Choosing the right exterior cladding solution can feel overwhelming, especially when you're weighing durability against aesthetics, maintenance requirements, and long-term costs. If you're considering metal siding for your commercial, industrial, or residential project, understanding its key characteristics is essential to making an informed decision. Vertical Metal Siding Sheets have emerged as a premier choice for modern architecture, offering unmatched weather resistance, minimal upkeep, and striking visual appeal that enhances any building's facade while providing decades of reliable protection.

1. Material Selection and Durability of Vertical Metal Siding Sheets

When investing in metal siding, the material you choose directly impacts your building's performance, longevity, and aesthetic appeal. Understanding the distinct properties of various metal options helps ensure your project meets both functional requirements and design expectations.

-

Galvanized Steel: The Industry Workhorse

Galvanized steel remains the most popular choice for Vertical Metal Siding Sheets in commercial and industrial applications due to its exceptional strength-to-cost ratio. The galvanization process involves coating steel with a protective zinc layer that creates a robust barrier against corrosion, extending the material's service life significantly. Premium manufacturers apply zinc coating to both sides of the panels, providing comprehensive protection that prevents rust from developing even in challenging environmental conditions. When selecting galvanized steel panels, gauge thickness matters considerably—lower gauge numbers indicate thicker, stronger material that better resists denting from hail, debris impacts, or accidental contact during maintenance activities. Standard offerings typically range from 24-gauge to 26-gauge, with 24-gauge providing enhanced durability for high-traffic areas or buildings exposed to severe weather patterns. The material's inherent strength allows it to withstand extreme temperature fluctuations, heavy wind loads, and moisture exposure without warping, expanding, or deteriorating, making it ideal for structures requiring long-term performance with minimal intervention.

-

Aluminum-Magnesium-Manganese Alloy: Premium Performance

Aluminum-magnesium-manganese plates represent the premium tier of Vertical Metal Siding Sheets, offering superior corrosion resistance that makes them particularly suitable for coastal environments where salt air accelerates metal degradation. This specialized alloy combines aluminum's lightweight properties with enhanced structural integrity derived from magnesium and manganese additions, creating panels that deliver exceptional performance across diverse climate zones. The material naturally forms a protective oxide layer that continuously regenerates, providing self-healing protection against scratches and surface damage that might compromise lesser materials. Buildings clad with aluminum-magnesium-manganese panels benefit from reduced structural loading requirements due to the material's low density, which can translate to cost savings in foundation and framework engineering. The alloy's thermal expansion coefficient closely matches that of supporting structures, minimizing stress-related failures at connection points during seasonal temperature swings. For projects prioritizing longevity and minimal lifecycle costs, aluminum-magnesium-manganese Vertical Metal Siding Sheets justify their higher initial investment through decades of maintenance-free service and sustained aesthetic appeal.

-

Stainless Steel and Specialty Metals

High-corrosion environments demand materials that exceed standard galvanized steel performance, making stainless steel Vertical Metal Siding Sheets the optimal choice for chemical processing facilities, pharmaceutical plants, food production buildings, and other specialized applications. Grade 316 stainless steel offers superior resistance to chloride-induced corrosion, while grade 304 provides excellent general-purpose protection at a more accessible price point. These materials maintain their structural integrity and appearance even when exposed to harsh chemicals, high humidity, or aggressive cleaning protocols that would rapidly degrade conventional siding options. Titanium-zinc plates represent another premium category, offering exceptional durability and a distinctive weathering characteristic where the surface develops a protective patina over time, creating a unique aesthetic that many architects embrace for contemporary design statements. The material's self-healing properties mean that minor scratches naturally blend into the patina layer, maintaining visual consistency without requiring remediation.

2. Profile Options and Architectural Applications

The profile configuration of Vertical Metal Siding Sheets significantly influences both the visual character of your building and its functional performance, making profile selection a critical decision that deserves careful consideration during the design phase.

-

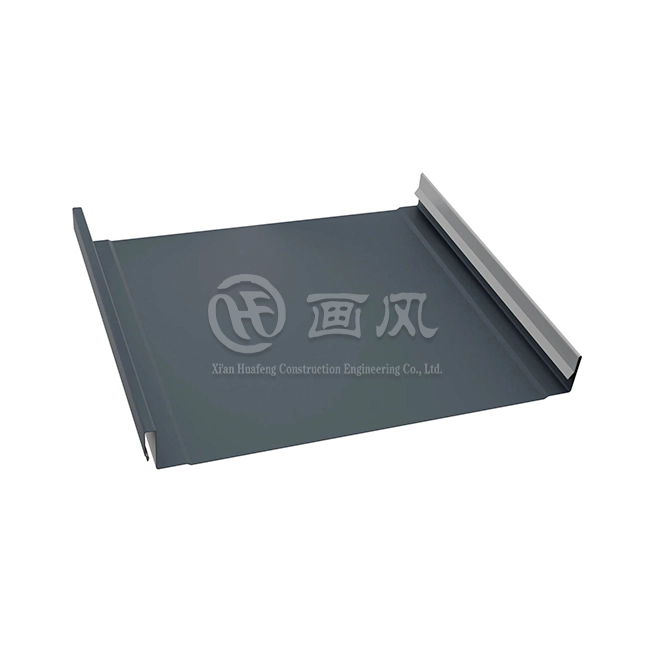

Standing Seam Systems: Modern Elegance

Standing seam Vertical Metal Siding Sheets deliver clean, contemporary lines that have become synonymous with modern architectural design. This profile features vertical panels with raised interlocking seams that run continuously from the building's base to its roofline, creating bold vertical emphasis that visually elongates structures and projects sophistication. The concealed fastener system represents a key advantage, as mounting clips attach to the building substrate beneath the seam caps, leaving the visible panel surfaces completely free of exposed screws or penetrations. This design approach serves both aesthetic and functional purposes—the uninterrupted metal surfaces present a sleek appearance while eliminating potential water intrusion points that plague exposed fastener systems. The raised seams themselves create natural drainage channels that efficiently direct rainwater downward, preventing moisture accumulation that could compromise building envelope integrity. Standing seam configurations accommodate substantial thermal expansion and contraction through floating clip systems that allow panels to move freely while maintaining weathertight seals, a critical feature for buildings spanning significant horizontal or vertical dimensions. These systems work exceptionally well on commercial office buildings, retail developments, institutional facilities, and high-end residential projects where architectural distinction justifies premium investment.

-

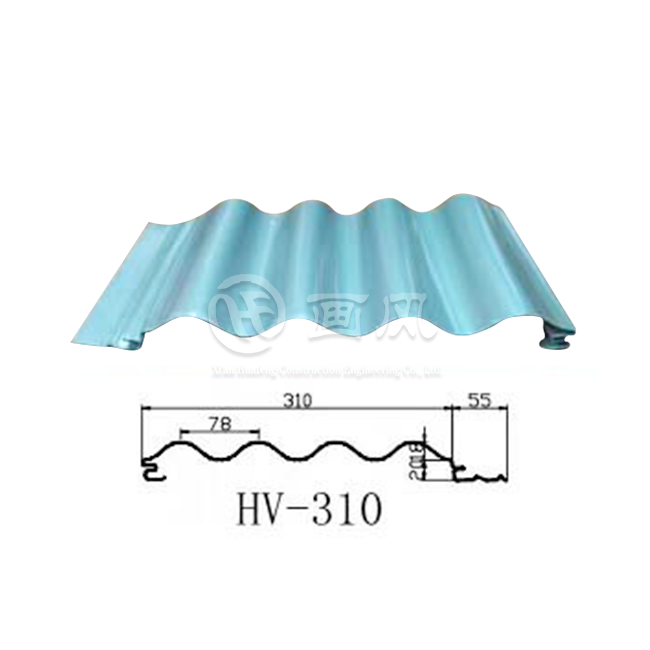

Ribbed and Corrugated Profiles

Ribbed and corrugated Vertical Metal Siding Sheets bring industrial strength and distinctive texture to building exteriors, making them ideal for warehouses, manufacturing facilities, agricultural structures, and contemporary residential designs embracing utilitarian aesthetics. The characteristic ridges and valleys inherent to these profiles serve structural purposes beyond visual interest—the corrugations significantly increase panel stiffness without adding material thickness or weight, allowing for wider unsupported spans that reduce framing requirements and accelerate installation timelines. This geometric reinforcement helps panels resist buckling under wind loads while maintaining dimensional stability during thermal cycling, contributing to long-term performance reliability. The pronounced surface texture creates dynamic shadow patterns that evolve throughout the day as sunlight angles change, adding visual depth and dimensional interest to what might otherwise present as monotonous flat surfaces. Corrugated panels excel in applications requiring maximum durability at economical price points, delivering exceptional value for projects where functional performance outweighs refined architectural expression. Modern manufacturing capabilities have expanded corrugated panel offerings beyond traditional industrial profiles to include refined ribbed patterns with subtle depth variations that bridge the gap between rugged utility and contemporary sophistication.

-

Flat Lock and Batten Seam Variations

Flat lock panels provide smooth, modern surfaces with concealed fastening systems that create seamless expanses of metal ideally suited to minimalist architectural visions. These Vertical Metal Siding Sheets utilize interlocking edge details that create virtually invisible joints, allowing the material itself to become the dominant design element without visual interruption from seam lines or fastener patterns. Batten-seam panels take a contrasting approach, featuring raised battens applied over panel joints to create pronounced vertical lines that add traditional character or contemporary rhythm depending on batten dimensions and spacing intervals. This profile offers flexibility for designers seeking to bridge historical precedent with modern materials, as batten configurations can echo classical architectural proportions while delivering metal siding's superior performance characteristics.

3. Protective Coatings and Color Retention Technology

The longevity and aesthetic durability of Vertical Metal Siding Sheets depends significantly on the protective coating system applied to the base metal, making coating selection as important as material choice for long-term project success.

-

PVDF Coating Systems: Premium Protection

Polyvinylidene fluoride coating technology, commonly marketed as PVDF, represents the pinnacle of metal siding finish systems, offering unparalleled color retention, gloss maintenance, and environmental resistance that justifies its premium positioning. This advanced resin chemistry creates molecular bonds that resist degradation from ultraviolet radiation, industrial pollutants, salt spray, and chemical exposure that rapidly compromise lesser coating systems. Buildings clad with PVDF-coated Vertical Metal Siding Sheets maintain their as-installed appearance for decades, avoiding the chalking, fading, and color shift that plague polyester-coated alternatives exposed to intense sunlight or harsh environmental conditions. The coating's low surface energy inhibits dirt adhesion, meaning that natural rainfall often provides sufficient cleaning to maintain visual appeal without regular manual washing interventions. For projects where sustained aesthetic quality directly impacts property value or brand image—such as corporate headquarters, retail developments, hospitality venues, and institutional buildings—PVDF coating systems deliver measurable return on investment through extended maintenance intervals and deferred replacement costs. Many premium manufacturers offer 30-year warranties on PVDF-coated products, providing documented assurance of long-term performance that facilitates lifecycle cost analysis and supports sustainable building practices through extended useful service lives.

-

Polyester and HDP Coating Options

High-durability polyester and standard polyester coating systems provide cost-effective protection for Vertical Metal Siding Sheets in applications where extreme environmental exposure or extended maintenance-free performance may not justify PVDF premium pricing. HDP formulations incorporate modified polyester resins that deliver enhanced UV resistance and improved color retention compared to standard polyester, positioning them as a middle-tier option that balances performance and economy. These coatings perform admirably in moderate climate zones with typical industrial or commercial use patterns, offering reliable protection against moisture infiltration, mild chemical exposure, and normal weathering processes. Buildings in temperate regions with regular maintenance programs can achieve satisfactory long-term results with polyester-coated panels, particularly when color selection emphasizes earth tones or neutral shades that naturally conceal subtle fading over extended service periods. Standard polyester coatings remain appropriate for agricultural buildings, light industrial facilities, and budget-conscious projects where functional protection takes precedence over sustained cosmetic perfection.

-

Color Selection and Architectural Integration

Modern Vertical Metal Siding Sheets are available in extensive color ranges that span neutral earth tones, bold accent hues, metallic finishes, and custom-matched specifications that align with corporate branding or design guidelines. Light-reflective colors in beige, gray, and white families help reduce solar heat gain, contributing to improved building energy performance by decreasing cooling loads during warm months. Dark colors create dramatic architectural statements but require PVDF coating systems to maintain their depth and richness under sustained UV exposure that would cause rapid degradation in lesser finishes. Metallic and textured finishes add dimensional interest and visual complexity that distinguishes buildings from conventional flat-finish installations, creating signature appearances that enhance brand recognition and architectural distinction.

4. Installation Methodology and Weather Sealing

Professional installation practices directly determine whether Vertical Metal Siding Sheets achieve their performance potential or suffer premature failures that compromise building envelope integrity and generate costly remediation requirements.

-

Substrate Preparation and Framing Requirements

Successful metal siding installation begins with proper substrate preparation that provides stable, planar mounting surfaces aligned to stringent tolerance standards. Structural framing must accommodate panel dimensions, thermal movement characteristics, and load transfer requirements specific to the selected profile and material specification. Standing seam systems require continuous structural members at clip locations to ensure adequate fastener engagement and load distribution, while corrugated profiles can span greater distances between supports due to their inherent stiffness. Building wrap or moisture barrier installation precedes panel mounting, creating a secondary weatherization layer that manages incidental water infiltration and provides additional protection against wind-driven moisture penetration. Proper flashing details at penetrations, terminations, and transitions represent critical junctures where installation quality separates successful long-term performance from premature failure modes. Professional installers understand that metal siding functions as part of an integrated building envelope system where each component—structural support, moisture barriers, insulation layers, and exterior cladding—must work cohesively to achieve design objectives.

-

Fastening Systems and Thermal Movement Accommodation

Concealed fastener systems employed in standing seam Vertical Metal Siding Sheets utilize specially designed clips that secure panels to the substrate while permitting controlled thermal expansion and contraction. These clips feature slotted mounting holes or elongated channels that allow panels to slide vertically as temperature variations induce dimensional changes, preventing stress accumulation that could cause fastener failure, panel buckling, or connection point tearing. Exposed fastener systems require careful selection of fastener types, spacing intervals, and sealing details to prevent water intrusion while maintaining adequate holding power under design wind loads. Self-drilling screws with integral EPDM or neoprene sealing washers create weathertight penetrations when installed at proper torque values that compress the washer without over-tightening to the point of metal deformation or washer damage. Installers must account for panel overlap requirements, ensuring that horizontal joints shed water effectively without creating pathways for moisture migration into the building envelope.

-

Quality Control and Performance Testing

Reputable manufacturers and installation contractors implement rigorous quality control protocols that verify dimensional accuracy, coating integrity, proper fastener installation, and weatherization system continuity throughout the construction process. Post-installation testing should include water penetration testing at critical details, thermal imaging to identify insulation deficiencies or air leakage paths, and visual inspection to confirm aesthetic consistency across the entire building facade. Professional installation teams visit construction sites in advance to verify substrate conditions, confirm material deliveries, and review installation sequences with trade coordination, preventing costly delays or rework from inadequate preparation. Upon completion, thorough testing ensures zero-leakage performance that protects building interiors and validates warranty coverage for long-term peace of mind.

5. Lifecycle Costs and Sustainability Considerations

Understanding the total cost of ownership for Vertical Metal Siding Sheets requires analysis beyond initial material and installation expenses to encompass maintenance requirements, energy performance impacts, and end-of-life material recovery potential.

-

Maintenance Requirements and Service Life Expectations

Metal siding's low-maintenance characteristics represent a compelling advantage over alternative cladding systems that demand regular painting, sealing, or replacement to maintain performance and appearance. Vertical Metal Siding Sheets with premium PVDF coatings require only periodic washing with mild detergent and water to remove accumulated dirt and environmental deposits, a simple maintenance protocol that building occupants or facility staff can execute without specialized equipment or contractor engagement. This contrasts sharply with wood siding requiring paint renewal every five to seven years, vinyl siding susceptible to brittleness and cracking necessitating periodic replacement, or stucco finishes prone to cracking and moisture intrusion requiring ongoing monitoring and remediation. Quality metal siding systems backed by comprehensive warranties provide 30-year to 50-year service life expectations with minimal intervention, allowing building owners to defer replacement costs and redirect maintenance budgets toward other facility priorities. The material's resistance to rot, insect damage, fire, and moisture-related deterioration eliminates entire categories of maintenance concerns that plague organic or composite materials.

-

Energy Performance and Thermal Management

Properly installed Vertical Metal Siding Sheets over continuous insulation layers contribute to improved building energy efficiency by creating thermal breaks that interrupt heat transfer pathways between exterior and interior environments. Metal's reflective properties help reject solar heat gain during warm months, reducing cooling loads and associated energy consumption in commercial and residential applications. Light-colored finishes enhance this effect by reflecting greater percentages of incident solar radiation rather than absorbing it as heat energy that must subsequently be removed by mechanical cooling systems. When integrated with comprehensive building envelope strategies including air sealing, vapor barriers, and appropriate insulation values, metal siding systems support high-performance building designs targeting reduced operating costs and enhanced occupant comfort. The material's dimensional stability prevents gaps and air leakage pathways from developing over time, maintaining designed thermal performance throughout the building's service life.

-

Environmental Impact and Material Recovery

Metal siding's sustainability credentials include high recycled content in manufacturing, complete recyclability at end of service life, and extended useful life spans that defer resource consumption associated with material replacement cycles. Steel and aluminum rank among the most recycled materials globally, with established collection, processing, and remanufacturing infrastructure that efficiently returns scrap material to productive use. Buildings decommissioned after decades of service yield metal siding panels that retain value as recyclable commodities, offsetting disposal costs while supporting circular economy principles. The material's durability reduces construction waste generation by eliminating premature replacement requirements that characterize less robust siding options, contributing to reduced landfill burden and resource conservation. For projects pursuing green building certifications or corporate sustainability objectives, metal siding specifications align with environmental stewardship goals while delivering superior functional performance.

Conclusion

Selecting Vertical Metal Siding Sheets for your building project represents a strategic investment in durability, aesthetic versatility, and long-term performance that protects your structure while minimizing lifecycle costs and maintenance obligations over decades of service.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 in Shaanxi Province, China, stands as a professional manufacturer specializing in metal roofing systems, building curtain wall systems, and steel structure enclosure solutions. Recognized as a high-tech enterprise in Shaanxi Province since 2020, Huafeng holds first-level qualification for building curtain walls and third-level qualification for building steel structures, demonstrating our commitment to industry excellence and regulatory compliance. Our manufacturing capabilities include a raw material production plant covering 200,000 square meters in Anhui, complemented by two plate and accessories processing facilities in Hangzhou and Xi'an. This integrated infrastructure encompasses seven color coating production lines, one laminating production line, ten longitudinal and transverse shearing production lines, fully automatic punching systems, and over 40 specialized processing machines, ensuring high-volume production capacity exceeding 1,000 tons monthly while maintaining stringent quality standards.

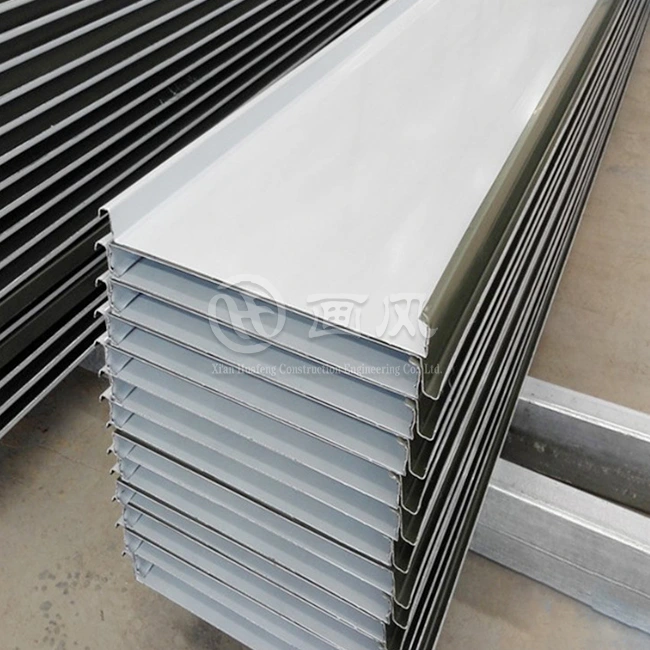

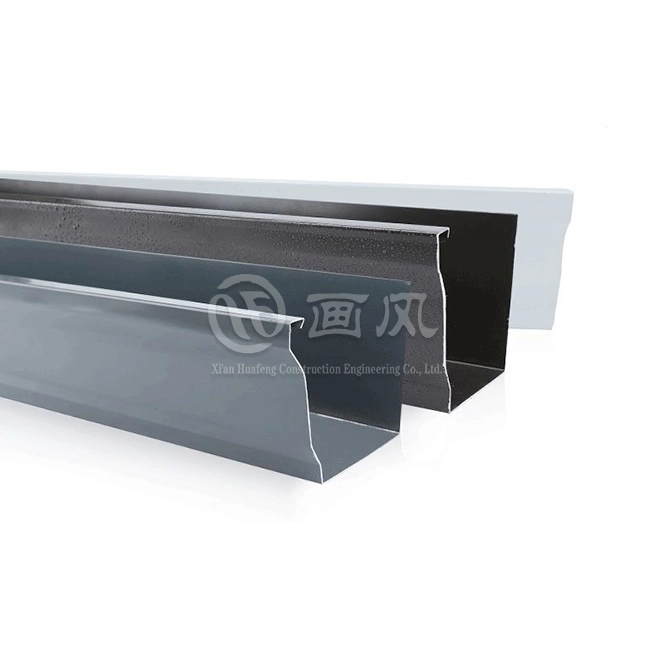

Our product portfolio features premium Vertical Metal Siding Sheets manufactured from carefully selected materials including aluminum alloys from Alucosuper, YATAI, and LIDAO; steel products from BAOSTEEL, GUANZHOU, and XINYU; stainless steel from Baosteel and Tsingshan; titanium-zinc plates from NedZink; and copper from Chinalco. Every material undergoes rigorous incoming inspection protocols including appearance verification, dimensional accuracy assessment, salt spray testing, adhesion evaluation, hardness measurement, impact resistance testing, film thickness verification, acid resistance confirmation, weather resistance validation, and color consistency analysis. This comprehensive quality assurance process, aligned with ISO9001, ISO14000:14001, and SGS guidelines, ensures that only materials meeting our exacting standards enter production. As a leading China Vertical Metal Siding Sheets factory, China Vertical Metal Siding Sheets supplier, and China Vertical Metal Siding Sheets manufacturer, we offer China Vertical Metal Siding Sheets wholesale solutions with competitive Vertical Metal Siding Sheets prices. Our High Quality Vertical Metal Siding Sheets for sale include specifications ranging from 25-330/400/430/500 to 65-400/430/500 profiles, available with PE, HDP, and PVDF coating finishes. Each project benefits from our 30-year warranty, 15-20 day delivery timeframes, and minimum order quantities starting at 500 square meters. We provide comprehensive customization services encompassing color selection, pattern design, and specification optimization tailored to your unique project requirements.

Our one-stop service model encompasses complete design optimization, technical drawing development with 1:1 node detailing, factory sample production for client approval, precision manufacturing with sequential numbering for installation efficiency, secure packaging divided by roof plan sections, and professional on-site construction guidance or installation services. With over 20 registered patents, multiple quality certifications including CE, ISO, and SGS approvals, and successful project delivery for Fortune 500 companies, we deliver comprehensive solutions from raw material procurement through final acceptance and ongoing maintenance support. Notable projects include Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, Xi'an Station East Auxiliary Building, Jinghe New City International Culture and Art Center, and Inner Mongolia Tongliao Art Museum, demonstrating our capability to execute complex, high-profile installations. Contact our team today at huafeng@hfmetalroof.com to discuss your Vertical Metal Siding Sheets requirements and discover how our engineering expertise, manufacturing excellence, and commitment to customer success can elevate your next building project with superior metal cladding solutions that deliver lasting value and architectural distinction.

References

1. American Institute of Steel Construction. (2022). Modern Steel Construction: Metal Building Systems Design Guide. Chicago: AISC Publications.

2. National Association of Architectural Metal Manufacturers. (2023). Metal Wall Panel Design Manual. Chicago: NAAMM Technical Publications.

3. Sheet Metal and Air Conditioning Contractors' National Association. (2021). Architectural Sheet Metal Manual (8th Edition). Chantilly: SMACNA.

4. Metal Construction Association. (2023). Guidelines for Proper Installation of Metal Wall Panels. Cleveland: MCA Technical Services.