temperature fluctuations, high humidity levels, and constant moisture exposure from sea spray and coastal fog further stress roofing systems. Water intrusion through improperly sealed penetrations or failed fasteners leads to accelerated degradation of underlying structural components. Understanding these environmental stressors is fundamental to selecting appropriate corrugated roofing metal panels that will perform reliably throughout their expected service life rather than requiring premature replacement.

Material Selection: Choosing the Right Base Metal for Corrugated Metal Sheets

The substrate material forms the foundation of corrugated roofing metal panels performance in coastal applications, with aluminum emerging as the most practical and cost-effective solution for saltwater environments. Unlike steel-based products, aluminum contains minimal iron content and therefore does not rust when exposed to salt spray. When aluminum does oxidize, it forms a protective aluminum oxide layer on the surface that actually shields the underlying metal from further corrosion, similar to how copper develops a protective patina. This self-protecting characteristic makes aluminum panels particularly suitable for aggressive coastal climates where other metals would rapidly deteriorate. Aluminum alloys commonly used in architectural applications include AA3003, AA3004, and AA5052, each offering excellent corrosion resistance while maintaining structural integrity. The material's lightweight properties also reduce structural loading requirements, though professional engineering review remains essential for hurricane-zone installations. Corrugated roofing metal panels manufactured from galvanized or galvalume steel should generally be avoided in direct coastal applications despite their popularity in inland regions. These steel-core products rely on sacrificial zinc or zinc-aluminum coatings to protect the underlying steel substrate. However, when the protective coating is scratched, cut, or penetrated by fasteners, the exposed steel beneath begins corroding rapidly in salt-laden environments. Many reputable manufacturers explicitly exclude coastal installations from their warranty coverage for steel-based products, recognizing the high failure risk. For property owners seeking maximum longevity and distinctive aesthetics, copper and zinc represent premium alternatives offering service lives exceeding 60 to 80 years in coastal settings. Copper develops its characteristic green patina over time, visible famously on structures like the Statue of Liberty, while zinc forms a protective carbonate layer. However, these premium materials typically cost two to three times more than aluminum, making them practical primarily for high-end architectural applications or historically significant structures where long-term value justifies the substantial initial investment.

Coating Systems: PVDF Protection for Enhanced Durability

For corrugated roofing metal panels requiring color rather than natural metal finishes, the coating system selection proves equally critical as the base material choice. Polyvinylidene fluoride coatings, commonly known as PVDF or Kynar 500, represent the gold standard for coastal applications due to their exceptional resistance to fading, chalking, and environmental degradation. PVDF resin-based coatings contain carbon-fluorine bonds, among the strongest chemical bonds known to science, which makes them virtually immune to breakdown from ultraviolet radiation, moisture, acids, pollutants, and chemical exposure. This molecular stability translates directly into superior color retention and gloss maintenance over decades of harsh coastal exposure. Manufacturers typically offer warranties covering film adhesion for 40 years and protection against chalking and fading for 30 to 40 years when PVDF coatings are applied to aluminum substrates in coastal environments. The performance difference between PVDF and lower-tier coating systems becomes dramatically apparent in side-by-side coastal installations. Documented case studies show PVDF-coated corrugated metal sheets maintaining their original appearance after eight years of exposure while adjacent sections coated with silicone-modified polyester systems exhibited significant fading and chalking during the same period. This superior performance comes from PVDF's ability to protect pigments from UV degradation, preventing the uneven fading that occurs when one roof section receives more direct sunlight than another. The coating's smooth, dense surface also resists dirt accumulation and mildew growth, reducing maintenance requirements. While PVDF coatings command premium pricing compared to polyester or SMP alternatives, the extended service life and reduced maintenance costs provide compelling long-term value. For coastal corrugated roofing metal panels installations where appearance and longevity matter, specifying PVDF coating on aluminum substrates delivers optimal performance justified by extensive real-world testing and proven track records in the most demanding saltwater environments.

Installation Considerations and Fastening Systems for Coastal Applications

Proper installation techniques and fastener selection prove absolutely critical for corrugated roofing metal panels in coastal climates, where inadequate attachment methods lead to catastrophic failures during severe weather events. Stainless steel fasteners should be specified universally for oceanfront installations, regardless of whether the system employs exposed or concealed fastening methods. When aluminum panels are used with non-stainless fasteners, galvanic corrosion occurs at the dissimilar metal interface, accelerating degradation of both the fastener and surrounding panel material. This electrochemical reaction intensifies in the presence of saltwater and moisture, creating visible corrosion stains and structural failures. Best practice for exposed fastener corrugated metal sheets involves predrilling pilot holes slightly larger than the fastener diameter, then sealing all edges with barrier coating or sealant before fastener installation to minimize direct metal-to-metal contact and reduce moisture infiltration. For hurricane-prone coastal zones, building codes often mandate specific wind uplift ratings and attachment schedules verified through rigorous testing protocols. Properties in Miami-Dade County, Florida, and similar high-risk areas require roofing systems with approvals demonstrating their ability to withstand wind speeds exceeding 140 miles per hour. Standing seam systems with concealed clip attachments generally provide superior wind resistance and weathertightness compared to exposed fastener corrugated profiles, though properly installed corrugated roofing metal panels with appropriate fastening patterns can meet code requirements when specified correctly. Panel overlapping must follow manufacturer recommendations precisely, typically requiring two corrugation overlaps for roofing applications to ensure adequate water shedding and leak prevention. All cut edges, penetrations, and terminations require sealing with compatible sealants to prevent moisture intrusion and protect exposed metal from accelerated corrosion.

Quality Control and Ongoing Maintenance Protocols

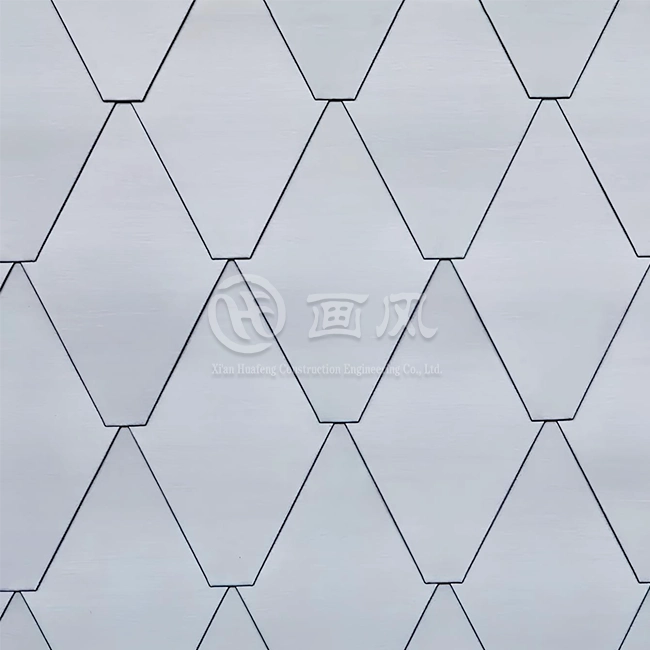

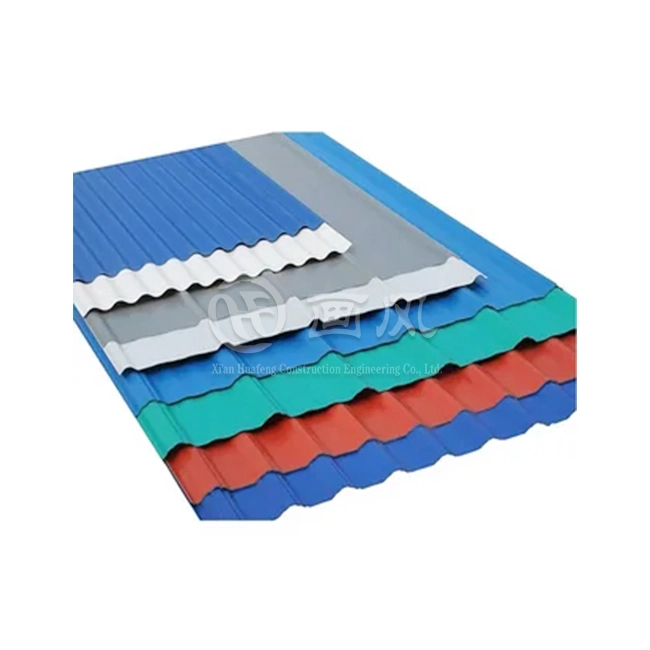

Maintaining corrugated roofing metal panels in coastal environments requires proactive inspection and maintenance protocols to maximize service life and prevent minor issues from escalating into major failures. Annual or bi-annual cleaning removes accumulated salt deposits, organic debris, and atmospheric pollutants that can compromise protective coatings over time. Cleaning should utilize mild detergent solutions and soft brushes or low-pressure water spray, avoiding abrasive materials or harsh chemicals that might damage PVDF coatings. Regular inspections should focus on fastener conditions, sealant integrity around penetrations, and any signs of coating damage from impacts or abrasion. Scratches, cut edges, or areas where protective coatings have been compromised should receive immediate touch-up treatment to prevent corrosion from initiating at these vulnerable points. Xi'an Huafeng Construction Engineering Co., Ltd. manufactures high-quality corrugated metal sheets with specifications optimized for demanding applications including coastal installations. Our corrugated roofing metal panels feature customizable widths from 750 to 1500 millimeters and thickness options ranging from 0.4 to 1.2 millimeters, allowing precise specification for wind load requirements and span conditions. Available with PE, HDP, or PVDF coating systems, our panels deliver the corrosion resistance and color retention essential for saltwater environments. With a 30-year warranty, supply capacity of 1000 tons monthly, and manufacturing capabilities across three factories utilizing seven production lines and more than 40 specialized machines, we provide reliable material solutions backed by comprehensive quality certifications including ASTM, DIN, JIS, BS, and GB/T standards. Our customization services encompass color selection, pattern design, and dimensional modifications to meet specific project requirements, with delivery timeframes of 15 to 20 days and minimum order quantities of 500 square meters making us accessible for projects of various scales.

Conclusion

Selecting appropriate corrugated roofing metal panels for coastal climates demands careful consideration of base materials, coating systems, fastening methods, and ongoing maintenance protocols to ensure decades of reliable performance in one of the most challenging environments any building material faces. Aluminum substrates with PVDF coatings provide optimal corrosion resistance and aesthetic longevity.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

As a China Corrugated Roofing metal panels factory, China Corrugated Roofing metal panels supplier, and China Corrugated Roofing metal panels manufacturer offering China Corrugated Roofing metal panels wholesale and Corrugated Roofing metal panels for sale at competitive Corrugated Roofing metal panels price points, Xi'an Huafeng delivers High Quality Corrugated Roofing metal panels backed by engineering design expertise, construction experience, seven raw material production lines, over 20 plate production machines, 20+ patent certificates, and CE, ISO, and SGS certifications. Our collaboration with Fortune 500 companies demonstrates our capability to provide customized production and one-stop procurement from raw materials through accessories, including design optimization services, material quality testing, customized products, multiple packaging options, and diverse transportation methods. Contact us at huafeng@hfmetalroof.com to discuss your coastal roofing requirements and discover how our comprehensive solutions can protect your investment for decades to come.

References

1. American Architectural Manufacturers Association. "AAMA 2605: Voluntary Specification, Performance Requirements and Test Procedures for Superior Performing Organic Coatings on Aluminum Extrusions and Panels." AAMA Standards.

2. Arkema Inc. "Kynar 500 PVDF Resin: Technical Performance Data for Architectural Coatings." Kynar 500 Technical Documentation.

3. National Oceanic and Atmospheric Administration. "Coastal Population Report: United States Coastal Counties and Their Economic Role." NOAA Office for Coastal Management.

4. Western States Metal Roofing. "Metal Roofing Materials Performance in Coastal Environments: Comparative Analysis." Metal Roofing Industry Technical Report.

5. Sherwin-Williams Coil Coatings Division. "Fluropon PVDF Coating Systems: Performance Testing in Extreme Coastal Environments." Sherwin-Williams Technical Bulletin.