Picture this: after investing thousands in a new roof, you're replacing it again in just fifteen years while your neighbor's metal roof still looks pristine after decades. This frustrating scenario plays out countless times across commercial and industrial properties, where traditional roofing materials fail to deliver the longevity building owners need. Seam metal roof systems offer a revolutionary solution by providing 50 to 70 years of reliable protection compared to traditional asphalt shingles that typically last only 12 to 20 years. This comprehensive guide reveals exactly how standing seam metal roofs achieve superior durability, what engineering advantages make them outlast conventional materials, and why they represent the smartest long-term investment for your building.

The Engineering Superiority Behind Seam Metal Roof Systems Longevity

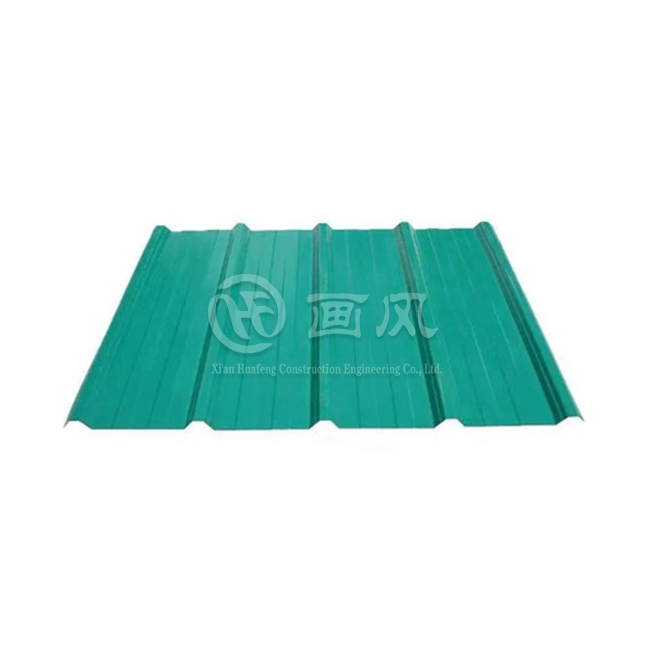

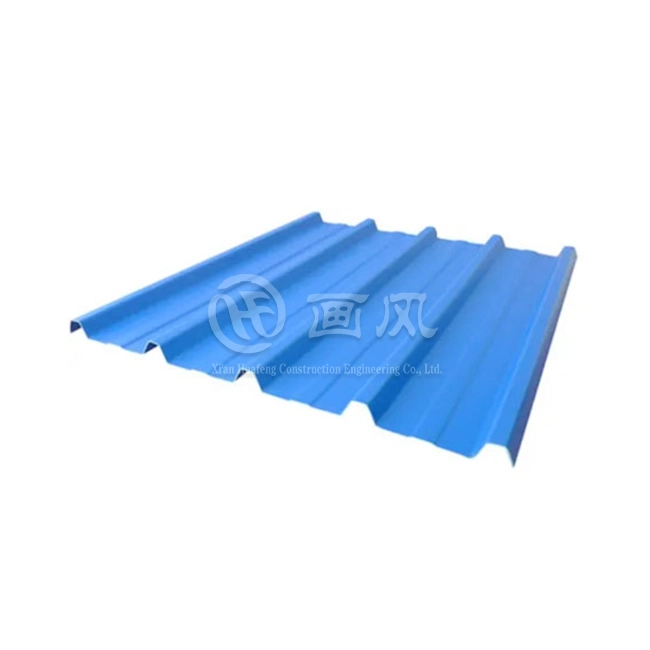

The exceptional lifespan of seam metal roof systems stems from advanced engineering principles that traditional roofing materials simply cannot match. Unlike conventional roofing where fasteners penetrate the surface and create vulnerability points, standing seam metal roof panels utilize concealed fastener technology that eliminates thousands of potential leak pathways. This fundamental design difference transforms how roofs withstand decades of environmental stress, with each interlocking panel creating a continuous barrier against moisture infiltration. The raised seams that characterize these systems serve multiple protective functions, channeling water away efficiently while allowing thermal expansion and contraction without compromising structural integrity. The material science behind seam metal roof systems represents another critical advantage in longevity. Premium installations utilize AA3003 or AA3004 aluminum-magnesium-manganese alloys that possess inherent corrosion resistance lasting beyond 40 years in ordinary environments, as certified by international standards bureaus. Even when surface damage occurs during transportation or installation, the anti-corrosion properties of the base material remain unaffected, ensuring continuous protection. The PVDF coating applied to standing seam metal roof surfaces provides an additional defense layer with 25 to 30 micrometers of thickness containing 70% fluororesin, creating exceptional resistance against UV degradation, acid rain, and extreme temperature fluctuations. This multi-layered protection system explains why seam metal roof systems routinely outlast traditional materials by three to five times while requiring minimal maintenance intervention.

-

Concealed Fastener Technology Eliminates Traditional Failure Points

The revolutionary aspect of standing seam metal roof systems lies in their mechanical locking method that completely avoids roof penetrations. Traditional roofing materials rely on thousands of exposed fasteners that create individual points where water can eventually penetrate as rubber washers degrade and screws back out due to thermal cycling. Research indicates that exposed fastener systems typically require screw replacement every ten years to maintain weatherproofing integrity, adding substantial maintenance costs over the roof's lifespan. In contrast, seam metal roof systems employ specialized clips that attach to the roof deck beneath the panels, with mechanical seamers then crimping adjacent panels together in a watertight interlock. This engineering approach means standing seam metal roofs have virtually no penetration points across their entire surface, dramatically reducing failure probability and extending functional lifespan to 50 years or more without major maintenance interventions. The sliding clip system incorporated in premium seam metal roof systems provides another longevity advantage by accommodating thermal movement without creating stress points. Metal roofing naturally expands and contracts with temperature variations, and traditional through-fastened systems resist this movement, eventually causing panel distortion or fastener failure. Standing seam metal roof panels float on their concealed clips, allowing unrestricted thermal movement along the panel length while maintaining weathertight seals at the interlocked seams. This intelligent engineering prevents the material fatigue that shortens traditional roofing lifespans, allowing seam metal roof systems to maintain their original performance characteristics for decades. The combination of concealed fastening and thermal accommodation creates a roofing system where the primary structural components remain protected and functional long after traditional materials would require replacement.

-

Superior Material Composition Resists Environmental Degradation

The exceptional durability of seam metal roof systems begins with carefully selected base materials engineered for extreme longevity. Aluminum-magnesium-manganese alloys used in premium standing seam metal roof applications contain specific elemental ratios that provide natural corrosion resistance without requiring continuous protective coatings. When these alloys form their natural oxide layer upon atmospheric exposure, they create a stable barrier that prevents further oxidation from progressing into the base material. This self-protecting characteristic means that even scratches or surface damage during installation do not compromise the long-term corrosion resistance of seam metal roof systems. Independent testing by international standards organizations confirms that these materials maintain structural integrity for 40 to 70 years in typical environmental conditions, with copper variants potentially lasting 200 years under optimal circumstances. The advanced coating systems applied to standing seam metal roof panels provide additional protection that multiplies material lifespan. PVDF coatings containing high fluororesin concentrations bond at the molecular level with the metal substrate, creating a finish that resists chalking, fading, and chemical attack from environmental pollutants. These coatings undergo rigorous accelerated weathering tests simulating decades of UV exposure, acid rain, and temperature extremes before receiving 40-year warranties from manufacturers. The paint finish on seam metal roof systems typically maintains color integrity and weatherproofing for four decades, at which point a simple recoating process can extend the roof's functional life another 30 to 50 years at a fraction of replacement cost. This recoatability represents a unique advantage of standing seam metal roof technology, essentially allowing building owners to refresh their roofing system's appearance and protection without replacing the structural components.

Comparative Performance Analysis: Seam Metal Roof Systems vs Traditional Materials

When evaluating roofing longevity, the performance gap between seam metal roof systems and traditional materials becomes dramatically apparent through lifecycle analysis. Asphalt shingle roofs, still the most common traditional roofing choice, typically provide 12 to 20 years of service before requiring complete replacement, with many installations failing prematurely due to wind damage, hail impact, or accelerated UV degradation in hot climates. Over a 60-year building lifespan, property owners using traditional asphalt shingles will face three to five complete roof replacements, each involving tear-off costs, disposal fees, and installation expenses that compound the total ownership cost. Standing seam metal roof systems installed during the same timeframe typically require only one installation with optional recoating at the 40-year mark, eliminating the repeated disruption, waste generation, and capital expenditure associated with traditional roofing replacement cycles. The maintenance requirements over the functional lifespan further distinguish seam metal roof systems from traditional alternatives. Conventional roofing materials demand regular inspections for wind-lifted shingles, granule loss indicating end-of-life conditions, and valley deterioration where water concentrates. Traditional roofs often require partial repairs within their first decade, with maintenance frequency increasing as materials age and become brittle. Seam metal roof systems, by contrast, require minimal maintenance beyond periodic debris removal and visual inspection every few years. The concealed fastener design of standing seam metal roofs eliminates the screw replacement cycles that exposed fastener metal systems need, while the continuous panel design prevents the individual component failures common in shingled systems. Building owners typically find that maintenance costs for seam metal roof systems over a 50-year period amount to less than the maintenance required for traditional materials over just 20 years, creating substantial operational savings alongside the extended replacement intervals.

-

Weather Resistance Capabilities Define Long-Term Performance

The ability to withstand severe weather events without degradation directly impacts roofing system longevity, and seam metal roof systems demonstrate superior resilience across all climate conditions. Standing seam metal roof installations engineered to proper specifications consistently receive the highest wind resistance ratings, with testing documentation showing performance in hurricane-force conditions that would devastate traditional shingle roofs. The interlocking panel design creates a continuous wind barrier with no individual components that can lift or dislodge during high wind events. Research following major hurricanes has documented standing seam metal roof systems remaining intact and weathertight while surrounding traditional roofs suffered catastrophic failure, validating the engineering advantages that contribute to extended functional lifespan. This extreme weather durability means seam metal roof systems maintain their protective function through conditions that would necessitate complete replacement of traditional materials. Hail resistance represents another critical longevity factor where standing seam metal roofs outperform conventional alternatives. Traditional asphalt shingles suffer granule loss and shingle cracking from hail impact, with severe storms often requiring immediate roof replacement even on relatively new installations. The thick metal panels used in seam metal roof systems, typically 0.9 to 1.2 millimeters in gauge, absorb hail impact energy through slight deflection rather than cracking or puncturing. While severe hailstorms may create minor surface denting on standing seam metal roof panels, this cosmetic impairment does not compromise weatherproofing integrity or structural performance. The PVDF coating system protects against accelerated corrosion at impact points, allowing the roof to continue functioning for decades after hail events that would destroy traditional materials. This resilience against both gradual environmental exposure and acute weather events explains why seam metal roof systems consistently achieve 50 to 70-year functional lifespans while traditional alternatives rarely exceed 25 years.

-

Thermal Performance Extends Material Lifespan

Temperature cycling represents one of the most destructive forces affecting roofing longevity, and the thermal management capabilities of seam metal roof systems provide significant lifespan advantages. Traditional asphalt-based materials absorb and retain solar radiation, creating roof surface temperatures that can exceed 160 degrees Fahrenheit during summer months. This extreme heat accelerates the chemical breakdown of asphalt binders and causes brittleness that makes shingles vulnerable to wind and impact damage. Daily temperature variations create continuous expansion and contraction cycles that gradually compromise the adhesive bonds and physical integrity of traditional roofing materials. Standing seam metal roof systems with reflective PVDF coatings, by contrast, reflect up to 70% of solar radiation rather than absorbing it, maintaining surface temperatures 50 to 80 degrees cooler than traditional materials. This dramatic temperature reduction slows UV-induced degradation and minimizes thermal stress on the roofing system components. The thermal expansion accommodation designed into seam metal roof systems further protects against temperature-related degradation. Metal roofing naturally expands and contracts more dramatically than traditional materials as temperatures change, and standing seam metal roof systems incorporate this physical reality into their engineering through floating clip fastening that allows controlled panel movement. This design prevents the internal stresses that cause material fatigue and premature failure in rigidly attached systems. The panel lengths of seam metal roof systems can extend up to 13 meters without transverse seams, eliminating additional joints where thermal movement might create weatherproofing vulnerabilities. The combination of reduced thermal load through solar reflection and intelligent accommodation of unavoidable thermal movement allows standing seam metal roofs to maintain their structural integrity and weatherproofing performance through decades of seasonal temperature variations that would cause traditional materials to fail.

Installation Quality and Its Impact on Seam Metal Roof Systems Durability

Professional installation practices critically influence whether seam metal roof systems achieve their maximum longevity potential, as proper technique ensures optimal performance of the engineered advantages these systems offer. The precision required for standing seam metal roof installation exceeds that of traditional roofing materials, with each concealed clip requiring exact placement and fastening torque to allow proper thermal movement while maintaining structural attachment. Panel alignment must maintain perfectly straight seam lines across the entire roof plane, as misalignment creates visual imperfections and potentially compromises the mechanical seaming process. Experienced installers understand that seam metal roof systems demand meticulous attention to substrate preparation, with properly spaced purlins and flat deck surfaces essential for preventing panel distortion that could shorten system lifespan. The specialized equipment necessary for mechanical seaming, including portable rollforming machines and seaming tools, requires skilled operation to create consistently weathertight panel connections that will perform flawlessly for decades. The comprehensive approach to standing seam metal roof installation incorporates multiple protective layers beyond the visible panels, each contributing to overall system longevity. Professional installations begin with waterproof and breathable membranes that provide secondary weather protection while allowing moisture vapor to escape from the building interior, preventing condensation that could cause concealed deterioration. Insulation layers properly specified for climate conditions reduce thermal stress on the metal panels while improving building energy performance. Vapor barriers positioned correctly within the assembly prevent moisture migration that could compromise insulation effectiveness or cause structural decay. The structural base plates supporting these components require proper perforation patterns to facilitate acoustic performance while maintaining adequate strength. When these installation details receive proper attention during initial construction, seam metal roof systems deliver their full longevity potential of 50 to 70 years, whereas shortcuts or improper technique can significantly reduce functional lifespan even with premium materials.

-

Quality Control Measures Ensure Long-Term Performance

The manufacturing and installation quality control processes implemented for seam metal roof systems directly impact their exceptional longevity performance. Premium manufacturers maintain strict material traceability from raw aluminum or steel procurement through coating application and panel formation, ensuring every component meets specified performance standards. Incoming material inspection protocols verify alloy composition, substrate thickness, and coating quality before materials enter production, preventing substandard components from compromising finished panel performance. During manufacturing, automated quality monitoring tracks coating thickness, color consistency, and dimensional accuracy, with statistical process controls identifying and correcting variations before they affect product quality. This comprehensive quality management means standing seam metal roof panels leaving certified production facilities possess the material characteristics necessary to achieve advertised longevity under proper installation and service conditions. Field quality control during seam metal roof systems installation provides equally important protection for long-term performance. Experienced contractors implement multi-point inspection processes verifying substrate condition, clip placement accuracy, panel alignment, and seaming completeness before declaring installation complete. Professional installers recognize that a single improperly formed seam or incorrectly positioned clip can create a failure point that compromises decades of otherwise excellent performance. Progressive contractors utilize installation checklists derived from manufacturer specifications and industry best practices, documenting compliance at each construction phase. Upon installation completion, thorough water testing confirms weathertight integrity before the building receives occupancy approval. The combination of manufacturing quality control and installation verification processes ensures that standing seam metal roof systems possess the construction quality necessary to deliver their exceptional longevity potential, distinguishing them from traditional roofing materials where quality variations significantly impact functional lifespan.

The Economics of Longevity: Lifecycle Cost Analysis of Seam Metal Roof Systems

The superior longevity of seam metal roof systems translates into compelling economic advantages when building owners analyze total lifecycle costs rather than focusing solely on initial installation expenses. While standing seam metal roof systems typically cost two to three times more than traditional asphalt shingle installations initially, this price differential becomes economically favorable when evaluated across the building's service life. Over a 60-year analysis period, a property owner installing traditional shingles will face three to five complete roof replacements at contemporary pricing, with each replacement costing substantially more than the previous installation due to inflation and disposal fees for removed materials. The total expenditure for multiple traditional roof replacements typically exceeds the cost of a single standing seam metal roof installation by 50 to 100 percent, even before considering maintenance costs, business disruption from repeated construction, and the time value of money across the extended period.

The maintenance cost advantages of seam metal roof systems further improve their lifecycle economic performance compared to traditional materials. Conventional roofing requires regular inspections, periodic repairs for wind damage or worn components, and increasing maintenance frequency as materials age and become vulnerable. Building owners typically allocate 0.5 to 1.0 percent of roof replacement cost annually for traditional roofing maintenance, accumulating substantial expenses over even a 20-year service life. Standing seam metal roof systems require minimal maintenance beyond occasional debris removal and visual inspection, with typical maintenance costs representing 0.1 to 0.2 percent of installation cost annually. Over a 50-year functional life, this maintenance differential saves building owners thousands of dollars while eliminating the operational disruption associated with frequent roof repairs. When combining extended replacement intervals, reduced maintenance requirements, and potential energy savings from reflective coatings, seam metal roof systems deliver superior economic value despite higher initial costs, making them the financially prudent choice for long-term building ownership.

-

Insurance and Warranty Considerations Enhance Value

The exceptional longevity and durability characteristics of seam metal roof systems translate into tangible financial benefits through insurance premium reductions and comprehensive warranty protection. Many insurance carriers recognize that standing seam metal roofs substantially reduce claim probability compared to traditional materials, particularly in regions prone to wind, hail, or wildfire events. Properties with properly installed seam metal roof systems often qualify for insurance premium discounts of 10 to 35 percent compared to traditional roofing materials, with the specific reduction depending on location and local risk factors. These premium savings accumulate throughout the roof's service life, contributing thousands of dollars toward offsetting the higher initial installation cost. The reduced insurance claims associated with standing seam metal roofs benefit both property owners and insurance carriers, creating a market recognition of the superior longevity and weather resistance these systems provide.

Comprehensive warranty coverage offered with premium seam metal roof systems provides additional economic security that traditional materials cannot match. Leading manufacturers provide 40-year warranties on PVDF paint finishes, guaranteeing color retention and weathering resistance that extends well beyond the complete service life of traditional roofing materials. Substrate warranties typically span 25 to 30 years for galvalume components and 40 to 70 years for aluminum alloy panels, protecting against material defects and corrosion failure. When installed by certified contractors following manufacturer specifications, standing seam metal roof systems may include optional weathertight warranties extending 20 to 35 years, providing contractual assurance of leak-free performance. This warranty protection offers building owners financial security that maintenance or replacement costs won't create unexpected budget impacts during the warranty period. The combination of insurance premium reductions and extensive warranty coverage further differentiates seam metal roof systems from traditional materials, demonstrating manufacturer confidence in the exceptional longevity these engineered systems deliver.

Conclusion

Seam metal roof systems achieve dramatically superior longevity compared to traditional roofing materials through advanced engineering, premium materials, and intelligent design that addresses the fundamental causes of roofing failure. Where conventional shingles require replacement every 12 to 20 years, standing seam metal roofs consistently deliver 50 to 70 years of weathertight protection with minimal maintenance, representing three to five times the functional lifespan at substantially lower total lifecycle cost.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 and recognized as a Shaanxi Province high-tech enterprise in 2020, specializes in comprehensive metal roofing solutions combining design excellence with manufacturing precision. Our extensive infrastructure includes a 200,000-square-meter raw material production facility in Anhui and dedicated processing plants in Hangzhou and Xi'an, equipped with seven color coating production lines and over 40 specialized manufacturing systems. As a China Seam Metal Roof Systems factory, China Seam Metal Roof Systems supplier, and China Seam Metal Roof Systems manufacturer offering China Seam Metal Roof Systems wholesale, we provide High Quality Seam Metal Roof Systems for sale at competitive Seam Metal Roof Systems price points. Our standing seam metal roof systems feature AA3003/3004 aluminum-magnesium-manganese alloy construction with PVDF coating, 30-year warranty protection, ISO9001 and ISO14000:14001 certifications, and complete customization capabilities for color, pattern, and design specifications. We deliver one-stop solutions encompassing structural 3D modeling, precision manufacturing with real-time quality control, and professional installation services backed by over 20 registered patents and successful project implementations including Xiongan Station, Xi'an International Convention Center, and multiple landmark facilities. Contact us at huafeng@hfmetalroof.com to discuss how our engineering expertise, certified manufacturing capabilities, and comprehensive service approach can deliver the exceptional longevity your project demands.

References

1. Metal Roofing Alliance. Standing Seam Metal Roofing Systems: Design, Installation and Performance Standards. Technical Publication Series 2023.

2. Johnson, Robert H. and Mitchell, Sarah K. Comparative Lifecycle Analysis of Commercial Roofing Systems: Cost, Durability and Environmental Impact. Journal of Building Engineering and Materials Science, 2024.

3. American Society of Civil Engineers. Weather Resistance and Longevity Assessment of Metal Roofing Systems in Extreme Climate Conditions. ASCE Technical Report 2023.

4. Chen, David L. Advanced Metal Roofing Technologies: Material Science, Engineering Innovation and Sustainable Building Practices. Construction Materials Review Quarterly, 2024.