Finding reliable Metal Corrugated Roofing Panel OEM suppliers becomes a critical challenge when your construction project timeline is tight, your budget is fixed, and quality cannot be compromised. Every contractor and procurement manager has faced the dilemma of choosing between unknown overseas manufacturers offering rock-bottom prices and established suppliers with premium rates. The stakes are high because poor quality panels lead to leakage, premature corrosion, and costly replacement within just a few years. This comprehensive guide reveals proven sourcing strategies, evaluation criteria for OEM manufacturers, and insider knowledge about production capabilities that will help you identify trustworthy corrugated roofing sheets suppliers who deliver consistent quality, meet international standards, and support your project success from initial inquiry through final installation.

Understanding Metal Corrugated Roofing Panel Manufacturing Capabilities

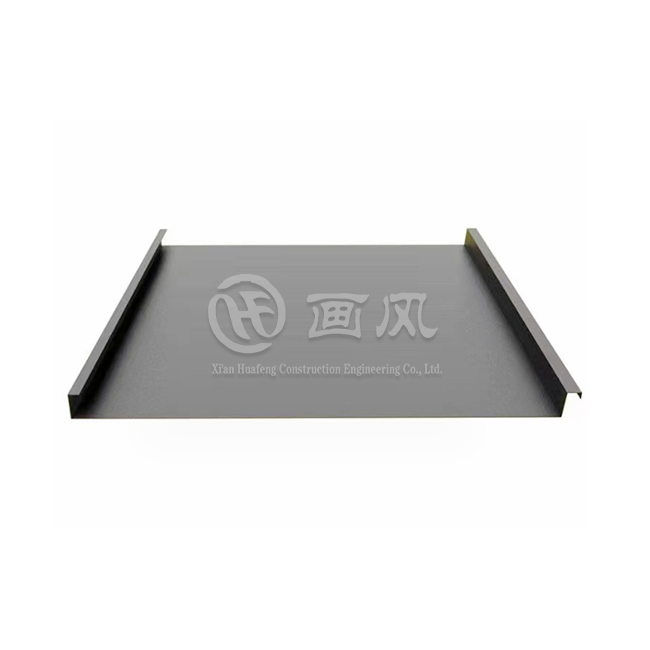

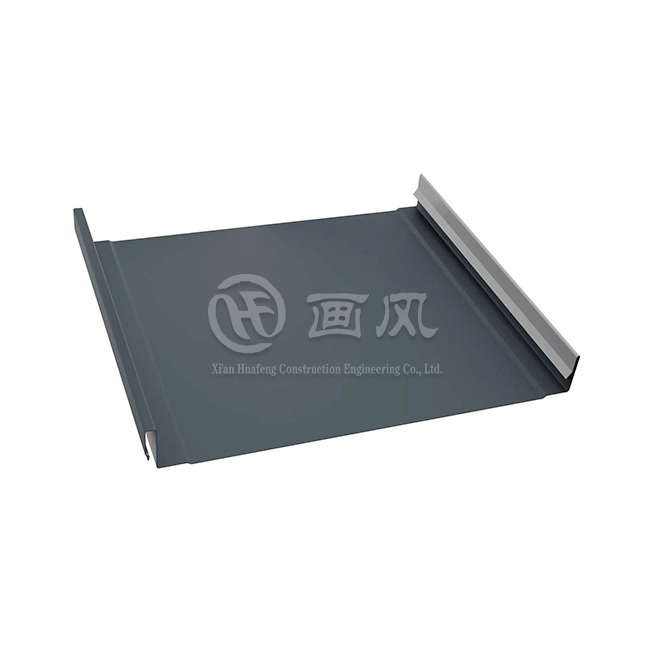

The production of Metal Corrugated Roofing Panel requires sophisticated manufacturing infrastructure that separates professional OEM suppliers from basic fabricators. Leading manufacturers operate multiple production lines with advanced roll-forming technology capable of processing various substrate materials including galvanized steel, aluminum-magnesium-manganese alloys, and color-coated steel sheets. The corrugated profile itself enhances structural rigidity through its distinctive wave pattern, typically ranging from twenty-five to fifty millimeters in pitch height. Premium suppliers maintain strict dimensional tolerances across panel widths of six hundred to twelve hundred fifty millimeters and can customize lengths from one point eight to twelve meters based on project specifications. The manufacturing process integrates automated punching systems for fastener holes, precision cutting equipment, and multi-stage quality inspection protocols that verify thickness consistency, coating adhesion, and profile accuracy. Factories with seven or more production lines demonstrate the capacity to handle large-scale orders while maintaining delivery schedules, which proves essential for commercial and industrial construction projects with tight timelines.

When evaluating OEM suppliers, their raw material procurement practices reveal much about final product quality. Established manufacturers source substrate materials from recognized steel mills and maintain traceability documentation including mill certificates and third-party test reports. The substrate coating represents a critical quality factor, with options including hot-dip galvanizing for corrosion resistance, aluminum-zinc alloy coatings for enhanced durability in coastal environments, and polyester or PVDF topcoats for color retention and weatherability. Superior corrugated roofing sheets feature coating weights meeting ASTM, DIN, JIS, BS, or GB/T standards with zinc coating masses typically ranging from one hundred to two hundred seventy-five grams per square meter. The color coating process itself requires controlled temperature curing in dedicated ovens to achieve proper paint adhesion and flexibility. Manufacturers who control their coating lines rather than outsourcing this process deliver more consistent color matching and finish quality across production batches, which matters significantly when panels from multiple shipments must be installed on the same visible roof surface.

Key Technical Specifications to Verify

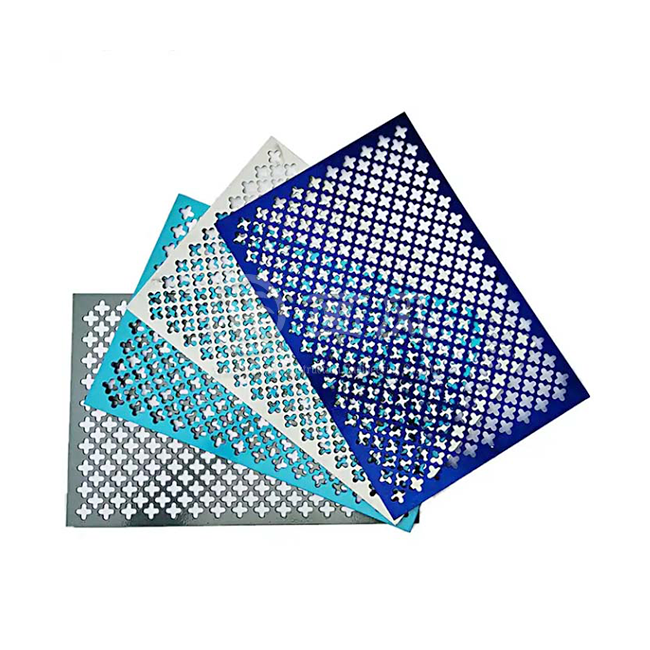

Professional Metal Corrugated Roofing Panel suppliers provide comprehensive technical documentation that enables informed purchasing decisions. The specification sheet should detail substrate material grade, thickness range from zero point four to one point two millimeters for standard applications, coating type and weight, corrugation pitch and depth measurements, panel coverage width after accounting for side laps, and load-bearing capacity under various wind and snow conditions. Suppliers who offer PE, HDP, and PVDF coating finishes demonstrate production flexibility to match different budget points and performance requirements. The thirty-year warranty period increasingly represents an industry standard for premium corrugated roofing sheets when proper installation and maintenance protocols are followed. Minimum order quantities vary by supplier, with five hundred square meters representing a typical threshold for customized specifications including color matching, perforation patterns, and edge treatments. Delivery timeframes of fifteen to twenty days for standard orders indicate well-organized production scheduling and adequate inventory of common substrate materials. Suppliers capable of providing design customization services add significant value by adapting panel profiles to specific architectural requirements and structural load calculations.

Geographic Considerations for OEM Supplier Selection

China has emerged as the dominant global manufacturing hub for Metal Corrugated Roofing Panel production, with distinct regional specializations that impact supplier capabilities and cost structures. Shandong Province accounts for approximately seventy percent of corrugated roofing suppliers, benefiting from proximity to major steel production facilities and mature logistics infrastructure connected to busy container ports. The industrial clusters in cities like Liaocheng, Jinan, and Linyi enable economies of scale through shared supply chains and specialized equipment vendors. Manufacturers in this region typically excel at high-volume production runs with competitive per-unit pricing due to lower material costs and efficient transportation networks. However, buyers should recognize that the lowest price quotes may come from suppliers with minimal quality control systems or limited technical support capabilities. Jiangsu Province suppliers located near Shanghai focus more on advanced manufacturing techniques including automated roll-forming lines and computer-controlled coating systems that achieve tighter dimensional tolerances and superior surface finishes compared to basic production equipment.

The geographic location of your OEM supplier affects not only product cost but also communication efficiency, intellectual property protection, and supply chain reliability. Suppliers established in recognized industrial parks typically demonstrate higher business maturity with proper registrations, certifications, and export documentation capabilities. Factory locations near major ports reduce inland transportation costs and minimize damage risks during domestic trucking before ocean shipment. When sourcing corrugated roofing sheets for projects in coastal or high-humidity environments, prioritize suppliers with experience serving similar climates who understand the importance of enhanced corrosion protection through upgraded coating specifications. Regional suppliers may also provide valuable insights about local building codes, installation practices, and compatible accessory components that complement their panel products. The ability to conduct video factory tours or arrange third-party inspections becomes easier when suppliers operate in established manufacturing zones rather than remote locations with limited infrastructure.

Evaluating Supplier Credentials and Certifications

Legitimate China Metal Corrugated Roofing Panel manufacturers maintain multiple quality certifications that demonstrate their commitment to international standards and systematic quality management. ISO 9001 certification verifies that a supplier has implemented documented quality management systems covering all aspects of production from incoming material inspection through final product testing and customer service. ISO 14001 environmental certification indicates proper handling of coating chemicals, waste management procedures, and compliance with environmental regulations that increasingly matter to multinational corporations with sustainability reporting requirements. SGS third-party testing reports provide independent verification of product specifications including coating thickness, adhesion strength, corrosion resistance, and weathering performance under accelerated testing conditions. CE marking enables direct sales into European markets and signals a supplier's understanding of international product safety and performance standards. When suppliers proudly display more than twenty registered patents for roofing system designs and manufacturing processes, this intellectual property portfolio suggests ongoing innovation rather than simple copying of competitor products.

Beyond certificates, investigate a supplier's operational track record through customer references and completed project documentation. High Quality Metal Corrugated Roofing Panel manufacturers willingly share case studies from significant installations including industrial facilities, commercial buildings, and public infrastructure projects. Payment terms and trade assurance programs offered through major B2B platforms provide additional security for first-time buyers concerned about quality consistency or delivery reliability. Response time to inquiries serves as an early indicator of customer service quality, with professional suppliers typically acknowledging questions within twenty-four hours and providing detailed technical answers within forty-eight hours. Reorder rates above sixty percent indicate strong customer satisfaction and product performance that meets or exceeds expectations. Suppliers with established technical support teams can assist with installation guidance, troubleshooting, and maintenance recommendations that extend panel service life and reduce total cost of ownership.

Production Flexibility and Customization Capabilities

Distinguishing Metal Corrugated Roofing Panel OEM suppliers from simple traders or brokers requires examining their actual production capabilities and willingness to customize products for specific applications. Genuine manufacturers operate their own factory equipment including decoilers, straightening machines, roll-forming stations, punching presses, cutting systems, and automated stacking equipment. The number of production lines directly correlates with capacity and delivery reliability, with facilities operating seven or more lines capable of handling multiple simultaneous orders without extending lead times. When suppliers maintain more than forty pieces of major equipment including shearing machines, press brakes, and specialized bending tools, they possess the manufacturing flexibility to produce not only standard corrugated profiles but also custom edge treatments, perforation patterns for ventilation, and trimmed panels that minimize field cutting and waste. This comprehensive equipment lineup enables true one-stop procurement where buyers source panels, trim pieces, fasteners, and closure strips from a single manufacturer ensuring component compatibility and simplified logistics. Customization services extend beyond simple color selection to encompass pattern design, gauge adjustments, coating upgrades, and specialized treatments for extreme environmental conditions. Premium corrugated roofing sheets suppliers provide design optimization consultation where their technical teams review architectural drawings and recommend panel specifications that balance performance, aesthetics, and budget constraints. Advanced manufacturers offer structural analysis services calculating deflection limits, wind uplift resistance, and snow load capacity to ensure specified panels meet local building code requirements without over-engineering that increases costs unnecessarily. The ability to produce samples based on confirmed parameters including board type, material grade, thickness, surface treatment method, and color represents a critical capability that eliminates miscommunication about expectations. Sample sealing procedures create reference standards for subsequent production batches, establishing clear acceptance criteria before committing to full-scale manufacturing.

Quality Control Systems and Inspection Protocols

Rigorous quality control separates Metal Corrugated Roofing Panel for sale from suppliers focused solely on volume shipping. Comprehensive incoming material inspection verifies that substrate coils meet specified grades with proper mill certifications and third-party test reports documenting chemical composition, mechanical properties, and coating weights. Inspection methods include both full inspection for high-value materials and statistical sampling for routine deliveries, with rejection protocols preventing defective materials from entering production. During manufacturing, real-time quality monitoring checks dimensional accuracy, profile consistency, and coating application uniformity at multiple production stages rather than relying solely on final inspection. Finished product inspection encompasses more than a dozen testing steps including appearance examination for surface defects, precise dimensional measurements, flatness and curvature verification, and performance testing for coating adhesion, salt spray resistance, impact resistance, and weatherability under accelerated aging conditions. Superior suppliers package finished products intelligently to facilitate construction site logistics and minimize handling damage during transportation and installation. Sectional packaging based on roof plan drawings enables installers to locate required panels quickly without opening multiple bundles or creating confusion with similar-looking pieces. Product identification cards attached to each package bundle include sectioned floor plans and numbered product lists that correspond to installation drawings, dramatically reducing field errors and installation time. This attention to packaging details reflects a supplier's understanding of the complete project lifecycle rather than viewing their responsibility as ending when products leave the factory gate. Manufacturers who provide installation guidance documents, technical specification sheets, and maintenance recommendations demonstrate commitment to long-term customer success rather than one-time transactions.

Building Long-Term Supplier Partnerships

Successful procurement of corrugated roofing sheets evolves from transactional purchasing to strategic partnerships when suppliers invest in understanding your business needs and consistently deliver value beyond basic product specifications. Established China Metal Corrugated Roofing Panel wholesale suppliers maintain customer relationship management systems tracking project histories, specification preferences, and delivery requirements that streamline repeat ordering and ensure consistency across multiple projects. The ability to scale production capacity for large orders without compromising quality or extending timelines provides critical flexibility for contractors managing multiple simultaneous projects or responding to emergency replacement needs. Suppliers offering flexible minimum order quantities accommodate both major commercial installations and smaller residential projects, though buyers should recognize that customization costs are typically amortized across order volume with lower per-unit pricing for larger quantities. Communication efficiency and technical responsiveness separate preferred suppliers from interchangeable commodity sources. Leading China Metal Corrugated Roofing Panel supplier organizations employ multilingual customer service teams familiar with international business practices, time zone coordination, and the detailed technical specifications common in construction procurement. Their sales staff can discuss coating chemistry, thermal expansion considerations, and accessory compatibility rather than simply quoting prices from standardized product catalogs. Engineering support teams review architectural drawings, identify potential installation challenges, and recommend specification adjustments that improve long-term performance without necessarily increasing costs. This consultative approach builds confidence and enables buyers to leverage supplier expertise rather than bearing full responsibility for technical decision-making with unfamiliar products.

Pricing Structures and Total Cost Analysis

Metal Corrugated Roofing Panel price varies significantly based on substrate material, coating specification, thickness, panel length, order quantity, and customization requirements. Understanding cost drivers enables more accurate supplier comparisons and identifies opportunities for value engineering without compromising essential performance characteristics. Base substrate cost fluctuates with global steel markets, making it important to lock pricing through purchase contracts when market conditions are favorable. Premium coating systems like PVDF add twenty to thirty percent to material costs compared to standard polyester finishes but deliver superior color retention and corrosion resistance that extends service life from fifteen to thirty-plus years. The apparently higher initial price delivers lower lifecycle costs when factoring in reduced maintenance, deferred replacement, and sustained appearance over decades of service. When comparing supplier quotations, evaluate total landed cost including not only FOB factory pricing but also domestic transportation to port, ocean freight, insurance, import duties, and inland delivery to your project site. Some High Quality Metal Corrugated Roofing Panel suppliers offer comprehensive pricing including technical documentation, material test reports, and installation guidance as standard services, while others charge separately for these valuable resources. Factory location relative to major ports affects inland transportation costs and potential damage during domestic trucking before ocean shipment. Suppliers offering flexible payment terms or trade assurance programs through major B2B platforms provide additional value and risk mitigation for international buyers concerned about prepayment requirements to unknown manufacturers. The incremental cost premium for working with established, certified suppliers typically ranges from five to fifteen percent compared to the absolute lowest market quotes but delivers substantially reduced risk of quality issues, delivery delays, and inadequate technical support.

Conclusion

Sourcing reliable Metal Corrugated Roofing Panel OEM suppliers requires systematic evaluation of manufacturing capabilities, quality systems, technical expertise, and long-term partnership potential rather than focusing solely on initial price quotations. Successful procurement balances cost efficiency with quality assurance, delivery reliability, and comprehensive technical support throughout project execution.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a premier China Metal Corrugated Roofing Panel factory established in 2018, specializing in comprehensive metal roofing systems, building curtain walls, and steel structure enclosure solutions. Recognized as a high-tech enterprise in Shaanxi Province since 2020, the company holds first-level qualifications for building curtain walls and third-level qualifications for building steel structures. Our manufacturing infrastructure includes a two hundred thousand square meter raw material production plant in Anhui, complemented by dedicated plate and accessories processing facilities in Hangzhou and Xi'an. With seven color coating production lines, one laminating line, ten longitudinal and transverse shearing production lines, and more than forty specialized machines including shearing equipment, presses, and bending machines, we maintain monthly production capacity exceeding one thousand tons of premium corrugated roofing sheets.

Our product portfolio encompasses standing seam metal roofing panels, aluminum-magnesium-manganese plates, titanium-zinc plates, standing seam metal wall sheets, corrugated roofing and wall sheets, flat lock panels, and comprehensive roofing system accessories. We provide complete customization services including color matching, pattern design, and specification adjustments with widths ranging from six hundred to twelve hundred fifty millimeters, thickness from zero point four to one point two millimeters, and finishes including PE, HDP, and PVDF coatings. Every product meets ASTM, DIN, JIS, BS, and GB/T standards with a thirty-year service life warranty. Our minimum order quantity of five hundred square meters and delivery timeframe of fifteen to twenty days accommodate diverse project requirements from commercial installations to industrial facilities.

As your trusted China Metal Corrugated Roofing Panel supplier and China Metal Corrugated Roofing Panel manufacturer, we deliver integrated value through engineering design experience, construction expertise, comprehensive quality certifications including ISO9001, ISO14000:14001, and SGS compliance, and more than twenty registered patents for roofing systems. Our successful project portfolio includes Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, Jinghe New City International Culture and Art Center, and Inner Mongolia Tongliao Art Museum. We provide one-stop solutions encompassing structural modeling, load analysis, drainage system design, material procurement, precision manufacturing with real-time quality control, raw material traceability, on-site construction guidance, and comprehensive acceptance procedures. Our commitment to green sustainable development and architectural innovation ensures your Metal Corrugated Roofing Panel for sale requirements receive professional attention with competitive Metal Corrugated Roofing Panel price structures. Contact us today at huafeng@hfmetalroof.com to discuss your project specifications and experience the Huafeng advantage in quality, service, and reliability. Bookmark this resource to reference our High Quality Metal Corrugated Roofing Panel solutions whenever procurement challenges arise.

References

1. Metal Roofing Systems Design and Installation Guide. National Roofing Contractors Association Technical Committee. 2023.

2. Corrosion Protection of Metal Roofing in Harsh Environments. American Society for Testing and Materials Standards Division. 2024.

3. Sustainable Building Envelope Solutions: Metal Panel Systems Performance Analysis. International Building Performance Simulation Association Research Group. 2023.

4. Quality Management Systems for Metal Construction Products Manufacturing. International Organization for Standardization Technical Advisory Group. 2024.

5. Comparative Analysis of Corrugated Metal Panel Coating Technologies. Society of Protective Coatings Industrial Applications Committee. 2023.